x-axis distance issue with Prusa Iteration 2 Github parts

Posted by derekmjenkins

|

x-axis distance issue with Prusa Iteration 2 Github parts June 08, 2013 08:39PM |

Registered: 10 years ago Posts: 14 |

I am building a Prusa iteration 2 and am having lots of issues due to the lack of correct documentation. Anyway I won't go on a rant, but man!

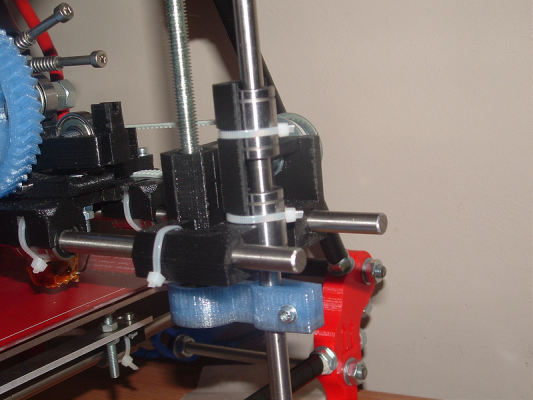

I have the current x-axis motor, idler, and carriage from GitHub that uses press fit for the 420mm smooth rods (i.e. no nut traps). When I press the smooth rods in as far as they can go in both the motor and idler pieces I end up with a center-center distance for the z-axis threaded rods of about 363mm.

However, after I built the frame the center-center distance for the z-axis motors is about 327mm. My z-motor mounts are right against the nuts that are going through the top vertex. So I need to either shorten the distance between the x-axis motor and idler or I need to increase the distance between the z-motor mounts.

Which should I do?

Was I supposed to drill out the two smooth-rod holes in the x-axis idler all the way through so that the distance between the motor and idler can be adjusted?

Are my z-motor mounts in the right spot?

Unfortunately the documentation is either for iteration 1 and doesn't cover these pieces, or the videos from engineglue where he decided not to use GitHub parts which use a different x-axis motor and idler pieces.

Thanks

Derek

I have the current x-axis motor, idler, and carriage from GitHub that uses press fit for the 420mm smooth rods (i.e. no nut traps). When I press the smooth rods in as far as they can go in both the motor and idler pieces I end up with a center-center distance for the z-axis threaded rods of about 363mm.

However, after I built the frame the center-center distance for the z-axis motors is about 327mm. My z-motor mounts are right against the nuts that are going through the top vertex. So I need to either shorten the distance between the x-axis motor and idler or I need to increase the distance between the z-motor mounts.

Which should I do?

Was I supposed to drill out the two smooth-rod holes in the x-axis idler all the way through so that the distance between the motor and idler can be adjusted?

Are my z-motor mounts in the right spot?

Unfortunately the documentation is either for iteration 1 and doesn't cover these pieces, or the videos from engineglue where he decided not to use GitHub parts which use a different x-axis motor and idler pieces.

Thanks

Derek

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 09, 2013 07:31AM |

Registered: 11 years ago Posts: 3 |

Derek,

I hit the same problem and this is how I solved it.

1) Don't drill out the smooth rod holes.

2) Swap the 420mm smooth rods for the shorter ones that the baseplate slides on, I think they're 406mm or a bit shorter but this helps reduce the overall width.

3) Use extra m8 nuts and washers as spacers between the z-motor mount and the frame to increase the width between the top motors so you're vertical threaded rods of the x-axis carriage align with your couplers. I think in the engineglue video he used washer/nut/washer but to get the right spacing I ended up using washer/nut/nut/nut. As a guide the final distance between my z-axis motors shafts is 350mm.

I hit the same problem and this is how I solved it.

1) Don't drill out the smooth rod holes.

2) Swap the 420mm smooth rods for the shorter ones that the baseplate slides on, I think they're 406mm or a bit shorter but this helps reduce the overall width.

3) Use extra m8 nuts and washers as spacers between the z-motor mount and the frame to increase the width between the top motors so you're vertical threaded rods of the x-axis carriage align with your couplers. I think in the engineglue video he used washer/nut/washer but to get the right spacing I ended up using washer/nut/nut/nut. As a guide the final distance between my z-axis motors shafts is 350mm.

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 09, 2013 09:30AM |

Registered: 10 years ago Posts: 59 |

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 09, 2013 06:59PM |

Registered: 11 years ago Posts: 3 |

Is there any downside to drilling the holes all the way through? I guess the rod doesn't have to be fixed at both ends if the x-axis parts together with the vertical smooth rods hold it in alignment. Did you use any glue to stop any sliding of the x-axis rods or just leave it free?

as an ammendment to my previous post:

3) Use extra m8 nuts and washers as spacers between the z-motor mount and the frame to increase the width between the top motors so you're vertical threaded rods of the x-axis carriage align with your couplers. I think in the engineglue video he used washer/nut/washer but to get the right spacing I ended up using washer/nut/nut/washer. As a guide the final distance between my z-axis motors shafts is 350mm.

as an ammendment to my previous post:

3) Use extra m8 nuts and washers as spacers between the z-motor mount and the frame to increase the width between the top motors so you're vertical threaded rods of the x-axis carriage align with your couplers. I think in the engineglue video he used washer/nut/washer but to get the right spacing I ended up using washer/nut/nut/washer. As a guide the final distance between my z-axis motors shafts is 350mm.

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 09, 2013 07:04PM |

Registered: 11 years ago Posts: 3 |

The other option I came across was to increase the distance between your tri-frames but I've already aligned those so I didn't really want to mess with them again. It's a lot easier to just increase the z-motor mounts by using an extra nut OR maybe try poete vogons idea of drilling through.

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 10, 2013 02:58AM |

Registered: 11 years ago Posts: 528 |

hi,

I had this issue, and I reamed the idle X axial and pushed the rods through works ok for, be sure NOT TO have the holes too lose,

but am about too print Improved X ends for Prusa with clamped rods http://www.thingiverse.com/thing:18384

I had this issue, and I reamed the idle X axial and pushed the rods through works ok for, be sure NOT TO have the holes too lose,

but am about too print Improved X ends for Prusa with clamped rods http://www.thingiverse.com/thing:18384

|

Re: x-axis distance issue with Prusa Iteration 2 Github parts June 12, 2013 05:23PM |

Registered: 11 years ago Posts: 661 |

Derek are you using these as your build instructions? [reprap.org] There are some things that don't hold true for all i2 versions as it was originally for an i1 but it's pretty comprehensive. A video tutorial for i2 is at [reprap.org] .

As for the X rod length issue I've experienced that in a couple of builds and several of my clients have as well. In those cases the rods are shortened. I've built with 386 mm smooth on the X. When you shorten them be sure to pay attention to the limits on the X carriage travel. Too short or not enough spacing on the Z smooth rods and the carriage will hit the Z bearing/drive brackets before clearing the print bed. It will work narrower but you'll reduce the build envelope and need to configure the machine with the smaller build envelope. Extending the Z motor brackets out on the top rods as well as a combination of shorter rods and extending the motor brackets out works also.

Dave

Edited 1 time(s). Last edit at 06/12/2013 05:24PM by vegasloki.

As for the X rod length issue I've experienced that in a couple of builds and several of my clients have as well. In those cases the rods are shortened. I've built with 386 mm smooth on the X. When you shorten them be sure to pay attention to the limits on the X carriage travel. Too short or not enough spacing on the Z smooth rods and the carriage will hit the Z bearing/drive brackets before clearing the print bed. It will work narrower but you'll reduce the build envelope and need to configure the machine with the smaller build envelope. Extending the Z motor brackets out on the top rods as well as a combination of shorter rods and extending the motor brackets out works also.

Dave

Edited 1 time(s). Last edit at 06/12/2013 05:24PM by vegasloki.

Sorry, only registered users may post in this forum.