heated bed desing - and usage of ABS

Posted by robvoi

|

heated bed desing - and usage of ABS February 11, 2019 07:59AM |

Registered: 8 years ago Posts: 55 |

I am designing the y-axis of my new i3 style 3D printer. I plan to use a borosilicat glass plate as top. Under this a kapton heater on 0.5mm aluminum. Below a wool insulation.

The mounting for the heater and the glass will be of aluminum as ABS would not be heat resistant enough.

I wonder how to go about connecting the carriage to the bearings. I can print a block/piece to connect to the bearings from ABS. But I need to connect the glass mount to the block. So the screws would transfer the heat to the ABS.

Does this work in practice or do you think it gets too hot?

Or is there a different solution? I need to gain some distance from the bearings to the plate (about 2 cm). So the plate can slide overt the motor.

The mounting for the heater and the glass will be of aluminum as ABS would not be heat resistant enough.

I wonder how to go about connecting the carriage to the bearings. I can print a block/piece to connect to the bearings from ABS. But I need to connect the glass mount to the block. So the screws would transfer the heat to the ABS.

Does this work in practice or do you think it gets too hot?

Or is there a different solution? I need to gain some distance from the bearings to the plate (about 2 cm). So the plate can slide overt the motor.

|

Re: heated bed desing - and usage of ABS February 11, 2019 10:34AM |

Registered: 11 years ago Posts: 5,780 |

I don't think 0.5mm aluminum is going to spread the heat well, and won't be flat, especially if it is "leveled" using 4 screws. That means heat won't transfer to the glass plate evenly and the temperature on the glass surface will vary a lot from one location to another. You're likely to have problems getting prints to stick reliably.

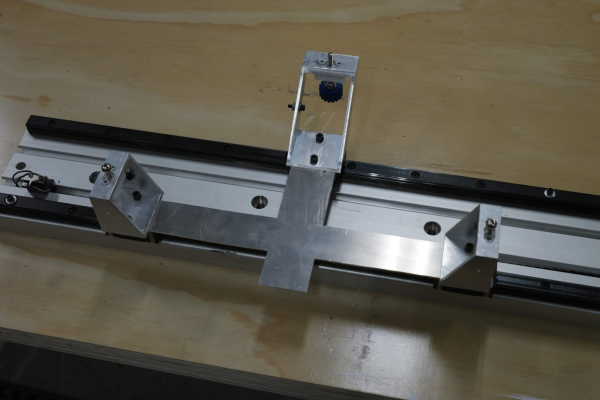

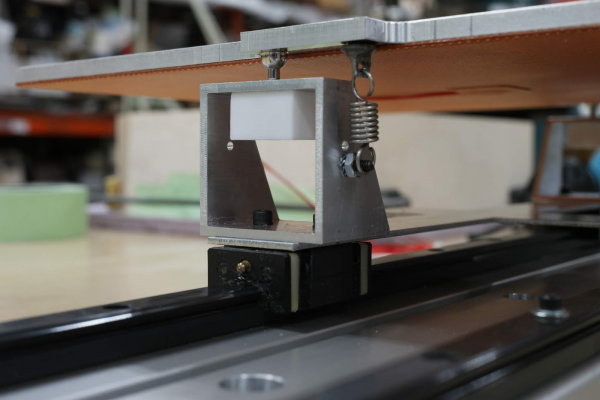

I recently rebuilt the Y axis in one of my printers including a kinematic mount for the 1/4" thick cast aluminum bed plate. There are 3 bearing blocks on the guide rails and 3 leveling screws, which are located as close to the bearing blocks as possible for maximum stability. I used square aluminum tubing mounted on the bearing blocks to hold Teflon blocks that the leveling screws are driven into.

Teflon doesn't soften or melt at 100C bed temperature (not sure I'd trust ABS to hold up for long at 100C) . There's no need to tap it- just drill a slightly undersized hole and let the leveling screws roll their own threads into the blocks. The screws will be held securely but will be easily adjustable for leveling the bed. I think you could get away with nylon if you can't find Teflon. I used plastic anchor type screws to hold the blocks to the aluminum tube, and drilled over-sized holes for the leveling screws so they don't touch the aluminum. You can buy small pieces of Teflon via ebay if you don't have a local plastics supplier.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I recently rebuilt the Y axis in one of my printers including a kinematic mount for the 1/4" thick cast aluminum bed plate. There are 3 bearing blocks on the guide rails and 3 leveling screws, which are located as close to the bearing blocks as possible for maximum stability. I used square aluminum tubing mounted on the bearing blocks to hold Teflon blocks that the leveling screws are driven into.

Teflon doesn't soften or melt at 100C bed temperature (not sure I'd trust ABS to hold up for long at 100C) . There's no need to tap it- just drill a slightly undersized hole and let the leveling screws roll their own threads into the blocks. The screws will be held securely but will be easily adjustable for leveling the bed. I think you could get away with nylon if you can't find Teflon. I used plastic anchor type screws to hold the blocks to the aluminum tube, and drilled over-sized holes for the leveling screws so they don't touch the aluminum. You can buy small pieces of Teflon via ebay if you don't have a local plastics supplier.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: heated bed desing - and usage of ABS February 15, 2019 10:06AM |

Registered: 8 years ago Posts: 55 |

I am looking at your printers a lot for design ideas. I also already saw your y-axis design.

My main issue is that I don’t have square but round bearings to which I need to mount. They are not of a standard size but very high quality. Got them as a present. I can print a mount. But I don’t know how to do the thermal decoupling. And if it is needed.

My main issue is that I don’t have square but round bearings to which I need to mount. They are not of a standard size but very high quality. Got them as a present. I can print a mount. But I don’t know how to do the thermal decoupling. And if it is needed.

|

Re: heated bed desing - and usage of ABS February 15, 2019 08:08PM |

Registered: 11 years ago Posts: 5,780 |

What thermal decoupling are you worried about?

The bearings in my Y axis are mostly decoupled by the steel leveling screw and teflon block that it sits in. The aluminum tube that the Teflon is mounted on might warm up a little due to proximity to the heater, (one reason I made the top surfaces smaller by cutting the tubes at angles) but they never get hot and they don't transfer much heat to the bearings. I'll try to make some thermal images the next time I see the guy with the thermal camera at the makerspace. I've been wanting to make thermal images of the A, B, and extruder motors anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The bearings in my Y axis are mostly decoupled by the steel leveling screw and teflon block that it sits in. The aluminum tube that the Teflon is mounted on might warm up a little due to proximity to the heater, (one reason I made the top surfaces smaller by cutting the tubes at angles) but they never get hot and they don't transfer much heat to the bearings. I'll try to make some thermal images the next time I see the guy with the thermal camera at the makerspace. I've been wanting to make thermal images of the A, B, and extruder motors anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: heated bed desing - and usage of ABS March 01, 2019 01:56AM |

Registered: 8 years ago Posts: 55 |

I meant the insulation from heated bed to the bearings. I utilized some of your ideas now.

I went for a 3 point leveled bed. And the Teflon insulation I did a bit different. I have the cariage mounted on a stand with M5 thread. In there I put a 4/2 Teflon tube. then I forced in a M3 screw, not long enough to touch the bottom of the thread.

Not a thick insulation. But better than nothing and with material I had at hand.

Will see how it works once the kapton heater is in.

Thanks for all the inspiration.

I went for a 3 point leveled bed. And the Teflon insulation I did a bit different. I have the cariage mounted on a stand with M5 thread. In there I put a 4/2 Teflon tube. then I forced in a M3 screw, not long enough to touch the bottom of the thread.

Not a thick insulation. But better than nothing and with material I had at hand.

Will see how it works once the kapton heater is in.

Thanks for all the inspiration.

Sorry, only registered users may post in this forum.