Tab and slot cantilever-style platform?

Posted by ruyvieira

|

Tab and slot cantilever-style platform? February 02, 2019 09:39PM |

Registered: 5 years ago Posts: 50 |

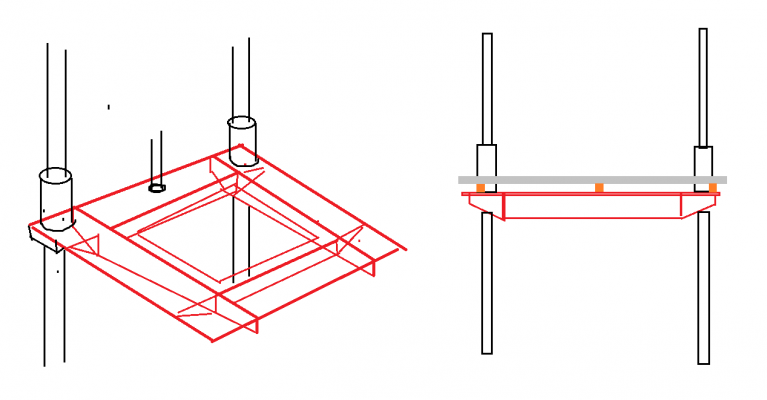

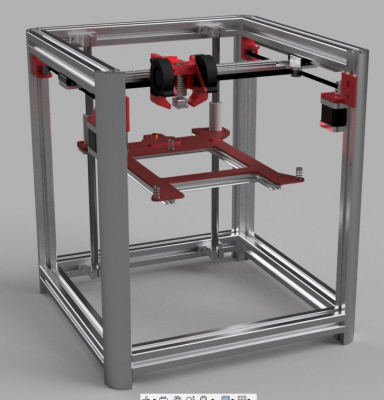

I want to build a 20x20x30 extrusion-cube type 3D printer, with a XY stage and Z axis that goes down. I don't want dozens of leadscrews and rods because I think that's not a very good idea, but I also don't want to use a thick plate or aluminum extrusions to hold the bed, since by doing this I can easily end up with an assembly that weights more than 1 kg. So, how about a tab-and slot platform with a thinner aluminum plate like 3.175mm? I've seen some examples of bent aluminum sheet that looked quite good, but since I can't do this with any sort of precision I want to use a tab and slot construction instead because I suspect it would be stiffer than a simple thick plate ( already have a printer with a thick-plate for a platform) and also flatter and lighter (maybe 500g or so?).

What I'm thinking is something that would look like this precision MS Paint technical drawing. The render is the look I'm going after, but I made it when I was considering using 15x15 extrusions to reinforce the plate. It's very important that it looks pretty.

What I'm thinking is something that would look like this precision MS Paint technical drawing. The render is the look I'm going after, but I made it when I was considering using 15x15 extrusions to reinforce the plate. It's very important that it looks pretty.

|

Re: Tab and slot cantilever-style platform? February 03, 2019 02:30AM |

Registered: 10 years ago Posts: 14,672 |

Have you looked at the E3D tool changer design? It uses a cantilever bed running on a single wide linear rail.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tab and slot cantilever-style platform? February 03, 2019 08:09AM |

Registered: 11 years ago Posts: 5,780 |

a few comments:

1) cantilevered beds usually bounce a lot, which limits print speeds to those that don't excite resonance. End supported Z axis rails contribute to the problem by flexing. Using fully supported linear guides is better.

2) why do you care how much it weighs?

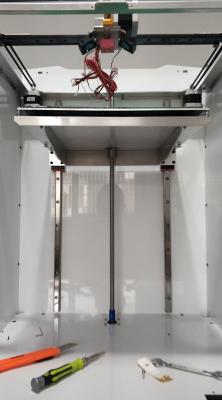

3) Leveling the bed with 4 screws is unstable. Use 3 screws for set-and-forget leveling. The bed support structure will be triangular, not square- simpler and less weight (not that that matters much). The Cubex and CubePro printers by 3Dsystems used a bed support similar to what you want to do with 5 mm thick aluminum webbing:

If you want more detail of that, there's a complete CAD model of the printer here: [mark.rehorst.com]

You'll need to run DesignSpark Mechanical (free) to open it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

1) cantilevered beds usually bounce a lot, which limits print speeds to those that don't excite resonance. End supported Z axis rails contribute to the problem by flexing. Using fully supported linear guides is better.

2) why do you care how much it weighs?

3) Leveling the bed with 4 screws is unstable. Use 3 screws for set-and-forget leveling. The bed support structure will be triangular, not square- simpler and less weight (not that that matters much). The Cubex and CubePro printers by 3Dsystems used a bed support similar to what you want to do with 5 mm thick aluminum webbing:

If you want more detail of that, there's a complete CAD model of the printer here: [mark.rehorst.com]

You'll need to run DesignSpark Mechanical (free) to open it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Tab and slot cantilever-style platform? February 03, 2019 09:11AM |

Registered: 5 years ago Posts: 50 |

Quote

dc42

Have you looked at the E3D tool changer design? It uses a cantilever bed running on a single wide linear rail.

I have, it's quite the work of art, but I have no way to precisely bend a sheet like that at the moment

Quote

the_digital_dentist

a few comments:

1) cantilevered beds usually bounce a lot, which limits print speeds to those that don't excite resonance. End supported Z axis rails contribute to the problem by flexing. Using fully supported linear guides is better.

2) why do you care how much it weighs?

3) Leveling the bed with 4 screws is unstable. Use 3 screws for set-and-forget leveling. The bed support structure will be triangular, not square- simpler and less weight (not that that matters much). The Cubex and CubePro printers by 3Dsystems used a bed support similar to what you want to do with 5 mm thick aluminum webbing:

If you want more detail of that, there's a complete CAD model of the printer here: [mark.rehorst.com]

You'll need to run DesignSpark Mechanical (free) to open it.

1- so far I've experienced resonance everywhere except on the bed itself, plus I intend to either move to a 32 bits controller at a higher stepper rate or change to TMC2208 drivers

2- The platform can be made stronger for the same weight as a thick plate if it's not just a simple plate , the above mentioned E3D toolchanger printer would be an excellent example of this. There are other positive side effects to having a lighter platform, such as it sagging less. Plus, it's cheaper to buy the materials, it's easier to cut (not as many passes and less chips produced).

3- Already doing that on a physical printer (a smaller version of this which I posted on the corexy machines subforum) and yes it works very well. If you look closely, you'll see that I placed 3 "leveling springs" on my fusion model. The aluminum in that platform looks more like 3mm, or else it's a really huge printer

This is a design by someone else, but it's scored and bent.

|

Re: Tab and slot cantilever-style platform? February 03, 2019 10:47AM |

Registered: 11 years ago Posts: 5,780 |

The resonance I mentioned isn't in the stepper/driver combo but mechanical. It's low frequency resonance that comes from the XY motion causing the frame of the printer to shake, which in turn shakes the cantilevered bed. End supported guide rails in the Z axis act like springs and at the right XY speeds, the thing will bounce like a diving board. The Cubex machines were limited to 30-40 mm/sec print speed because of the bed bouncing if you tried to go much faster. The Z axis bearings in the CubeX machines are 80mm long on 12mm guide rails- significantly longer and sturdier than typical amateur construction, and it still bounces.

I think lifting the bed from one side and getting good print quality at more "normal" print speeds is possible but it requires a lot of vertical support for the bed- fully supported linear guide(s) with two bearing blocks spaced vertically, and a support beam from the lower block to the far edge of the bed. I don't know if that would still be considered cantilevered. It would require the printer to be taller, and most people seem to have an aversion to making printers that are any larger than they absolutely need to be for a specific print volume. Few would build a Z axis that is 400 mm long for 200 mm of motion. The result is a lot of poorly executed cantilevered beds.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I think lifting the bed from one side and getting good print quality at more "normal" print speeds is possible but it requires a lot of vertical support for the bed- fully supported linear guide(s) with two bearing blocks spaced vertically, and a support beam from the lower block to the far edge of the bed. I don't know if that would still be considered cantilevered. It would require the printer to be taller, and most people seem to have an aversion to making printers that are any larger than they absolutely need to be for a specific print volume. Few would build a Z axis that is 400 mm long for 200 mm of motion. The result is a lot of poorly executed cantilevered beds.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.