Problem with Z height when printing.

Posted by Jimthree

|

Problem with Z height when printing. July 05, 2013 07:31PM |

Registered: 10 years ago Posts: 13 |

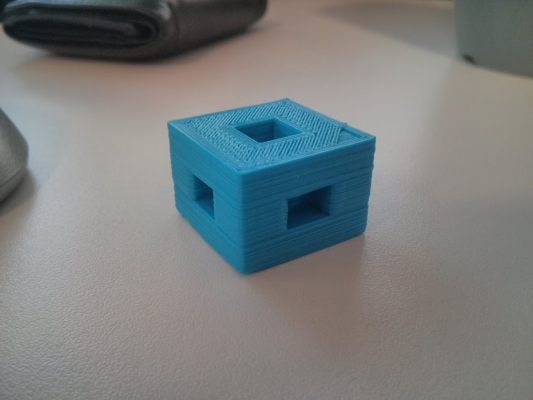

Hi folks. I have a problem with my i3 which I've been wrestling with since my first calibration print a couple of days ago. All my prints are coming out about 75% of the intended height. You can see it here: (supposed to be a cube!)

and here: (1cm cubes!)

I've double checked the Z steps/mm calibration in the firmware, and I'm really pleased with how tight it is. If I command it to rise 100mm, I can measure 99.98mm travel or better, so I don't think it's as simple a calibration issue.

My build chain is i3->Marlin->Slic3r->Repeteir (or Pronterface)

My current theory is there is a small amount of slippage in the PTE tubing that binds the Z steppers to the load screws. This would be imperceptible during a 100mm travel, but would be a compound error of significant proportions on a 50+ layer print. This was idea was given weight when I remembered that I was so pleased with the Z accuracy during calibration, that I didn't bother putting the zip ties round the tubing.

This evening I applied the zip ties, and used extreme levels of violence to get them as tight as possible. I printed another 1cm cube, but was disappointed to see only a very slight improvement in the height in Z (prob up from 7.5mm to 8mm)

I've tried this with both Repeteir and Pronterface, but there is no difference. Does anyone know if there is anything in Marlin or Slic3r that could be the cause of this?

This is the start of the gCode:

And Marlin config extract:

If I can assist diagnosis with any more data or photos let me know, any help would be gratefully received!

Jim

and here: (1cm cubes!)

I've double checked the Z steps/mm calibration in the firmware, and I'm really pleased with how tight it is. If I command it to rise 100mm, I can measure 99.98mm travel or better, so I don't think it's as simple a calibration issue.

My build chain is i3->Marlin->Slic3r->Repeteir (or Pronterface)

My current theory is there is a small amount of slippage in the PTE tubing that binds the Z steppers to the load screws. This would be imperceptible during a 100mm travel, but would be a compound error of significant proportions on a 50+ layer print. This was idea was given weight when I remembered that I was so pleased with the Z accuracy during calibration, that I didn't bother putting the zip ties round the tubing.

This evening I applied the zip ties, and used extreme levels of violence to get them as tight as possible. I printed another 1cm cube, but was disappointed to see only a very slight improvement in the height in Z (prob up from 7.5mm to 8mm)

I've tried this with both Repeteir and Pronterface, but there is no difference. Does anyone know if there is anything in Marlin or Slic3r that could be the cause of this?

This is the start of the gCode:

; generated by Slic3r 0.9.10b on 2013-07-05 at 23:16:44 ; layer_height = 0.4 ; perimeters = 3 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 0.4 ; perimeter_speed = 30 ; infill_speed = 60 ; travel_speed = 130 ; nozzle_diameter = 0.5 ; filament_diameter = 3 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.53mm ; infill extrusion width = 0.53mm ; solid infill extrusion width = 0.53mm ; top infill extrusion width = 0.53mm ; first layer extrusion width = 0.80mm

And Marlin config extract:

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {80.2691,80.8389,3973.6676,695.6} // default steps per unit for ultimaker

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for r retracts

// The speed change that does not require acceleration (i.e. the software might assume it can be done instanteneously)

#define DEFAULT_XYJERK 20.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

If I can assist diagnosis with any more data or photos let me know, any help would be gratefully received!

Jim

|

Re: Problem with Z height when printing. July 06, 2013 12:12AM |

Registered: 11 years ago Posts: 661 |

I use about those same config settings and get accurate Z height. I use 5mm shaft couplers though there is an indication that a more solid coupler works better. Nophead posted one in another thread that uses tubing as a sleeve with a 7mm accommodation in the coupler.

Blog post here...

[hydraraptor.blogspot.co.uk]

Couplers here...

[www.thingiverse.com]

Blog post here...

[hydraraptor.blogspot.co.uk]

Couplers here...

[www.thingiverse.com]

|

Re: Problem with Z height when printing. July 06, 2013 04:33AM |

Registered: 10 years ago Posts: 46 |

|

Re: Problem with Z height when printing. July 06, 2013 04:38AM |

Registered: 10 years ago Posts: 13 |

|

Re: Problem with Z height when printing. July 06, 2013 05:33AM |

Registered: 11 years ago Posts: 75 |

|

Re: Problem with Z height when printing. July 06, 2013 05:46AM |

Registered: 10 years ago Posts: 46 |

have you used calibration settings for your firmware settings ?

using M5 (0.8mm pitch) for z-axis, firmware would be :

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,760*1.1)

If you haven't seen Calibration guide might also be worth going through the stuff there.

Edited 1 time(s). Last edit at 07/06/2013 05:48AM by Masnachu.

using M5 (0.8mm pitch) for z-axis, firmware would be :

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,760*1.1)

If you haven't seen Calibration guide might also be worth going through the stuff there.

Edited 1 time(s). Last edit at 07/06/2013 05:48AM by Masnachu.

|

Re: Problem with Z height when printing. July 06, 2013 05:55PM |

Registered: 10 years ago Posts: 13 |

|

Re: Problem with Z height when printing. July 06, 2013 07:40PM |

Registered: 11 years ago Posts: 1,592 |

|

Re: Problem with Z height when printing. July 07, 2013 07:37AM |

Registered: 10 years ago Posts: 46 |

|

Re: Problem with Z height when printing. July 07, 2013 07:46AM |

Registered: 11 years ago Posts: 973 |

but isnt a rounded number better than having a decimal in there?

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Problem with Z height when printing. July 07, 2013 09:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

The values in the firmware are floats so better to use a decimal and let the firmware round the Z value when it converts to motor steps.

I expect the problem is that the Z max speed of 5 is too high for M5 rods, I use 4 for M6 rods.

[www.hydraraptor.blogspot.com]

I expect the problem is that the Z max speed of 5 is too high for M5 rods, I use 4 for M6 rods.

[www.hydraraptor.blogspot.com]

|

Re: Problem with Z height when printing. July 07, 2013 07:22PM |

Registered: 10 years ago Posts: 13 |

Thanks for the comments folks. I'll certainly take a look at that Max speed for the Z axis. The more I look at this, the more convinced I am that it's related to Slop in the connection between the steppers and the load screws. The variants of the Z Axis couplers that NopHead put on thingiverse look cool, but they arn't designed for M5 and I don't think they will have clearance around the i3's Z axis stepper mounting brackets.

I did read about the ability to configure the hysteresis for different axis, and I think there could be something here that I could use. If I could let the firmware know that it needs to turn a bit more than expected to counter the elastic nature of the tube connecting the stepper to the screws, this could be a short term fix (until I find/make better couplers). Anyone got any experience/comments on this idea?

cheers

Jim

I did read about the ability to configure the hysteresis for different axis, and I think there could be something here that I could use. If I could let the firmware know that it needs to turn a bit more than expected to counter the elastic nature of the tube connecting the stepper to the screws, this could be a short term fix (until I find/make better couplers). Anyone got any experience/comments on this idea?

cheers

Jim

|

Re: Problem with Z height when printing. July 07, 2013 08:27PM |

Registered: 11 years ago Posts: 661 |

I'd look for a mechanical solution for what appears to be a mechanical issue. I use couplers,many use tubing and with little work Nopheads couplers could be modified. If you change firmware you'll have to maintain those changes through any upgrades. As a mechanical issue it is likely that it may not respond in a consistent manner.

|

Re: Problem with Z height when printing. July 07, 2013 09:43PM |

Registered: 11 years ago Posts: 973 |

I tried couplers although not printing yet and everything wobbled like help went too tubing as the flex compensahes it

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Problem with Z height when printing. July 10, 2013 06:11AM |

Registered: 10 years ago Posts: 13 |

I took some video last night of the problem as far as I can see it, The tubing I'm using feels like it has too much radial 'slop'. In the video, I'm holding the stepper spindle and lightly turning the loadscrew with my other hand (out of shot). Does this flex look like other people's tubes?

Video of Loadscrew tube connectors

Jim

Video of Loadscrew tube connectors

Jim

|

Re: Problem with Z height when printing. July 10, 2013 12:58PM |

Registered: 11 years ago Posts: 973 |

ok i first had on mine cable tied cable insulation on my z, there m5 threaded rods slightly wobbled but the wasnt no wobble on the x carriage or the motors wobbled, then i tried printed couplings the spiral looking ones and everything wobbled motors and x carriage and m5 threaded rod the wobble was immense, now im using tubing without cable ties because the inner diameter of the tube was around 3.5 to 4mm so it had give a lot of force to get them over the motor shaft the the threaded rod, also on the i3 the m5 is constraint at the top, because to my understanding that you can never get perfect straight rods and the tubing with a bit of flex and they m5 not being constraint at the top compensate any wobble i know i aint printing yet but just thought it give you a idea when i get mine going im going to print some coupling out of flexi pla see if that works

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Problem with Z height when printing. July 12, 2013 05:57AM |

Registered: 10 years ago Posts: 13 |

Sorry, only registered users may post in this forum.