Anti-wobble bearing for Leadscrews

Posted by o_lampe

|

Anti-wobble bearing for Leadscrews April 20, 2018 04:06AM |

Registered: 8 years ago Posts: 5,232 |

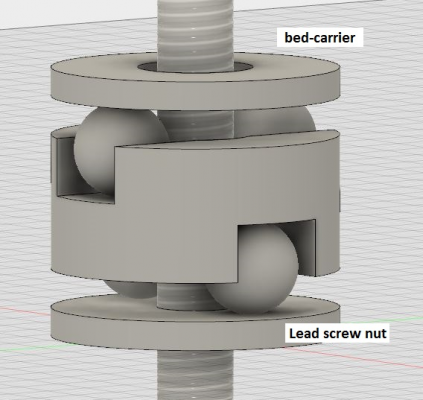

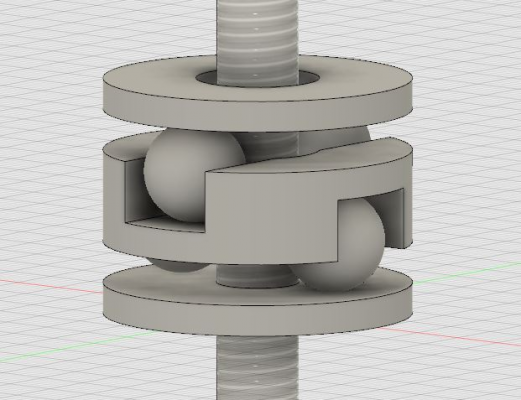

Just made a quick drawing based on the 10mm Delrin balls I have laying around. It would fit between a 8mm leadscrew and the top would connect to the bed or any Carrier ( for leadscrew Delta )

I'm sure a printed version wouldn't run nicely, especially the center part would need smooth surfaces. But it's a starting point for discussions.

Sorry, came up with a more compact version, while I posted it...

Edited 1 time(s). Last edit at 04/20/2018 04:34AM by o_lampe.

I'm sure a printed version wouldn't run nicely, especially the center part would need smooth surfaces. But it's a starting point for discussions.

Sorry, came up with a more compact version, while I posted it...

Edited 1 time(s). Last edit at 04/20/2018 04:34AM by o_lampe.

|

Re: Anti-wobble bearing for Leadscrews April 20, 2018 04:45AM |

Registered: 8 years ago Posts: 5,232 |

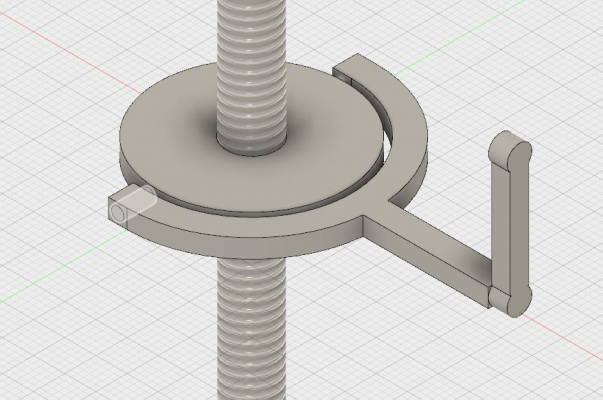

I just figured, we'd have to keep the leadscrew nut from rotating.

Imagine, there is a short arm connecting the bottom disk ( leadscrew ) with the bed.

Ok, the arm isn't that trivial. It's more like a wishbone suspension with a rod end arm.

Hmm, still not happy with the arm. It needs a different rodend. I need a brake...

Edited 2 time(s). Last edit at 04/20/2018 05:52AM by o_lampe.

Imagine, there is a short arm connecting the bottom disk ( leadscrew ) with the bed.

Ok, the arm isn't that trivial. It's more like a wishbone suspension with a rod end arm.

Hmm, still not happy with the arm. It needs a different rodend. I need a brake...

Edited 2 time(s). Last edit at 04/20/2018 05:52AM by o_lampe.

|

Re: Anti-wobble bearing for Leadscrews April 20, 2018 07:15AM |

Registered: 11 years ago Posts: 5,780 |

I think the lever arm has to loosely attach the nut to the guide rail. Not a rigid coupling like a bearing, but a slotted (the slot width matching the diameter of the guide rail) lever that allows the distance between the guide rail and the nut riding on the wobbly screw to vary. Then the bed support just rests on top of the nuts that are free to follow the wobbles of the screws as they slide against the underside of the bed support. You might want to use a low friction material between the top of the nut and the bottom of the bed support. A teflon washer?

Edited 1 time(s). Last edit at 04/20/2018 07:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 04/20/2018 07:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Anti-wobble bearing for Leadscrews April 20, 2018 09:44AM |

Registered: 7 years ago Posts: 507 |

I've seen this sort of gimbal like coupler used for leadscrews. I think I remember seeing a thingiverse version for the tevo tarantula a while ago. I'm not sure a printed version would be an improvement though because of the tolerances most printers work to. That being said I think the craftbot uses a double dovetail slider (two dovetails, orientated at 90 degrees to each other) as anti wobble coupler.

Also, for your first coupler design, wouldn't a v groove be better than a rectangular groove? it would have a self centering effect on the balls and you wouldn't have to worry about the fit so much. With a rectangular slot you'd need it just the right size, too big and you introduce rotational backlash as the ball disengages from one side of the slot and then engages with the other during a direction change. Too small and the ball wont fit. Otherwise I think it's a really elegant way to solve wobble issues.

Also, for your first coupler design, wouldn't a v groove be better than a rectangular groove? it would have a self centering effect on the balls and you wouldn't have to worry about the fit so much. With a rectangular slot you'd need it just the right size, too big and you introduce rotational backlash as the ball disengages from one side of the slot and then engages with the other during a direction change. Too small and the ball wont fit. Otherwise I think it's a really elegant way to solve wobble issues.

|

Re: Anti-wobble bearing for Leadscrews April 20, 2018 01:56PM |

Registered: 6 years ago Posts: 1,007 |

Wobble is due to a wrong design: incorrect use of coupler, improper leadscrew mount and aggravated by the poor parts quality, e.g. use of standard M screws unsuitable for the task, often bent.

So, instead of trying to reduce the effect, it is better to do it the correct way.

[us.misumi-ec.com]

On a 3D Z axis, the bearing opposite to the one motor side, is not required due to the low speed and it simplifies the alignment. Some guys put one on their 3D printer as a magic solution, with luck it may improves but most of the time it makes thing worse.

Also, better to have the motor mounted at the top so the lead screw works in tension. For a two lead screws (or 3), one motor belt and pulleys, no coupler needed.

Edited 1 time(s). Last edit at 04/20/2018 01:58PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

So, instead of trying to reduce the effect, it is better to do it the correct way.

[us.misumi-ec.com]

On a 3D Z axis, the bearing opposite to the one motor side, is not required due to the low speed and it simplifies the alignment. Some guys put one on their 3D printer as a magic solution, with luck it may improves but most of the time it makes thing worse.

Also, better to have the motor mounted at the top so the lead screw works in tension. For a two lead screws (or 3), one motor belt and pulleys, no coupler needed.

Edited 1 time(s). Last edit at 04/20/2018 01:58PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Anti-wobble bearing for Leadscrews April 21, 2018 02:10AM |

Registered: 8 years ago Posts: 5,232 |

Thanks for all the input guys, I really appreciate it. I even agree with MKSA, that you better look for wobble free parts instead of adding band_aids. But it's a cost reduction issue.

I think the V-groove and the slotted guide for the lever are improving matters.

I know what a dovetail is in woodworks, but I can't picture how it would help here?

I think the V-groove and the slotted guide for the lever are improving matters.

I know what a dovetail is in woodworks, but I can't picture how it would help here?

|

Re: Anti-wobble bearing for Leadscrews April 21, 2018 05:38AM |

Registered: 7 years ago Posts: 507 |

It's a double dovetail slider. Dovetail slider as in the ones use in machine ways/rails like on a heavy duty lathe or mill. One is rotated 90 to the other so one dovetail slides in X, the other in Y. It effectively lets the leadscrew nut wobble around in X and Y without affecting whatever it's lifting.

video of it in action

[www.youtube.com]

I've always thought the double dovetail is a bit overly complicated though for what it does (at least on a 3d printer application). You could do basically the same thing by having the nut bolted on a plate, then having a seperate plate riding on top of that that mounts to your bed/x axis. The two plates should be able to slide past each other freely so any movement of the first plate in the XY direction (wobble) isn't transmitted to the second plate (and so your bed/X axis). Z axis movement is of course still transferred since the first plate with the nut pushes the second plate up and gravity handles the down.

[www.youtube.com]

~2:50 shows another example of the double dovetail and give its proper name.

finally found that gimbal/gyroscope looking anti wobble mount as well

[www.thingiverse.com]

found this as well, looks sort of like your first coupler but the "balls" are integrated into the plates for fewer overall parts

[www.thingiverse.com]

Edited 1 time(s). Last edit at 04/21/2018 05:41AM by Trakyan.

video of it in action

[www.youtube.com]

I've always thought the double dovetail is a bit overly complicated though for what it does (at least on a 3d printer application). You could do basically the same thing by having the nut bolted on a plate, then having a seperate plate riding on top of that that mounts to your bed/x axis. The two plates should be able to slide past each other freely so any movement of the first plate in the XY direction (wobble) isn't transmitted to the second plate (and so your bed/X axis). Z axis movement is of course still transferred since the first plate with the nut pushes the second plate up and gravity handles the down.

[www.youtube.com]

~2:50 shows another example of the double dovetail and give its proper name.

finally found that gimbal/gyroscope looking anti wobble mount as well

[www.thingiverse.com]

found this as well, looks sort of like your first coupler but the "balls" are integrated into the plates for fewer overall parts

[www.thingiverse.com]

Edited 1 time(s). Last edit at 04/21/2018 05:41AM by Trakyan.

|

Re: Anti-wobble bearing for Leadscrews May 03, 2018 03:44PM |

Registered: 8 years ago Posts: 28 |

Very cool design -- in terms of constraint, leadscrew nuts operate on the same principle as motor shaft couplings, so the designs should be similar. Have you considered using V-ways instead of square slots to house the balls? Right now the ball constraints flip from one side of the square slot to the other, creating backlash, but with a V, the balls will always stay nested.

Blanding has a number of novel leadscrew nut designs, I think around pg95, in Exact Constraint. If I remember right, some look similar, and perhaps could be a source of design inspiration.

edit: that's what I get for not reading the thread! doh

Edited 1 time(s). Last edit at 05/03/2018 03:45PM by golfwolf.

Blanding has a number of novel leadscrew nut designs, I think around pg95, in Exact Constraint. If I remember right, some look similar, and perhaps could be a source of design inspiration.

edit: that's what I get for not reading the thread! doh

Edited 1 time(s). Last edit at 05/03/2018 03:45PM by golfwolf.

|

Re: Anti-wobble bearing for Leadscrews May 04, 2018 02:44AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.