Brake vs. shorting stepper coils

Posted by Schild0r

|

Brake vs. shorting stepper coils October 21, 2020 03:33AM |

Registered: 7 years ago Posts: 126 |

So I am building a new printer with triple z motors and SFU1204 ballscrews for independent movement and true bed leveling.

I recently noticed that my build plate may be a little bit heavy and fall when the steppers are powered off and I am now considering to implement some sort of braking mechanism, that brakes z movement once the 24V main power is cut (I still have 5V auxiliary power wired to the board for standby).

As I see it there are two possibilities for that.

1: Buy stepper motors like this one

With an integrated brake and connect the brake wires to the 24V PSU so the brake engages when the PSU is turned off.

2: Someone told me that Lulzbot had an approach where they had designed a breakout board which connects to power and the steppers and when it senses a power drop it will cut the connections from the steppers to the drivers and will instead connect/short each stepper coil which results in greater rotational resistance preventing the bed from falling.

Well since my motors are independently controlled (whereas Lulzbot had them connected in series on a single driver) I think I could get away with one of these relays

With 4x change over contacts per motor and connect it the following way:

EDIT: I did an oopsie when sketching things up. The relay needs to be rotated 180° so that the motor coils are at the common contact of course. I don't mean to short the driver /EDIT

Each of the four wires from the motor run to one of the change over contacts.

In engaged state (24V on the relay) the stepper coils will be connected to the driver as usual.

In disengaged state (0V on the relay/ PSU off/ see picture for reference) each change over contact disconnects the stepper wire from the driver and instead the two coils of the stepper are shorted by a bridge (orange in the picture) which leads to higher rotational resistance -> braking moment -> the bed won't fall.

First of all: is there any misconception or did I understand anything wrong so that these approaches would not work in the way I described it?

If both approaches do work, which one would you go for and why?

----------

Lemme start:

The "shorting coils" approach is cheaper at 10 bucks per motor whereas a new 0.9 NEMA17 with integrated brake is rare and 50 bucks a piece

Edited 2 time(s). Last edit at 10/21/2020 03:37PM by Schild0r.

I recently noticed that my build plate may be a little bit heavy and fall when the steppers are powered off and I am now considering to implement some sort of braking mechanism, that brakes z movement once the 24V main power is cut (I still have 5V auxiliary power wired to the board for standby).

As I see it there are two possibilities for that.

1: Buy stepper motors like this one

With an integrated brake and connect the brake wires to the 24V PSU so the brake engages when the PSU is turned off.

2: Someone told me that Lulzbot had an approach where they had designed a breakout board which connects to power and the steppers and when it senses a power drop it will cut the connections from the steppers to the drivers and will instead connect/short each stepper coil which results in greater rotational resistance preventing the bed from falling.

Well since my motors are independently controlled (whereas Lulzbot had them connected in series on a single driver) I think I could get away with one of these relays

With 4x change over contacts per motor and connect it the following way:

EDIT: I did an oopsie when sketching things up. The relay needs to be rotated 180° so that the motor coils are at the common contact of course. I don't mean to short the driver /EDIT

Each of the four wires from the motor run to one of the change over contacts.

In engaged state (24V on the relay) the stepper coils will be connected to the driver as usual.

In disengaged state (0V on the relay/ PSU off/ see picture for reference) each change over contact disconnects the stepper wire from the driver and instead the two coils of the stepper are shorted by a bridge (orange in the picture) which leads to higher rotational resistance -> braking moment -> the bed won't fall.

First of all: is there any misconception or did I understand anything wrong so that these approaches would not work in the way I described it?

If both approaches do work, which one would you go for and why?

----------

Lemme start:

The "shorting coils" approach is cheaper at 10 bucks per motor whereas a new 0.9 NEMA17 with integrated brake is rare and 50 bucks a piece

Edited 2 time(s). Last edit at 10/21/2020 03:37PM by Schild0r.

|

Re: Brake vs. shorting stepper coils October 21, 2020 06:38AM |

Admin Registered: 16 years ago Posts: 13,888 |

... disconnecting the coils from the driver under load could/will wreck/burn the driver !!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Brake vs. shorting stepper coils October 21, 2020 08:46AM |

Registered: 7 years ago Posts: 126 |

Quote

VDX

... disconnecting the coils from the driver under load could/will wreck/burn the driver !!

true that is something to consider but would this even be possible in my case? Since disconnection from the drivers will only happen if the PSU that runs the drivers is turned off.

So disconnection only happens when there is no load (bc the PSU is off) <=> and load is only possible when the PSU is on which connects the steppers to the drivers.

Only point where this could happen is when the relay suddenly fails while the steppers are under load.

|

Re: Brake vs. shorting stepper coils October 21, 2020 10:29AM |

Registered: 11 years ago Posts: 5,780 |

While you're solving chicken and egg dilemmas, here's another one to think about:

Why does shorting the coils brake the motor? When the bed drops the motor spins and generates EMF through the shorted coils that create a magnetic field that bucks the rotation of the motor and the dropping of the bed. But, if the motor isn't spinning, there's no current being generated and no magnetic field, so no braking. In order for the braking to work at all, the motor must spin, so the bed must drop. At best, shorting the coils will slow the drop- i.e. it adds friction. There are other ways to add friction if you want. Otherwise, it would be much easier and more reliable to simply fit the bottom of the bed or Z axis with springs so it won't do any damage when the bed hits the bottom of the Z axis, assuming it will, which isn't necessarily a good assumption.

Ball screws are usually low friction, relatively long lead devices. That almost guarantees the bed will drop when Z motor power is cut. If you use short-lead lead screws (1 or 2 mm, for example), the bed may not move at all when Z motor power is cut and Z axis resolution will increase (as maximum speed decreases). Using ball screws almost guarantees the bed will drop, but will it drop equally at each screw? Unlikely. Differences in friction at each screw will probably cause the bed to tilt as it drops, maybe to the point that it will bind and stop the movement at some odd bed surface angle, long before it hits the bottom of the Z axis. When you next power up the Z axis, the motors will jump (which is the reason for using autoleveling). Will they jump in a way that releases the binding or enhances it? Will your autoleveling be working against the bed being wedged tightly, every time? Maybe you can apply EM braking to one of the motors to ensure higher friction at that screw and force the bed to tilt so it binds and never hits bottom...

Some people think they want to do autoleveling, so they use multiple motors to drive Z axis screws. But it's actually the opposite- they have to do autoleveling because they used multiple motors. The screws get out of sync when the machine is powered up because there are multiple motors attached to them, and each motor jumps a little on power up. If the goal is to make youtube videos, autoleveling is OK, but it was more impressive a few years ago when the first one did it. Now there are lots of those videos and it's sort of "meh". If the goal is to make a printer that "just works" connecting all the screws to a single motor will keep them from ever getting out of sync so no autoleveling will be needed. You'll level the bed manually, one time, and never have to do it again unless you take the Z axis apart. If you have the funds to buy the extra motors, bed sensor, and controller expansion board, you could, instead, buy a flat bed plate and do without all the other junk and end up with a more reliable printer, probably for lower cost, definitely much simpler set-up, operation, and maintenance.

My corexy printer lifts the bed assembly with two belts driven by a single motor. The belts never get out of sync and the flat, tooling plate bed never tilts. The machine "just works". The single, Z axis motor is driven directly by one of the drivers on the Duet board. It has a 30:1 worm gear reducer that prevents bed movement when the Z axis is powered down. I routinely transport the machine laying on its back (Z axis is 695mm) in my car or in a truck and when I get where I'm going, take the machine out, stand it back up and start printing without any adjustments. It uses an old-school Z=0 switch (well, OK< it's a little more than that) mounted on the frame instead of a sensor on the extruder carriage, so doesn't require a moving cable.

Put a flat plate on a kinematic mount and lift it with a single motor. It's not hard to do...

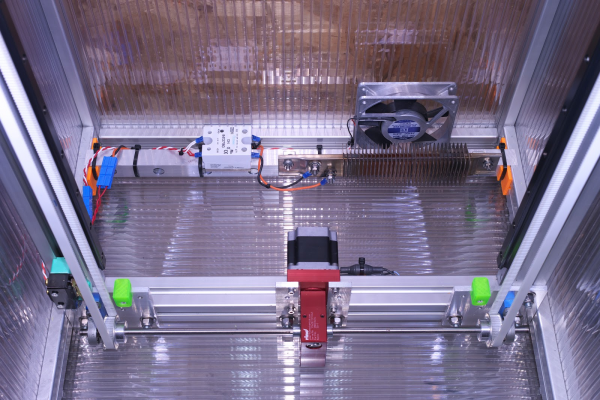

This is the Z axis in my printer. The red box near the motor is the 30:1 worm gear reducer. A single long shaft drives the pulleys that drive the belts. It no longer uses steel core belts, and I have added a heat shield to protect the Z axis motor from the heat blowing off the chamber heater toward the back of the photo. You can see the two Z axis linear guides right next to the belts.

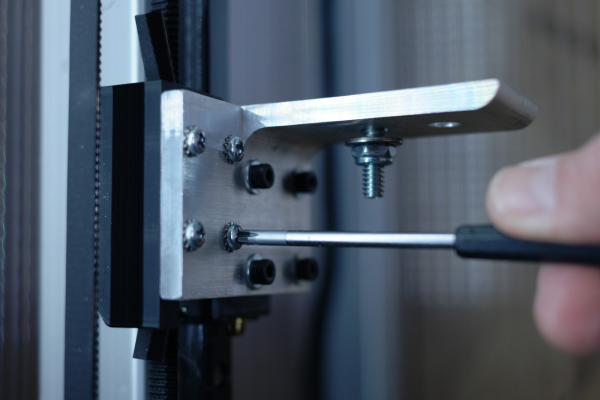

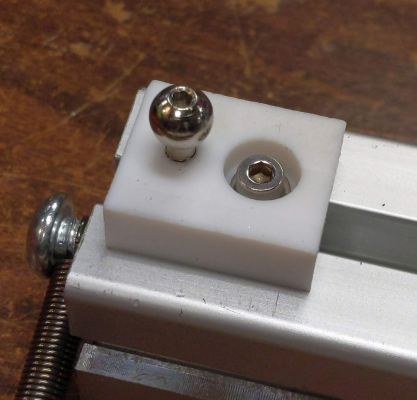

This is one of the two Z axis lifters:

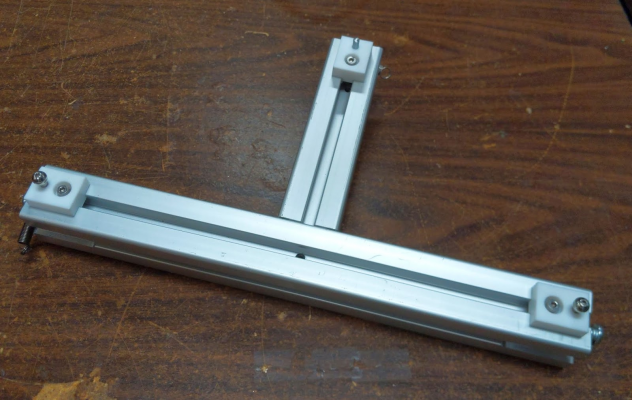

And this is what they lift (bed plate removed):

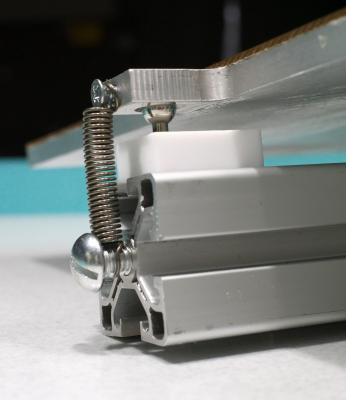

The bed plate sits on the three screws with springs holding it down. The two ball-head screws sit in a chamfered hole and slot in the bed plate that allow the plate to expand along the X axis when heated without making anything flex or lifting or dropping the bed plate. The third screw just touches the smooth underside of the bed plate and allows expansion in X and Y.:

You can see most of the bed in operation here: [vimeo.com]

Edited 4 time(s). Last edit at 10/21/2020 11:07AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Why does shorting the coils brake the motor? When the bed drops the motor spins and generates EMF through the shorted coils that create a magnetic field that bucks the rotation of the motor and the dropping of the bed. But, if the motor isn't spinning, there's no current being generated and no magnetic field, so no braking. In order for the braking to work at all, the motor must spin, so the bed must drop. At best, shorting the coils will slow the drop- i.e. it adds friction. There are other ways to add friction if you want. Otherwise, it would be much easier and more reliable to simply fit the bottom of the bed or Z axis with springs so it won't do any damage when the bed hits the bottom of the Z axis, assuming it will, which isn't necessarily a good assumption.

Ball screws are usually low friction, relatively long lead devices. That almost guarantees the bed will drop when Z motor power is cut. If you use short-lead lead screws (1 or 2 mm, for example), the bed may not move at all when Z motor power is cut and Z axis resolution will increase (as maximum speed decreases). Using ball screws almost guarantees the bed will drop, but will it drop equally at each screw? Unlikely. Differences in friction at each screw will probably cause the bed to tilt as it drops, maybe to the point that it will bind and stop the movement at some odd bed surface angle, long before it hits the bottom of the Z axis. When you next power up the Z axis, the motors will jump (which is the reason for using autoleveling). Will they jump in a way that releases the binding or enhances it? Will your autoleveling be working against the bed being wedged tightly, every time? Maybe you can apply EM braking to one of the motors to ensure higher friction at that screw and force the bed to tilt so it binds and never hits bottom...

Some people think they want to do autoleveling, so they use multiple motors to drive Z axis screws. But it's actually the opposite- they have to do autoleveling because they used multiple motors. The screws get out of sync when the machine is powered up because there are multiple motors attached to them, and each motor jumps a little on power up. If the goal is to make youtube videos, autoleveling is OK, but it was more impressive a few years ago when the first one did it. Now there are lots of those videos and it's sort of "meh". If the goal is to make a printer that "just works" connecting all the screws to a single motor will keep them from ever getting out of sync so no autoleveling will be needed. You'll level the bed manually, one time, and never have to do it again unless you take the Z axis apart. If you have the funds to buy the extra motors, bed sensor, and controller expansion board, you could, instead, buy a flat bed plate and do without all the other junk and end up with a more reliable printer, probably for lower cost, definitely much simpler set-up, operation, and maintenance.

My corexy printer lifts the bed assembly with two belts driven by a single motor. The belts never get out of sync and the flat, tooling plate bed never tilts. The machine "just works". The single, Z axis motor is driven directly by one of the drivers on the Duet board. It has a 30:1 worm gear reducer that prevents bed movement when the Z axis is powered down. I routinely transport the machine laying on its back (Z axis is 695mm) in my car or in a truck and when I get where I'm going, take the machine out, stand it back up and start printing without any adjustments. It uses an old-school Z=0 switch (well, OK< it's a little more than that) mounted on the frame instead of a sensor on the extruder carriage, so doesn't require a moving cable.

Put a flat plate on a kinematic mount and lift it with a single motor. It's not hard to do...

This is the Z axis in my printer. The red box near the motor is the 30:1 worm gear reducer. A single long shaft drives the pulleys that drive the belts. It no longer uses steel core belts, and I have added a heat shield to protect the Z axis motor from the heat blowing off the chamber heater toward the back of the photo. You can see the two Z axis linear guides right next to the belts.

This is one of the two Z axis lifters:

And this is what they lift (bed plate removed):

The bed plate sits on the three screws with springs holding it down. The two ball-head screws sit in a chamfered hole and slot in the bed plate that allow the plate to expand along the X axis when heated without making anything flex or lifting or dropping the bed plate. The third screw just touches the smooth underside of the bed plate and allows expansion in X and Y.:

You can see most of the bed in operation here: [vimeo.com]

Edited 4 time(s). Last edit at 10/21/2020 11:07AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Brake vs. shorting stepper coils October 21, 2020 10:36AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

the_digital_dentist

While you're solving chicken and egg dilemmas, here's another one to think about:

Great writeup, food for thought

http://www.marinusdebeer.nl/

|

Re: Brake vs. shorting stepper coils October 21, 2020 10:56AM |

Registered: 7 years ago Posts: 126 |

Well that sounds like a chicken and egg problem to me...Quote

the_digital_dentist

While you're solving chicken and egg dilemmas, here's another one to think about:

Why does shorting the coils brake the motor? When the bed drops the motor spins and generates EMF through the shorted coils that create a magnetic field that bucks the rotation of the motor and the dropping of the bed. But, if the motor isn't spinning, there's no current being generated and no magnetic field, so no braking.

I am not sure whether Lenz's law is all there is to it. That would mean that if you just turn the motor shaft slow enough with shorted coils the rotational resistance would be the same as with no shorted coils. I tried that but even the initial increment of a degree is harder to turn that way no matter how slow you try it. And if Lenz's law IS all there is to it, this would be one reason to use a braked stepper instead.

What was I thinking posting a request for a solution to a problem with set boundary conditions. Everyone knows when you post a request like "I want to build a printer with this and that hardware configuration and want advice on one particular problem" the answer will be "Rather build a CNC instead, this won't have this problem, duh" No wonder the forum is dying...Quote

the_digital_dentist

Ball screws are usually low friction, relatively long lead devices. That almost guarantees the bed will drop when Z motor power is cut. If you use short-lead lead screws (1 or 2 mm, for example), the bed may not move at all when Z motor power is cut and Z axis resolution will increase (as maximum speed decreases). [...]

Some people think they want to do autoleveling, so they use multiple motors to drive Z axis screws. But it's actually the opposite- they have to do autoleveling because they used multiple motors. The screws get out of sync when the machine is powered up because there are multiple motors attached to them, and each motor jumps a little on power up. If the goal is to make youtube videos, autoleveling is OK, but it was more impressive a few years ago when the first one did it. Now there are lots of those videos and it's sort of "meh". If the goal is to make a printer that "just works" connecting all the screws to a single motor will keep them from ever getting out of sync so no autoleveling will be needed. You'll level the bed manually, one time, and never have to do it again unless you take the Z axis apart. If you have the funds to buy the extra motors, bed sensor, and controller expansion board, you could, instead, buy a flat bed plate and do without all the other junk and end up with a more reliable printer, probably for lower cost, definitely much simpler set-up, operation, and maintenance.

My corexy printer lifts the bed assembly with two belts driven by a single motor. The belts never get out of sync and the flat, tooling plate bed, never tilts. The machine "just works". The single, Z axis motor is driven directly by one of the drivers on the Duet board. It has a 30:1 worm gear reducer that prevents bed movement when the Z axis is powered down. I routinely transport the machine laying on its back (Z axis is 695mm) in my car or in a truck and when I get where I'm going, take the machine out, stand it back up and start printing without any adjustments.

Put a flat plate on a kinematic mount and lift it with a single motor. It's not hard to do...

If I run into the problem and see the tripple z is causing much more work than convenience I will probably change over to a synchronized approach but I already have one printer in that configuration which sometimes is a bit of a hastle so for now I want to try tripple z.

Z won't bind because I am using a kinematic mount on which the bed is completely separable from the Z axis which is one of the reasons I am building tripple z in the first place.Quote

the_digital_dentist

Using ball screws almost guarantees the bed will drop, but will it drop equally at each screw? Unlikely. Differences in friction at each screw will probably cause the bed to tilt as it drops, maybe to the point that it will bind and stop the movement at some odd bed surface angle, long before it hits the bottom of the Z axis. When you next power up the Z axis, the motors will jump (which is the reason for using autoleveling). Will they jump in a way that releases the binding or enhances it? Will your autoleveling be working against the bed being wedged tightly, every time? Maybe you can apply EM braking to one of the motors to ensure higher friction at that screw and force the bed to tilt so it binds and never hits bottom...

|

Re: Brake vs. shorting stepper coils October 21, 2020 12:35PM |

Registered: 11 years ago Posts: 5,780 |

Before I put the 30:1 reducer in my printer, I tried shorting the motor coils to see if it would stop the bed from dropping, or at least slow it down so it wouldn't hit the bottom of the printer like a sledge hammer (about 3.5 kg). It didn't do either. It slowed the drop a little at first, but once the rotation got to some speed, it pretty much stopped braking and the bed slammed anyway. I priced out motors with brakes and found them to cost as much as the motor with 30:1 reduction so I went with the gear reduction because it increased Z axis resolution. It uses a NEMA-23 motor rated for about 2.4A IRIC, but I run it at about half that current, also IRIC, so the controller has no problems driving it at all. The bed doesn't move at all when Z power is cut, and the 30:1 reduction means that when the motor jumps a little upon power up, the bed won't move much so prints that are interrupted by power failure can be resumed with minimal effect on quality (assuming the print didn't cool enough to come off the bed).

In a lower mass, higher friction, and/or physically shorter Z axis, shorting the coils might work well enough. I guess it depends on your goal for the braking. Are you trying to stop all movement so you can resume a power-interrupted print or just trying to keep the bed from banging into the bottom of the printer? I don't think I'd trust shorting the motor coils to stop all movement.

For me 3D printer design and construction seems difficult enough without deliberately adding complications. If you have a kinematic mount on the screws, why use 3 motors? Lifting with a single motor would ensure that the bed remains level. That's a really good reason to avoid using 3 motors and all the problems it creates. If a single motor doesn't have sufficient torque to lift your bed, get a gear reduced motor. If you get a worm gear reduced motor (instead of a planetary drive type) it will stop the bed from dropping and increase Z resolution. Some planetary gear reduced motors may work fine, too, depending on the reduction ratio and bed mass, etc. Someone at the makerspace used a motor like this to drive a 3 screw Z axis and it makes prints that are free of Z axis defects that are as good as any I have ever seen.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In a lower mass, higher friction, and/or physically shorter Z axis, shorting the coils might work well enough. I guess it depends on your goal for the braking. Are you trying to stop all movement so you can resume a power-interrupted print or just trying to keep the bed from banging into the bottom of the printer? I don't think I'd trust shorting the motor coils to stop all movement.

For me 3D printer design and construction seems difficult enough without deliberately adding complications. If you have a kinematic mount on the screws, why use 3 motors? Lifting with a single motor would ensure that the bed remains level. That's a really good reason to avoid using 3 motors and all the problems it creates. If a single motor doesn't have sufficient torque to lift your bed, get a gear reduced motor. If you get a worm gear reduced motor (instead of a planetary drive type) it will stop the bed from dropping and increase Z resolution. Some planetary gear reduced motors may work fine, too, depending on the reduction ratio and bed mass, etc. Someone at the makerspace used a motor like this to drive a 3 screw Z axis and it makes prints that are free of Z axis defects that are as good as any I have ever seen.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Brake vs. shorting stepper coils October 21, 2020 01:23PM |

Registered: 7 years ago Posts: 126 |

I am not planning on adding a power loss recovery feature to my printer. Power is so stable around here and I did not have an outage in years or even a decade and neither did I blow a fuse on that my printer runs so the brake would only be used for keeping the bed from falling when the printer is turned off.

You said that once the falling bed gains some speed there is no braking happening anymore. This is curious since the braking moment you get from the bed falling down and turning the motors inducing current that counters the rotation (Lenz's law) would behave like a damper with the braking moment being proportional to the turning (and thus falling) speed wouldn't it.

I am not sure why a kinematic bed mount would speak against 3 motors and for a single motor. I don't have any adjusting knobs for manual adjustment so if something goes out of level, restoring level would be difficult.

You said that once the falling bed gains some speed there is no braking happening anymore. This is curious since the braking moment you get from the bed falling down and turning the motors inducing current that counters the rotation (Lenz's law) would behave like a damper with the braking moment being proportional to the turning (and thus falling) speed wouldn't it.

I am not sure why a kinematic bed mount would speak against 3 motors and for a single motor. I don't have any adjusting knobs for manual adjustment so if something goes out of level, restoring level would be difficult.

|

Re: Brake vs. shorting stepper coils October 21, 2020 01:42PM |

Registered: 11 years ago Posts: 5,780 |

I suspect it has to do with the phase of the voltage and current as the motor spins. The motors are inductive, so current and voltage are not going to be in phase at every rotational speed. At some rotational speed the current through the coils probably drops enough that the magnetic field it produces is too weak to brake the motion and it resumes acceleration.

Simple modifications to the kinematic mount should enable manual adjustment. In my mount, the ball head screws have hex holes that I access from the top side of the bed through holes in the bed. The roll screw is adjusted using a thumbwheel from the underside of the bed. It would be very easy to make it all adjustable from the underside. It would certainly be easier, cheaper, and more reliable than adding in all the autoleveling stuff. What does your kinematic mount look like?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Simple modifications to the kinematic mount should enable manual adjustment. In my mount, the ball head screws have hex holes that I access from the top side of the bed through holes in the bed. The roll screw is adjusted using a thumbwheel from the underside of the bed. It would be very easy to make it all adjustable from the underside. It would certainly be easier, cheaper, and more reliable than adding in all the autoleveling stuff. What does your kinematic mount look like?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Brake vs. shorting stepper coils October 21, 2020 02:21PM |

Registered: 7 years ago Posts: 126 |

Did not consider the phase, that might be true indeed.

I use a magnetic mount (made sure the magnets can handle 120°C if I ever want to heat the build volume) I am not near my computer to take screenshots of the mounts but you can see them here: [www.thingiverse.com] and download the step file of the assembly to take a closer look.

I am using threaded steel balls that thread on M4 grub screws as magnet counterparts which then thread into the build plate and are countered with nuts from the underside. So I could indeed use an allen wrench to reach through the trough hole in the build plate to the hex socket of the maggot screw to adjust the levelness of the build plate and retighten the counter nut. This would be tedious compared to a leveling knob but hopefully I would not have to do that often.

That being said I really want to try the triple z but if I don't like it I will change over to a synchronized z with one geared NEMA23 (that's a really good idea) but I would probably keep the ballscrews then and would need to come up with a belt path that synchronizes them and so on.

I use a magnetic mount (made sure the magnets can handle 120°C if I ever want to heat the build volume) I am not near my computer to take screenshots of the mounts but you can see them here: [www.thingiverse.com] and download the step file of the assembly to take a closer look.

I am using threaded steel balls that thread on M4 grub screws as magnet counterparts which then thread into the build plate and are countered with nuts from the underside. So I could indeed use an allen wrench to reach through the trough hole in the build plate to the hex socket of the maggot screw to adjust the levelness of the build plate and retighten the counter nut. This would be tedious compared to a leveling knob but hopefully I would not have to do that often.

That being said I really want to try the triple z but if I don't like it I will change over to a synchronized z with one geared NEMA23 (that's a really good idea) but I would probably keep the ballscrews then and would need to come up with a belt path that synchronizes them and so on.

|

Re: Brake vs. shorting stepper coils October 21, 2020 10:46PM |

Registered: 3 years ago Posts: 92 |

|

Re: Brake vs. shorting stepper coils October 22, 2020 01:52AM |

Registered: 7 years ago Posts: 126 |

You forgot to mention wobbly. For my other printer I need 450mm leadscrews TR8x2. For once they are hard to come by from a reputable source since the actual standard is either 4 start TR8 with 8mm lead or 1 start TR8 with 1.5mm lead (which makes some crooked positional accuracy number for a full step). For that printer I ordered 10 or so leadscrews because they all come from overseas they are either bend from the factory or bent during shipping. This was so frustrating and the reason why I went for ballscrews.Quote

dekutree64

If the bed is heavy enough to backdrive ballscrews, it's heavy enough to preload leadscrews. Use 'em. They're cheap, compact, and work just as well in this case. 1mm or 2mm lead.

Edited 1 time(s). Last edit at 10/22/2020 01:52AM by Schild0r.

|

Re: Brake vs. shorting stepper coils October 22, 2020 03:29AM |

Registered: 3 years ago Posts: 92 |

Dang, that's some rotten luck. I just bought a 1200mm T8x2 off ebay last week for $35 and it's straight as can be. It had foam pads taped around it, then placed into a tube with more pads stuffed into the ends, and then the tube placed into a long skinny box. Never had any trouble with 500mm screws off banggood either.

But fair enough. The stepper motors with built-in brake would be nicest, but for the price I'd probably just rig something up to put friction on the motors all the time. They'll have to work harder to turn, but I doubt it would cause any problems. As others have said, the coil shorting probably won't work. Although I suppose you could test it easily enough with the power off using some jumper wires, if you have some spare steppers lying around.

But fair enough. The stepper motors with built-in brake would be nicest, but for the price I'd probably just rig something up to put friction on the motors all the time. They'll have to work harder to turn, but I doubt it would cause any problems. As others have said, the coil shorting probably won't work. Although I suppose you could test it easily enough with the power off using some jumper wires, if you have some spare steppers lying around.

|

Re: Brake vs. shorting stepper coils October 22, 2020 03:55AM |

Registered: 6 years ago Posts: 1,007 |

TR8 in 450mm is unsuitable. TR12 and above would be OK.

Bed leveling with 3 lead screws and motors ?

Deja vu !

Indeed the very same set up has already been proposed and discussed here.

Too bad but so far and unlike the "chicken and egg" that is real and works, these proposals went the path of the Dodo bird and are buried in this forum.

Fact is, to make it work needs expertise and knowledge that leads to the conclusion it is not justified

DD explained why many times already.

I like on youtube "Forgotten weapon". Many similarities between these weird, over complex gun designs and hobbyist 3D printers.

Edited 2 time(s). Last edit at 10/22/2020 09:10AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Bed leveling with 3 lead screws and motors ?

Deja vu !

Indeed the very same set up has already been proposed and discussed here.

Too bad but so far and unlike the "chicken and egg" that is real and works, these proposals went the path of the Dodo bird and are buried in this forum.

Fact is, to make it work needs expertise and knowledge that leads to the conclusion it is not justified

DD explained why many times already.

I like on youtube "Forgotten weapon". Many similarities between these weird, over complex gun designs and hobbyist 3D printers.

Edited 2 time(s). Last edit at 10/22/2020 09:10AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Brake vs. shorting stepper coils October 22, 2020 09:21AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Schild0r

So I could indeed use an allen wrench to reach through the trough hole in the build plate to the hex socket of the maggot screw to adjust the levelness of the build plate and retighten the counter nut. This would be tedious compared to a leveling knob but hopefully I would not have to do that often.

I threaded the leveling screws into pilot holes in PTFE blocks so there's no need for counter nuts to lock them in place. The trick is to not tap the holes that the screws are going into, and to use a material that doesn't mind the heat transferred from the bed plate via the leveling screws. PTFE is just about perfect for this. The metal screws roll their own threads into the plastic and are gripped tightly but still easily adjustable. I tried this once using nylon instead of PTFE and quickly discovered why they use nylon in nylock nuts. I could no longer turn the screws once they got about 5 mm into the plastic. There are about 13 mm of threads in the PTFE and it is still pretty easy to turn the screws.

Edited 2 time(s). Last edit at 10/22/2020 09:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.