Teacup_Firmware: How can i add other board to the firmware?

Posted by tatubias

|

Teacup_Firmware: How can i add other board to the firmware? May 19, 2015 10:54AM |

Registered: 9 years ago Posts: 792 |

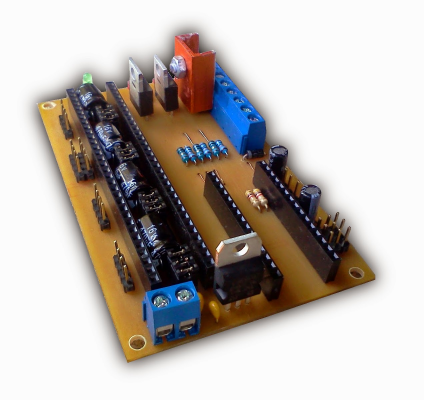

guys we have developed other board based on a arduino nano board, it is called SinapTec-AT328-02.h.

This is the WIKI: [www.reprap.org]

we are using teacup firmware and we want to add our configuration file so its added into the main firmware.

This is the board it self:

Im trying to undestand github but i dont undestan how to add this to it.

All is already configured and pins are mapped as it should.

file name: config.SinapTec-AT328-02.h

Edited 4 time(s). Last edit at 05/19/2015 10:58AM by tatubias.

This is the WIKI: [www.reprap.org]

we are using teacup firmware and we want to add our configuration file so its added into the main firmware.

This is the board it self:

Im trying to undestand github but i dont undestan how to add this to it.

All is already configured and pins are mapped as it should.

file name: config.SinapTec-AT328-02.h

/* Notice to developers: this file is intentionally included twice. */

/* NOTE: this config files is configured for CoreXY printer if you need a KINEMATICS_STRAIGHT please update for your printer.*/

/** \file

\brief Sample Configuration

\note this sample uses AIO0 for both X_STEP and thermistor, and is intended to be an example only!

*/

/*

CONTENTS

1. Mechanical/Hardware

2. Acceleration settings

3. Pinouts

4. Temperature sensors

5. Heaters

6. Communication options

7. Miscellaneous

8. Appendix A - PWMable pins and mappings

*/

/***************************************************************************\

* *

* 1. MECHANICAL/HARDWARE *

* *

\***************************************************************************/

/*

Set your microcontroller type in Makefile! atmega168/atmega328p/atmega644p/atmega1280

If you want to port this to a new chip, start off with arduino.h and see how you go.

*/

/** \def F_CPU

CPU clock rate

*/

#ifndef F_CPU

#define F_CPU 16000000UL

#endif

/** \def MOTHERBOARD

This is the motherboard, as opposed to the extruder. See extruder/ directory for GEN3 extruder firmware

*/

#define MOTHERBOARD

/** \def KINEMATICS

This defines the type of kinematics your printer uses. That's essential!

Valid values (see dda_kinematics.h):

KINEMATICS_STRAIGHT Motors move axis directions directly. This is the

traditional type, found in many printers, including

Mendel, Prusa i3, Mendel90, Ormerod, Mantis.

KINEMATICS_COREXY A bot using CoreXY kinematics. Typical for CoreXY are

long and crossing toothed belts and a print head moving

on the X-Y-plane.

*/

#define KINEMATICS_COREXY

/** \def STEPS_PER_M

steps per meter ( = steps per mm * 1000 )

calculate these values appropriate for your machine

for threaded rods, this is

(steps motor per turn) / (pitch of the thread) * 1000

for belts, this is

(steps per motor turn) / (number of gear teeth) / (belt module) * 1000

half-stepping doubles the number, quarter stepping requires * 4, etc.

valid range = 20 to 4'0960'000 (0.02 to 40960 steps/mm)

all numbers are integers, so no decimal point, please :-)

*/

#define STEPS_PER_M_X 167600

#define STEPS_PER_M_Y 167600

#define STEPS_PER_M_Z 4571428

/// [blog.arcol.hu] may help with this one

#define STEPS_PER_M_E 678400

/*

Values depending on the capabilities of your stepper motors and other mechanics.

All numbers are integers, no decimals allowed.

Units are mm/min

*/

/// used for G0 rapid moves and as a cap for all other feedrates

#define MAXIMUM_FEEDRATE_X 7200

#define MAXIMUM_FEEDRATE_Y 7200

#define MAXIMUM_FEEDRATE_Z 200

#define MAXIMUM_FEEDRATE_E 960

/// Used when doing precision endstop search and as default feedrate.

#define SEARCH_FEEDRATE_X 1200

#define SEARCH_FEEDRATE_Y 1200

#define SEARCH_FEEDRATE_Z 72

// no SEARCH_FEEDRATE_E, as E can't be searched

/** \def ENDSTOP_CLEARANCE_X

\def ENDSTOP_CLEARANCE_Y

\def ENDSTOP_CLEARANCE_Z

When hitting an endstop, Teacup properly decelerates instead of doing an

aprupt stop to save your mechanics. Ineviteably, this means it overshoots

the endstop trigger point by some distance.

To deal with this, Teacup adapts homing movement speeds to what your

endstops can deal with. The higher the allowed acceleration ( = deceleration,

see #define ACCELERATION) and the more clearance the endstop comes with,

the faster Teacup will do homing movements.

Set here how many micrometers (mm * 1000) your endstop allows the carriage

to overshoot the trigger point. Typically 1000 or 2000 for mechanical

endstops, more for optical ones. You can set it to zero, in which case

SEARCH_FEEDRATE_{XYZ} is used, but expect very slow homing movements.

Units: micrometers

Sane values: 0 to 20000 (0 to 20 mm)

Valid range: 0 to 1000000

*/

#define ENDSTOP_CLEARANCE_X 1000

#define ENDSTOP_CLEARANCE_Y 1000

#define ENDSTOP_CLEARANCE_Z 100

/**

Soft axis limits, in mm.

Define them to your machine's size relative to what your host considers to be the origin.

*/

#define X_MIN 0.0

#define X_MAX 110.0

#define Y_MIN 0.0

#define Y_MAX 110.0

#define Z_MIN 0.0

#define Z_MAX 85.0

/** \def E_ABSOLUTE

Some G-Code creators produce relative length commands for the extruder, others absolute ones. G-Code using absolute lengths can be recognized when there are G92 E0 commands from time to time. If you have G92 E0 in your G-Code, define this flag.

This is the startup default and can be changed with M82/M83 while running.

*/

#define E_ABSOLUTE

/***************************************************************************\

* *

* 2. ACCELERATION *

* *

* Choose optionally one of ACCELERATION_REPRAP, ACCELERATION_RAMPING or *

* ACCELERATION_TEMPORAL. With none of them defined, movements are done *

* without acceleration. Recommended is ACCELERATION_RAMPING. *

* *

* LOOKAHEAD is experimental for now and works in conjunction with *

* ACCELERATION_RAMPING, only. That's why it's off by default. *

* *

* Also don't forget to adjust ACCELERATION to the capabilities of your *

* printer. The default is very moderate to be on the safe side. *

* *

\***************************************************************************/

/** \def ACCELERATION_REPRAP

acceleration, reprap style.

Each movement starts at the speed of the previous command and accelerates or decelerates linearly to reach target speed at the end of the movement.

*/

// #define ACCELERATION_REPRAP

/** \def ACCELERATION_RAMPING

acceleration and deceleration ramping.

Each movement starts at (almost) no speed, linearly accelerates to target speed and decelerates just in time to smoothly stop at the target. alternative to ACCELERATION_REPRAP

*/

#define ACCELERATION_RAMPING

/** \def ACCELERATION

how fast to accelerate when using ACCELERATION_RAMPING.

given in mm/s^2, decimal allowed, useful range 1. to 10'000. Start with 10. for milling (high precision) or 1000. for printing

*/

#define ACCELERATION 1000

/** \def ACCELERATION_TEMPORAL

temporal step algorithm

This algorithm causes the timer to fire when any axis needs to step, instead of synchronising to the axis with the most steps ala bresenham.

This algorithm is not a type of acceleration, and I haven't worked out how to integrate acceleration with it.

However it does control step timing, so acceleration algorithms seemed appropriate

The Bresenham algorithm is great for drawing lines, but not so good for steppers - In the case where X steps 3 times to Y's two, Y experiences massive jitter as it steps in sync with X every 2 out of 3 X steps. This is a worst-case, but the problem exists for most non-45/90 degree moves. At higher speeds, the jitter /will/ cause position loss and unnecessary vibration.

This algorithm instead calculates when a step occurs on any axis, and sets the timer to that value.

// TODO: figure out how to add acceleration to this algorithm

*/

// #define ACCELERATION_TEMPORAL

/** \def LOOKAHEAD

Define this to enable look-ahead during *ramping* acceleration to smoothly

transition between moves instead of performing a dead stop every move.

Enabling look-ahead requires about 3600 bytes of flash memory.

*/

#define LOOKAHEAD

/** \def MAX_JERK_X

\def MAX_JERK_Y

\def MAX_JERK_Z

\def MAX_JERK_E

When performing look-ahead, we need to decide what an acceptable jerk to the

mechanics is. Look-ahead attempts to instantly change direction at movement

crossings, which means instant changes in the speed of the axes participating

in the movement. Define here how big the speed bumps on each of the axes is

allowed to be.

If you want a full stop before and after moving a specific axis, define

MAX_JERK of this axis to 0. This is often wanted for the Z axis. If you want

to ignore jerk on an axis, define it to twice the maximum feedrate of this

axis.

Having these values too low results in more than neccessary slowdown at

movement crossings, but is otherwise harmless. Too high values can result

in stepper motors suddenly stalling. If angles between movements in your

G-code are small and your printer runs through entire curves full speed,

there's no point in raising the values.

Units: mm/min

Sane values: 0 to 400

Valid range: 0 to 65535

*/

#define MAX_JERK_X 120

#define MAX_JERK_Y 120

#define MAX_JERK_Z 24

#define MAX_JERK_E 120

/***************************************************************************\

* *

* 3. PINOUTS *

* *

\***************************************************************************/

/*

Machine Pin Definitions

- make sure to avoid duplicate usage of a pin

- comment out pins not in use, as this drops the corresponding code and makes operations faster

*/

#include "arduino.h"

/** \def USE_INTERNAL_PULLUPS

internal pullup resistors

the ATmega has internal pullup resistors on it's input pins which are counterproductive with the commonly used eletronic endstops, so they should be switched off. For other endstops, like mechanical ones, you may want to uncomment this.

*/

#define USE_INTERNAL_PULLUPS

/*

user defined pins

adjust to suit your electronics,

or adjust your electronics to suit this

*/

#define X_STEP_PIN DIO12

#define X_DIR_PIN DIO11

#define X_MIN_PIN AIO0

//#define X_MAX_PIN xxxx

#define X_ENABLE_PIN DIO10

#define X_INVERT_DIR

#define X_INVERT_MIN

//#define X_INVERT_MAX

#define X_INVERT_ENABLE

#define Y_STEP_PIN DIO9

#define Y_DIR_PIN DIO8

#define Y_MIN_PIN AIO1

//#define Y_MAX_PIN xxxx

#define Y_ENABLE_PIN DIO10

#define Y_INVERT_DIR

#define Y_INVERT_MIN

//#define Y_INVERT_MAX

#define Y_INVERT_ENABLE

#define Z_STEP_PIN DIO4

#define Z_DIR_PIN DIO2

#define Z_MIN_PIN AIO2

//#define Z_MAX_PIN xxxx

#define Z_ENABLE_PIN DIO7

#define Z_INVERT_DIR

#define Z_INVERT_MIN

//#define Z_INVERT_MAX

#define Z_INVERT_ENABLE

#define E_STEP_PIN AIO4

#define E_DIR_PIN AIO5

#define E_ENABLE_PIN AIO3

//#define E_INVERT_DIR

#define E_INVERT_ENABLE

//#define PS_ON_PIN DIO9

//#define PS_MOSFET_PIN xxxx

//#define STEPPER_ENABLE_PIN DIO8

//#define STEPPER_INVERT_ENABLE

/** \def DEBUG_LED_PIN

Enable flashing of a LED during motor stepping.

Disabled by default. Uncommenting this makes the binary a few bytes larger

and adds a few cycles to the step timing interrrupt in timer.c. Also used

for precision profiling (profiling works even without actually having such

a LED in hardware), see

[reprap.org]

*/

// #define DEBUG_LED_PIN DIO13

/***************************************************************************\

* *

* 4. TEMPERATURE SENSORS *

* *

\***************************************************************************/

/** \def TEMP_HYSTERESIS

Actual temperature must be target +/- this hysteresis before target

temperature is considered to be achieved. Also, BANG_BANG tries to stay

within half of this hysteresis.

Unit: degree Celsius

*/

#define TEMP_HYSTERESIS 2

/**

TEMP_RESIDENCY_TIME: actual temperature must be close to target (within

set temperature +- TEMP_HYSTERESIS) for this long before target is achieved

(and a M116 succeeds). Unit is seconds.

*/

#define TEMP_RESIDENCY_TIME 10

/**

TEMP_EWMA: Smooth noisy temperature sensors. Good hardware shouldn't be

noisy. Set to 1.0 for unfiltered data (and a 140 bytes smaller binary).

Instrument Engineer's Handbook, 4th ed, Vol 2 p126 says values of

0.05 to 0.1 are typical. Smaller is smoother but slower adjusting, larger is

quicker but rougher. If you need to use this, set the PID parameter to zero

(M132 S0) to make the PID loop insensitive to noise.

Valid range: 0.001 to 1.0

*/

#define TEMP_EWMA 1.0

/// which temperature sensors are you using? List every type of sensor you use here once, to enable the appropriate code. Intercom is the gen3-style separate extruder board.

// #define TEMP_MAX6675

#define TEMP_THERMISTOR

// #define TEMP_AD595

// #define TEMP_PT100

// #define TEMP_INTERCOM

/***************************************************************************\

* *

* Define your temperature sensors here. One line for each sensor, only *

* limited by the number of available ATmega pins. *

* *

* Types are same as TEMP_ list above - TT_MAX6675, TT_THERMISTOR, TT_AD595, *

* TT_PT100, TT_INTERCOM. See list in temp.c. *

* *

* The "additional" field is used for TT_THERMISTOR only. It defines the *

* name of the table(s) in ThermistorTable.h to use. Typically, this is *

* THERMISTOR_EXTRUDER for the first or only table, or THERMISTOR_BED for *

* the second table. See also early in ThermistorTable.{single|double}.h. *

* *

* For a GEN3 set temp_type to TT_INTERCOM and temp_pin to AIO0. The pin *

* won't be used in this case. *

* *

\***************************************************************************/

#ifndef DEFINE_TEMP_SENSOR

#define DEFINE_TEMP_SENSOR(...)

#endif

// name type pin additional

DEFINE_TEMP_SENSOR(extruder, TT_THERMISTOR, AIO7, THERMISTOR_EXTRUDER)

DEFINE_TEMP_SENSOR(bed, TT_THERMISTOR, AIO6, THERMISTOR_EXTRUDER)

// "noheater" is a special name for a sensor which doesn't have a heater.

// Use "M105 P#" to read it, where # is a zero-based index into this list.

// DEFINE_TEMP_SENSOR(noheater, TT_THERMISTOR, 1, 0)

/***************************************************************************\

* *

* 5. HEATERS *

* *

\***************************************************************************/

/** \def HEATER_SANITY_CHECK

check if heater responds to changes in target temperature, disable and spit errors if not

largely untested, please comment in forum if this works, or doesn't work for you!

*/

// #define HEATER_SANITY_CHECK

/***************************************************************************\

* *

* Define your heaters and devices here. *

* *

* To attach a heater to a temp sensor above, simply use exactly the same *

* name - copy+paste is your friend. Some common names are 'extruder', *

* 'bed', 'fan', 'motor', ... names with special meaning can be found *

* in gcode_process.c. Currently, these are: *

* HEATER_extruder (M104) *

* HEATER_bed (M140) *

* HEATER_fan (M106) *

* *

* Devices don't neccessarily have a temperature sensor, e.g. fans or *

* milling spindles. Operate such devices by setting their power (M106), *

* instead of setting their temperature (M104). *

* *

* Also note, the index of a heater (M106 P#) can differ from the index of *

* its attached temperature sensor (M104 P#) in case sensor-less devices *

* are defined or the order of the definitions differs. The first defined *

* device has the index 0 (zero). *

* *

* Set 'pwm' to ... *

* 1 for using PWM on a PWM-able pin and on/off on other pins. *

* 0 for using on/off on a PWM-able pin, too. *

* Using PWM usually gives smoother temperature control but can conflict *

* with slow switches, like solid state relays. PWM frequency can be *

* influenced globally with FAST_PWM, see below. *

* *

\***************************************************************************/

#ifndef DEFINE_HEATER

#define DEFINE_HEATER(...)

#endif

// name port pwm

DEFINE_HEATER(extruder, PD3, 1)

DEFINE_HEATER(bed, PD6, 1)

DEFINE_HEATER(fan, PD5, 1)

// DEFINE_HEATER(chamber, PIND7, 1)

// DEFINE_HEATER(motor, PIND6, 1)

/// and now because the c preprocessor isn't as smart as it could be,

/// uncomment the ones you've listed above and comment the rest.

/// NOTE: these are used to enable various capability-specific chunks of code, you do NOT need to create new entries unless you are adding new capabilities elsewhere in the code!

/// so if you list a bed above, uncomment HEATER_BED, but if you list a chamber you do NOT need to create HEATED_CHAMBER

/// I have searched high and low for a way to make the preprocessor do this for us, but so far I have not found a way.

#define HEATER_EXTRUDER HEATER_extruder

#define HEATER_BED HEATER_bed

#define HEATER_FAN HEATER_fan

// #define HEATER_CHAMBER HEATER_chamber

// #define HEATER_MOTOR HEATER_motor

/***************************************************************************\

* *

* 6. COMMUNICATION OPTIONS *

* *

\***************************************************************************/

/** \def BAUD

Baud rate for the serial RS232 protocol connection to the host. Usually

115200, other common values are 19200, 38400 or 57600. Ignored when USB_SERIAL

is defined.

*/

#define BAUD 115200

/** \def USB_SERIAL

Define this for using USB instead of the serial RS232 protocol. Works on

USB-equipped ATmegas, like the ATmega32U4, only.

*/

// #define USB_SERIAL

/** \def XONXOFF

Xon/Xoff flow control.

Redundant when using RepRap Host for sending GCode, but mandatory when sending GCode files with a plain terminal emulator, like GtkTerm (Linux), CoolTerm (Mac) or HyperTerminal (Windows).

Can also be set in Makefile

*/

// #define XONXOFF

/***************************************************************************\

* *

* 7. MISCELLANEOUS OPTIONS *

* *

\***************************************************************************/

/** \def EECONFIG

EECONFIG: Enable EEPROM configuration storage.

Enabled by default. Commenting this out makes the binary several hundred

bytes smaller, so you might want to disable EEPROM storage on small MCUs,

like the ATmega168.

*/

#define EECONFIG

/** \def DEBUG

DEBUG

enables /heaps/ of extra output, and some extra M-codes.

WARNING: this WILL break most host-side talkers that expect particular responses from firmware such as reprap host and replicatorG

use with serial terminal or other suitable talker only.

*/

// #define DEBUG

/** \def BANG_BANG

BANG_BANG

drops PID loop from heater control, reduces code size significantly (1300 bytes!)

may allow DEBUG on '168

*/

// #define BANG_BANG

/** \def BANG_BANG_ON

BANG_BANG_ON

PWM value for 'on'

*/

// #define BANG_BANG_ON 255

/** \def BANG_BANG_OFF

BANG_BANG_OFF

PWM value for 'off'

*/

// #define BANG_BANG_OFF 0

/**

move buffer size, in number of moves

note that each move takes a fair chunk of ram (69 bytes as of this writing) so don't make the buffer too big - a bigger serial readbuffer may help more than increasing this unless your gcodes are more than 70 characters long on average.

however, a larger movebuffer will probably help with lots of short consecutive moves, as each move takes a bunch of math (hence time) to set up so a longer buffer allows more of the math to be done during preceding longer moves

*/

#define MOVEBUFFER_SIZE 8

/** \def DC_EXTRUDER

DC extruder

If you have a DC motor extruder, configure it as a "heater" above and define this value as the index or name. You probably also want to comment out E_STEP_PIN and E_DIR_PIN in the Pinouts section above.

*/

// #define DC_EXTRUDER HEATER_motor

// #define DC_EXTRUDER_PWM 180

/** \def USE_WATCHDOG

Teacup implements a watchdog, which has to be reset every 250ms or it will reboot the controller. As rebooting (and letting the GCode sending application trying to continue the build with a then different Home point) is probably even worse than just hanging, and there is no better restore code in place, this is disabled for now.

*/

// #define USE_WATCHDOG

/**

analog subsystem stuff

REFERENCE - which analog reference to use. see analog.h for choices

*/

#define REFERENCE REFERENCE_AVCC

/** \def STEP_INTERRUPT_INTERRUPTIBLE

this option makes the step interrupt interruptible (nested).

this should help immensely with dropped serial characters, but may also make debugging infuriating due to the complexities arising from nested interrupts

\note disable this option if you're using a '168 or for some reason your ram usage is above 90%. This option hugely increases likelihood of stack smashing.

*/

#define STEP_INTERRUPT_INTERRUPTIBLE 1

/**

temperature history count. This is how many temperature readings to keep in order to calculate derivative in PID loop

higher values make PID derivative term more stable at the expense of reaction time

*/

#define TH_COUNT 8

/** \def FAST_PWM

Teacup offers two PWM frequencies, 76(61) Hz and 78000(62500) Hz on a

20(16) MHz electronics. The slower one is the default, as it's the safer

choice. Drawback is, in a quiet environment you might notice the heaters

and your power supply humming.

Uncomment this option if you want to get rid of this humming or want

faster PWM for other reasons.

See also: [reprap.org]

*/

// #define FAST_PWM

/// this is the scaling of internally stored PID values. 1024L is a good value

#define PID_SCALE 1024L

/** \def ENDSTOP_STEPS

number of steps to run into the endstops intentionally

As Endstops trigger false alarm sometimes, Teacup debounces them by counting a number of consecutive positives. Valid range is 1...255. Use 4 or less for reliable endstops, 8 or even more for flaky ones.

*/

#define ENDSTOP_STEPS 4

/** \def CANNED_CYCLE

G-code commands in this string will be executed over and over again, without

user interaction or even a serial connection. It's purpose is e.g. for

exhibitions or when using Teacup for other purposes than printing. You can

add any G-code supported by Teacup.

Note: don't miss these newlines (\n) and backslashes (\).

*/

/*

#define CANNED_CYCLE "G1 X100 F3000\n" \

"G4 P500\n" \

"G1 X0\n" \

"G4 P500\n"

*/

/***************************************************************************\

* *

* 8. APPENDIX A - PWMABLE PINS AND MAPPINGS *

* *

* *

* list of PWM-able pins and corresponding timers *

* timer1 is used for step timing so don't use OC1A/OC1B *

* they are omitted from this listing for that reason *

* *

* For the atmega168/328, timer/pin mappings are as follows *

* *

* OCR0A - PD6 - DIO6 *

* OCR0B - PD5 - DIO5 *

* OCR2A - PB3 - DIO11 *

* OCR2B - PD3 - DIO3 *

* *

* For the atmega644, timer/pin mappings are as follows *

* *

* OCR0A - PB3 - DIO3 *

* OCR0B - PB4 - DIO4 *

* OCR2A - PD7 - DIO15 *

* OCR2B - PD6 - DIO14 *

* *

* For the atmega1280, timer/pin mappings are as follows *

* *

* OCR0A - PB7 - DIO13 *

* OCR0B - PG5 - DIO4 *

* OCR2A - PB4 - DIO10 *

* OCR2B - PH6 - DIO9 *

* OCR3AL - PE3 - DIO5 *

* OCR3BL - PE4 - DIO2 *

* OCR3CL - PE5 - DIO3 *

* OCR4AL - PH3 - DIO6 *

* OCR4BL - PH4 - DIO7 *

* OCR4CL - PH5 - DIO8 *

* OCR5AL - PL3 - DIO46 *

* OCR5BL - PL4 - DIO45 *

* OCR5CL - PL5 - DIO44 *

* *

\***************************************************************************/

Edited 4 time(s). Last edit at 05/19/2015 10:58AM by tatubias.

|

Re: Teacup_Firmware: How can i add other board to the firmware? May 19, 2015 11:46AM |

Registered: 9 years ago Posts: 792 |

i was able to do the fork, and now send the request to the main stream.

[github.com]

it seems now that now i need to wait so some one from the team acept the change.

udpate: here its the pull request [github.com]

Edited 1 time(s). Last edit at 05/19/2015 01:46PM by tatubias.

[github.com]

it seems now that now i need to wait so some one from the team acept the change.

udpate: here its the pull request [github.com]

Edited 1 time(s). Last edit at 05/19/2015 01:46PM by tatubias.

Sorry, only registered users may post in this forum.