Thinking of buying a Prusa i3

Posted by Antslake

|

Re: Thinking of buying a Prusa i3 November 17, 2013 05:54PM |

Registered: 10 years ago Posts: 1,433 |

On the Z axis there are a couple of issues:

1) You *really* don't know what your zero is

2) You only can make normal things an integer number of layers high

3) You really want to get it right.

4) Changing layer height messes a number of things up

WhenI calibrate the Z steps / mm here's what I do:

1) Print a low part (say 5 mm)

2) Print a tall part (say 35 mm)

3) Print a very tall tall part (say 65 mm)

When I measure them they each should be about 30 mm apart in height. That confirms that what ever the Z zero is, it's stable. The difference between the tallest and the shortest can be big enough that a layer isn't as big an issue. It's also helpful if you pre-plan the heights to be an integer number of layers. Setting first layer height to equal the rest helps with that part of it.

If you are trying to calibrate something else - none of that may be of any use ....

1) You *really* don't know what your zero is

2) You only can make normal things an integer number of layers high

3) You really want to get it right.

4) Changing layer height messes a number of things up

WhenI calibrate the Z steps / mm here's what I do:

1) Print a low part (say 5 mm)

2) Print a tall part (say 35 mm)

3) Print a very tall tall part (say 65 mm)

When I measure them they each should be about 30 mm apart in height. That confirms that what ever the Z zero is, it's stable. The difference between the tallest and the shortest can be big enough that a layer isn't as big an issue. It's also helpful if you pre-plan the heights to be an integer number of layers. Setting first layer height to equal the rest helps with that part of it.

If you are trying to calibrate something else - none of that may be of any use ....

|

Re: Thinking of buying a Prusa i3 November 17, 2013 08:09PM |

Registered: 11 years ago Posts: 160 |

Calibrating the Z steps seems confusing to me. I am going to have to spend some time figuring that out, and try those other suggestions. But actually, if you saw my last post, the 50mm tower came out 45mm. But the 3mm box came out taller. But that was 2 different color plastics also.

Would the nozzle diameter thing we were talking about before have anything to do with it? Being that I have a .4mm nozzle and it is spitting out .6mm filament? Would changing nozzle diameter in settings affect height? Almost seems to me that instead of inputting filament diameter, and nozzle diameter, that setting the diameter of the extruded piece, and length would have been a better way for calculations. But I am speaking out of ignorance, not knowing the code.

Would the nozzle diameter thing we were talking about before have anything to do with it? Being that I have a .4mm nozzle and it is spitting out .6mm filament? Would changing nozzle diameter in settings affect height? Almost seems to me that instead of inputting filament diameter, and nozzle diameter, that setting the diameter of the extruded piece, and length would have been a better way for calculations. But I am speaking out of ignorance, not knowing the code.

|

Re: Thinking of buying a Prusa i3 November 18, 2013 12:25PM |

Registered: 10 years ago Posts: 1,433 |

All the slicing stuff is going to do is to decide to put out 2 cubic inches of material for a 2 cubic inch part. The diameters, thicknesses, and extruder steps are simply a way to let it work out how to do that. There are a multitude of ways it might be done. The code is set up to do it a fairly specific way.

Ideally the head would put out a rectangular strip of melted filament exactly one layer height high and exactly some well known width. Since the carriage moves up some number of Z steps each time, the height is pretty well controlled. The width is the open issue. The shape of the edges (rounded not square) is something we simply have to live with.

You have a certain size hole in the end of the hot end. That limits the practical range of widths you can get. The strip is not going to be more narrow than the hole. There are a few limits on thickness to width. Printing a strip that is taller than it is wide – not so much (won’t stick to the plastic under it). Printing a strip that’s much wider than it is tall (say 4X) certainly is a problem for me and the filaments I use. Others may have more success ….

Back to the Z axis:

The head only moves up some number of Z steps when you tell it to. Except for globs of stuff being pushed around, it will not print higher than the bottom of the head. It can drop filament through mid air to fall down to a print, so it can print lower than the head. Flow rate is the key to making sure it does not have to fall through air. That needs to be correct to do the calibration below.

When you zero your Z axis in bed leveling – do you use a piece of paper or a feeler gauge? What is the thickness of the thing you use? You need to level the bed before you do prints. Mechanical setup first, calibration second.

Here’s a bit of a crazy example. Say you use a 0.2 mm feeler gauge for your z leveling. You get so you can just barely slide it under the hot end at each corner of the print area. You do not compensate for it in Slic3r. You go ahead and print with the default 200% flow on the first layer in Slic3r. The plastic comes out, falls down to the mass of hair spray on the hot glass bed and sticks. You come back and print 9 more layers. All (including the first) are at your setting of 0.30 mm layer height. You part comes out 3.20 mm high. You print a 25 mm tall part, it’s 25.2 mm tall. If both the zero and the steps are off, you might get a 3.17mm (instead of 3) short part and a 99.2 (instead of 100) mm tall part.

Here’s another example. You have a 0.2 mm leveling issue. You have your layer height set to 0.32 mm. You tell it to print a 3 mm tall item. The slicer can either decide to print 10 layers (3.2 mm tall) or 9 layers (2.88 mm). There’s no way it can hit 3.0 exactly. It does not know how to print a fractional layer. You would either get a 3.4 mm tall or a 3.08 mm tall result (both off by the 0.2 mm zero error). In this case you could get a “perfect” result (3.08) when you actually have two errors combining to zero each other out. You could also get a pretty far out result (3.4 mm) when they combine the other way. Pronterface would give you a hint when it showed how tall the part is as it loads it.

What you most likely have is two issues at once. You can print several parts and evaluate them as a set. Then attacking each issue one at a time, you can get the issues figured out. A series of progressively taller parts will let you calibrate the Z steps by ignoring the zero error. They will also tell you if you Z is non-linear (slipping …). Once the Z is right, you can work out the zero error. You can also do it the other way around (zero first then axis) – your choice.

Ideally the head would put out a rectangular strip of melted filament exactly one layer height high and exactly some well known width. Since the carriage moves up some number of Z steps each time, the height is pretty well controlled. The width is the open issue. The shape of the edges (rounded not square) is something we simply have to live with.

You have a certain size hole in the end of the hot end. That limits the practical range of widths you can get. The strip is not going to be more narrow than the hole. There are a few limits on thickness to width. Printing a strip that is taller than it is wide – not so much (won’t stick to the plastic under it). Printing a strip that’s much wider than it is tall (say 4X) certainly is a problem for me and the filaments I use. Others may have more success ….

Back to the Z axis:

The head only moves up some number of Z steps when you tell it to. Except for globs of stuff being pushed around, it will not print higher than the bottom of the head. It can drop filament through mid air to fall down to a print, so it can print lower than the head. Flow rate is the key to making sure it does not have to fall through air. That needs to be correct to do the calibration below.

When you zero your Z axis in bed leveling – do you use a piece of paper or a feeler gauge? What is the thickness of the thing you use? You need to level the bed before you do prints. Mechanical setup first, calibration second.

Here’s a bit of a crazy example. Say you use a 0.2 mm feeler gauge for your z leveling. You get so you can just barely slide it under the hot end at each corner of the print area. You do not compensate for it in Slic3r. You go ahead and print with the default 200% flow on the first layer in Slic3r. The plastic comes out, falls down to the mass of hair spray on the hot glass bed and sticks. You come back and print 9 more layers. All (including the first) are at your setting of 0.30 mm layer height. You part comes out 3.20 mm high. You print a 25 mm tall part, it’s 25.2 mm tall. If both the zero and the steps are off, you might get a 3.17mm (instead of 3) short part and a 99.2 (instead of 100) mm tall part.

Here’s another example. You have a 0.2 mm leveling issue. You have your layer height set to 0.32 mm. You tell it to print a 3 mm tall item. The slicer can either decide to print 10 layers (3.2 mm tall) or 9 layers (2.88 mm). There’s no way it can hit 3.0 exactly. It does not know how to print a fractional layer. You would either get a 3.4 mm tall or a 3.08 mm tall result (both off by the 0.2 mm zero error). In this case you could get a “perfect” result (3.08) when you actually have two errors combining to zero each other out. You could also get a pretty far out result (3.4 mm) when they combine the other way. Pronterface would give you a hint when it showed how tall the part is as it loads it.

What you most likely have is two issues at once. You can print several parts and evaluate them as a set. Then attacking each issue one at a time, you can get the issues figured out. A series of progressively taller parts will let you calibrate the Z steps by ignoring the zero error. They will also tell you if you Z is non-linear (slipping …). Once the Z is right, you can work out the zero error. You can also do it the other way around (zero first then axis) – your choice.

|

Re: Thinking of buying a Prusa i3 November 18, 2013 06:35PM |

Registered: 11 years ago Posts: 160 |

Ok, I get all what you are saying. Just a little FYI, I build race engines for fun, build and fly RC planes, and own a HVAC/plumbing business, so setting up mechanical things....is my thing. So long as I understand how it works. Nothing like a good set of instructions. You explaining it to me helps a lot. Sometimes I am reading through the wiki and not getting what they are saying really, I think some of it may be outdated.

Now it appears to me that the Z axis is possibly going up to high for the amount of plastic being extruded. I don't know why I would have to calibrate Z axis steps, as Colin provides a config file. I asked Colin, and he said to increase the flow rate on the LCD. I did, and the prints are now sticking better. Then I upped the temp in 5degree increments until it really started sticking good. I am at 245 now, and the parts are pretty rock solid. I don't think the measurements are entirely accurate though, I have to go back to the calibration objects and try again.

Now if my heights were off by the same amount every time, I would have considered that the height off the bed was the cause, but it is a proportional numbers, not a fixed number.

Now it appears to me that the Z axis is possibly going up to high for the amount of plastic being extruded. I don't know why I would have to calibrate Z axis steps, as Colin provides a config file. I asked Colin, and he said to increase the flow rate on the LCD. I did, and the prints are now sticking better. Then I upped the temp in 5degree increments until it really started sticking good. I am at 245 now, and the parts are pretty rock solid. I don't think the measurements are entirely accurate though, I have to go back to the calibration objects and try again.

Now if my heights were off by the same amount every time, I would have considered that the height off the bed was the cause, but it is a proportional numbers, not a fixed number.

|

Re: Thinking of buying a Prusa i3 November 18, 2013 07:44PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 November 18, 2013 10:22PM |

Registered: 11 years ago Posts: 160 |

Ok, I will just have to keep experimenting. I am real close, although I have to have the flow set at 124. I printed a part that is 20mm high, and was only taller by .21mm. Is this acceptable? Or amI just being too picky?

On another note, I just ordered some tallman618. This ABS I think is too brittle for what I am trying to do currently.

You know Bob, you are a great person, thanks for all the help, and the help you give others. It won't go to waste with me, I tend to pass it on

On another note, I just ordered some tallman618. This ABS I think is too brittle for what I am trying to do currently.

You know Bob, you are a great person, thanks for all the help, and the help you give others. It won't go to waste with me, I tend to pass it on

|

Re: Thinking of buying a Prusa i3 November 19, 2013 01:15PM |

Registered: 10 years ago Posts: 1,433 |

I think that anything under 1 or 2% is doing just fine with these printers on any one step. It's really a set of steps and you go around them a couple of times to get it all right. I think that hanging up to long on one stage may keep you from finding something further down the line. Since it all interacts, what you find later will change what you have done before.

The end goal is what counts - You want a print that looks good, holds together well, and prints right the first time. All the calibration does is make it easier to do this.

One thing to watch – as you go through this, your flow rate adjust should get closer to 1.0 it may never be 1.000. Something in the 0.9 to 1.1 range is pretty likely. No idea which step will move you closer, some steps may move you the other way. It all depends on what you find as you work through them.

Thanks for the kind words.

The end goal is what counts - You want a print that looks good, holds together well, and prints right the first time. All the calibration does is make it easier to do this.

One thing to watch – as you go through this, your flow rate adjust should get closer to 1.0 it may never be 1.000. Something in the 0.9 to 1.1 range is pretty likely. No idea which step will move you closer, some steps may move you the other way. It all depends on what you find as you work through them.

Thanks for the kind words.

|

Re: Thinking of buying a Prusa i3 November 23, 2013 12:55AM |

Registered: 11 years ago Posts: 160 |

well been busy printing. got my Taulman 618 today, and boy is it a pain to get to stick to the bed. I've done a lot of reading on it, just got to play around a little more. The piece I was printing probably needs a brim, so I just figured out how to do that. Plus my 618 is in the oven now, because it seems like it has moisture in it as I see little puffs of smoke coming out with the filament. Guessing that is moisture.

Anyway, here are some things I've been printing.

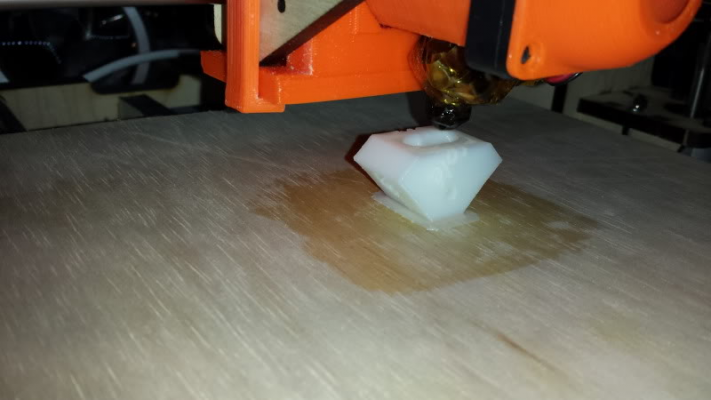

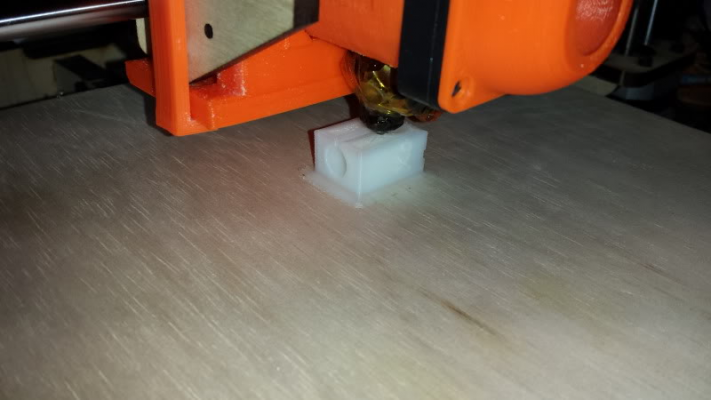

Napikin holders for Thanksgiving:

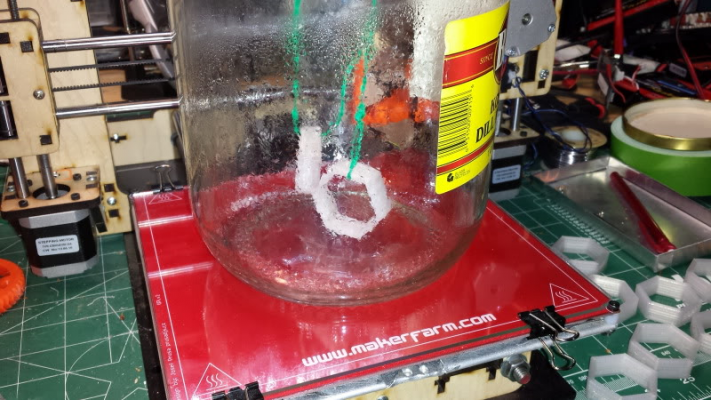

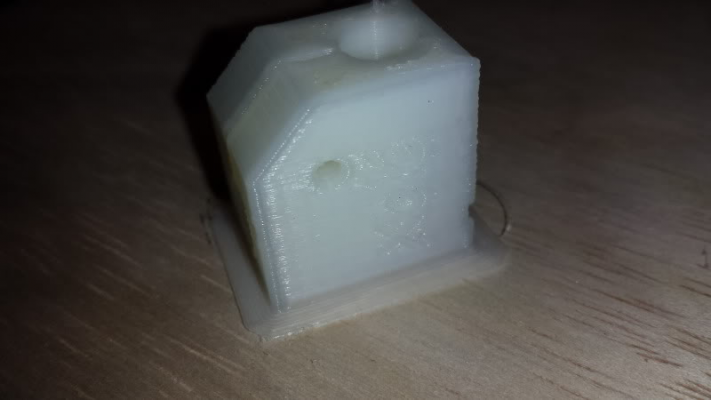

Acetone smoothing:

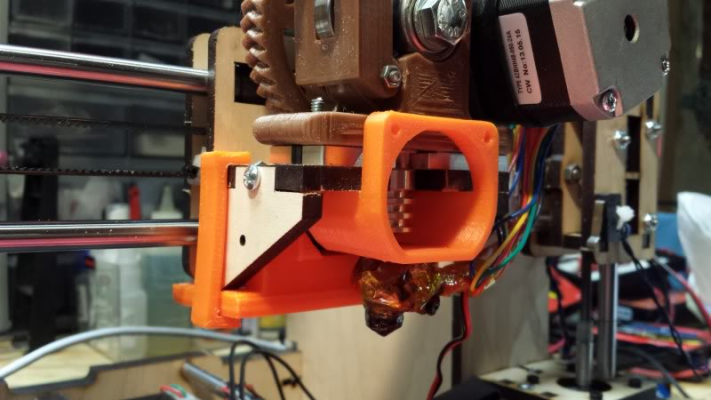

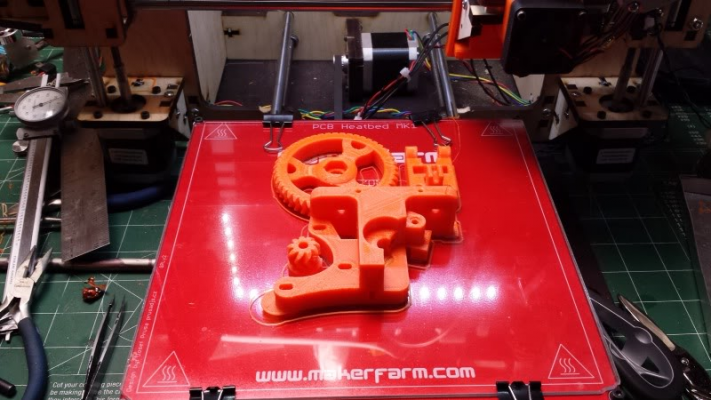

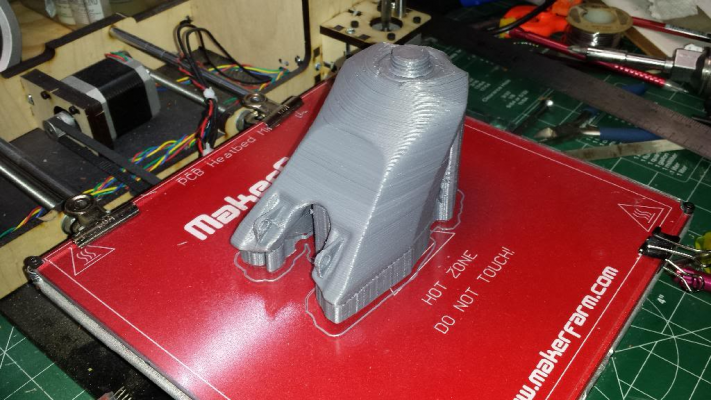

And after 3 tries got my spare extruder printed:

Anyway, here are some things I've been printing.

Napikin holders for Thanksgiving:

Acetone smoothing:

And after 3 tries got my spare extruder printed:

|

Re: Thinking of buying a Prusa i3 November 23, 2013 10:58AM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 November 23, 2013 11:31PM |

Registered: 11 years ago Posts: 160 |

Ok after lots of reading, I could not get the taulman 618 to stick to anything. I dried it in the oven for 4 hours at 200f. Still no luck. I haven't tried G10 yet, or garolite. But I was in the hardware store looking at some luan, and brought home a piece and tried it. Success so far! I just did it plain at first, then I used the washable elmers glue stick, and it holds really well. Some fibers came up with the piece, but very little. Even less when I used the glue. I did 2 pieces so far, so time will tell. Anyway, luan is very cheap and it's easy enough to cut out a bunch of work platforms.

|

Re: Thinking of buying a Prusa i3 November 23, 2013 11:39PM |

Registered: 11 years ago Posts: 661 |

|

Re: Thinking of buying a Prusa i3 November 24, 2013 10:45AM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 November 25, 2013 10:09AM |

Registered: 11 years ago Posts: 160 |

I can see that. I am printing parts with a small base right now, so as long as it starts fine, then it goes good. I am not sure what the center part of luan is. I just ordered some garolite from mcmaster carr, we will see how that goes.

I need to get better at 3D programs for now. I reached the limits of sketchup trying to make some of the parts I want to design, so after spending so much time learning sketchup, I have to start using another program. Going with Fusion 360.

I need to get better at 3D programs for now. I reached the limits of sketchup trying to make some of the parts I want to design, so after spending so much time learning sketchup, I have to start using another program. Going with Fusion 360.

|

Re: Thinking of buying a Prusa i3 November 25, 2013 12:37PM |

Registered: 10 years ago Posts: 1,433 |

Luan has some sort of generic hard wood in the center. You can get the same sort of stuff with MDF in the middle and hardwood on the outside. It's not easy to find or cheap. It supposedly is more stable. I'd go with someting else like the Garolite. If that does not work and wood is the long term solution - epoxy a sheet of *thin* plywood to a piece of 3mm thick glass or 1/4" aluminum. It still will not be perfect, but it will be better than plywood alone.

|

Re: Thinking of buying a Prusa i3 November 26, 2013 05:49PM |

Registered: 11 years ago Posts: 160 |

Nice idea. It is working very well for these smaller prints so far.

Sad thing though, I was printing away my quadcopter pieces, then noticed when testing that the layers were not sticking together well. So now I am back to calibrating to get better lamination. Shame cause the prints look so good. I wrote taulman for advice on which way to go. He is corresponding with me to find a solution. I will post it when I do.

I ordered the garolite Sunday night, and got it today! Printed two calibration pieces so far, looks good.

Sad thing though, I was printing away my quadcopter pieces, then noticed when testing that the layers were not sticking together well. So now I am back to calibrating to get better lamination. Shame cause the prints look so good. I wrote taulman for advice on which way to go. He is corresponding with me to find a solution. I will post it when I do.

I ordered the garolite Sunday night, and got it today! Printed two calibration pieces so far, looks good.

|

Re: Thinking of buying a Prusa i3 November 26, 2013 07:58PM |

Registered: 10 years ago Posts: 1,433 |

If you are having adhesion problems, slow your speeds way down. Work with simple / small / fast / cheap parts. Vary your temps and your layer height until you get things to stick. Once that's taken care of go back to fancy stuff. Layers that are to thin or to thick can case problems with a given set of temperatures and materials. There's often a sweet spot where the material / hot end / temps / layers all play well together. Once you get into that region, you can tweak your way to other working settings.

|

Re: Thinking of buying a Prusa i3 November 27, 2013 01:23AM |

Registered: 11 years ago Posts: 160 |

Yea I think my temp is incorrect. I have to print way higher than what is recommened to make the layers stick. Both with abs and 618. But both my thermisters show correct temps at room temp. I have an expensive meter I use for work, but has a 200f limit. Anyway I am printing 618 at 270 on garolite now. Sticks beautiful and bonds super strong.[m.youtube.com]

Is there a guide for what the commads in the lcd do? Specifically A-retract. Colin did not know.

Edited 1 time(s). Last edit at 11/27/2013 01:25AM by Antslake.

Is there a guide for what the commads in the lcd do? Specifically A-retract. Colin did not know.

Edited 1 time(s). Last edit at 11/27/2013 01:25AM by Antslake.

|

Re: Thinking of buying a Prusa i3 November 27, 2013 08:23AM |

Registered: 10 years ago Posts: 1,433 |

The only way I know to check the therms quickly is to put the hot end in a large plastic bag and drop it into a pot of boiling water. Yes you need to be sure that your bag is rated for boiling water temperatures first.

The problem with using any sort of meter is coupling the probe to the hot end. It's not as easy as it seems.

The is a wide range of things sold as ABS filament. Some of the stuff out there needs a 260C hot end to make it work. You need to check what the supplier has sent you before you assume it's a normal temp range version.

The problem with using any sort of meter is coupling the probe to the hot end. It's not as easy as it seems.

The is a wide range of things sold as ABS filament. Some of the stuff out there needs a 260C hot end to make it work. You need to check what the supplier has sent you before you assume it's a normal temp range version.

|

Re: Thinking of buying a Prusa i3 November 27, 2013 10:43PM |

Registered: 11 years ago Posts: 160 |

Well the ABS makerfarm sent me, I was told to run it at 225. I had to run it at 235-245 to get good adhesion. The 618 is the taulman nylon, and was told to run it at a true 238, I am on 270.

Do you know if there is a detailed description of the LCD configs for the marlin software? I am not sure what each one does, and I am sure I can use them for real time tuning.

Do you know if there is a detailed description of the LCD configs for the marlin software? I am not sure what each one does, and I am sure I can use them for real time tuning.

|

Re: Thinking of buying a Prusa i3 November 28, 2013 02:46PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 December 01, 2013 03:30PM |

Registered: 11 years ago Posts: 160 |

For the first time I tried to print sometbing and a part of my design was missing on one piece, then on the other it filled in a hole that it shouldn't have. Why would that happen and how can I correct it?

I designed the part in sketchup like I always do, then sliced it in cura. I guess there must be some holes?

I designed the part in sketchup like I always do, then sliced it in cura. I guess there must be some holes?

|

Re: Thinking of buying a Prusa i3 December 01, 2013 04:10PM |

Registered: 10 years ago Posts: 1,433 |

Most of the time the printer does what it's told to by the gcode....

Quality time with an stl viewer / editor is one approach. Since sketch up generated the stl, it's not really your error to fix. You will learn a lot about stl files but that's not a lot of fun. You can try the cloud based repair programs. They seem to work pretty well.

Rather than printing the result to find errors, find a good gcode viewer that works on what ever OS you are running and look at the gcode. Things like missing holes should be a findable thing.

Quality time with an stl viewer / editor is one approach. Since sketch up generated the stl, it's not really your error to fix. You will learn a lot about stl files but that's not a lot of fun. You can try the cloud based repair programs. They seem to work pretty well.

Rather than printing the result to find errors, find a good gcode viewer that works on what ever OS you are running and look at the gcode. Things like missing holes should be a findable thing.

|

Re: Thinking of buying a Prusa i3 December 02, 2013 11:17PM |

Registered: 11 years ago Posts: 160 |

Well it was me. The file had huge holes in it that I missed while editing and designing it.

I ordered a new material today:

[www.fennerdrives.com]

Let's see how this one checks out.

I fine tuned my esteps tonight, next I have to fine tune the bridging, or figure out how to fine tune it. I noticed some of the bridging is not happening too well. Could be the high temps I like to print at for maximum adhesion.

Oh and here is my thingiverse page:

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/02/2013 11:18PM by Antslake.

I ordered a new material today:

[www.fennerdrives.com]

Let's see how this one checks out.

I fine tuned my esteps tonight, next I have to fine tune the bridging, or figure out how to fine tune it. I noticed some of the bridging is not happening too well. Could be the high temps I like to print at for maximum adhesion.

Oh and here is my thingiverse page:

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/02/2013 11:18PM by Antslake.

|

Re: Thinking of buying a Prusa i3 December 03, 2013 09:00PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Thinking of buying a Prusa i3 December 06, 2013 12:34AM |

Registered: 11 years ago Posts: 160 |

Well first print went ok. I just printed out a 1/32 slotcar tire, and it worked! Stuff is absolutely amazing how it bonds together and streches. Seems like it will be very easy to print with. However after that I couldn't get the stuff to work, but I believe I found the cause. It seems my X carriage the part that the extruder sits on was kind of flopping in the breeze. So the head was getting clogged. Kind of amazing I was getting anything good out of these prints at all. It was literally moving up and down 1/8-3/32 of an inch. I could never figure out why every time I came down to my machine I would have to recalibrate the bed. So I took it apart and not to happy with the way it is designed, it was bound to come loose again. I glued all the wood pieces together now.

I put ABS back into it for calibration again, and low and behold it is producing the finest prints so far! This was more what I was expecting. TO think I wasted so much time banging my head against the wall with certain problems. I printed out the tornado vase and it is beautiful and very very strong. I was having trouble with layer separations. Will post up some pictures tomorrow.

I did find another filament similar to the one I just bought for much less.

www.recreus.com

[www.youtube.com]

I put ABS back into it for calibration again, and low and behold it is producing the finest prints so far! This was more what I was expecting. TO think I wasted so much time banging my head against the wall with certain problems. I printed out the tornado vase and it is beautiful and very very strong. I was having trouble with layer separations. Will post up some pictures tomorrow.

I did find another filament similar to the one I just bought for much less.

www.recreus.com

[www.youtube.com]

|

Re: Thinking of buying a Prusa i3 December 10, 2013 12:23AM |

Registered: 11 years ago Posts: 160 |

Yea jammed my head and broke the thermistor trying to take it apart. Got a new one in 2 days back up and running.

Printed some more stuff. Not perfect but getting there on those harder prints:Will mess with the ninjaflex some more this week.

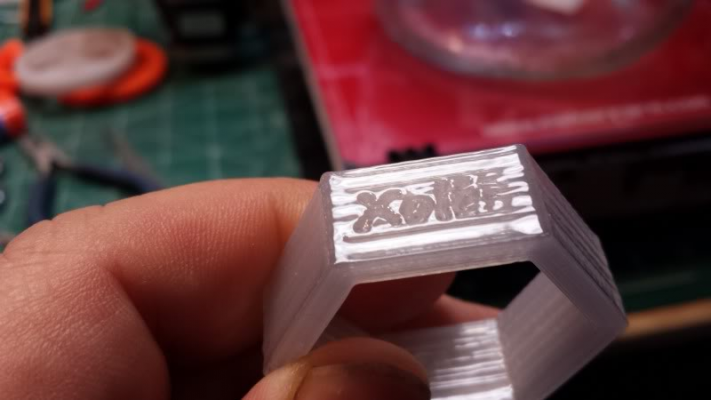

Scale model of a short track racing gas tank from a ATC250R 3 wheeler. Did the acetone fume bath:

Completed quad frame designed

Printed some more stuff. Not perfect but getting there on those harder prints:Will mess with the ninjaflex some more this week.

Scale model of a short track racing gas tank from a ATC250R 3 wheeler. Did the acetone fume bath:

Completed quad frame designed

|

Re: Thinking of buying a Prusa i3 December 13, 2013 04:21AM |

Registered: 12 years ago Posts: 82 |

If you're still having bed sticking issues, try yellow masking tape (not painters tape). It's basically a cheaper variant of blue painters tape, but for some reason sticks way better with my PLA tests. I've tested it with the bed cold, 40c, 50c and 60c and it's stuck amazingly well every time. In comparison I couldn't get PLA to stick to glass or painters for some reason.

I cant comment for ABS but some people have had success with painters, so might be worth a try with the masking tape, it's only about £0.50 a roll in the UK.

I cant comment for ABS but some people have had success with painters, so might be worth a try with the masking tape, it's only about £0.50 a roll in the UK.

|

Re: Thinking of buying a Prusa i3 December 15, 2013 10:15PM |

Registered: 11 years ago Posts: 160 |

Quote

RickM

If you're still having bed sticking issues, try yellow masking tape (not painters tape). It's basically a cheaper variant of blue painters tape, but for some reason sticks way better with my PLA tests. I've tested it with the bed cold, 40c, 50c and 60c and it's stuck amazingly well every time. In comparison I couldn't get PLA to stick to glass or painters for some reason.

I cant comment for ABS but some people have had success with painters, so might be worth a try with the masking tape, it's only about £0.50 a roll in the UK.

It depends which material I am trying to print with. I've tried blue tape, green frog tape, masking tape, with not much success with nylon and ABS.

Here is where I am at now,

ABS, on glass with Fuitcos extreme #5 at 110C. Make sure to clean the glass completely, and put a liberal coating of hair spray on it. I printed for one month on one can. I got 3 cans on sale for $10. You can do several prints before running the glass under hot water to clean off the build up. I usually just hit it with a quick shot over the are where the last print peeled off. Be sure to shield your machine from getting hair spray on it as this will mess up the bearings. I take the glass off and do it. I have 2 pieces of glass and alternate, while one cools, I can start another.

For nylon, I am using garolite from mcmaster carr 1/4" thick. No heat required. It sticks a bit too well, and some of the garolite is peeling off when I remove the print, which sucks because the garolite cost $30. The Garolite is also warped. Going to have to figure out how to make it perfectly flat. For now, I am printing small things, and I just calibrate the bed in the area I am printing. I have also had great success with luan. But the luan peels off as well, and will not last that long. However it is cheap and you can get many pieces out of a 4x8 sheet of luan. Again, the luan is not perfectly flat. PRobably goping to experiment with clamping it down to glass to remove the warp.

The last material I just started playing with is ninjaflex. It sticks to glass, no heat. I had one pretty successful print with it, now it is just not going through the extruder. I have to redesign the Greg's extruder to remove that small air gap under the hobbed bolt to stop the extremely flexible material from bunching up there.

Sorry, only registered users may post in this forum.