Unsupported linear rail X axis

Posted by cos4

|

Unsupported linear rail X axis February 09, 2020 10:00AM |

Registered: 4 years ago Posts: 6 |

I'm planning to build a printer in with CoreXY kinematics based on the Hypercube evolution design. For the X and Y axis I want to use MGN linear rails. In the installation manuals it seems that these rails are meant to be always mounted on a stiff, flat surface. However I see quite some designs using an unsupported rail as X axis (e.g. here: [www.thingiverse.com]). Since I'm planning for a relatively small build volume (MK52 Prusa bed, so approximately 300mm of X axis) I'm looking for advise if it's ok to use a linear rail this way or better to mount it on some aluminum extrusion or the like.

|

Re: Unsupported linear rail X axis February 09, 2020 11:59AM |

Registered: 11 years ago Posts: 5,780 |

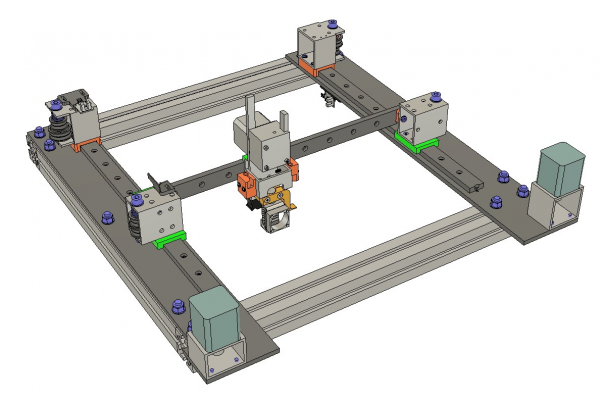

I'd say it depends on how big a rail you intend to use, how massive the extruder carriage will be, and the kind of speed/acceleration/jerk you expect to use. That said, it's all but impossible to predict what sort of ringing you might get. My printer has a 24x8 mm guide rail for the X axis with nothing behind it, and it has a pretty heavy extruder carriage with direct extruder and lots of aluminum. I get a little ringing in the prints. This is the XY assembly in my printer:

Linear guides are flat and rigid, but just like round guide rail, when they are only end-supported, small ones may flex a bit as the Y axis moves back and forth.

Beware of "MGN" designated rails. That part designation comes from HiWin which makes high quality linear guides, but there are about a thousand Chinese companies that make copies of HiWin parts using the same part numbers but none of the quality. I buy used and NOS Japanese/German/US made guide rails via ebay for prices that are only a little higher than crappy HiWin knockoffs. Look for brands like NSK, THK, IKO, Thomson, Bosch. You may not be able to get the exact size called out in the BOM, but if you're able to build from someone's BOM you should be able to figure out what needs to be modified to fit whatever linear guides you end up with. You can cut linear guide rail to required length with a cut-off wheel on a grinder.

Do you plan to enclose/heat this printer? If so you may want to add a second bearing block to the X axis guide rail. Linear guides are intolerant of mechanical errors in mounting. When the printer's aluminum frame heats up, the Y axis guide rails will move apart. It only takes a few 10s of microns to cause the mechanism to bind or cause excessive wear on the rails. The second bearing block on the X axis is used to mount the X axis rail to one of the Y axis pulley blocks. It let's the rail slide a little to allow for expansion/contraction as temperature changes. In the picture above, the X axis rail bolts to the pulley block on the right with a spacer (orange). On the left side pulley block, there a second bearing block attaching the rail to the pulley mount.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Linear guides are flat and rigid, but just like round guide rail, when they are only end-supported, small ones may flex a bit as the Y axis moves back and forth.

Beware of "MGN" designated rails. That part designation comes from HiWin which makes high quality linear guides, but there are about a thousand Chinese companies that make copies of HiWin parts using the same part numbers but none of the quality. I buy used and NOS Japanese/German/US made guide rails via ebay for prices that are only a little higher than crappy HiWin knockoffs. Look for brands like NSK, THK, IKO, Thomson, Bosch. You may not be able to get the exact size called out in the BOM, but if you're able to build from someone's BOM you should be able to figure out what needs to be modified to fit whatever linear guides you end up with. You can cut linear guide rail to required length with a cut-off wheel on a grinder.

Do you plan to enclose/heat this printer? If so you may want to add a second bearing block to the X axis guide rail. Linear guides are intolerant of mechanical errors in mounting. When the printer's aluminum frame heats up, the Y axis guide rails will move apart. It only takes a few 10s of microns to cause the mechanism to bind or cause excessive wear on the rails. The second bearing block on the X axis is used to mount the X axis rail to one of the Y axis pulley blocks. It let's the rail slide a little to allow for expansion/contraction as temperature changes. In the picture above, the X axis rail bolts to the pulley block on the right with a spacer (orange). On the left side pulley block, there a second bearing block attaching the rail to the pulley mount.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Unsupported linear rail X axis February 09, 2020 12:12PM |

Registered: 6 years ago Posts: 1,007 |

Misalignment and thermal expansion are compensated by mounting the rails, etc with plastic printed parts that are not very sturdy. This can be seen on the machine.

Fact is, the better the parts, the design you use, the more you have to know about proper rail mounting.

Cheap chinese rails have certainly enough play or are soft enough to prevent binding

Edited 1 time(s). Last edit at 02/09/2020 12:13PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Fact is, the better the parts, the design you use, the more you have to know about proper rail mounting.

Cheap chinese rails have certainly enough play or are soft enough to prevent binding

Edited 1 time(s). Last edit at 02/09/2020 12:13PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Unsupported linear rail X axis February 09, 2020 03:18PM |

Registered: 4 years ago Posts: 6 |

Thank you very much for the detailed answer.

I'm using a direct drive E3D Hemera, so the extruder carriage will be relatively heavy. As for the acceleration/jerk values I need to have a look what is the maximum that makes sense taking the limitations of the extrusion process for a good print quality into consideration. I plan to calculate the resulting forces then before choosing the actual dimensions of the linear rails.

I plan on using quality parts, no cheap copies. I don't plan a full enclosure for now, since I mostly print PLA and PETG but it's an option to add it later. I really like the idea about the second bearing block. Did you mount your Y axis rails on a steel sheet? Mostly I see people mounting the steel linear rails on aluminum frames which should also cause problems due to different thermal expansions coefficients (or am I overthinking this as an engineer?).

I'll definitely have a look for other manufacturers like Bosch, since they seem to be easier to get in good quality in Europe (Germany).

I'm using a direct drive E3D Hemera, so the extruder carriage will be relatively heavy. As for the acceleration/jerk values I need to have a look what is the maximum that makes sense taking the limitations of the extrusion process for a good print quality into consideration. I plan to calculate the resulting forces then before choosing the actual dimensions of the linear rails.

I plan on using quality parts, no cheap copies. I don't plan a full enclosure for now, since I mostly print PLA and PETG but it's an option to add it later. I really like the idea about the second bearing block. Did you mount your Y axis rails on a steel sheet? Mostly I see people mounting the steel linear rails on aluminum frames which should also cause problems due to different thermal expansions coefficients (or am I overthinking this as an engineer?).

I'll definitely have a look for other manufacturers like Bosch, since they seem to be easier to get in good quality in Europe (Germany).

|

Re: Unsupported linear rail X axis February 10, 2020 12:18AM |

Registered: 11 years ago Posts: 5,780 |

In my printer, the frame is 4040 t-slot and the Y axis linear guides and motors are mounted on 6.35 mm cast aluminum tooling plate. The motor mounts, pulley mounts, and part of the extruder carriage are made from rectangular aluminum tubing. I haven't seen anything that I can identify as a problem due to steel guide rails bolted to aluminum plates, but I don't know exactly what happens as temperature changes there. The aluminum expands more than the steel, and the steel is screwed down tightly. Either the rail slides a bit against the aluminum or the whole thing should bow. If it slides, I'd expect the rails to get out of alignment after many temperature cycles, but they have maintained alignment for years, so maybe it bows. But not by any amount that I can detect.

I've seen posts from people who made corexy printers using linear guides and they complained that they put the machine together in summer and when temperature in their shop dropped 10-20 degrees in winter, the mechanism would bind. The extra bearing block on the X axis prevents that sort of behavior completely. You could mount the X axis rail on an aluminum plate or tube, and it would expand at the same rate as the frame, but then you're back to the mystery behavior- does it slide or does it bend when the temperature changes? I've built printers both ways and both seem to work OK. A bearing block is probably lower mass than an aluminum plate or tube that's as long as the guide rail.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I've seen posts from people who made corexy printers using linear guides and they complained that they put the machine together in summer and when temperature in their shop dropped 10-20 degrees in winter, the mechanism would bind. The extra bearing block on the X axis prevents that sort of behavior completely. You could mount the X axis rail on an aluminum plate or tube, and it would expand at the same rate as the frame, but then you're back to the mystery behavior- does it slide or does it bend when the temperature changes? I've built printers both ways and both seem to work OK. A bearing block is probably lower mass than an aluminum plate or tube that's as long as the guide rail.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.