V slot wheels on precision shafts

Posted by hobbymods

|

V slot wheels on precision shafts June 17, 2020 07:08AM |

Registered: 7 years ago Posts: 168 |

Hi All,

I've got a kit coming that runs genuine openbuilds v slot wheels, and I'd like to mount them a little better than with a screw through the bearing and a plate on one side.

I've approached the kit manufacturer about an extra set of gantry plates and spacers. It seems they are custom, not off the shelf openbuilds.

My thoughts are to have the standard plate/spacers on both sides of the wheels, with something like this through the middle:

[www.ebay.com.au]

Obviously I'll need to measure the exact length I need, and these shoulder bolts may possibly not be a precision tolerance, but it's worth a shot. 5mm shoulder bolts with 4mm threads are not common. The only others I found were on Aliexpress, and had 3mm threads.

As for the eccentric adjusters, I thought I would use one both sides and align them correctly by making a special spanner that turned them both at once for proper alignment/adjustment. I feel that the bearing being supported both sides and mounted on a shaft rather than a screw would have to off some improvement in accuracy/reliability.

Has anyone tried this and was their any benefit?

Edited 1 time(s). Last edit at 06/17/2020 07:09AM by hobbymods.

I've got a kit coming that runs genuine openbuilds v slot wheels, and I'd like to mount them a little better than with a screw through the bearing and a plate on one side.

I've approached the kit manufacturer about an extra set of gantry plates and spacers. It seems they are custom, not off the shelf openbuilds.

My thoughts are to have the standard plate/spacers on both sides of the wheels, with something like this through the middle:

[www.ebay.com.au]

Obviously I'll need to measure the exact length I need, and these shoulder bolts may possibly not be a precision tolerance, but it's worth a shot. 5mm shoulder bolts with 4mm threads are not common. The only others I found were on Aliexpress, and had 3mm threads.

As for the eccentric adjusters, I thought I would use one both sides and align them correctly by making a special spanner that turned them both at once for proper alignment/adjustment. I feel that the bearing being supported both sides and mounted on a shaft rather than a screw would have to off some improvement in accuracy/reliability.

Has anyone tried this and was their any benefit?

Edited 1 time(s). Last edit at 06/17/2020 07:09AM by hobbymods.

|

Re: V slot wheels on precision shafts June 17, 2020 08:06AM |

Registered: 11 years ago Posts: 5,780 |

As my rustic grandmother in the Tennessee hill country used to say, "you can't make a silk purse out of a sow's ear".

Adding shoulder screws won't change the fact that the surface the wheels are riding on is not ground and polished to ensure flatness or straightness. It also won't ensure that the molded plastic wheels are round, smooth, and perfectly centered on the bearings, and have a perfectly smooth surface, or that the bearings don't wobble.

All that said, the are plenty of good printers that use t- or v-slot systems. I wouldn't worry about substituting shoulder screws for whatever comes with the kit. Build the kit and then start picking at it based on things you don't like that you see in the prints or the way the printer forces you to operate it, or things you want to do with it but can't. I suggest you do what I did after I built my first printer. Every time you run into any kind of problem that is a function of the way the printer is built or the way it has to be operated because of the controller, etc., add it to a list. It doesn't matter. If it bothers you, put it on the list. After a few months you'll have a long list of stuff. Once you've run out of things to put on the list, rank each item in terms of importance - it might be important because it makes doing certain things difficult or because it affects print quality. Next, for each of the items, make a list of possible solutions. Don't get sold on a solution that fixes a couple problems and then try to shoehorn it into fixing other problems- make the list first. After you've made the list of potential fixes for the problems, start to look for commonalities. Maybe replacing wheel axles with shoulder screws will be in there, maybe it won't. Maybe you'll decide that the controller has to be replaced with something better. Maybe that will solve 10 problems at once (assuming you pick the right new controller). At some point you can also factor in the cost of the fixes. You might find that $50 well spent will fix 90% of the problems and that fixing the the last 10% will cost $500. You'll have to decide what your tolerance for pain is...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Adding shoulder screws won't change the fact that the surface the wheels are riding on is not ground and polished to ensure flatness or straightness. It also won't ensure that the molded plastic wheels are round, smooth, and perfectly centered on the bearings, and have a perfectly smooth surface, or that the bearings don't wobble.

All that said, the are plenty of good printers that use t- or v-slot systems. I wouldn't worry about substituting shoulder screws for whatever comes with the kit. Build the kit and then start picking at it based on things you don't like that you see in the prints or the way the printer forces you to operate it, or things you want to do with it but can't. I suggest you do what I did after I built my first printer. Every time you run into any kind of problem that is a function of the way the printer is built or the way it has to be operated because of the controller, etc., add it to a list. It doesn't matter. If it bothers you, put it on the list. After a few months you'll have a long list of stuff. Once you've run out of things to put on the list, rank each item in terms of importance - it might be important because it makes doing certain things difficult or because it affects print quality. Next, for each of the items, make a list of possible solutions. Don't get sold on a solution that fixes a couple problems and then try to shoehorn it into fixing other problems- make the list first. After you've made the list of potential fixes for the problems, start to look for commonalities. Maybe replacing wheel axles with shoulder screws will be in there, maybe it won't. Maybe you'll decide that the controller has to be replaced with something better. Maybe that will solve 10 problems at once (assuming you pick the right new controller). At some point you can also factor in the cost of the fixes. You might find that $50 well spent will fix 90% of the problems and that fixing the the last 10% will cost $500. You'll have to decide what your tolerance for pain is...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: V slot wheels on precision shafts June 17, 2020 09:45AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

As my rustic grandmother in the Tennessee hill country used to say, "you can't make a silk purse out of a sow's ear".

Adding shoulder screws won't change the fact that the surface the wheels are riding on is not ground and polished to ensure flatness or straightness. It also won't ensure that the molded plastic wheels are round, smooth, and perfectly centered on the bearings, and have a perfectly smooth surface, or that the bearings don't wobble.

All that said, the are plenty of good printers that use t- or v-slot systems. I wouldn't worry about substituting shoulder screws for whatever comes with the kit. Build the kit and then start picking at it based on things you don't like that you see in the prints or the way the printer forces you to operate it, or things you want to do with it but can't. I suggest you do what I did after I built my first printer. Every time you run into any kind of problem that is a function of the way the printer is built or the way it has to be operated because of the controller, etc., add it to a list. It doesn't matter. If it bothers you, put it on the list. After a few months you'll have a long list of stuff. Once you've run out of things to put on the list, rank each item in terms of importance - it might be important because it makes doing certain things difficult or because it affects print quality. Next, for each of the items, make a list of possible solutions. Don't get sold on a solution that fixes a couple problems and then try to shoehorn it into fixing other problems- make the list first. After you've made the list of potential fixes for the problems, start to look for commonalities. Maybe replacing wheel axles with shoulder screws will be in there, maybe it won't. Maybe you'll decide that the controller has to be replaced with something better. Maybe that will solve 10 problems at once (assuming you pick the right new controller). At some point you can also factor in the cost of the fixes. You might find that $50 well spent will fix 90% of the problems and that fixing the the last 10% will cost $500. You'll have to decide what your tolerance for pain is...

Hi Mark, thanks for the reply

I do agree with your point about not just upgrading for no reason, and waiting for an issue to arise rather than pre empting things. I actually have a bit of prior form for doing that too, so I'll think about it more before going that way.

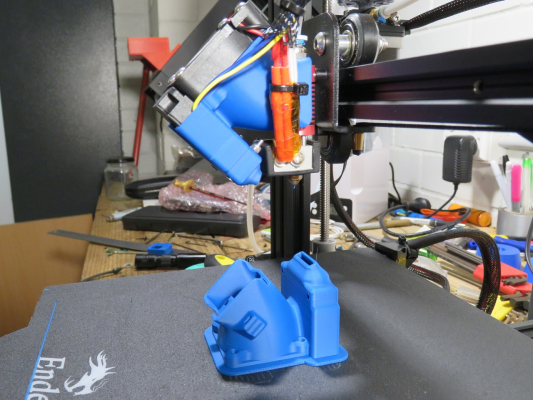

I would have agreed with what you say about v slot rollers until my duet machine broke down and I grabbed a little E3 Pro just to keep me printing in the meantime. I viewed it very skeptically, but for my amusement I watched a few videos and set it up very carefully. I was very surprised when it started knocking out prints like this, and continued to do so consistently after 100's of hours of heavy use:

These are off a bone stock machine, but I am an instrument tech off the mines/oil rigs and can swing a spanner. I also have some experience with linear motion in aggressive environments. I've been printing for 10 years on various machines, and would like to think I've got a few tricks up my sleeve, but also plenty more to learn as well.

While I absolutely agree that linear bearings are better than chinese v rollers, a point that is often missed in printers is that linear bearings are rarely if ever installed as they are meant to be, and v slot rollers are often incorrectly adjusted. They are supposed to be mounted on a precision machined/ground surface with a reference edge that they are then also clamped against to ensure they meet their spec. Bolting them onto a length of t slot is not really realizing the potential of the linear bearing, and to be honest isn't truly precision.

Bolting them onto a "halo" of toolplate as you do is as close as you can get to fully meeting the spec as you can get without expensive machining, and is most likely the best solution for 3D printers IMHO. It's certainly the way I'd go if I was using linear bearings.

I bought this kit in the roller option because it was cheaper, at a time when the "pacific peso" wasn't buying much USD. But also because I wanted a boltup kit, as I live in a quiet suburb and didn't want noise and aluminium shavings everywhere. It's just easier, and I've got a bunch of components to go with it.

What I don't like about this kit is the 4x Z roller uprights with 3x lead screws straight onto the bed frame. No kinematics and expansion compensation. They also make it to be used with 3x Z stepper, which I don't like either. I plan to use a single motor with belt drive. It looks like they're counting on the "rubberiness" of the wheels to take up some slack.

For this reason I want to go to 3x upright rail, but have the lead screw and bed fixing point straight on each carriage, attached to a sliding pin through a ball joint which will allow full expansion compensation in the X and Y axis's. There's only about 100AUD involved, and I'll spend that much at least on my toolplate bed so I'd like it leveled perfectly.

That's the reason why I'd like gantry plates both sides, so as to get that Z axis right and consistent, but to be honest you may well be right and the single plate with existing setup my be all that is needed.

In short, yes linear rails are better and I would use them definitely if I'm building my own design, as I would install them close to their spec.

I'm not arguing a point with this long reply by the way, just swapping notes.

Cheers,

Edited 5 time(s). Last edit at 06/17/2020 09:56AM by hobbymods.

|

Re: V slot wheels on precision shafts June 18, 2020 05:37PM |

Registered: 7 years ago Posts: 168 |

Having thought about it for a while, I will just assemble it and see how it all works in standard trim.

One of the main reasons I wanted to mod it from new is that I will spend up pretty big on the build plate, and didn't want to be chopping and changing it down the track and seeing a rough looking result. The plate that comes with it is 4mm anodized sheet aluminium, which might not be satisfactory for me.

So I think I'll just run it up mechanically and see how it moves and levels, before I attach all of the "hot stuff".

@the_digital_dentist

I just needed to think about it for a bit, and let common sense override the ideas I'd gotten into. I'm still keen to make changes, but what you said makes sense.

Edited 2 time(s). Last edit at 06/18/2020 05:46PM by hobbymods.

One of the main reasons I wanted to mod it from new is that I will spend up pretty big on the build plate, and didn't want to be chopping and changing it down the track and seeing a rough looking result. The plate that comes with it is 4mm anodized sheet aluminium, which might not be satisfactory for me.

So I think I'll just run it up mechanically and see how it moves and levels, before I attach all of the "hot stuff".

@the_digital_dentist

I just needed to think about it for a bit, and let common sense override the ideas I'd gotten into. I'm still keen to make changes, but what you said makes sense.

Edited 2 time(s). Last edit at 06/18/2020 05:46PM by hobbymods.

|

Re: V slot wheels on precision shafts June 18, 2020 06:40PM |

Registered: 11 years ago Posts: 5,780 |

It's hard to argue with the quality of those prints.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: V slot wheels on precision shafts June 19, 2020 02:32AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

It's hard to argue with the quality of those prints.

And that's a very nice compliment coming from you, thank you. That's the original 8 bit Creality board as well, on stock firmware and no leveling or sensor other than the microswitch for setting the nozzle height.

Funny thing is that I am totally crap on the keyboard! I've driven poor old David and his team nuts on the Duet forum over the years, just getting into all manner of trouble every time I go near the config file (lol). In fairness they've been pretty tolerant of my antics.

My thoughts are that people build/adjust things all over the place, and then want software compensation to "soak up" their multitude of sins. I'm dead against that. I want my machine to be tight, square and level to the highest standards before I even switch anything on. Software compensation should be a subtle last resort at best, and preferably not required at all. I don't believe I'll get that with the bed setup on this machine (pictured above), but I'll at least have a look first.

If I can get a 400x400 cast ally (Aus slang for aluminium) plate that's perfectly flat I may well go with a simple microswitch again for this printer, although on my Duet machine I do enjoy the mini IR probe with leveling/mesh switched off and just used for nozzle height.

Best thing about the point you've made is that it will save me money. Instead of throwing bucks at perceived potential problems, I can direct them at specific actual issues.

Unfortunately, the 3 packages my printer kit is coming in have been separated...one's arrived, one's on it's way locally, and it looks like one's still in customs. Still better than an imaginary tracking number from BG or AE and a 6 week wait.

Edited 3 time(s). Last edit at 06/19/2020 02:51AM by hobbymods.

|

Re: V slot wheels on precision shafts June 19, 2020 07:35AM |

Registered: 11 years ago Posts: 5,780 |

I prefer my machines to be well built, too, with minimal software tricks to try to compensate for a poor mechanical build. I have access to materials (cheap t-slot, cheap cast plate) and machine tools (Milwaukee Makerspace) that a lot of people don't, so the software tricks are useful for people who have to rely on others to cut parts accurately, or are stuck with printed parts in critical positions.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: V slot wheels on precision shafts June 19, 2020 06:48PM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

I prefer my machines to be well built, too, with minimal software tricks to try to compensate for a poor mechanical build. I have access to materials (cheap t-slot, cheap cast plate) and machine tools (Milwaukee Makerspace) that a lot of people don't, so the software tricks are useful for people who have to rely on others to cut parts accurately, or are stuck with printed parts in critical positions.

Yes, you are lucky to be so well equipped and supplied. The US must be awesome for niche hobbyists.

There's no such thing as cheap cast plate in Australia, but I do have access to a water jet cutting guy who takes care of me. I don't have anything that would cut or machine aluminium to the tolerances required, which is why I've opted for a frame kit.

I do have the gear to make really good wiring harnesses in silicone RC wire, and can crimp any of the little plugs (with my glasses on) we use, so there's no solder joints/slicing in my wiring. Good connections and cable routing certainly help.

I did just order a second set of Z and X gantry plates for this kit. It cost bugger all and will be handy to have them there just in case.

|

Re: V slot wheels on precision shafts June 20, 2020 08:14AM |

Registered: 10 years ago Posts: 341 |

Quote

hobbymods

Yes, you are lucky to be so well equipped and supplied. The US must be awesome for niche hobbyists.

There's no such thing as cheap cast plate in Australia, but I do have access to a water jet cutting guy who takes care of me. I don't have anything that would cut or machine aluminium to the tolerances required, which is why I've opted for a frame kit.

I do have the gear to make really good wiring harnesses in silicone RC wire, and can crimp any of the little plugs (with my glasses on) we use, so there's no solder joints/slicing in my wiring. Good connections and cable routing certainly help.

I did just order a second set of Z and X gantry plates for this kit. It cost bugger all and will be handy to have them there just in case.

Few of years ago when i was building my printer, finding a place that had the reprap favourite MIC6 here in aus wasn't easy. I ended up using a piece of 6.35mm cast ATP-5 from a place in Syd that was also happy to cut a piece the size i wanted (270x230mm).

|

Re: V slot wheels on precision shafts June 20, 2020 06:08PM |

Registered: 7 years ago Posts: 168 |

Quote

sdavi

Quote

hobbymods

Yes, you are lucky to be so well equipped and supplied. The US must be awesome for niche hobbyists.

There's no such thing as cheap cast plate in Australia, but I do have access to a water jet cutting guy who takes care of me. I don't have anything that would cut or machine aluminium to the tolerances required, which is why I've opted for a frame kit.

I do have the gear to make really good wiring harnesses in silicone RC wire, and can crimp any of the little plugs (with my glasses on) we use, so there's no solder joints/slicing in my wiring. Good connections and cable routing certainly help.

I did just order a second set of Z and X gantry plates for this kit. It cost bugger all and will be handy to have them there just in case.

Few of years ago when i was building my printer, finding a place that had the reprap favourite MIC6 here in aus wasn't easy. I ended up using a piece of 6.35mm cast ATP-5 from a place in Syd that was also happy to cut a piece the size i wanted (270x230mm).

Was that "Calm Aluminium"?

I got them to cut me a piece of 1/4" (which is 6.35mm) for my Zortrax conversion. Mine is "Vista Metals ATP5" as well. I don't know if that's better or worse than MIC6, but that's all I could find as well.

It wasn't perfectly flat by the way, but still pretty good compared to any other plate I've used and heats nicely.

|

Re: V slot wheels on precision shafts June 20, 2020 09:06PM |

Registered: 10 years ago Posts: 341 |

Quote

hobbymods

Was that "Calm Aluminium"?

I got them to cut me a piece of 1/4" (which is 6.35mm) for my Zortrax conversion. Mine is "Vista Metals ATP5" as well. I don't know if that's better or worse than MIC6, but that's all I could find as well.

It wasn't perfectly flat by the way, but still pretty good compared to any other plate I've used and heats nicely.

Yeah that was the place. Mine has a very slight fall in one corner but the main printing area is flat and probably more importantly remains flat when heated. It was still one the best upgrades to my printer though.

|

Re: V slot wheels on precision shafts June 20, 2020 09:14PM |

Registered: 7 years ago Posts: 168 |

Quote

sdavi

Quote

hobbymods

Was that "Calm Aluminium"?

I got them to cut me a piece of 1/4" (which is 6.35mm) for my Zortrax conversion. Mine is "Vista Metals ATP5" as well. I don't know if that's better or worse than MIC6, but that's all I could find as well.

It wasn't perfectly flat by the way, but still pretty good compared to any other plate I've used and heats nicely.

Yeah that was the place. Mine has a very slight fall in one corner but the main printing area is flat and probably more importantly remains flat when heated. It was still one the best upgrades to my printer though.

Same here mate.

The only difference I'll go with on this next printer is that I'll use 10mm thick, as apparently the flatness tolerance is better and this bed will be 400x400 with an AC heater.

If I'm to build my "forever" big printer, I really want to get the bed right as it's the foundation of successful printing. One of them anyway...

Edited 2 time(s). Last edit at 06/22/2020 02:53AM by hobbymods.

|

Re: V slot wheels on precision shafts June 22, 2020 12:55AM |

Registered: 7 years ago Posts: 168 |

The kit arrived today.

It'll be weeks before I can start it, as it's a busy time in my industry and I'm in the middle of a home reno project.

But I did take a moment to pull out the build plate (400x400) and lay a straight edge on it. It's not a "banana" like some of the Chinese printers, but it's certainly not flat. I was seeing easily 0.2-0.4mm of sunlight under that straight edge, so it's not totally ideal from my point of view.

But considering it's only 4mm sheet it's still pretty reasonable and would work as designed with mesh probing and leveling compensation, but I probably would prefer something better for my build. I imagine it might run out a bit more when heated right up as well.

** After ringing Calm Aluminium just now, I've been told a piece of ATP 5 in 500x500x3/8" will cost me 175 AUD, and it's flatness is only guaranteed to be 0.381mm (15 thou), as well as that's before any waterjet cutting. I guess that's OK if you get lucky and get a bit that's flat, but it could be no better than the standard plate. My understanding is that the cast toolplate stays the same when heated up, where the rolled plate doesn't? Either way it may be hard to avoid the need for level compensation in a printer this size if I want use of the full plate, which I do.

Edited 3 time(s). Last edit at 06/22/2020 02:39AM by hobbymods.

It'll be weeks before I can start it, as it's a busy time in my industry and I'm in the middle of a home reno project.

But I did take a moment to pull out the build plate (400x400) and lay a straight edge on it. It's not a "banana" like some of the Chinese printers, but it's certainly not flat. I was seeing easily 0.2-0.4mm of sunlight under that straight edge, so it's not totally ideal from my point of view.

But considering it's only 4mm sheet it's still pretty reasonable and would work as designed with mesh probing and leveling compensation, but I probably would prefer something better for my build. I imagine it might run out a bit more when heated right up as well.

** After ringing Calm Aluminium just now, I've been told a piece of ATP 5 in 500x500x3/8" will cost me 175 AUD, and it's flatness is only guaranteed to be 0.381mm (15 thou), as well as that's before any waterjet cutting. I guess that's OK if you get lucky and get a bit that's flat, but it could be no better than the standard plate. My understanding is that the cast toolplate stays the same when heated up, where the rolled plate doesn't? Either way it may be hard to avoid the need for level compensation in a printer this size if I want use of the full plate, which I do.

Edited 3 time(s). Last edit at 06/22/2020 02:39AM by hobbymods.

|

Re: V slot wheels on precision shafts June 23, 2020 04:40AM |

Registered: 10 years ago Posts: 341 |

|

Re: V slot wheels on precision shafts June 23, 2020 07:22AM |

Registered: 11 years ago Posts: 5,780 |

If you're talking about the spec for milled, cast aluminum, that number applies to the entire sheet which is usually > 1m x 2m. The flatness of a small piece like we use for a printer's bed is usually much better, but it isn't specced.

I have built 4 machines with 300x300 mm cast tooling plate beds, usually MIC6 and usually 6.35 mm thick, and all are flat enough to print edge to edge without any additional processing of the aluminum. Cast plate has an amorphous structure so it expands evenly. Rolled or extruded plate has grains aligned in one direction so expansion isn't even and it tends to warp as it's heated more than cast plate will. That's why cast plate is used in machine shops to make fixtures - it's predictable.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have built 4 machines with 300x300 mm cast tooling plate beds, usually MIC6 and usually 6.35 mm thick, and all are flat enough to print edge to edge without any additional processing of the aluminum. Cast plate has an amorphous structure so it expands evenly. Rolled or extruded plate has grains aligned in one direction so expansion isn't even and it tends to warp as it's heated more than cast plate will. That's why cast plate is used in machine shops to make fixtures - it's predictable.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: V slot wheels on precision shafts June 23, 2020 08:22AM |

Registered: 10 years ago Posts: 341 |

|

Re: V slot wheels on precision shafts June 23, 2020 09:44AM |

Registered: 11 years ago Posts: 5,780 |

That error includes variation in the PEI thickness and in the adhesive layer under the PEI. The metal plate itself is probably much flatter. I would bet most of the error comes from variations in the adhesive thickness.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: V slot wheels on precision shafts June 23, 2020 10:28PM |

Registered: 6 years ago Posts: 61 |

Quote

hobbymods

Mine is "Vista Metals ATP5" as well. I don't know if that's better or worse than MIC6, but that's all I could find as well.

ATP-5 and Alca 5 are basically two trade names for the same alloy. Alca 5 at least is produced in a vertical continuous process that I understand is supposed to improve isotropy. I think ATP-5 might be horizontal continuous process but I'm not sure about that.

I looked this up back in the days of google+ (remember that?) and wrote up what I learned.

[forum.makerforums.info]

Quote

MIC-6 is 7000-series (purer aluminum IIRC) and is softer and more difficult to mill; ATP-5 and Alca 5 are both 5083 aluminum-magnesium alloy and are harder and mill more easily; they have less thermal expansion and I think around 1% lower thermal conductivity. All three have consistently good results reported for 3d printing.

Between being easier to mill smooth features (such as for kinematic mounting) and having a lower coefficient of expansion, I think that ATP-5 and Alca 5 are slightly preferable to MIC-6, all other things being equal. It's just that MIC-6 has been more widely known and available from more suppliers.

I'm in the US, in North Carolina, and I order my aluminum from TDD's local supplier Howard Precision 1500km away from me, rather than from my local metal shop that doesn't even recognize common aluminum alloys. ☺ They are an industrial supplier so I can't just do an online order; I have to talk/email with someone to finish the order I start online. But they are helpful and friendly. 500 x 500 x 3/8 Alca 5 would be a bit less from them, I think, but it's not cheap.

To understand the flatness of cast plate, you have to understand how it's made. (I haven't seen this done, just looked online, so people with more expertise are welcome to correct me.) It is surfaced with a giant face mill as wide as the plate. I think I've heard of a 15-foot-wide face mill being used. The greatest source of variation would be scalloping between the extreme edges and the center from the head being slightly out of tram in the direction of travel, but that variation will be relatively smoothly distributed across the face, and so any particular piece substantially smaller will exhibit much less variation. (Any variation in tram across the direction of travel is not relevant to 3D printing as it does not affect surface flatness.)

|

Re: V slot wheels on precision shafts June 26, 2020 07:12AM |

Registered: 7 years ago Posts: 168 |

Regardless of the spec, ATP5 is what it's going to be as that's the only one available in my country.

As DD has pointed out, 0.381mm is the max runout and is unlikely to be the case on my 400x400 sheet. And as well, my stick on or magnetic print surface will most likely have some further errors.

While I'm not keen on 3x Z stepper, I will assess the situation once I've built it as to whether I use some leveling mesh compensation with my belt connected 3x screws, if my bed ends up not being flat enough. I'd prefer not, but it's there if I need it, and I'm not building this large printer to only be able to use the "flat bit" of the bed.

As DD has pointed out, 0.381mm is the max runout and is unlikely to be the case on my 400x400 sheet. And as well, my stick on or magnetic print surface will most likely have some further errors.

While I'm not keen on 3x Z stepper, I will assess the situation once I've built it as to whether I use some leveling mesh compensation with my belt connected 3x screws, if my bed ends up not being flat enough. I'd prefer not, but it's there if I need it, and I'm not building this large printer to only be able to use the "flat bit" of the bed.

Sorry, only registered users may post in this forum.