Best way to make use of these Powdered Bronze Bushings?

Posted by Ohmarinus

|

Best way to make use of these Powdered Bronze Bushings? May 10, 2019 12:13PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi all, it's been a while since I've ordered these bushings in the dimensions 8*12*15:

[www.robotdigg.com]

I've been trying to design a couple of holders in which the bushings are press-fit into a slightly smaller hole. The thing is, no matter how correct I line then up, the bushings keep binding to the hard-chromed rods. I have a few sets of hard chromed rods, with different specifications and this happens to all of the rods I've tried so far. From what I understood bronze bushings are better for hard chromed linear rods than plastic type and I don't want to use LM8UU's this time.

I've been also looking at making them 'click' into a holder, maybe this leaves the bearings a little bit less tight so it might bind less fast..? I'm not sure if this is going to work at all, maybe I should just put the bearings in a small pipe and fix the pipe in the 3D-printed part. It just seems like a printed part might not be straight enough even though my printer is absolutely square and configured really well.

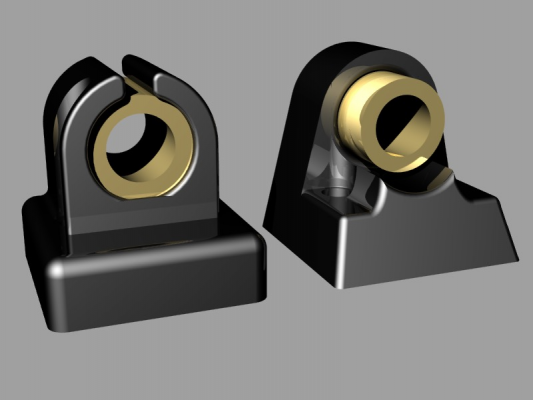

Models of bushing holders I tried for example:

Right now I'm only trying to get these to work on my Y-axis, but I've also tried to make a nice coreXY machine with these nifty little things and it hasn't worked out for me in the past. Since I have ordered around 24 a few years back, they're just laying around staring at me all the time and I thought it was about time to start doing something with them since I have bought all these expensive linear rods in the past and I feel like I'm wasting away those rods if I just use LM8UU's all the time.

Does anyone have tips for me on how to get this to work?

http://www.marinusdebeer.nl/

[www.robotdigg.com]

I've been trying to design a couple of holders in which the bushings are press-fit into a slightly smaller hole. The thing is, no matter how correct I line then up, the bushings keep binding to the hard-chromed rods. I have a few sets of hard chromed rods, with different specifications and this happens to all of the rods I've tried so far. From what I understood bronze bushings are better for hard chromed linear rods than plastic type and I don't want to use LM8UU's this time.

I've been also looking at making them 'click' into a holder, maybe this leaves the bearings a little bit less tight so it might bind less fast..? I'm not sure if this is going to work at all, maybe I should just put the bearings in a small pipe and fix the pipe in the 3D-printed part. It just seems like a printed part might not be straight enough even though my printer is absolutely square and configured really well.

Models of bushing holders I tried for example:

Right now I'm only trying to get these to work on my Y-axis, but I've also tried to make a nice coreXY machine with these nifty little things and it hasn't worked out for me in the past. Since I have ordered around 24 a few years back, they're just laying around staring at me all the time and I thought it was about time to start doing something with them since I have bought all these expensive linear rods in the past and I feel like I'm wasting away those rods if I just use LM8UU's all the time.

Does anyone have tips for me on how to get this to work?

http://www.marinusdebeer.nl/

|

Re: Best way to make use of these Powdered Bronze Bushings? May 13, 2019 12:57AM |

Registered: 6 years ago Posts: 93 |

I noticed some time ago, the original corexy epoxied the bushings to the carriage plate instead of trying to constrain them in a holder. It would seem smarter to let gravity do the perfect alignments (assuming the rods are perfectly parallel).

I've also built an X axis trying this method, and it glides so smooth and fast, it's quite ridiculous. Soon I'll be getting back to that project.

Edit: Here's a pic of my solution, epoxied while oriented vertically above one side's bushings, then to the other side's bushings. The carriage was modeled with 1mm extra clearance for the epoxy.

Edited 1 time(s). Last edit at 05/13/2019 01:14AM by Diggrr.

I've also built an X axis trying this method, and it glides so smooth and fast, it's quite ridiculous. Soon I'll be getting back to that project.

Edit: Here's a pic of my solution, epoxied while oriented vertically above one side's bushings, then to the other side's bushings. The carriage was modeled with 1mm extra clearance for the epoxy.

Edited 1 time(s). Last edit at 05/13/2019 01:14AM by Diggrr.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 13, 2019 04:37AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Diggrr

I noticed some time ago, the original corexy epoxied the bushings to the carriage plate instead of trying to constrain them in a holder. It would seem smarter to let gravity do the perfect alignments (assuming the rods are perfectly parallel).

I've also built an X axis trying this method, and it glides so smooth and fast, it's quite ridiculous. Soon I'll be getting back to that project.

Edit: Here's a pic of my solution, epoxied while oriented vertically above one side's bushings, then to the other side's bushings. The carriage was modeled with 1mm extra clearance for the epoxy.

Indeed, that was the first thing I noticed too when I first made a CoreXY design in 2014. The original uses epoxy. However, I've never worked with epoxy and I'm a bit afraid of it somehow. I shall see if I can source some over here for a good price. In my country everything slightly industrial cannot be bought at stores. The Netherlands is a terrible country to live in when you're a DIY type of person and it's really hard to find sellers that sell more industrial type of goods without having minimum order quantities or forcing you to only be able to buy it with a business account.

Did you mount the bushings with the rods flat on a table or did you mount the rods in the machine first and only then glued it? I also notice your bushings are longer than mine, maybe that makes them less bindy.

Edited 1 time(s). Last edit at 05/13/2019 04:38AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Best way to make use of these Powdered Bronze Bushings? May 13, 2019 06:53PM |

Registered: 7 years ago Posts: 507 |

You could try and "float" the sbushings on the second rail of each axis. Since the only reason you need two rails is to prevent rotation about the axis of the first rail, the second one can have a bit of "slop", ideally a slot that is parallel to the plane created by the two rails. If you look at lathe beds and saddles, ton the bed here is usually one V way (or similar), this is where the saddle registers. On the other side its just two flat surfaces sliding against each other. This avoids over constraint and binding. For instance, if you had V ways on both sides, and your saddle experiences thermal expansion, or the rails move further or closer together for whatever reason, it would bind. The two V ways would be fighting each other to stay in position (similar to how the bushings would) and bind up. With one V way and the second being just a flat surface, even if the saddle thermally expands or the rails move in and out, the second "bushing" on the saddle (the non V way one) can slide perpendicular across the rail (i.e. not in the direction of travel) to accomodate and avoid binding, while the "bushing" on the V way keeps registration and alignment. If done right, you lose no accuracy or precision, since the second rail/bushing moving in and out will not cause the carriage to rotate, and the first rail will keep it going in a straight line.

Not sure if I explained this very well.

Not sure if I explained this very well.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 15, 2019 01:14AM |

Registered: 6 years ago Posts: 93 |

Quote

Ohmarinus

Did you mount the bushings with the rods flat on a table or did you mount the rods in the machine first and only then glued it? I also notice your bushings are longer than mine, maybe that makes them less bindy.

I had the rods mounted securely to the axis plates on each end and on a flat surface, but not installed in the machine. You want them in their final position to make sure the rods are parallel and planar so the bushings line up to them correctly. In the machine would be fine as long as you have room to work.

I had another thought for easier alignment. Design the hole of your bushing mounts to be 1mm or two larger than the bushing, with a small hole on the side. You can insert a silicone or glue into that small side hole. This should let them self-align inside the holder without the need for an epoxy. Just assemble everything first, without belts, then add glue/silicone.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 15, 2019 01:37AM |

Registered: 6 years ago Posts: 93 |

I get what you're saying Trakyan, the bushings on one side could even be the looser Igus bushings (they're slightly loose when not pressed into a specially sized carrier block). Then the carriage would follow one rail on bronze bushings, and the second rail would simply register the carriage in 3D space.

I think the main problem comes from multi-part printing on a non-perfect surface (who has one?? lol), the carriers will always tip very slightly out alignment with each other once fastened to something. I've even had trouble with one piece systems, maybe reaching the limits of FDM accuracy, bushings have no forgiveness.

I think the main problem comes from multi-part printing on a non-perfect surface (who has one?? lol), the carriers will always tip very slightly out alignment with each other once fastened to something. I've even had trouble with one piece systems, maybe reaching the limits of FDM accuracy, bushings have no forgiveness.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 23, 2019 03:27AM |

Registered: 7 years ago Posts: 507 |

You're right, you're sort of pushing the limits of the sort of tolerances an FDM printer can hold. Something like a bushing can be unforgiving with alignment, and a sufficiently bulky and stiff part that isn't to the correct tolerance will force it out of alignment and cause it to bind. You can either design more flexibl (less rigid) parts, which isn't the best solution, or design in "slop" that allows for misalignment. That second solution isn't as much of a cop out as it seems, professional machines (i.e. big honking industrial lathes) do this as well, though they're usually compensating for thermal expansion and the likes rather than the sloppier tolerances we get from fdm.

Aside from putting the second bushing in a slot rather than a hole sized for the bushing, you could also forgo the second bushing altogether. You could replace it with block (technically a bushing, but different sort) that sits on top of the second rail. This of course only works for rods that are in horizontal plane, rather than vertical plane. The solidoodle 2 (i think?) did this. Simple, very forgiving but depending on where your center of mass is and your acceleration, the block can lift off the rail during acceleration/deceleration. You could always add some kind of preload holding it against the rail. This second solution in theory is a bit more forgiving to misalignment, without sacrificing accuracy, because it is less overconstrained. That being said, a second bushing in a slot seems a bit more elegant.

Also, like you said, a more "flexible" bushing could be used for the second bushing. There are some 3D printed bushings on thingiverse with what look like angled fins that hold the rail. These seems like they could have some radial give as to absorb misalignment, the fins could also be designed to bend and get preloaded by the rod, as to remove the slight bit of play bronze bushings need to have.

Aside from putting the second bushing in a slot rather than a hole sized for the bushing, you could also forgo the second bushing altogether. You could replace it with block (technically a bushing, but different sort) that sits on top of the second rail. This of course only works for rods that are in horizontal plane, rather than vertical plane. The solidoodle 2 (i think?) did this. Simple, very forgiving but depending on where your center of mass is and your acceleration, the block can lift off the rail during acceleration/deceleration. You could always add some kind of preload holding it against the rail. This second solution in theory is a bit more forgiving to misalignment, without sacrificing accuracy, because it is less overconstrained. That being said, a second bushing in a slot seems a bit more elegant.

Also, like you said, a more "flexible" bushing could be used for the second bushing. There are some 3D printed bushings on thingiverse with what look like angled fins that hold the rail. These seems like they could have some radial give as to absorb misalignment, the fins could also be designed to bend and get preloaded by the rod, as to remove the slight bit of play bronze bushings need to have.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 23, 2019 04:06AM |

Admin Registered: 16 years ago Posts: 13,886 |

... or search for "self aligning spherical bearings" -- here some from Igus

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Best way to make use of these Powdered Bronze Bushings? May 24, 2019 04:34AM |

Registered: 7 years ago Posts: 507 |

Those would allow for the bushings to rotate, but I don't think that's what's causing the binding here. If the rods are out of parallel, or bent etc. the distance between them changes and thats what I think causes binding. There is some binding if you try to force the bushing itself out of paralle with the rail, in which case the spherical bearings would help, but I don't think thats the whole issue.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 24, 2019 04:50AM |

Admin Registered: 16 years ago Posts: 13,886 |

... "non-parallel" binding can be avoided by designing one rail "fixed" and the other with some "play" towards the fixed one (evantually supported with springs for heavy masses) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Best way to make use of these Powdered Bronze Bushings? May 24, 2019 08:20AM |

Registered: 6 years ago Posts: 1,007 |

Quote

VDX

... "non-parallel" binding can be avoided by designing one rail "fixed" and the other with some "play" towards the fixed one (evantually supported with springs for heavy masses) ...

Indeed, I make my own using Igus filament that I can integrate directly thus further saving weight and they work fine.

Similar shape in sintered bronze can be used too. Can be found in electric appliance motor.

Straight bushings are fine too but require the proper technique to mount/align and a rigid frame to keep them that way.

Unlike LM series that will straighten the flexible improperly built/aligned frame even make their own track on soft SS bars, they will bind. Even less forgiving if made with Igus material.

This for the fixed guide, the other, indeed just a flat bearing. Easy to make, just crush a piece of Igus filament and you got your flat bearing.

Edited 1 time(s). Last edit at 05/25/2019 09:34AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Best way to make use of these Powdered Bronze Bushings? May 24, 2019 08:51PM |

Registered: 7 years ago Posts: 507 |

Wouldn't allowing the second bushing to float rather than the second rail to float be easier? One smaller component that is attached at a single point, rather than a larger component fixed at two ends? There could be something I'm missing here but on most machines I've seen the rails are fixed rigidly and the second bushing is allowed to move perpendicularly across them, like the flat way on a lathe bed, or it has some play where it is mounted to the carriage and can move that way.

|

Re: Best way to make use of these Powdered Bronze Bushings? May 26, 2019 05:07AM |

Admin Registered: 11 years ago Posts: 3,096 |

Thanks for all the input! I will soon try out a few of these methods, maybe combining the bushing on one side with LM8UU's on the other side, I also have found a box of push-fit PTFE-lined bushings which seem to run better on my machine but they need to be press-fit into tolerance and it's really hard to 3D-print exactly withing the desired tolerance.

Haven't found any epoxy glue that is available at a good price (it's either bulk cans of a liter or so or buying a small double-barreled dispenser for €15~20) plus shipping cost.. This is not worth it. I can obsess about every little detail and it's going to be too expensive.

I have printed four new bushing holders and will try to install these soon when I am going to replace the kapton tape on my print bed. It got damaged pretty good when I was working on my machine two weeks ago and I'm going to remove the spring-loaded bed and turn it into a fixed bed with brass standoff nuts (since I have an inductive proximity sensor now and an all aluminium bed anyway). Might as well add some (uncompressed) cork in between since I have a huge slice of that laying around.

I'll update when I got it to work

http://www.marinusdebeer.nl/

Haven't found any epoxy glue that is available at a good price (it's either bulk cans of a liter or so or buying a small double-barreled dispenser for €15~20) plus shipping cost.. This is not worth it. I can obsess about every little detail and it's going to be too expensive.

I have printed four new bushing holders and will try to install these soon when I am going to replace the kapton tape on my print bed. It got damaged pretty good when I was working on my machine two weeks ago and I'm going to remove the spring-loaded bed and turn it into a fixed bed with brass standoff nuts (since I have an inductive proximity sensor now and an all aluminium bed anyway). Might as well add some (uncompressed) cork in between since I have a huge slice of that laying around.

I'll update when I got it to work

http://www.marinusdebeer.nl/

|

Re: Best way to make use of these Powdered Bronze Bushings? May 29, 2019 08:22AM |

Registered: 6 years ago Posts: 1,007 |

Epoxy can be found in plenty of stores ! It is not cheap but you dont need a lot !

This:

[reprap.org]

is a good example of a bad use of it (not strong) and a waste !

You have to make the hole of the bearing holders oversized, smear the inside and the bushings outside with epoxy, install the bushings in them, then install the smooth rod through the bushings and let the epoxy hardens.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

This:

[reprap.org]

is a good example of a bad use of it (not strong) and a waste !

You have to make the hole of the bearing holders oversized, smear the inside and the bushings outside with epoxy, install the bushings in them, then install the smooth rod through the bushings and let the epoxy hardens.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.