Building A Delta

Posted by LetumEternum

|

Building A Delta July 28, 2019 10:25AM |

Registered: 4 years ago Posts: 3 |

Hi guys, so a little over a month ago I finally purchased a HE3D printer from amazon and after playing with it for 2 weeks the power supply started to smoke one night. I ended up returning it and decided that I could put something together that would work better probably only for a little more.

Now before the power supply had failed I had downloaded fusion 360 (never used a cad program before) to learn and to design a new effector to hold an E3D hot end (I know I could have found one online). With the return of the printer, the project had evolved into something else and in the past several weeks I put together something quite neat that I would love to share.

Now I have to say I'm no engineer and have no background in mechanical design or anything like that, so if anything is off that is why.

Here is some info on the entire design thus far.

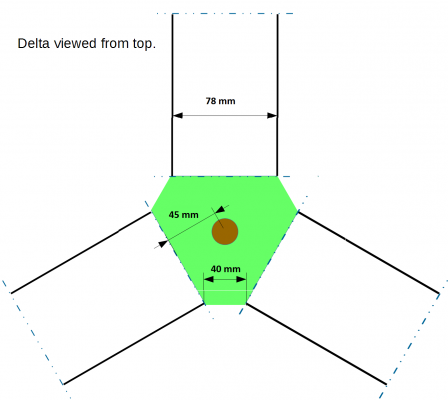

The distance between the arms is 78 mm (carriage width).

Arm Length 360 mm (not final)

Bed Diameter of 300 mm

Hot End: E3DV6

Board: Duet 2 Wifi

x3 20 mm Piezoelectric Sensors

Frame

Height: 1000 mm

Width: 450 mm Aluminum extrusions + Corners

At the moment my design is setup to uses 2020 Aluminum Extrusions, however, for the height pieces, I currently have Misumi 60 degree extrusions.

With these current extrusions, I have no real way to connect the linear rails, I have however found these extrusions from Germany and would like to try and acquire three.

Linear Rails:

I will be using three HGH15CA blocks (Cheap Chinese ones) I will be replacing the bearings inside with some g5 silicone nitride ones to hopefully improve performance. (I totally know I could use the smaller profile ones but man do I just love how they look). I think I can get away with 800 mm rails, I haven't yet decided on which ones I want yet.

Carriages:

I don't have any zoomed-in shots atm other from the renderings I included, what I have done differently though is the way I mounted the belt. Instead of having it run perpendicular to the carriage I will have it run parallel through a slot in the carriage. A set screw in the top and bottom of the belt retainer on the carriage will provide tightening for the belt.

Belt:

I plan on using either a 10 or 12 mm wide GT2 belt

Rod Ends:

For the rod ends I'm doing something a little different than I've seen most people do. I wanted to originally go with those magnetic balls but I finally decided to use this awesome igus EARM-05 rod end. I feel they will be super reliable and very tight compared to some of the other rod ends I've seen. Now, something I did a little different in my design is how I aligned the end links, instead of mounting them parallel with the bed I mounted them perpendicular and at a 60-degree angle. The reason I did this comes from a thesis paper that I found Design, Construction, Control, and Analysis of Linear Delta Robot.

Rods:

At the moment I think I will be using 9 mm OD carbon fiber rods with a 5 mm ID for a 2 mm thick wall.

Z-Offset sensor:

Here is where the entire idea for this effector came to mind in the first place, refer to the effector animation I made to help better understand. Essentially the hotend, cooling fans and cooling channels are mounted to a triangular plate, this plate is held in place by three 37 mm long, 6mm wide rods which ride on three igus RJMP-01-06 linear slide bearings. Now, towards the end of these rods will be two 19 mm in diameter discs, the bottom disc will sit on a piezoelectric sensor, the upper disc will hold a very light spring that will press the rods down onto the sensor. When the nozzle presses against the bed it will push against the springs and lift the plates of the sensors. From my understanding, this should give a 0 Z offset for the effector.

Part Cooling:

I pieced together 2 cooling ducts (which I have not decided how to mount yet) that will be powered by two 3010 radial fans.

That is all I can think of at the moment, I'll update as I go forward.

Animations:

Effector Tour

Effector Exploded

Complete Tour

Carriage Exploded

Carriage Tour

Edited 2 time(s). Last edit at 07/28/2019 08:22PM by LetumEternum.

Now before the power supply had failed I had downloaded fusion 360 (never used a cad program before) to learn and to design a new effector to hold an E3D hot end (I know I could have found one online). With the return of the printer, the project had evolved into something else and in the past several weeks I put together something quite neat that I would love to share.

Now I have to say I'm no engineer and have no background in mechanical design or anything like that, so if anything is off that is why.

Here is some info on the entire design thus far.

The distance between the arms is 78 mm (carriage width).

Arm Length 360 mm (not final)

Bed Diameter of 300 mm

Hot End: E3DV6

Board: Duet 2 Wifi

x3 20 mm Piezoelectric Sensors

Frame

Height: 1000 mm

Width: 450 mm Aluminum extrusions + Corners

At the moment my design is setup to uses 2020 Aluminum Extrusions, however, for the height pieces, I currently have Misumi 60 degree extrusions.

With these current extrusions, I have no real way to connect the linear rails, I have however found these extrusions from Germany and would like to try and acquire three.

Linear Rails:

I will be using three HGH15CA blocks (Cheap Chinese ones) I will be replacing the bearings inside with some g5 silicone nitride ones to hopefully improve performance. (I totally know I could use the smaller profile ones but man do I just love how they look). I think I can get away with 800 mm rails, I haven't yet decided on which ones I want yet.

Carriages:

I don't have any zoomed-in shots atm other from the renderings I included, what I have done differently though is the way I mounted the belt. Instead of having it run perpendicular to the carriage I will have it run parallel through a slot in the carriage. A set screw in the top and bottom of the belt retainer on the carriage will provide tightening for the belt.

Belt:

I plan on using either a 10 or 12 mm wide GT2 belt

Rod Ends:

For the rod ends I'm doing something a little different than I've seen most people do. I wanted to originally go with those magnetic balls but I finally decided to use this awesome igus EARM-05 rod end. I feel they will be super reliable and very tight compared to some of the other rod ends I've seen. Now, something I did a little different in my design is how I aligned the end links, instead of mounting them parallel with the bed I mounted them perpendicular and at a 60-degree angle. The reason I did this comes from a thesis paper that I found Design, Construction, Control, and Analysis of Linear Delta Robot.

Rods:

At the moment I think I will be using 9 mm OD carbon fiber rods with a 5 mm ID for a 2 mm thick wall.

Z-Offset sensor:

Here is where the entire idea for this effector came to mind in the first place, refer to the effector animation I made to help better understand. Essentially the hotend, cooling fans and cooling channels are mounted to a triangular plate, this plate is held in place by three 37 mm long, 6mm wide rods which ride on three igus RJMP-01-06 linear slide bearings. Now, towards the end of these rods will be two 19 mm in diameter discs, the bottom disc will sit on a piezoelectric sensor, the upper disc will hold a very light spring that will press the rods down onto the sensor. When the nozzle presses against the bed it will push against the springs and lift the plates of the sensors. From my understanding, this should give a 0 Z offset for the effector.

Part Cooling:

I pieced together 2 cooling ducts (which I have not decided how to mount yet) that will be powered by two 3010 radial fans.

That is all I can think of at the moment, I'll update as I go forward.

Animations:

Effector Tour

Effector Exploded

Complete Tour

Carriage Exploded

Carriage Tour

Edited 2 time(s). Last edit at 07/28/2019 08:22PM by LetumEternum.

|

Re: Building A Delta July 29, 2019 02:52PM |

Registered: 10 years ago Posts: 14,672 |

Sounds good; but have you considered using the Duet3D Smart Effector and carriage adapters? It combines precise geometry with a built-in Z probe. [www.duet3d.com]

I tried Igus rod ends about 3 years ago but they didn't work very well for me. In particular, the range of movement was too small - less than both Traxxas rod ends that I used previously and the magnetic joints that I use now.

Edited 1 time(s). Last edit at 07/29/2019 03:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I tried Igus rod ends about 3 years ago but they didn't work very well for me. In particular, the range of movement was too small - less than both Traxxas rod ends that I used previously and the magnetic joints that I use now.

Edited 1 time(s). Last edit at 07/29/2019 03:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building A Delta July 29, 2019 04:50PM |

Registered: 4 years ago Posts: 3 |

Quote

dc42

Sounds good; but have you considered using the Duet3D Smart Effector and carriage adapters? It combines precise geometry with a built-in Z probe. [www.duet3d.com]

I tried Igus rod ends about 3 years ago but they didn't work very well for me. In particular, the range of movement was too small - less than both Traxxas rod ends that I used previously and the magnetic joints that I use now.

Yup, I've seen them and they look great, I just really wanted to try the whole piezoelectric sensor setup I put together, I find it to look awesome. I wanted to go with magnetic balls for a while but something about the igus rod ends has really become aesthetically attractive to me

I've taken the range of motion into account and from the simulations I did in fusion 360 (pulling the effector around with the joint constraints I put in place) by flipping the rod ends to be perpendicular to the bed at 60 degrees I managed to get the effector to just reach the 300 mm diameter boundary of the build platform. The only reason I didn't go the Traxxas route is that from what I've heard I didn't feel like cherry-picking for 12 good rod ends when I know I can order 12 and have them be a specified tolerance.

|

Re: Building A Delta July 30, 2019 11:43AM |

Registered: 4 years ago Posts: 3 |

Some Updates:

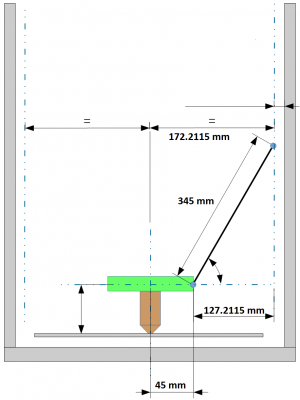

I have most of the geometry numbers setup now as per the images. Also added the two parts below to my list.

Power Supply

0.9 deg stepper motor

Edited 1 time(s). Last edit at 07/30/2019 11:44AM by LetumEternum.

I have most of the geometry numbers setup now as per the images. Also added the two parts below to my list.

Power Supply

0.9 deg stepper motor

Edited 1 time(s). Last edit at 07/30/2019 11:44AM by LetumEternum.

Sorry, only registered users may post in this forum.