How can you do 3D printing without a traditional nozzle

Posted by alsten

|

How can you do 3D printing without a traditional nozzle November 11, 2021 02:45PM |

Registered: 2 years ago Posts: 3 |

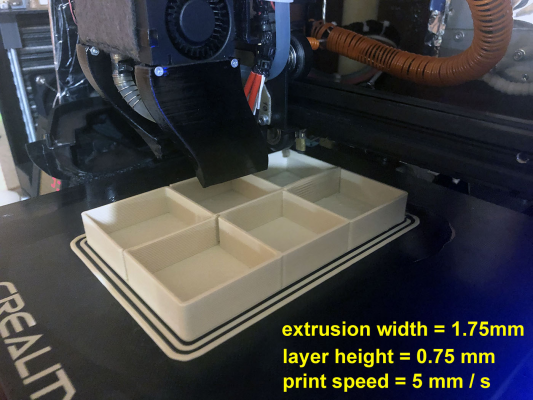

I did an experiment with a direct extruder. He unscrewed the nozzle from the hotend, pushed the Teflon tube out of the thermal barrier to the level of the bed and started printing with PLA. Good printing started, as you can see in the photo:

This nozzleless print has interesting features:

1. In the hot end, it is no longer necessary to hermetically assemble the threads between the heater body, the thermal barrier and the nozzle. Plastic will now not be able to leak into the thread.

2. Now the PTFE tube does not need to be precisely fitted to the nozzle. Plastic will now not be able to leak into the thermal barrier.

These advantages can be used to quickly print large parts.

Method formula:

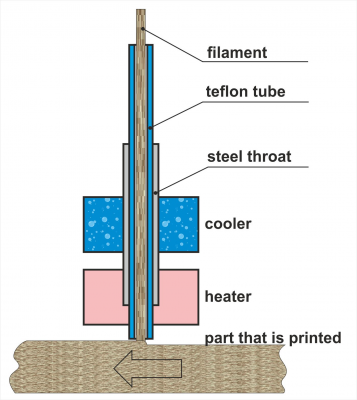

molten plastic is extruded onto the model directly from the open end of the hot-end fluoroplastic tube. From the moment of melting to the moment of extrusion, the plastic does not come into contact with anything other than the tube. The filament enters the tube in the cold zone:

Description of the experiment.

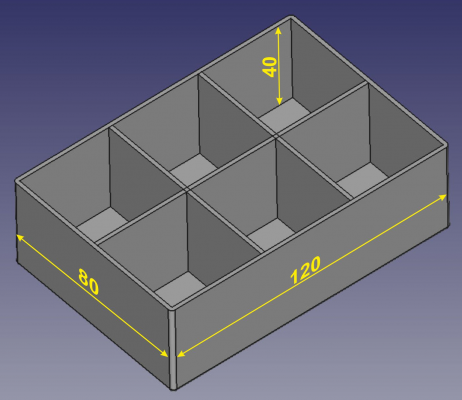

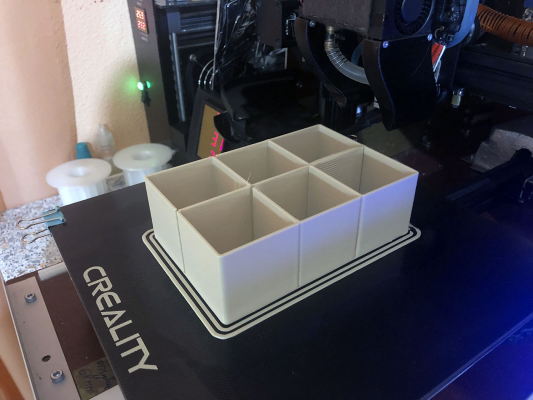

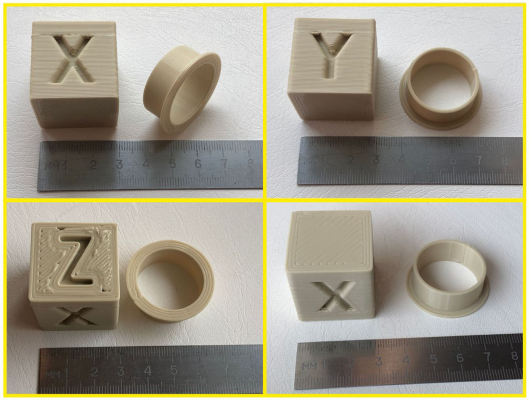

I needed to print a detail that does not require special precision. This is a pallet with partitions made of PLA, dimensions 120x80x40:

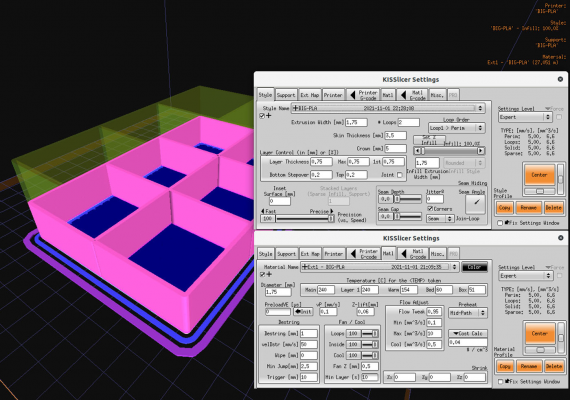

I made all the walls of the model 1.75 mm thick. In KISSlicer, I set an extrusion width of 1.75 mm, a layer thickness of 0.75 mm and a print speed of 5 mm / s. The slicer determined the print time at 3 hours 39 minutes, which is 2 hours faster than with conventional printing with a 0.4 mm nozzle.

I intuitively set the temperature of the virtual nozzle in the slicer to 240C instead of 225C.

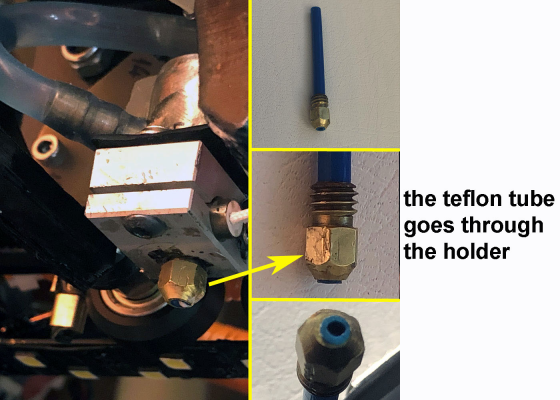

To prevent the tube from falling out of the hotend, I made a holder from an old brass nozzle. I drilled a stepped hole in the nozzle and inserted a teflon tube into it. I cut off the end of the tube a little like a cone with a sharp knife. The end of the tube now protrudes from the nozzle by 0.5 mm. I screwed the holder with the tube into the thermoblock simply by hand, without a spanner.

I made the print at a bed temperature of 60C, without airflow, with a 1 mm retract:

https://youtu.be/4eNPry25egY

The print turned out to be very even, with clear edges of the lines, with a shiny surface of the layers. All dimensions are accurate, just like in classic printing.

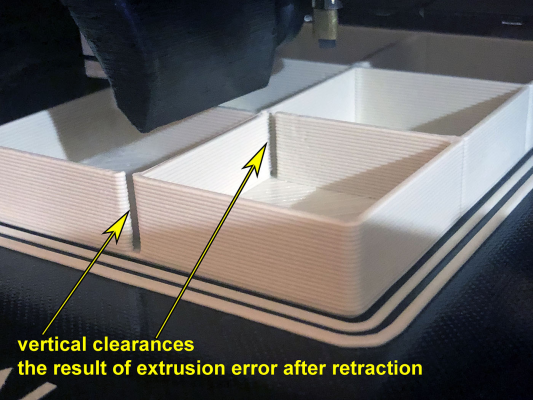

I didn't expect, but the part has three vertical gaps near the corners of some of the compartments. The gaps are due to a delay in the start of extrusion after the retraction. I concluded that retracts should be disabled with this type of printing. I didn’t fix the part, because such gaps are acceptable for me.

After the model was completely printed, I could not determine from a distance that it was made in an exotic way:

Conclusions about the advantages of the method:

1. It turned out to quickly print a large, durable part. The dimensions of the part turned out to be exactly the same as in normal printing.

2. No metal nozzle was needed for printing, the risk of plastic leakage into the metal throat and into the threads of the heating block is eliminated.

3. PTFE tube is not prone to blockages, it is slippery inside and does not have a difference in diameter. The tube can be easily removed and installed.

Conclusions about the disadvantages of the method:

1. Printing requires a higher heater temperature than printing through a metal nozzle.

2. Printing with refractory plastics is not possible in this way.

3. Large extrusion width is required for such printing. This prevents small details from being printed.

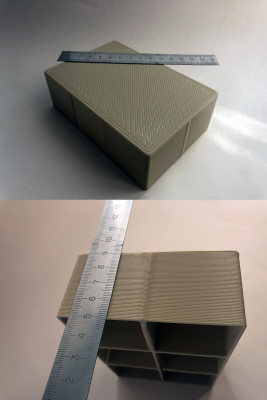

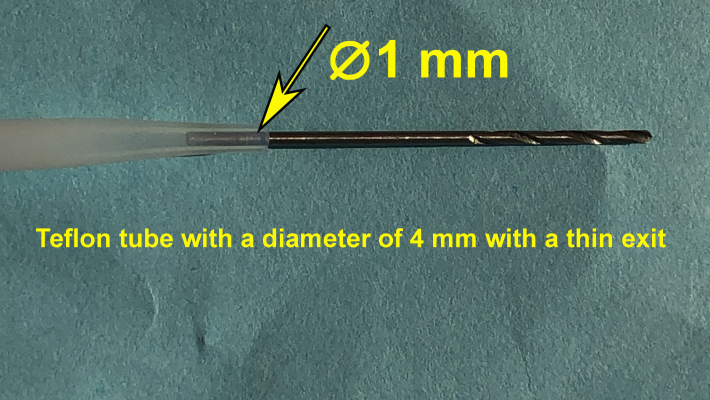

To expand the possibilities of the method, I tried the same printing through fluoroplastic tubing of tubing with an elongated end:

Printing through a 1mm bore tube was also successful.

Thanks, this is my first post on reprap.org.

This nozzleless print has interesting features:

1. In the hot end, it is no longer necessary to hermetically assemble the threads between the heater body, the thermal barrier and the nozzle. Plastic will now not be able to leak into the thread.

2. Now the PTFE tube does not need to be precisely fitted to the nozzle. Plastic will now not be able to leak into the thermal barrier.

These advantages can be used to quickly print large parts.

Method formula:

molten plastic is extruded onto the model directly from the open end of the hot-end fluoroplastic tube. From the moment of melting to the moment of extrusion, the plastic does not come into contact with anything other than the tube. The filament enters the tube in the cold zone:

Description of the experiment.

I needed to print a detail that does not require special precision. This is a pallet with partitions made of PLA, dimensions 120x80x40:

I made all the walls of the model 1.75 mm thick. In KISSlicer, I set an extrusion width of 1.75 mm, a layer thickness of 0.75 mm and a print speed of 5 mm / s. The slicer determined the print time at 3 hours 39 minutes, which is 2 hours faster than with conventional printing with a 0.4 mm nozzle.

I intuitively set the temperature of the virtual nozzle in the slicer to 240C instead of 225C.

To prevent the tube from falling out of the hotend, I made a holder from an old brass nozzle. I drilled a stepped hole in the nozzle and inserted a teflon tube into it. I cut off the end of the tube a little like a cone with a sharp knife. The end of the tube now protrudes from the nozzle by 0.5 mm. I screwed the holder with the tube into the thermoblock simply by hand, without a spanner.

I made the print at a bed temperature of 60C, without airflow, with a 1 mm retract:

https://youtu.be/4eNPry25egY

The print turned out to be very even, with clear edges of the lines, with a shiny surface of the layers. All dimensions are accurate, just like in classic printing.

I didn't expect, but the part has three vertical gaps near the corners of some of the compartments. The gaps are due to a delay in the start of extrusion after the retraction. I concluded that retracts should be disabled with this type of printing. I didn’t fix the part, because such gaps are acceptable for me.

After the model was completely printed, I could not determine from a distance that it was made in an exotic way:

Conclusions about the advantages of the method:

1. It turned out to quickly print a large, durable part. The dimensions of the part turned out to be exactly the same as in normal printing.

2. No metal nozzle was needed for printing, the risk of plastic leakage into the metal throat and into the threads of the heating block is eliminated.

3. PTFE tube is not prone to blockages, it is slippery inside and does not have a difference in diameter. The tube can be easily removed and installed.

Conclusions about the disadvantages of the method:

1. Printing requires a higher heater temperature than printing through a metal nozzle.

2. Printing with refractory plastics is not possible in this way.

3. Large extrusion width is required for such printing. This prevents small details from being printed.

To expand the possibilities of the method, I tried the same printing through fluoroplastic tubing of tubing with an elongated end:

Printing through a 1mm bore tube was also successful.

Thanks, this is my first post on reprap.org.

|

Re: How can you do 3D printing without a traditional nozzle November 11, 2021 05:06PM |

Admin Registered: 16 years ago Posts: 13,884 |

... good prints!

It's depending on your specific needs, if finer or "fatter" printing is better -- printing houses is more into the "fatter" range

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It's depending on your specific needs, if finer or "fatter" printing is better -- printing houses is more into the "fatter" range

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: How can you do 3D printing without a traditional nozzle November 11, 2021 07:33PM |

Registered: 9 years ago Posts: 204 |

|

Re: How can you do 3D printing without a traditional nozzle November 11, 2021 11:37PM |

Registered: 11 years ago Posts: 5,780 |

Interesting. I wonder what the temperature gradient is across the teflon tube inside the heater block. It might be getting close to the decomposition temperature of the teflon.

What was the print speed? It looked pretty slow in the video. I imagine it takes quite a bit of time to melt the filament through the teflon tube. At 1.75 mm line width and probably1 mm layer height, even if it goes slow, it's going to finish the print pretty quickly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

What was the print speed? It looked pretty slow in the video. I imagine it takes quite a bit of time to melt the filament through the teflon tube. At 1.75 mm line width and probably1 mm layer height, even if it goes slow, it's going to finish the print pretty quickly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can you do 3D printing without a traditional nozzle November 12, 2021 01:57AM |

Registered: 2 years ago Posts: 3 |

I haven’t spent time on selecting temperature and typing speed

I have set the temperature and print speed intuitively, according to my ideas.

I was hoping to reduce the temperature and speed during the printing process if there were problems.

Now I think I'm lucky.

And the metal holder at the end of the tube was also helpful, It slows down the cooling of the extruded plastic.

I have set the temperature and print speed intuitively, according to my ideas.

I was hoping to reduce the temperature and speed during the printing process if there were problems.

Now I think I'm lucky.

And the metal holder at the end of the tube was also helpful, It slows down the cooling of the extruded plastic.

|

Re: How can you do 3D printing without a traditional nozzle November 12, 2021 02:30AM |

Registered: 2 years ago Posts: 3 |

Quote

the_digital_dentist

Interesting. I wonder what the temperature gradient is across the teflon tube inside the heater block. It might be getting close to the decomposition temperature of the teflon.

What was the print speed? It looked pretty slow in the video. I imagine it takes quite a bit of time to melt the filament through the teflon tube. At 1.75 mm line width and probably1 mm layer height, even if it goes slow, it's going to finish the print pretty quickly.

The manuals indicate the operating temperature range for Teflon to 260C, and inside the heater the temperature did not rise more than 240C.

Of course, the temperature gradient in the Teflon tube depends on the rate of tepple extraction with plastic.

But if plastic is not consumed at all (during a pause), then it will warm up to 240C and the temperature gradient will be 0.

In my case, the line printing speed was 5 mm/s and the line thickness was 0.75 mm. According to the calculation of the slicer, this corresponds to the extrusion speed of 6.6 mm^3/s.

As can be seen, at this speed of extrusion, the plastic manages to warm up enough for high-quality printing, and the adhesion in this case is excellent.

Sorry, only registered users may post in this forum.