30x30 print bed with single rail

Posted by robvoi

|

30x30 print bed with single rail January 28, 2019 02:56AM |

Registered: 8 years ago Posts: 55 |

Hi,

I wonder if a single MGN12 400mm rail would be sufficient for a 30x30 heated bed.

Some question goes for the x-axis with a direct drive extruder.

In general I am currently checking how to do the y-axis for my new printer.

a) 1x MGN12

b) 2x MGN12

c) supported rails - [www.ebay.de]

d) unsupported rails - [www.ebay.de]

It is an old question I know.

Edited 1 time(s). Last edit at 01/28/2019 04:56AM by robvoi.

I wonder if a single MGN12 400mm rail would be sufficient for a 30x30 heated bed.

Some question goes for the x-axis with a direct drive extruder.

In general I am currently checking how to do the y-axis for my new printer.

a) 1x MGN12

b) 2x MGN12

c) supported rails - [www.ebay.de]

d) unsupported rails - [www.ebay.de]

It is an old question I know.

Edited 1 time(s). Last edit at 01/28/2019 04:56AM by robvoi.

|

Re: 30x30 print bed with single rail January 28, 2019 07:14AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: 30x30 print bed with single rail January 28, 2019 08:50AM |

Registered: 8 years ago Posts: 55 |

Quote

the_digital_dentist

How do you intend to use them?

I am in the early idea collection phase of this project. So not completely clear yet.

I got some 4040 extrutions and 3 steppers from my dad. So I thought I build a new printer. I have a well working i3 clone (modded). So I can print parts.

The 30x30 bed would be bigger than the one on the i3 and is the reason for me to spend money on this project - maybe more precision, at least I hope. Besides having fun.

because I like the simplicity of the design, I will most likely stay with the i3 style.

What I could imagine:

For a) (1xMGN12) -> mount them on a 4040 extrusion which would be part of the frame. Question here is if a single rail is stable enough for the bed. And how to construct the belt as the center is used for the rail. Having the belt off center doesn’t feel right.

For b) (2xMGN12) -> have a wood board mounted below the 4040 frame and mount the rails directly on the board (need to find something that is this fine/streight)

For c) (supported rails) -> either the board solution or mount both ends on the frame. Middle would be unsupported.

For d) (unsupported rails) -> mount on the frame

In general I would like to prevent having the board under the printer.

I think d) might not be an option as getting rods which are 100% straight is nearly impossible. Or at least gets so expensive that the other options kick in.

Hope this is what you meant with the question.

Edited 1 time(s). Last edit at 01/28/2019 08:57AM by robvoi.

|

Re: 30x30 print bed with single rail January 28, 2019 10:08AM |

Registered: 11 years ago Posts: 5,780 |

If you use a single rail for the Y axis and a single bearing block, you'll have a large mass (the bed and it's support) moving back and forth on a small base (the bearing block). Each time it reverses direction it is likely to wobble, forward and backward, because the bed support will probably flex a bit. Adding a second bearing block and supporting the bed near the front and back edges would improve the forward-backward stability. There isn't a lot of force that will affect lateral stability, so it might work with a single linear guide.

Two fully supported linear guides for the Y axis, with 3 bearing blocks work well (my printer SoM is built that way- see link in my sig, below). I mounted the rails on a 1" thick aluminum plate.

For a 30x30 cm(?) bed, I would not build a printer (again) with the bed moving in the Y axis. It is a lot of moving mass and keeping it under control is difficult. It also requires the footprint of the printer to be at least 60 cm long to accommodate the bed motion. Move the bed in Z.

I recently rebuilt the Y axis in SoM, converting from ball screw to belt drive, switching to a line powered heater, and using a kinematic mount for the bed plate. You can see how that was done here.

End supported round rails can be made to work (all the cheap printers and some decent one use them) but they have to be used in pairs and it can be tricky to align them parallel to each other. If you go cheap and buy thin ones, they will flex, and you need hardened rails if you're going to use ball bearings on them. It's usually pretty easy to mount linear guides parallel to each other if they are mounting on the same flat surface.

You can buy cheapo hi-win knock-off linear guides, but based on what I've read in posts on these and other forums, they are very poorly made and provide only the look of linear guides without the normally associated precision. I buy quality used linear guides via ebay for maybe a little more than the crappy hi-win knock-offs and have yet to get a bad one. If you search ebay for linear guides, then filter out all the hi-win knock-offs ("-MGN, -MGH"), you'll be left with about 20 pages of mostly overpriced stuff with a few very reasonably priced parts. Here's two now:

12mm linear guide

15mm linear guide

Look for IKO, NSK, THK, Bosch, and Rexroth brand parts. 12, 15, and 24x8 mm rails are most common.

Buy rails that are long enough and have enough bearing blocks for your printer design. You can always cut the rails to the needed length with a cutoff wheel on a grinder. Don't try to buy rails and bearing blocks separately. That gets crazy expensive, and the block may not fit the rail properly.

Edited 1 time(s). Last edit at 01/28/2019 10:14AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Two fully supported linear guides for the Y axis, with 3 bearing blocks work well (my printer SoM is built that way- see link in my sig, below). I mounted the rails on a 1" thick aluminum plate.

For a 30x30 cm(?) bed, I would not build a printer (again) with the bed moving in the Y axis. It is a lot of moving mass and keeping it under control is difficult. It also requires the footprint of the printer to be at least 60 cm long to accommodate the bed motion. Move the bed in Z.

I recently rebuilt the Y axis in SoM, converting from ball screw to belt drive, switching to a line powered heater, and using a kinematic mount for the bed plate. You can see how that was done here.

End supported round rails can be made to work (all the cheap printers and some decent one use them) but they have to be used in pairs and it can be tricky to align them parallel to each other. If you go cheap and buy thin ones, they will flex, and you need hardened rails if you're going to use ball bearings on them. It's usually pretty easy to mount linear guides parallel to each other if they are mounting on the same flat surface.

You can buy cheapo hi-win knock-off linear guides, but based on what I've read in posts on these and other forums, they are very poorly made and provide only the look of linear guides without the normally associated precision. I buy quality used linear guides via ebay for maybe a little more than the crappy hi-win knock-offs and have yet to get a bad one. If you search ebay for linear guides, then filter out all the hi-win knock-offs ("-MGN, -MGH"), you'll be left with about 20 pages of mostly overpriced stuff with a few very reasonably priced parts. Here's two now:

12mm linear guide

15mm linear guide

Look for IKO, NSK, THK, Bosch, and Rexroth brand parts. 12, 15, and 24x8 mm rails are most common.

Buy rails that are long enough and have enough bearing blocks for your printer design. You can always cut the rails to the needed length with a cutoff wheel on a grinder. Don't try to buy rails and bearing blocks separately. That gets crazy expensive, and the block may not fit the rail properly.

Edited 1 time(s). Last edit at 01/28/2019 10:14AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 30x30 print bed with single rail January 28, 2019 10:22AM |

Registered: 8 years ago Posts: 55 |

Thanks a lot for your respone. The bed itself flexing is indeed an issue - didn't think about it. And thanks on the tip not to buy block separately. Was looking at them.

With the 3 blocks you mean 3 per rail?

Is the mass of the 30x30 bed indeed such an issue compared to the 22x22 I got on my cheap i3 clone? What is your experience here?

Any experience or opinion on the supported rails for the y-axis?

Edited 1 time(s). Last edit at 01/28/2019 10:24AM by robvoi.

With the 3 blocks you mean 3 per rail?

Is the mass of the 30x30 bed indeed such an issue compared to the 22x22 I got on my cheap i3 clone? What is your experience here?

Any experience or opinion on the supported rails for the y-axis?

Edited 1 time(s). Last edit at 01/28/2019 10:24AM by robvoi.

|

Re: 30x30 print bed with single rail January 28, 2019 12:58PM |

Registered: 11 years ago Posts: 5,780 |

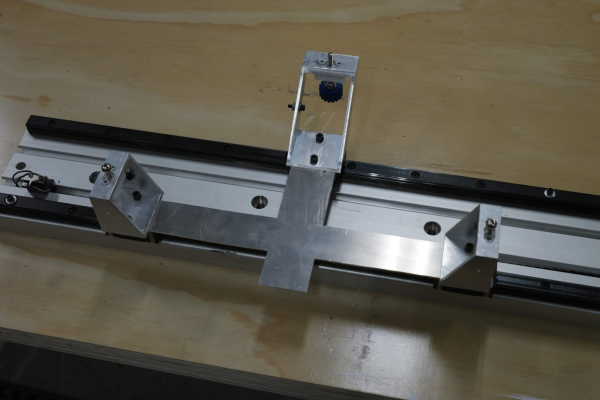

Three blocks means two on one rail and one on the other, like this:

Bed support/leveling on 4 screws is nonsense- 3 points define a plane. 4 bearing blocks on two guide rails is equally nonsensical. Mount the plate so the leveling screws are above the bearing blocks for maximum stability -i.e. put the bearing blocks along the edges of the plate where the leveling screws are.

I use 1/4" cast aluminum tooling plate for the bed for thermal conduction, flat surfaces, and rigidity. 3 point kinematic mount ensures stability- set it level once and don't touch it again. No autoleveling is needed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Bed support/leveling on 4 screws is nonsense- 3 points define a plane. 4 bearing blocks on two guide rails is equally nonsensical. Mount the plate so the leveling screws are above the bearing blocks for maximum stability -i.e. put the bearing blocks along the edges of the plate where the leveling screws are.

I use 1/4" cast aluminum tooling plate for the bed for thermal conduction, flat surfaces, and rigidity. 3 point kinematic mount ensures stability- set it level once and don't touch it again. No autoleveling is needed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: 30x30 print bed with single rail January 29, 2019 01:42AM |

Registered: 8 years ago Posts: 55 |

|

Re: 30x30 print bed with single rail January 29, 2019 02:35AM |

Registered: 8 years ago Posts: 55 |

What do you think about a square aluminium tube from the DIY market as support for the rails on the y-axis. Are they straight enough?

[stockcarsteel.com]

[stockcarsteel.com]

Sorry, only registered users may post in this forum.