Is this due to Z wobble?

Posted by KLee

|

Is this due to Z wobble? July 16, 2013 08:52AM |

Registered: 10 years ago Posts: 13 |

Hi everyone.

I've run into some problems with banding on my Makerfarm Prusa i3.

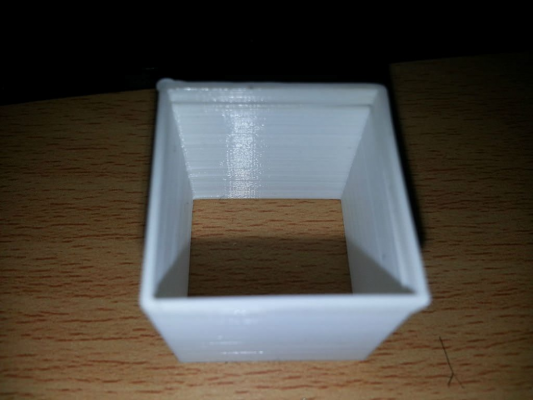

The above image was a print of the Gameclip (http://www.thingiverse.com/thing:43977), and I realized there was a lot of banding on the Z axis which I didn't notice much before. Also, the whole print is on a very slight lean.

So I printed a calibration cube (hollow) and noticed this:

Sorry about the delamination, that's because I pulled it off the bed and the bottom stuck.

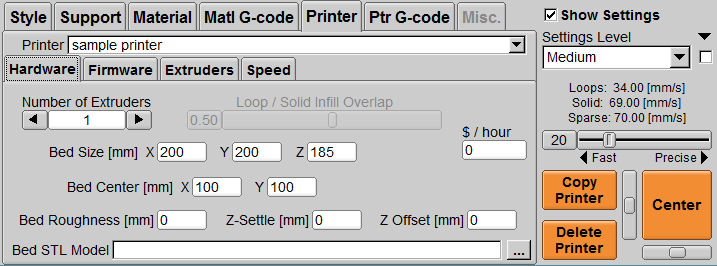

For both prints I was using white PLA from diamondage (3 +-0.06 mm) at 190 degrees (all layers) and the bed was set to 60 degrees for the Gameclip and off for the cube. The slicer used was KISSlicer with the following settings:

Extrusion and infil extrusion width: 0.6mm (measured)

Skin thickness: 0.8mm

Layer thickness 0.2mm

Infil: 20% octagonal for the Gameclip, off for the cube

Support: off

Filament diamter: 3mm

Flow tweak:1

Z-lift: off

Destring: [default]

Bed roughness: 0mm

Z-settle: 0.25mm

Z-offset: 0mm

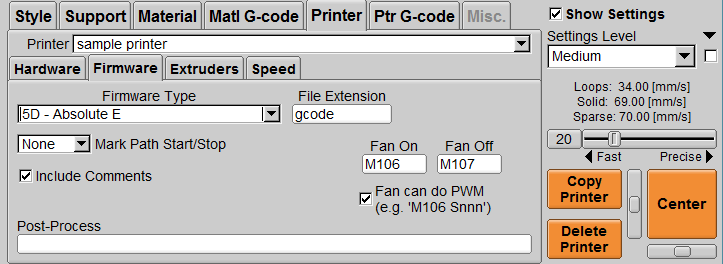

Firmware type: 5D - Absolute

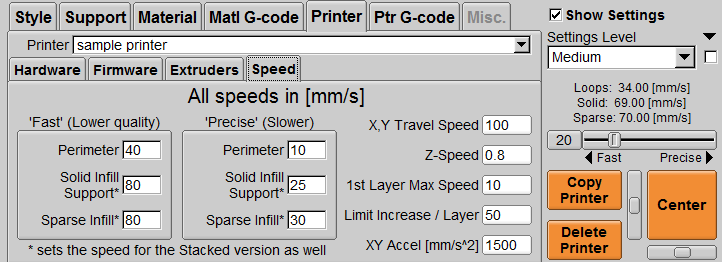

Loop speed: 17.5mm/s

Solid speed: 38.75mm/s

Sparse speed: 42.5mm/s

As for the printer itself, the M5 rods appear to be straight, and a flexible tube is being used as the coupler.

Any help and suggestions will be greatly appreciated

I've run into some problems with banding on my Makerfarm Prusa i3.

The above image was a print of the Gameclip (http://www.thingiverse.com/thing:43977), and I realized there was a lot of banding on the Z axis which I didn't notice much before. Also, the whole print is on a very slight lean.

So I printed a calibration cube (hollow) and noticed this:

Sorry about the delamination, that's because I pulled it off the bed and the bottom stuck.

For both prints I was using white PLA from diamondage (3 +-0.06 mm) at 190 degrees (all layers) and the bed was set to 60 degrees for the Gameclip and off for the cube. The slicer used was KISSlicer with the following settings:

Extrusion and infil extrusion width: 0.6mm (measured)

Skin thickness: 0.8mm

Layer thickness 0.2mm

Infil: 20% octagonal for the Gameclip, off for the cube

Support: off

Filament diamter: 3mm

Flow tweak:1

Z-lift: off

Destring: [default]

Bed roughness: 0mm

Z-settle: 0.25mm

Z-offset: 0mm

Firmware type: 5D - Absolute

Loop speed: 17.5mm/s

Solid speed: 38.75mm/s

Sparse speed: 42.5mm/s

As for the printer itself, the M5 rods appear to be straight, and a flexible tube is being used as the coupler.

Any help and suggestions will be greatly appreciated

|

Re: Is this due to Z wobble? July 27, 2013 02:21AM |

Registered: 10 years ago Posts: 13 |

I had some time during the weekend to try and figure out what's wrong, and I still can't seem to get rid of the banding.

Firstly, I took a knife and carved off a bit of the frame which might have been constraining one of the threaded rods. The rod is now free to move around (it was leaning against the hole before). This hasn't solved the problem, but it seems to have reduced the intensity of the ribbing.

Then I went back and did another PID autotune on the hotend. The hotend temperature stayed within 0.2 degrees of the target temperature, but the banding still remains. I've been keeping the heated bed off to eliminate a potential variable.

I wondered if the banding issues was due to the coldend. On closer inspection of the Wades accessible extruder, I noticed the hobbed bolt has moved, and it's almost completely covered the hole where the filament is supposed to go down. Other than that, the hobbed bolt is clean, and the gears appear to turn freely.

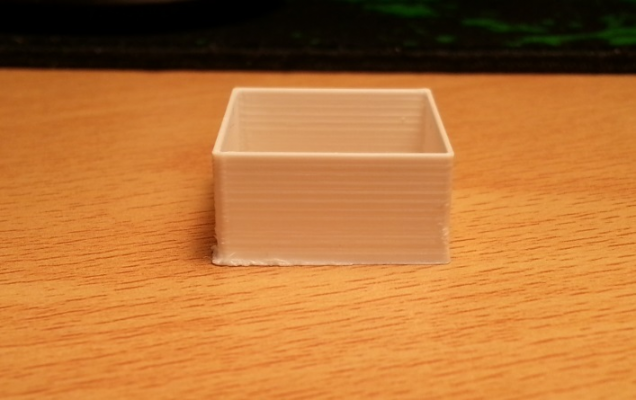

This was the last cube (20mm, 0.5mm thickness cube) I printed:

The banding occurs every 0.5mm, regardless of the layer height setting.

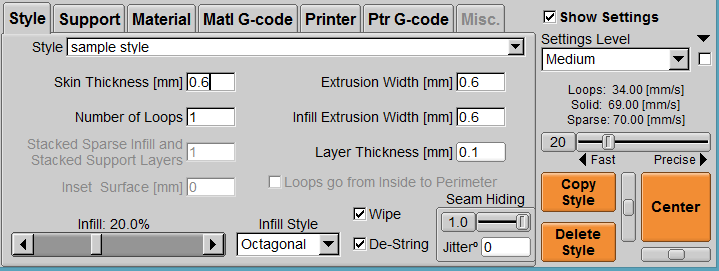

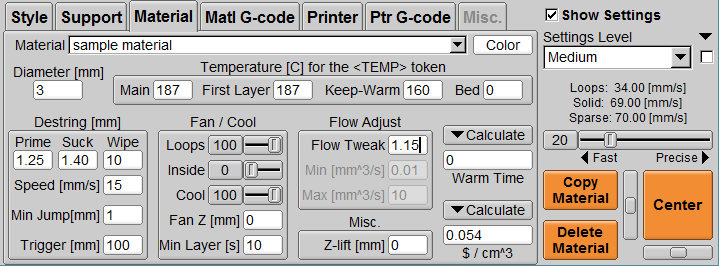

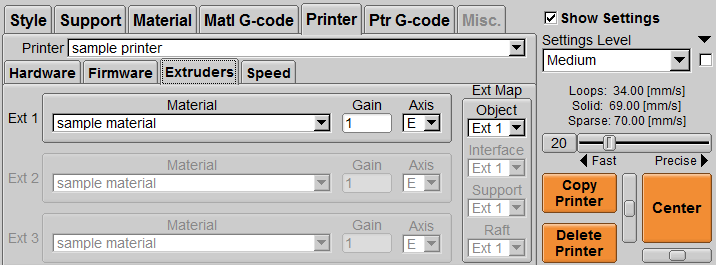

These are the settings I used to print it:

If you have any suggestions or advice, I'd love to hear from you.

Thanks

Firstly, I took a knife and carved off a bit of the frame which might have been constraining one of the threaded rods. The rod is now free to move around (it was leaning against the hole before). This hasn't solved the problem, but it seems to have reduced the intensity of the ribbing.

Then I went back and did another PID autotune on the hotend. The hotend temperature stayed within 0.2 degrees of the target temperature, but the banding still remains. I've been keeping the heated bed off to eliminate a potential variable.

I wondered if the banding issues was due to the coldend. On closer inspection of the Wades accessible extruder, I noticed the hobbed bolt has moved, and it's almost completely covered the hole where the filament is supposed to go down. Other than that, the hobbed bolt is clean, and the gears appear to turn freely.

This was the last cube (20mm, 0.5mm thickness cube) I printed:

The banding occurs every 0.5mm, regardless of the layer height setting.

These are the settings I used to print it:

If you have any suggestions or advice, I'd love to hear from you.

Thanks

|

Re: Is this due to Z wobble? July 27, 2013 12:41PM |

Registered: 11 years ago Posts: 114 |

|

Re: Is this due to Z wobble? July 27, 2013 03:06PM |

Registered: 10 years ago Posts: 13 |

|

Re: Is this due to Z wobble? July 28, 2013 02:42AM |

Registered: 11 years ago Posts: 114 |

Then I looks like minor z wobble, I had that problem with mine and too me several attempts to lower it. Basically I just repositioned the leadscrews so that they didn't wobble as much. There are some different ideas and models floating around on thingiverse that help with z wobble. I ended up making custom motor/leadscrews couplers myself.

|

Re: Is this due to Z wobble? July 28, 2013 06:25AM |

Registered: 10 years ago Posts: 13 |

|

Re: Is this due to Z wobble? August 21, 2013 05:09AM |

Registered: 11 years ago Posts: 5 |

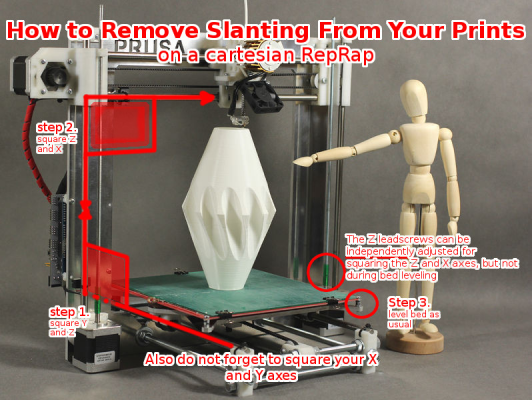

You mentioned that the print had a lean to it when it should have been square, I think that this may be caused because your axes are not all square to each other (although it *could* be something else this is a good place to start from as it is most likely). Say your Z rods are slanting to the left a bit but your bed appears to be perfectly level: as your Z axis moves upwards, all your layers will be level/parallel to the ones underneath, but they will each be progressively displaced a little bit to the left. Thus a square object can come out as a slight parallelogram-like shape.

To fix this, make sure your Z rods are at 90 degrees to your Y rods and that your X rods are also at 90 degrees to your Z rods. Of course your X and Y rods have to be square to each other as well. After squaring stuff up, level your bed, when leveling your bed, NEVER do it by turning a Z leadscrew to push or pull down an X end.

If this doesn't make sense, I made this instructional diagram for you which has been attached to this post.

You may need a really interestingly shaped ruler or something else to be able to measure how square the axes are while avoiding all the obstacles that get in the way. I've been thinking that a nicely square cube of wood with some bits cut out to avoid obstacles would do the trick perfectly.

Good luck and I hope this helps a bit.

Edited 1 time(s). Last edit at 08/21/2013 05:10AM by BillyW.

To fix this, make sure your Z rods are at 90 degrees to your Y rods and that your X rods are also at 90 degrees to your Z rods. Of course your X and Y rods have to be square to each other as well. After squaring stuff up, level your bed, when leveling your bed, NEVER do it by turning a Z leadscrew to push or pull down an X end.

If this doesn't make sense, I made this instructional diagram for you which has been attached to this post.

You may need a really interestingly shaped ruler or something else to be able to measure how square the axes are while avoiding all the obstacles that get in the way. I've been thinking that a nicely square cube of wood with some bits cut out to avoid obstacles would do the trick perfectly.

Good luck and I hope this helps a bit.

Edited 1 time(s). Last edit at 08/21/2013 05:10AM by BillyW.

|

Re: Is this due to Z wobble? October 07, 2013 05:29AM |

Registered: 10 years ago Posts: 13 |

Thank you very much for the information on how to fix this slant. I was just coming by to ask for help with it.

I'll start on checking to see if the axes are square as soon as I get free time, but something which bothers me is the lack of bed leveling options in this kit. In that picture, it appears there are springs to keep the heated bed off the.. erm, bed... which should allow the printing surface to be adjusted. All I got was plastic spacers which don't allow for any adjustment. Should I try to source some springs to replace these spacers, or are they rigid for a purpose?

Thanks

I'll start on checking to see if the axes are square as soon as I get free time, but something which bothers me is the lack of bed leveling options in this kit. In that picture, it appears there are springs to keep the heated bed off the.. erm, bed... which should allow the printing surface to be adjusted. All I got was plastic spacers which don't allow for any adjustment. Should I try to source some springs to replace these spacers, or are they rigid for a purpose?

Thanks

|

Re: Is this due to Z wobble? October 07, 2013 11:29AM |

Registered: 10 years ago Posts: 22 |

|

Re: Is this due to Z wobble? October 12, 2013 09:05AM |

Registered: 10 years ago Posts: 13 |

I think I fixed the slanting issue. Turns out the bed was moving along an incline since the entire printer was resting on top of an uneven surface (a tea towel... bad, bad idea). I haven't been able to get a tool to help me measure how square everything is, but a print of a cube (see below) was found to have a height of 44.4mm on all 4 sides so I'm going to assume the slanting has gone away since the slanting was occurring along the Y axis (which caused a difference in height depending on Y position).

As for the Z wobble. It's driving me up the wall since it's been getting worse... I printed a few new couplers, but they haven't improved anything. Aquarium tubing (~4mm ID) didn't help at all (seemed to make things worse).

This is what my prints look like at the moment:

Sorry for the large image, I can't figure out how to resize images with BBCode without breaking it.

Currently, I'm using a customized version of these couplers (but made made shorter so it'll fit): [www.thingiverse.com]

I'm not using set screws to secure the shaft since it's so tight (I had to lightly hammer these couplers on), but I am using set screws for securing the threaded rods.

When I watch my printer, there's no horizontal movement in the left threaded rod, but a very slight movement in the right rod. Yet, I'm still getting these massive ridges.

Lastly, my layer height was set to 140 microns. Since I'm using M5 threaded rods, the layer height seems to be right (140 is divisible by 4), so it's not ribbing due to bad layer height.

Can anyone give me some advice on how to fix this? Everything I seem to try has no effect so far. Thanks in advance.

As for the Z wobble. It's driving me up the wall since it's been getting worse... I printed a few new couplers, but they haven't improved anything. Aquarium tubing (~4mm ID) didn't help at all (seemed to make things worse).

This is what my prints look like at the moment:

Sorry for the large image, I can't figure out how to resize images with BBCode without breaking it.

Currently, I'm using a customized version of these couplers (but made made shorter so it'll fit): [www.thingiverse.com]

I'm not using set screws to secure the shaft since it's so tight (I had to lightly hammer these couplers on), but I am using set screws for securing the threaded rods.

When I watch my printer, there's no horizontal movement in the left threaded rod, but a very slight movement in the right rod. Yet, I'm still getting these massive ridges.

Lastly, my layer height was set to 140 microns. Since I'm using M5 threaded rods, the layer height seems to be right (140 is divisible by 4), so it's not ribbing due to bad layer height.

Can anyone give me some advice on how to fix this? Everything I seem to try has no effect so far. Thanks in advance.

|

Re: Is this due to Z wobble? October 12, 2013 09:55AM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Is this due to Z wobble? October 15, 2013 01:33PM |

Registered: 10 years ago Posts: 10 |

Hi, i have the same probleme, i posted on the french groupe and someone liked me here.

So i search "3d pritner banding" on google and found this : Taxonomy of Z axis artifacts in extrusion-based 3d printing

I can't try changing my z rods because i'm far from home, that can be my probleme because i wonder the rods is not straigt.

I hope that could help you and i hope you understand my dirty english.

Seeya

So i search "3d pritner banding" on google and found this : Taxonomy of Z axis artifacts in extrusion-based 3d printing

I can't try changing my z rods because i'm far from home, that can be my probleme because i wonder the rods is not straigt.

I hope that could help you and i hope you understand my dirty english.

Seeya

|

Re: Is this due to Z wobble? October 25, 2013 01:09PM |

Registered: 10 years ago Posts: 1,433 |

On a normal Maker Farm I3 the Z rods are free to move at the top. They are mounted to the motors with flexable plastic tube. That allows the Z rods to move if they are not straight. Since they move rather than bind or flex they stay reasonably correct for driving the carrage. If you have the rods hitting the frame at the top, or mount them with solid blocks then you will have issues unless the rods are perfectly straignt *and* perfectly parallel to the smooth rods. Since there are no adjustments in the design for aligning the rods, getting that all right would take a lot of shim stock and time.

You would think that a non-straight rod could not drive the Z axis properly. The trick is that the rod is bowed over it's entire length. You will have a "smooth" Z axis error rather than banding from the rod. If you do care about the 0.1 to 0.4 mm total error over the length of the Z axis, you will need a *very* different printer design.

To get overly techie, the banding error is a "differential linearity" issue. The error from the bend is an "integeral linearity" issue.

You would think that a non-straight rod could not drive the Z axis properly. The trick is that the rod is bowed over it's entire length. You will have a "smooth" Z axis error rather than banding from the rod. If you do care about the 0.1 to 0.4 mm total error over the length of the Z axis, you will need a *very* different printer design.

To get overly techie, the banding error is a "differential linearity" issue. The error from the bend is an "integeral linearity" issue.

|

Re: Is this due to Z wobble? December 03, 2013 07:54AM |

Registered: 10 years ago Posts: 13 |

Yep, I found one of the Z rods were binding at the top since the holes weren't cut big enough. I carved out a bit, and that seemed to reduce the wobble a bit.

However, I eliminated most of the wobble (but some remains) by upgrading my couplers to machined couplers seemed to do the trick.

Thank you everyone for your help.

However, I eliminated most of the wobble (but some remains) by upgrading my couplers to machined couplers seemed to do the trick.

Thank you everyone for your help.

Sorry, only registered users may post in this forum.