X-axis skipping

Posted by strtrkn

|

X-axis skipping April 23, 2013 04:04PM |

Registered: 11 years ago Posts: 19 |

My bf & I have been building on our Prusa Mendel for over a year now. The one problem we can't seem to fix is x-axis skipping or drifting. & I mean about 1cm to the left on almost every single print.

Here's our specs:

Prusa Mendel

Printrboard running Marlin firmware

.9 stepper motors

Wade gears extruder with a Jhead Mk IV-b .35mm hotend

Heated bed with glass with heat resistant tape on it

Printing with abs

T2.5 aluminum gears and belts for both the x & y axes

Z-axis stabilizers

Pronterface with the latest Slic3r (through we've tried many versions)

What we've tried:

Lowering & upping the pots by just a little with no effect

Pointing a fan at the drivers to ensure they're not overheating (they haven't) with no effect

Different brands of abs filament just in case with no effect.

Switching the x & y drivers with no effect.

Tightening & loosening the x-axis belt. Regardless of how tight the belt seems to drift to the left & starts to rub on the fender washer. We have found no way to prevent this.

Watched prints from start to finish w/o seeing the x-axis gear skipping a tooth.

About the only thing we haven't tried is slowing the print down. Right now it's at default for slic3r (which i think is 60 or lower for most things).

Does anyone have any other suggestions on what we can try. We would REALLY like to start printing on a regular basis & this is our last problem to overcome.

Thanks for any advice you can offer!

Lindsay

Here's our specs:

Prusa Mendel

Printrboard running Marlin firmware

.9 stepper motors

Wade gears extruder with a Jhead Mk IV-b .35mm hotend

Heated bed with glass with heat resistant tape on it

Printing with abs

T2.5 aluminum gears and belts for both the x & y axes

Z-axis stabilizers

Pronterface with the latest Slic3r (through we've tried many versions)

What we've tried:

Lowering & upping the pots by just a little with no effect

Pointing a fan at the drivers to ensure they're not overheating (they haven't) with no effect

Different brands of abs filament just in case with no effect.

Switching the x & y drivers with no effect.

Tightening & loosening the x-axis belt. Regardless of how tight the belt seems to drift to the left & starts to rub on the fender washer. We have found no way to prevent this.

Watched prints from start to finish w/o seeing the x-axis gear skipping a tooth.

About the only thing we haven't tried is slowing the print down. Right now it's at default for slic3r (which i think is 60 or lower for most things).

Does anyone have any other suggestions on what we can try. We would REALLY like to start printing on a regular basis & this is our last problem to overcome.

Thanks for any advice you can offer!

Lindsay

|

Re: X-axis skipping April 23, 2013 07:08PM |

Registered: 11 years ago Posts: 1,592 |

As far as the fender washer problem is concerned, just remove them and fit a second bearing back to back. If your setup is o.k, then the belt should track somewhere in-between of the two. You could also twist the top of the belt as Nophead suggested so the flat part of the belt runs on the bearings.

|

Re: X-axis skipping April 24, 2013 05:50AM |

Registered: 11 years ago Posts: 75 |

|

Re: X-axis skipping April 26, 2013 01:38PM |

Registered: 11 years ago Posts: 19 |

|

Re: X-axis skipping April 27, 2013 12:56PM |

Registered: 11 years ago Posts: 469 |

i strongly recommend not to twist the belts ever. I have yet to see a belt that is made to work that way

the re enforcement is bonded to only work for the teeth facing the pivot point. By running the belt with its back to the bearing/ idler

you are effectively overstretching the teeth pitch and shortening the service life

If you are concerned about the teeth being compressed "on" the bearing then print a toothed idler..plenty on thingiverse.

As for the belt issue check the alignment of the pulley. Belts will always climb to the high point of a pulley. I know its counter intuitive but they do,

if the pulley and axle on which its sits are not perpendicular to the belt the belt will "climb" to the high point.

Have you tried swapping the actual stepper motors ?

IS the drift consistent on all prints or some yes some no?

Good luck

Edited 1 time(s). Last edit at 04/27/2013 01:01PM by bigfilsing.

the re enforcement is bonded to only work for the teeth facing the pivot point. By running the belt with its back to the bearing/ idler

you are effectively overstretching the teeth pitch and shortening the service life

If you are concerned about the teeth being compressed "on" the bearing then print a toothed idler..plenty on thingiverse.

As for the belt issue check the alignment of the pulley. Belts will always climb to the high point of a pulley. I know its counter intuitive but they do,

if the pulley and axle on which its sits are not perpendicular to the belt the belt will "climb" to the high point.

Have you tried swapping the actual stepper motors ?

IS the drift consistent on all prints or some yes some no?

Good luck

Edited 1 time(s). Last edit at 04/27/2013 01:01PM by bigfilsing.

|

Re: X-axis skipping May 01, 2013 04:21PM |

|

Re: X-axis skipping May 04, 2013 06:42PM |

Registered: 13 years ago Posts: 248 |

Hi there,

Have you ever decreased the Max Acceleration in the Marlin Firmware?

If you are ok with Firmware changes then try reduce the Default Max Acceleration in the Configuration.h tab in Marlin.

I've set mine quite low, and it cleared up skipping problems I was having a long time ago.

#define DEFAULT_MAX_ACCELERATION {2500,2500,100,10000}

Also, 60mm/s is quite high of you are still working out issues. You could drop the speed down to 20 or so and then work back up once things are going more smoothly.

Have you any picture of a print that shows the "drift"? That would allow readers to make a more informed assessment of the issue.

Regards,

NumberSix

[numbersixreprap.blogspot.com]

Have you ever decreased the Max Acceleration in the Marlin Firmware?

If you are ok with Firmware changes then try reduce the Default Max Acceleration in the Configuration.h tab in Marlin.

I've set mine quite low, and it cleared up skipping problems I was having a long time ago.

#define DEFAULT_MAX_ACCELERATION {2500,2500,100,10000}

Also, 60mm/s is quite high of you are still working out issues. You could drop the speed down to 20 or so and then work back up once things are going more smoothly.

Have you any picture of a print that shows the "drift"? That would allow readers to make a more informed assessment of the issue.

Regards,

NumberSix

[numbersixreprap.blogspot.com]

|

Re: X-axis skipping May 06, 2013 05:47PM |

Registered: 11 years ago Posts: 19 |

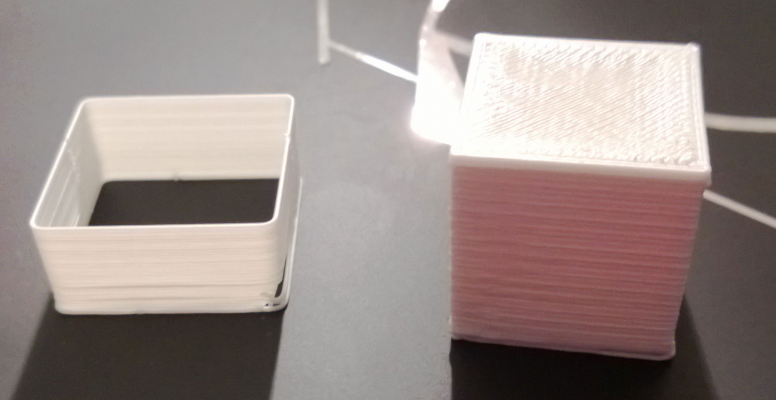

So I'm waiting on extra bearings, to try to get rid of the fender washer. Our belts & pulleys look good (other than the belt rubbing problem which I mentioned earlier). We did slow our acceleration WAAAY down (I halved everything). I got through 1 print (which looks horrible) (see image). After that I changed the layers to be a bit thinner. And then the bf decided we needed to try Repetier, so I'm in the middle of tweaking that. We'll see if the problem still exists once the new firmware is tweaked properly.

FYI this is one of our better prints. (sad I know)

FYI this is one of our better prints. (sad I know)

|

Re: X-axis skipping May 06, 2013 08:44PM |

Registered: 11 years ago Posts: 469 |

Well at least its printing ...some people cant even get that to work

One thing I've learned ( from this forum) is to pick a test object and stick to it while trying to identify issues

Many ( including me) use the 20mm hollow cube and /or the 0.5 mm thin wall

20mm hollow cube.stl

0.5 mm thin wall.stl

These have the advantage that many of us have experience with them and can better judge pictures of your print.

They are also recommended on the calibration wiki

Calibration page

Slow your speed right down to 15 maybe even 10mm/s and try printing the test pieces above then post some pics

My gut instinct on the picture you posted is too hot , too fast, too much material and not enough retract.

I don't think swapping to Repetier will help other than to waste a few days while you arrive back to where you are now.

Good luck

Edited 1 time(s). Last edit at 05/06/2013 08:47PM by bigfilsing.

One thing I've learned ( from this forum) is to pick a test object and stick to it while trying to identify issues

Many ( including me) use the 20mm hollow cube and /or the 0.5 mm thin wall

20mm hollow cube.stl

0.5 mm thin wall.stl

These have the advantage that many of us have experience with them and can better judge pictures of your print.

They are also recommended on the calibration wiki

Calibration page

Slow your speed right down to 15 maybe even 10mm/s and try printing the test pieces above then post some pics

My gut instinct on the picture you posted is too hot , too fast, too much material and not enough retract.

I don't think swapping to Repetier will help other than to waste a few days while you arrive back to where you are now.

Good luck

Edited 1 time(s). Last edit at 05/06/2013 08:47PM by bigfilsing.

|

Re: X-axis skipping May 07, 2013 04:53PM |

Registered: 11 years ago Posts: 75 |

I very much agree with all of bigfilsing's last post, the 0.5 mm thin wall and the 20 mm boxes are your friends.

The picture you posted looks like the belt guide I recommended, I have printed a few of them

and the wall should be no thicker than your nozzle. It looks to me as though there is either too much

filament being extruded or if you are using slicer then more than one perimeter is set.

I have attached a (poor) photo of one of my prints so you can see what it should look like.

Just so you know, the measurements of the belt guide should be,

small: inside wall diameter just less than 22 mm, outside wall diameter 23 mm, shoulder height 1 mm, overall height 8 mm

large :inside wall diameter 23 mm, outside wall diameter 24 mm, shoulder height 1 mm, overall height 8 mm

A 608 ZZ bearing should be a tight fit in the smaller part, and the larger part a tight fit to the smaller.

from experience, stick with 1 slicer to start with,

now I must work on improving my photos

all the best

The picture you posted looks like the belt guide I recommended, I have printed a few of them

and the wall should be no thicker than your nozzle. It looks to me as though there is either too much

filament being extruded or if you are using slicer then more than one perimeter is set.

I have attached a (poor) photo of one of my prints so you can see what it should look like.

Just so you know, the measurements of the belt guide should be,

small: inside wall diameter just less than 22 mm, outside wall diameter 23 mm, shoulder height 1 mm, overall height 8 mm

large :inside wall diameter 23 mm, outside wall diameter 24 mm, shoulder height 1 mm, overall height 8 mm

A 608 ZZ bearing should be a tight fit in the smaller part, and the larger part a tight fit to the smaller.

from experience, stick with 1 slicer to start with,

now I must work on improving my photos

all the best

|

Re: X-axis skipping May 09, 2013 02:19PM |

Registered: 11 years ago Posts: 19 |

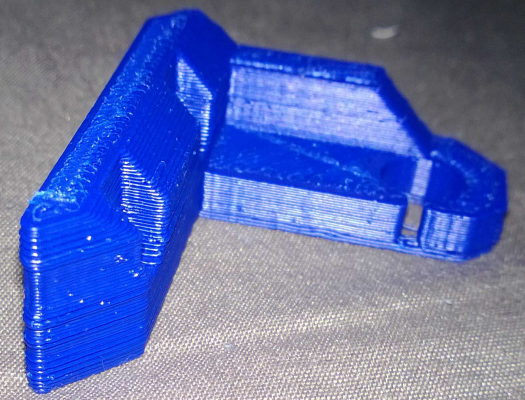

So we went back to the known working Marlin firmware with a few tweaks. I did slow down the max acceleration in the firmware as suggested by NumberSix. We slowed the printing WAAAAY down on everything & so far it looks pretty good. We also did a number of changes using that calibration wiki as suggested by bigfilsing. Knocking down the bed & extruder temps by a small margin seemed to help a great deal. & actually measuring the filament has helped too I think. I still think we need a bit more work, as I tried to print the bearing guide suggested by Myles, but they don't quite fit together yet.  I'm still waiting on my extra bearings to be delivered, so we'll see how it works (the 3rd attached pic are the bearing guides. There was some junk on the extruder that i didn't see that deposited itself at the very top. I can file that off. Other than that, I would just like to see the circles print a bit smoother.)

I'm still waiting on my extra bearings to be delivered, so we'll see how it works (the 3rd attached pic are the bearing guides. There was some junk on the extruder that i didn't see that deposited itself at the very top. I can file that off. Other than that, I would just like to see the circles print a bit smoother.)

I've attached some pics. The first set show the good prints using Pronterface. The second set shows the same things only using Repetier software. I can't figure out for the life of me why the nozzle was burrying itself in previous layers ONLY with the Repetier software when the slic3r settings for both it & Pronterface are identical. But as soon as I changed back to Pronterface, the prints started printing properly w/o the nozzle embedding itself in the previous layer.

I think we're almost there. I know that slowing down things is for troubleshooting & the prints were indeed SLOW. I want to try to print some actual parts now, but don't want to print at super slow speeds. Any suggestions as to what I can try w/o going back to the garbly mess I had previous?

Thank you everyone so much for all of your help!

I'm still waiting on my extra bearings to be delivered, so we'll see how it works (the 3rd attached pic are the bearing guides. There was some junk on the extruder that i didn't see that deposited itself at the very top. I can file that off. Other than that, I would just like to see the circles print a bit smoother.)

I'm still waiting on my extra bearings to be delivered, so we'll see how it works (the 3rd attached pic are the bearing guides. There was some junk on the extruder that i didn't see that deposited itself at the very top. I can file that off. Other than that, I would just like to see the circles print a bit smoother.)I've attached some pics. The first set show the good prints using Pronterface. The second set shows the same things only using Repetier software. I can't figure out for the life of me why the nozzle was burrying itself in previous layers ONLY with the Repetier software when the slic3r settings for both it & Pronterface are identical. But as soon as I changed back to Pronterface, the prints started printing properly w/o the nozzle embedding itself in the previous layer.

I think we're almost there. I know that slowing down things is for troubleshooting & the prints were indeed SLOW. I want to try to print some actual parts now, but don't want to print at super slow speeds. Any suggestions as to what I can try w/o going back to the garbly mess I had previous?

Thank you everyone so much for all of your help!

|

Re: X-axis skipping May 09, 2013 04:42PM |

Registered: 11 years ago Posts: 75 |

Well done, that's progress.

I would suggest reducing the E steps slightly, " Edit 1: ( M92 E*** and M500 to save) " ,looks like

a bit too much is being extruded.

A small fan might also help when doing the thin wall object, you could try printing a part

from your Mendel, a clip or the idler for the extruder. Gives you something to compare to.

I am sure you could increase the speed a little with out too much harm, as long as you feel

comfortable with it. Small adjustments is what does it. If you have a 0.35 nozzle then I suggest

keeping the layer height to 0.25 mm for now, get the extrusion steps right and then you are on

your way.

And loads of things to download from thingiverse.

You are getting there, all the best

Edit 2, too many asterisk's

Edit 3, change to nozzle and layer dimensions !

Edited 3 time(s). Last edit at 05/09/2013 06:42PM by Myles.

I would suggest reducing the E steps slightly, " Edit 1: ( M92 E*** and M500 to save) " ,looks like

a bit too much is being extruded.

A small fan might also help when doing the thin wall object, you could try printing a part

from your Mendel, a clip or the idler for the extruder. Gives you something to compare to.

I am sure you could increase the speed a little with out too much harm, as long as you feel

comfortable with it. Small adjustments is what does it. If you have a 0.35 nozzle then I suggest

keeping the layer height to 0.25 mm for now, get the extrusion steps right and then you are on

your way.

And loads of things to download from thingiverse.

You are getting there, all the best

Edit 2, too many asterisk's

Edit 3, change to nozzle and layer dimensions !

Edited 3 time(s). Last edit at 05/09/2013 06:42PM by Myles.

|

Re: X-axis skipping May 12, 2013 05:31PM |

Registered: 11 years ago Posts: 525 |

With an object that small it probably isn't the lack of fan on the extruder unless you are printing for hours on end and leave the hot end on all the time. Skipping steps is one of the more common problems posted here and probably due to insufficient current in the x-axis stepper motor. It seems to only ever happen in the X and y axes and for me more often the x-axis which might be something to do with the mass of the carriage and extruder being more than the y-carriage. Try tweaking the pot on the x-axis motor clockwise just a fraction and run another test print. If you tweak it too far the stepper will start running hot and you may need to add a fan to cool it but for short printing times it will probably be OK. I've never burned out a stepper anyway (yet).

The picture of your print looks pretty straight so that's a good sign, just need to clean up the extruder issues which are either too hot at the hot end or lack of fan causes the PLA to get squidgy and not retract cleanly. The soft filament will eventually block the nozzle so think about adding a fan to cool the barrel of the hot end (not the tip, just half way up where the fins are).

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

The picture of your print looks pretty straight so that's a good sign, just need to clean up the extruder issues which are either too hot at the hot end or lack of fan causes the PLA to get squidgy and not retract cleanly. The soft filament will eventually block the nozzle so think about adding a fan to cool the barrel of the hot end (not the tip, just half way up where the fins are).

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: X-axis skipping May 13, 2013 11:03PM |

Registered: 11 years ago Posts: 19 |

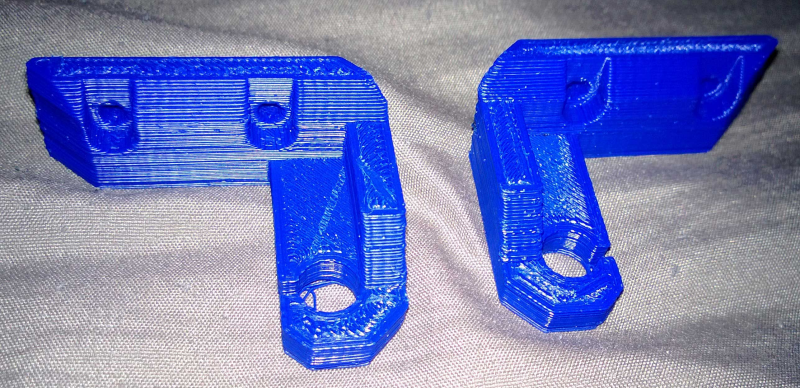

So here are a few photos of some z-axis tops for a Prusa i3. They were printed at the same settings as the other thingsI posted one post previous. Still a few tweaks left to do, obviously, as the part's layers shifted a bit on one side (though I'm not sure why, as it was still set for super slow).

ABS 3.0mm filament at 230 C w/ 60% infill on a heated bed.

ABS 3.0mm filament at 230 C w/ 60% infill on a heated bed.

|

Re: X-axis skipping May 14, 2013 02:00AM |

Registered: 11 years ago Posts: 469 |

big improvements

Looking at the top layer it seems to me like you still have a little bit too much material being extruded

Go back to the thin wall ( 0.5 mm) cube and try reducing your x steps per mm till the cube wall is 0.5

( to experiment send the X steps thru pronterface >>> M92 X nnn)

Good luck

strtrkn Wrote:

-------------------------------------------------------

> So here are a few photos of some z-axis tops for a

> Prusa i3. They were printed at the same settings

> as the other thingsI posted one post previous.

> Still a few tweaks left to do, obviously, as the

> part's layers shifted a bit on one side (though

> I'm not sure why, as it was still set for super

> slow).

>

> ABS 3.0mm filament at 230 C w/ 60% infill on a

> heated bed.

>

>

>

Looking at the top layer it seems to me like you still have a little bit too much material being extruded

Go back to the thin wall ( 0.5 mm) cube and try reducing your x steps per mm till the cube wall is 0.5

( to experiment send the X steps thru pronterface >>> M92 X nnn)

Good luck

strtrkn Wrote:

-------------------------------------------------------

> So here are a few photos of some z-axis tops for a

> Prusa i3. They were printed at the same settings

> as the other thingsI posted one post previous.

> Still a few tweaks left to do, obviously, as the

> part's layers shifted a bit on one side (though

> I'm not sure why, as it was still set for super

> slow).

>

> ABS 3.0mm filament at 230 C w/ 60% infill on a

> heated bed.

>

>

>

|

Re: X-axis skipping May 14, 2013 07:23AM |

Registered: 11 years ago Posts: 75 |

Apart from a little too much being extruded, I can't see a lot wrong with your most recent prints,

I have attached a photo of the same part ( the old version) that I have printed myself.

I do NOT recommend messing about with X and Y steps unless the printed object is the wrong size.

I also attach a set square stl which is 100 mm x 100 mm for you to print and measure, this can be used to set

the X and Y steps.

All the best

I have attached a photo of the same part ( the old version) that I have printed myself.

I do NOT recommend messing about with X and Y steps unless the printed object is the wrong size.

I also attach a set square stl which is 100 mm x 100 mm for you to print and measure, this can be used to set

the X and Y steps.

All the best

|

Re: X-axis skipping May 18, 2013 02:47PM |

Registered: 11 years ago Posts: 19 |

So I tried changing my E steps per mm based on the formula I found in the configuration.h of the marlin firmware for my printrboard. The cube came out kind of awful. So then I tried a value based on the original formula on the prusa wiki page. Again w/ the not so happy cube print. So I reflashed the firmware back to my original & am printing another cube to make sure it goes back to what it was. Is there any way for me to get the printrboard to tell me what it's using for e steps per mm? I tried using M503 in Pronterface hoping it would print out the settings so I could see what it was currently using, but no go.

|

Re: X-axis skipping May 18, 2013 05:03PM |

Registered: 11 years ago Posts: 75 |

Does it not come up when you connect pronterface to your printer?

I have a melzi controller, so I don't know the other controllers.

It may be M501,

Here is the wiki for gcode [reprap.org]

Good luck

Edit, added signature.

Edited 1 time(s). Last edit at 05/19/2013 07:04AM by Myles.

Please support W.Afate 3D printer project in Togo at [www.ulule.com]

I have a melzi controller, so I don't know the other controllers.

It may be M501,

Here is the wiki for gcode [reprap.org]

Good luck

Edit, added signature.

Edited 1 time(s). Last edit at 05/19/2013 07:04AM by Myles.

Please support W.Afate 3D printer project in Togo at [www.ulule.com]

|

Re: X-axis skipping May 20, 2013 02:15AM |

Registered: 11 years ago Posts: 469 |

|

Re: X-axis skipping May 20, 2013 06:47PM |

Registered: 11 years ago Posts: 19 |

|

Re: X-axis skipping May 20, 2013 07:57PM |

Registered: 11 years ago Posts: 469 |

|

Re: X-axis skipping May 20, 2013 10:16PM |

Registered: 11 years ago Posts: 19 |

I hope not. This is what the portion for the e steps of my configuration.h looks like. The formulas I'm referring to are in the first few lines.

//=========================================================================== //===========================CALIBRATION PARAMETERS========================== //=========================================================================== // Formula for X and Y steps per mm = [(Number of Motor Steps per Revolution)*(1/(microstepping ratio)]/(BeltPitch*ToothCount) // Formula for Z steps per mm = (Motor Steps per revolution)*(1/(microstepping ratio)/(Vertical Movement per revolution) where Vert. Movement per revolution = 1.25mm for directly driven M8 rods on Prusa // Formula for Extruder steps per mm = [(PackingDensity)*(Number of Motor Steps per Revolution)*(Gear Ratio of Extruder)*(1/(microstepping ratio)]/(pi*(Diamter of Hobbed Bolt or Pinch Wheel)) // -Equation based on: [www.brokentoaster.com] and [hydraraptor.blogspot.com] // -The term ((NozzleDiameter^2)/(ExtrudedFilamentDiamter^2) from the above articles is consolidated to the term "PackingDensity" // INSTRUCTIONS: ENTER PARAMETERS BELOW FOR YOUR EQUIPMENT. #define MICROSTEPPING_RATIO 0.0625 // Enter microstepping ratio of electronics. Printrboard and Pololu = 1/16, Gen6 = 1/8, etc. #define XY_MTR_STPS 400 // Enter number of steps per one revolution of the X and Y motors. See motor datasheet, 1.8degree = 200 steps, 0.9degree = 400 steps #define Z_MTR_STPS 400 // Enter number of steps per one revolution of the Z motor(s). #define EXTRUDER_MTR_STPS 400 // Enter number of steps per one revolution of the extruder motor. Default is 200 #define PACKING_DENSITY 1.0 // Leave at 1.0 and adjust in Skeinforge 40+. Alternatively, leave at 1.0 in Skeinforge and calculate manually: Packing_Density = (NozzleDiameter^2)/(Measured_Extruded_Filament_Diamter^2) #define BOLT_DIAMETER 6.00 // Enter measured diameter of hobbed bolt or pinch wheel #define EXTRUDER_GEAR_RATIO 39/11 // Enter gear ratio of extruder. Wade's Extruder: 39/11, Accessible Wade's by Greg Frost: 43/10, Adrian's Extruder: 59/11, etc. #define BELT_PITCH 2.5 // Enter pitch of X and Y belts in millimeters (space from tooth to tooth). XL belts = 5.08mm #define GEAR_TEETH 18 // Enter number of teeth on X and Y gears #define Z_ROD_PITCH 1.411 // Enter pitch of Z rods in millimeters. Pitch = 1.25mm for directly driven M8 rods. // ************* End MECHANICAL Calibration ************* #define PI 3.14159265359 #define DEFAULT_AXIS_STEPS_PER_UNIT {((XY_MTR_STPS/MICROSTEPPING_RATIO)/(BELT_PITCH*GEAR_TEETH)), ((XY_MTR_STPS/MICROSTEPPING_RATIO)/(BELT_PITCH*GEAR_TEETH)), ((Z_MTR_STPS/MICROSTEPPING_RATIO)/Z_ROD_PITCH),((PACKING_DENSITY*EXTRUDER_MTR_STPS*EXTRUDER_GEAR_RATIO*(1/MICROSTEPPING_RATIO))/(PI*BOLT_DIAMETER))} #define DEFAULT_MAX_FEEDRATE {500, 500, 5, 45} // (mm/sec) #define DEFAULT_MAX_ACCELERATION {2500,2500,100,10000} // Original 9k,7k,100,10k X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot. #define DEFAULT_ACCELERATION 2000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves #define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for r retracts // #define DEFAULT_XYJERK 20.0 // (mm/sec) #define DEFAULT_ZJERK 0.4 // (mm/sec) #define DEFAULT_EJERK 5.0 // (mm/sec)

|

Re: X-axis skipping May 21, 2013 01:03AM |

Registered: 11 years ago Posts: 469 |

Ah ok you are right. Your board has enough memory to allow for extensive comments areas in your config file.

Due to the memory limitation on my board ( Gen6d) my config.h file is very sparse and i have to refer to external sources for formulas for calibration.

Apologies for the confusion

Due to the memory limitation on my board ( Gen6d) my config.h file is very sparse and i have to refer to external sources for formulas for calibration.

Apologies for the confusion

Sorry, only registered users may post in this forum.