Thinking of buying a Prusa i3

Posted by Antslake

|

Re: Thinking of buying a Prusa i3 November 08, 2013 11:46AM |

Registered: 10 years ago Posts: 16 |

|

Re: Thinking of buying a Prusa i3 November 08, 2013 12:36PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 November 08, 2013 11:32PM |

Registered: 11 years ago Posts: 160 |

I added LED lighting from my airplanes, looks so cool all lit up.

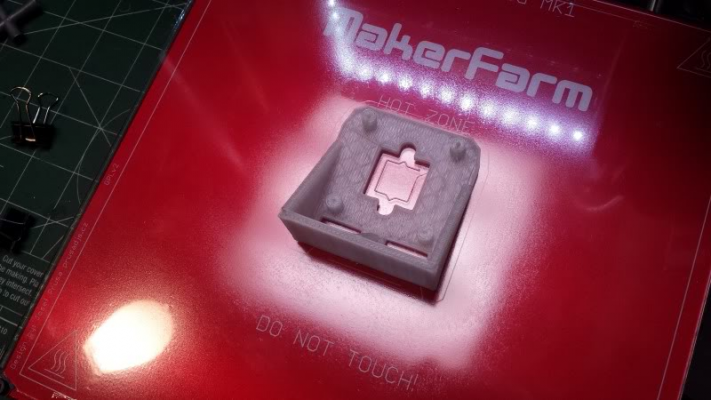

The first box I printed had some "bubbling" on 2 sides, other than that it came out pretty good. Then I printed an earring for my wife, and that was ok. I was having trouble with the Z end switch "losing" it's place only to realize that I forgot to tighten down some bolts on the Z carraige from working on it so many times. Fixed that and leveled the bed again and printed out a knob for the LCD, came out very good. I know there is way more calibration I have to do....and learn how to do. I'll get it little by little. I think I have to calibrate the motors as they seem to be getting hot.

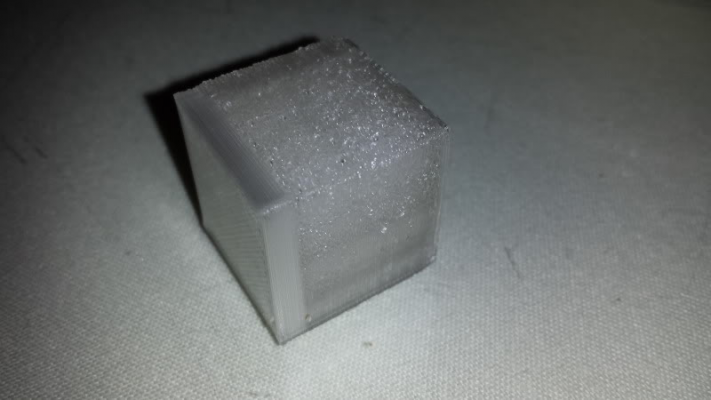

Bubbling:

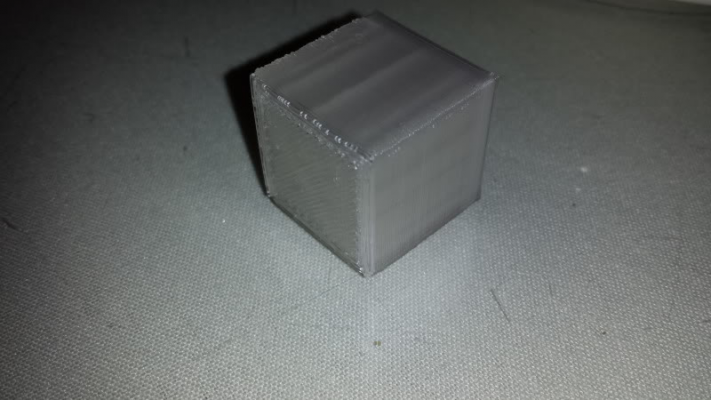

Good side:

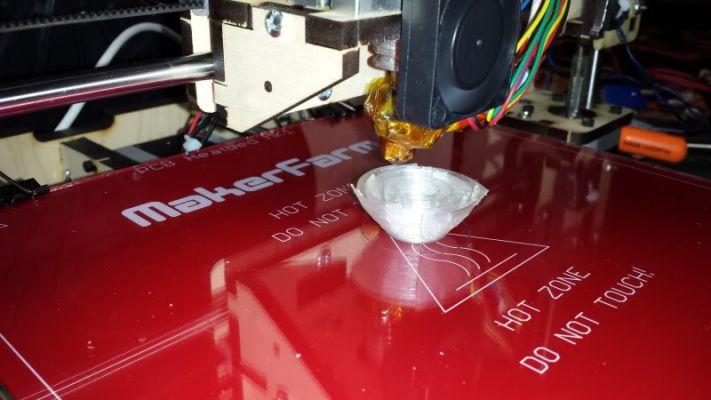

Printing a Rose now:

Earing:

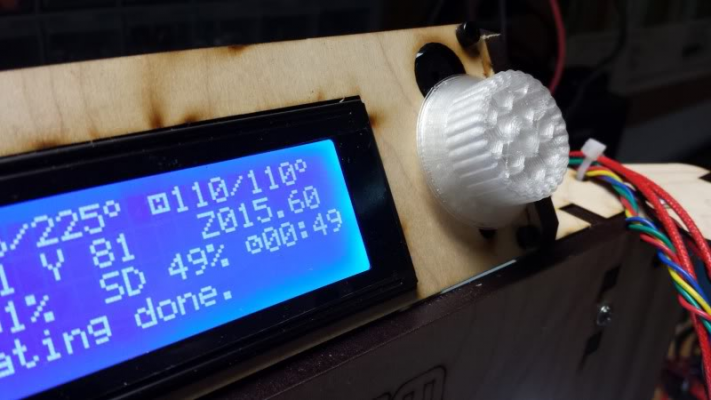

Knob:

The first box I printed had some "bubbling" on 2 sides, other than that it came out pretty good. Then I printed an earring for my wife, and that was ok. I was having trouble with the Z end switch "losing" it's place only to realize that I forgot to tighten down some bolts on the Z carraige from working on it so many times. Fixed that and leveled the bed again and printed out a knob for the LCD, came out very good. I know there is way more calibration I have to do....and learn how to do. I'll get it little by little. I think I have to calibrate the motors as they seem to be getting hot.

Bubbling:

Good side:

Printing a Rose now:

Earing:

Knob:

|

Re: Thinking of buying a Prusa i3 November 08, 2013 11:36PM |

Registered: 10 years ago Posts: 36 |

|

Re: Thinking of buying a Prusa i3 November 08, 2013 11:50PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 09, 2013 08:53AM |

Registered: 10 years ago Posts: 1,433 |

There is a lot of fiddling with settings and temperatures to get the prints just right. You are doing fine at the monument, so its just calibration / adjustment from where you are.

Some of the models you download do indeed have issues. You may need to do some repairs to get them to work. There are a *lot* of things that pop up when you search "repair stl file".

Some of the models you download do indeed have issues. You may need to do some repairs to get them to work. There are a *lot* of things that pop up when you search "repair stl file".

|

Re: Thinking of buying a Prusa i3 November 10, 2013 05:30AM |

Registered: 12 years ago Posts: 82 |

Quote

Antslake

Well the Rose didn't make it to the end. My head seems to drip a little too much. I guess I up the retraction in slicr? It's at 1mm now.

Slicr also said it had a hole in it, but It messed up in a few places. Got over 50% through it though. I think that was a pretty tough print?

Have you tried using Cura instead of Slic3r? I found that with little to no changes, not only were Cura prints a lot faster, but I didn't have as many issues with my nozzle dripping too much. It uses a slightly different algorithm and seems to get better results on the i3. It's pretty easy to use and only takes a few minutes to download - might be worth a quick test.

Also, what material are you using?

One thing I hated about Slic3r was that for PLA it was set to 180c as default. 210 gives a MUCH better end finish. 180 is actually the lowest recommended temperature (whilst 220 is the highest) for PLA printing.

Edited 1 time(s). Last edit at 11/10/2013 05:32AM by RickM.

|

Re: Thinking of buying a Prusa i3 November 10, 2013 05:52AM |

Registered: 11 years ago Posts: 14 |

|

Re: Thinking of buying a Prusa i3 November 10, 2013 12:02PM |

Registered: 11 years ago Posts: 160 |

Oh man, thanks. I will give that a try.

I am using clear ABS, and using the config file from makerfarm.

The sides of the rose had trouble sticking together also. Each pedal is only one pass thick. That's got to be tough to print. Any movement at all in the pedal and the next layer is going to miss. I think it was the dripping that caused the layers to start to get messed up.

I am using clear ABS, and using the config file from makerfarm.

The sides of the rose had trouble sticking together also. Each pedal is only one pass thick. That's got to be tough to print. Any movement at all in the pedal and the next layer is going to miss. I think it was the dripping that caused the layers to start to get messed up.

|

Re: Thinking of buying a Prusa i3 November 10, 2013 01:22PM |

Registered: 10 years ago Posts: 1,433 |

If you have single layer prints slumping (sagging), there are a couple of fixes:

1) Get your bed temperature down to a lower temp. At some point you will have the part pop off he glass. That's to low. 80C is not to crazy, 50C likely will not work.

2) Drop your hot end temperature for single layer prints. It's a compromise between sticking and slumping. 230C is pretty hot, 220 or even 215 may work ok. It depends on your filament and a few other things.

3) Make sure your z axis / extruder flow / layer height / flow rate is all set up right. A single wall box is great for this - make sure the filament lines are straight between the corners.

4) If you still have slumping, open a window. If it's still an issue, try a fan. (I've never had to go that far).

1) Get your bed temperature down to a lower temp. At some point you will have the part pop off he glass. That's to low. 80C is not to crazy, 50C likely will not work.

2) Drop your hot end temperature for single layer prints. It's a compromise between sticking and slumping. 230C is pretty hot, 220 or even 215 may work ok. It depends on your filament and a few other things.

3) Make sure your z axis / extruder flow / layer height / flow rate is all set up right. A single wall box is great for this - make sure the filament lines are straight between the corners.

4) If you still have slumping, open a window. If it's still an issue, try a fan. (I've never had to go that far).

|

Re: Thinking of buying a Prusa i3 November 10, 2013 04:59PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 10, 2013 05:22PM |

Registered: 10 years ago Posts: 1,433 |

I probably assumed a bit to much....

If the print is not sticking together, then you need hotter filament and warmer temperatures for the heated bed. You might also need a warmer room. Again, the hollow single wall cube (spiral vase in Slic3r) is your friend. If it separates then indeed you have an issue. If the cube prints ok, then the rose may need some tweaking to get it to print right (speed / flow / layer height ....).

If the print is not sticking together, then you need hotter filament and warmer temperatures for the heated bed. You might also need a warmer room. Again, the hollow single wall cube (spiral vase in Slic3r) is your friend. If it separates then indeed you have an issue. If the cube prints ok, then the rose may need some tweaking to get it to print right (speed / flow / layer height ....).

|

Re: Thinking of buying a Prusa i3 November 10, 2013 07:40PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 11, 2013 02:52AM |

Registered: 11 years ago Posts: 661 |

Someone elses settings aren't necessarily going to translate to your machine. While they can be a good place to start, the most important take away is the experience and familiarity with your machine to see what is happening and adjust accordingly. Once you start to print more you'll be able to get a better understanding of how your machine responds in terms of settings. It involves a good deal of trial and error. You can start small by printing parts that have similar attributes to the rose and get tuning experience from there. Things like print speeds, flow rates and the structure of the geometry of the printed part are going to determine the results. Keep at it.

|

Re: Thinking of buying a Prusa i3 November 11, 2013 10:48PM |

Registered: 11 years ago Posts: 160 |

Yea was just looking for a place to start, or compare with what I got. I think it is printing pretty well now, but there is still "drool" coming out of the head when it goes from one location to another without printing. What should I adjust to correct that? Is there a test object for calibrating retraction?

Something else I noticed if anyone is thinking of buying this machine. You absolutely must have it on a flat surface, and do not move it after you calibrate it. My work table is very flat but there are some imperfections, and this wood frame will twist on those imperfections. What I've done now is take a plate of aircraft aluminum (probably 6061 or 7025) that I picked up at my local machine shop for dirt cheap, and set my machine on it. Now it won't twist, and I can slide it around a bit without the bed losing it's calibration.

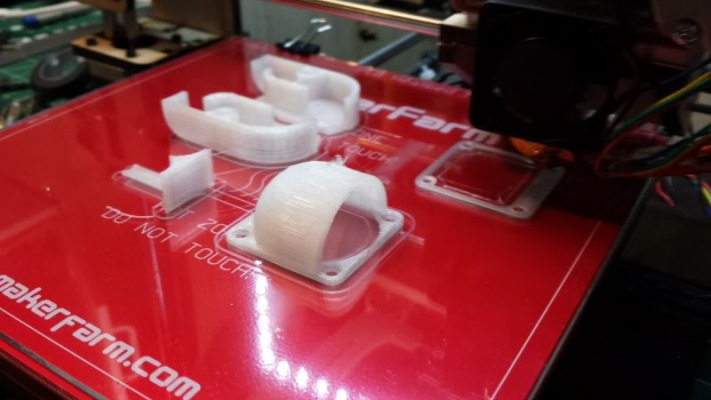

Working on a cooling fan duct for the magma head now, looks to be a 2 hour print.

I've been printing at 100mm, is that good?

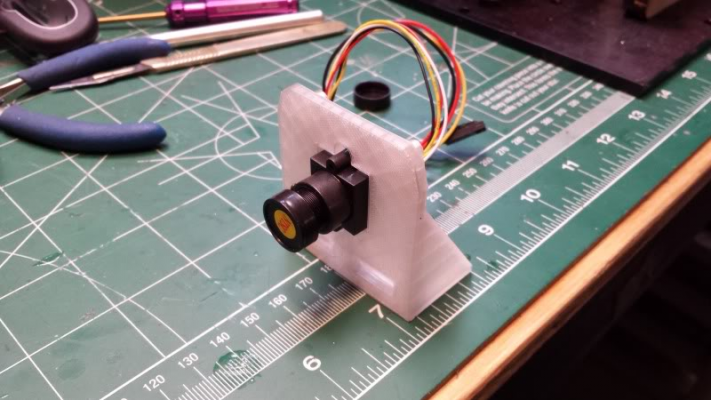

Here are some objects I made:

FPV mount for my quad

Arms to hold spool

Something else I noticed if anyone is thinking of buying this machine. You absolutely must have it on a flat surface, and do not move it after you calibrate it. My work table is very flat but there are some imperfections, and this wood frame will twist on those imperfections. What I've done now is take a plate of aircraft aluminum (probably 6061 or 7025) that I picked up at my local machine shop for dirt cheap, and set my machine on it. Now it won't twist, and I can slide it around a bit without the bed losing it's calibration.

Working on a cooling fan duct for the magma head now, looks to be a 2 hour print.

I've been printing at 100mm, is that good?

Here are some objects I made:

FPV mount for my quad

Arms to hold spool

|

Re: Thinking of buying a Prusa i3 November 11, 2013 11:28PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 12, 2013 09:25AM |

Registered: 10 years ago Posts: 13 |

|

Re: Thinking of buying a Prusa i3 November 12, 2013 10:59PM |

Registered: 11 years ago Posts: 160 |

I tried that fan shroud out, and my head kept getting jammed. I don't think it was doing a very efficient job at directing the air flow. I say that with authority because I've been in the HVAC business for 35 years, and design duct work. I played with heat settings but no luck. It prints fine without it.

Just having trouble with layers sticking together, or maybe this is how they are supposed to be? Not sure if I have to go up in heat or down. Colin recommended 225. I tried 235 once and the filament got jammed.

Made a quad arm tonight, and a really cool bio-gear for the extruder. Funny thing is my gear looks better than the gear that came with the kit

Just having trouble with layers sticking together, or maybe this is how they are supposed to be? Not sure if I have to go up in heat or down. Colin recommended 225. I tried 235 once and the filament got jammed.

Made a quad arm tonight, and a really cool bio-gear for the extruder. Funny thing is my gear looks better than the gear that came with the kit

|

Re: Thinking of buying a Prusa i3 November 12, 2013 11:23PM |

Registered: 11 years ago Posts: 661 |

Quote

Antslake

Yea was just looking for a place to start, or compare with what I got. I think it is printing pretty well now, but there is still "drool" coming out of the head when it goes from one location to another without printing. What should I adjust to correct that? Is there a test object for calibrating retraction?

That phenomenon is called "ooze". There is a calibration part called oozebane in the wiki under calibration. [reprap.org] I use retraction and temp to get none to minimal ooze. I have more when using a PTFE lined hotend than an all metal but that could be that I've spent more time tuning the all metal. There are also a couple of files to help with bridging/overhang.

|

Re: Thinking of buying a Prusa i3 November 13, 2013 09:10PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 13, 2013 09:25PM |

Registered: 10 years ago Posts: 1,433 |

If you set up Pronterface and hit the button labeled "extrude" it will push out how ever many mm you have selected in the length (mm) box at what ever speed you have set in t the speed (mm/min) box. If you ask for 10 mm of filament that's how much it will try to push through the hot end. If you measure how much filament *actually* gets moved by the extruder that will tell you if it was 10 mm or not. If it's 10mm your firmware is set right. If it's something else you need to change the firmware steps / mm for the extruder so it comes out correctly.

|

Re: Thinking of buying a Prusa i3 November 14, 2013 11:25AM |

Registered: 11 years ago Posts: 160 |

Ah ok. Came to halt last night as I realized the bed is warping. So it is hitting the front support on the y axis and cannot travel all the way. Colin is shipping me a new one. I might make one out of aluminum. This was my biggest fear having a wood kit.

Edited 2 time(s). Last edit at 11/14/2013 11:26AM by Antslake.

Edited 2 time(s). Last edit at 11/14/2013 11:26AM by Antslake.

|

Re: Thinking of buying a Prusa i3 November 14, 2013 12:34PM |

Registered: 10 years ago Posts: 1,433 |

The gotcha with the beds seems to be the laminante shrinking on only one side. Since you have one that's not much use (and a spare on the way) try this:

Put it in a warm (like 150-170 F / 65-75 C) oven for 4 to 6 hours. That should dry both sides out quite a bit. If simple heat does not flatten it, weight it down in the oven. Once it flattens it out, hit it with spray urethane varnish (or urethane anything) on both sides while it's still warm. It should soak the stuff up like crazy, you may have to spray on more than you would think. The varnish will reduce it's afinity for moisture quite a bit.

I've never done this on that particular piece (mine hasn't warped - yet...). It's a pretty common woodworking fix though.

Put it in a warm (like 150-170 F / 65-75 C) oven for 4 to 6 hours. That should dry both sides out quite a bit. If simple heat does not flatten it, weight it down in the oven. Once it flattens it out, hit it with spray urethane varnish (or urethane anything) on both sides while it's still warm. It should soak the stuff up like crazy, you may have to spray on more than you would think. The varnish will reduce it's afinity for moisture quite a bit.

I've never done this on that particular piece (mine hasn't warped - yet...). It's a pretty common woodworking fix though.

|

Re: Thinking of buying a Prusa i3 November 15, 2013 09:19AM |

Registered: 11 years ago Posts: 160 |

Good tip, I will try it. I did make a bed out of thin gauge aluminum I had lying around in my shop. Going to test it now.

Back to the extrude button. Mine is set at 5mm@30mm min. When I hit extrude, it pumps out plastic for 8 seconds and is around 160mm, sort of confused since my prints are coming out pretty good except for bonding of the layers. you would think with that much being off that my prints would be a mess?

Back to the extrude button. Mine is set at 5mm@30mm min. When I hit extrude, it pumps out plastic for 8 seconds and is around 160mm, sort of confused since my prints are coming out pretty good except for bonding of the layers. you would think with that much being off that my prints would be a mess?

|

Re: Thinking of buying a Prusa i3 November 15, 2013 10:18AM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

Antslake

Good tip, I will try it. I did make a bed out of thin gauge aluminum I had lying around in my shop. Going to test it now.

Back to the extrude button. Mine is set at 5mm@30mm min. When I hit extrude, it pumps out plastic for 8 seconds and is around 160mm, sort of confused since my prints are coming out pretty good except for bonding of the layers. you would think with that much being off that my prints would be a mess?

You're looking for the length of filament pulled into the extruder, not the amount extruded out of the nozzle.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Thinking of buying a Prusa i3 November 15, 2013 12:23PM |

Registered: 10 years ago Posts: 1,433 |

^^ yup.

The extruder pushes filament in. That's all it knows about. It has no idea what size nozzle you have on the machine. All the fiddling around with flow rates really comes from the fact that you control the input to, not the output from, the hot end.

Don't throw away your 160 mm long piece of extruded filament quite yet though. Grab your calipers and measure it's diameter in a few places. It will give you a pretty good idea of what the real hole diameter on your hot end is. There's a tolerance on everything and 0.35 is never 0.3500000. The closer you know this stuff the easier you can control it.

The extruder pushes filament in. That's all it knows about. It has no idea what size nozzle you have on the machine. All the fiddling around with flow rates really comes from the fact that you control the input to, not the output from, the hot end.

Don't throw away your 160 mm long piece of extruded filament quite yet though. Grab your calipers and measure it's diameter in a few places. It will give you a pretty good idea of what the real hole diameter on your hot end is. There's a tolerance on everything and 0.35 is never 0.3500000. The closer you know this stuff the easier you can control it.

|

Re: Thinking of buying a Prusa i3 November 15, 2013 02:02PM |

Registered: 11 years ago Posts: 160 |

|

Re: Thinking of buying a Prusa i3 November 15, 2013 06:24PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 November 15, 2013 07:29PM |

Registered: 11 years ago Posts: 160 |

I figured I would have to extrude a straight piece, so I had lifted up the Z axis and extrude a straight piece without pulling on it too much. When I changed the setting to .6 in slicr, and printed the 50mm test object the head was dragging through the tower, and eventually went off making the tower into steps. But I did notice that now the layer are sticking together very strong.

So as an experiment I changed the nozzle size to .42, and did the 50mm tower again. It came out 45mm tall. The middle looks funny too. But it is nice and strong.

So as an experiment I changed the nozzle size to .42, and did the 50mm tower again. It came out 45mm tall. The middle looks funny too. But it is nice and strong.

|

Re: Thinking of buying a Prusa i3 November 17, 2013 04:09PM |

Registered: 11 years ago Posts: 160 |

Sorry, only registered users may post in this forum.