Help with low quality prints

Posted by nivlac64

|

Help with low quality prints August 11, 2014 05:49PM |

Registered: 9 years ago Posts: 7 |

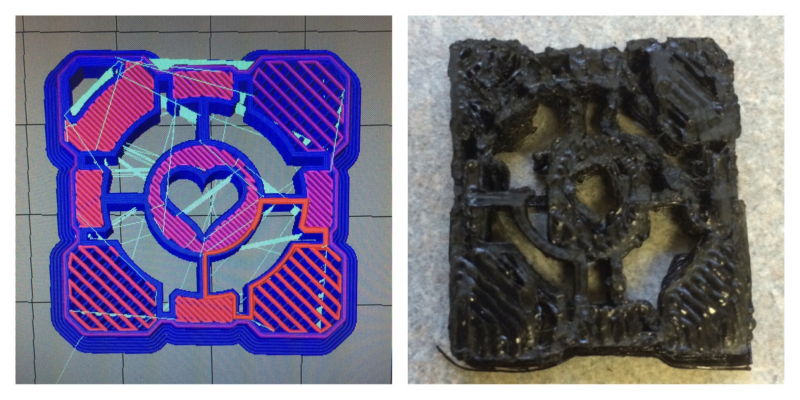

Hi I'me having trouble with getting our parts to print cleanly as you can see in the 2 images attached

I've already gone through the calibration guides as listed here

[reprap.org]

and here

[reprap.org]

I've gone through all the different calibration processes at least once, but I'm still having this clean print issue. I dont know which setting this problem is associated with so I dont know which calibration to rerun and which setting to tweak

Which calibration or what setting should I change to clean up the prints?

I've already gone through the calibration guides as listed here

[reprap.org]

and here

[reprap.org]

I've gone through all the different calibration processes at least once, but I'm still having this clean print issue. I dont know which setting this problem is associated with so I dont know which calibration to rerun and which setting to tweak

Which calibration or what setting should I change to clean up the prints?

|

Re: Help with low quality prints August 11, 2014 08:40PM |

Registered: 10 years ago Posts: 10 |

|

Re: Help with low quality prints August 11, 2014 09:20PM |

Registered: 9 years ago Posts: 7 |

|

Re: Help with low quality prints August 12, 2014 03:57PM |

Registered: 9 years ago Posts: 7 |

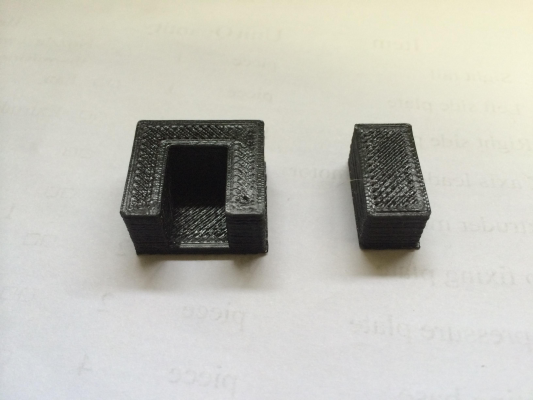

so tightening that z-axis gear screw really helped clear up our prints.

you can see the before on the left and the after the tightening on the right

But we still have blotches on the perimeter and the edges of the prints look flakey . what would cause that?

you can see the before on the left and the after the tightening on the right

But we still have blotches on the perimeter and the edges of the prints look flakey . what would cause that?

|

Re: Help with low quality prints August 12, 2014 08:25PM |

Registered: 10 years ago Posts: 167 |

|

Re: Help with low quality prints August 12, 2014 09:36PM |

Registered: 9 years ago Posts: 7 |

which extrusion setting are you referring to?

so we originally had the perimeter extrusion width set to 0.95 after some initial calibration. We changed it back to 0 (or default) and printed out the part as referenced in the perimeter width calibration guide here

[reprap.org]

so the result we got was great.it really cleaned up the part

however the two pieces dont fit each other. what can i change to make them fit each other? Im using repetier host. what is my equivalent of the edge width over height as all I can change is the extrusion width?

so we originally had the perimeter extrusion width set to 0.95 after some initial calibration. We changed it back to 0 (or default) and printed out the part as referenced in the perimeter width calibration guide here

[reprap.org]

so the result we got was great.it really cleaned up the part

however the two pieces dont fit each other. what can i change to make them fit each other? Im using repetier host. what is my equivalent of the edge width over height as all I can change is the extrusion width?

|

Re: Help with low quality prints August 13, 2014 01:39AM |

Registered: 11 years ago Posts: 661 |

|

Re: Help with low quality prints August 13, 2014 09:14AM |

Registered: 9 years ago Posts: 3 |

I'm also new to 3D printing (one week actual printing everyday sort of thing) but am experienced in making physical objects via machining/building/casting.

When you want to make one object fit perfectly into another, you must allow for tolerances. An 8mm bolt will not fit into an 8mm hole - either you make the bolt a bit smaller or the hole a bit bigger.

Other variables are, as the previous poster said, that material will be squashed out of the nozzle and actually get in the way.

Shrinkage is another factor - big blobs of material seem to shrink a bit more, while honeycomb bits shrink a bit less. This is because all 3D printed plastic shrinks a certain amount, while the air in the honeycomb doesn't shrink at all - so a part made of 100% plastic will entirely shrink, while a part made of 50% plastic 50% air will experience only the 50% made of plastic shrinking, and not the air.

It is also my understanding (but please someone correct me if I'm wrong) that when this happens, at some point, one of the higher layers in the print is adjusted to make up for the difference - so it might lead to a situation where your machine is trying to print an object 1.00mm high, with the first layer 0.24mm, the next 0.24mm, the next 0.24mm, and then the last is 0.28mm - and so you find that when you look at the object from the side, you get some layers now and again that seem odd.

Btw my surface layers looked rough like yours until I increased my filament temperature, and they smoothed out very noticeably.

3D printers are fussy little things until you figure them out, in my experience.

Edited 1 time(s). Last edit at 08/13/2014 09:16AM by justgeorge.

When you want to make one object fit perfectly into another, you must allow for tolerances. An 8mm bolt will not fit into an 8mm hole - either you make the bolt a bit smaller or the hole a bit bigger.

Other variables are, as the previous poster said, that material will be squashed out of the nozzle and actually get in the way.

Shrinkage is another factor - big blobs of material seem to shrink a bit more, while honeycomb bits shrink a bit less. This is because all 3D printed plastic shrinks a certain amount, while the air in the honeycomb doesn't shrink at all - so a part made of 100% plastic will entirely shrink, while a part made of 50% plastic 50% air will experience only the 50% made of plastic shrinking, and not the air.

It is also my understanding (but please someone correct me if I'm wrong) that when this happens, at some point, one of the higher layers in the print is adjusted to make up for the difference - so it might lead to a situation where your machine is trying to print an object 1.00mm high, with the first layer 0.24mm, the next 0.24mm, the next 0.24mm, and then the last is 0.28mm - and so you find that when you look at the object from the side, you get some layers now and again that seem odd.

Btw my surface layers looked rough like yours until I increased my filament temperature, and they smoothed out very noticeably.

3D printers are fussy little things until you figure them out, in my experience.

Edited 1 time(s). Last edit at 08/13/2014 09:16AM by justgeorge.

|

Re: Help with low quality prints August 13, 2014 01:50PM |

Registered: 9 years ago Posts: 7 |

|

Re: Help with low quality prints August 13, 2014 01:51PM |

Registered: 9 years ago Posts: 7 |

|

Re: Help with low quality prints August 13, 2014 02:02PM |

Registered: 11 years ago Posts: 661 |

Quote

nivlac64

I already changed the extrusion multiplier to get the proper steps/mm (ie i ask for 10mm of filament, it used up 10mm) but I'll definately go back and take a look at it

That is an adjustment of the steps on your motors. The extrusion multiplier is different. I don't have a copy of Reprtier on this machine but on other hosts the setting is where you set the filament diameter. If you haven't set the extrusion multiplier it's likely the actual filament diameter isn't correct as well. Both of those parameters can lead to over extrusion. When parts don't fit together that should too much material being extruded could be the cause.

|

Re: Help with low quality prints August 13, 2014 02:22PM |

Registered: 11 years ago Posts: 661 |

Quote

justgeorge

I

It is also my understanding (but please someone correct me if I'm wrong) that when this happens, at some point, one of the higher layers in the print is adjusted to make up for the difference - so it might lead to a situation where your machine is trying to print an object 1.00mm high, with the first layer 0.24mm, the next 0.24mm, the next 0.24mm, and then the last is 0.28mm - and so you find that when you look at the object from the side, you get some layers now and again that seem odd.

.

A properly configured and tuned machine will consistently extrude layers at the thickness it was instructed. What you are likely seeing in your prints are "Z artifacts". Those are variations in layer thickness due to either mechanical issues or configuration issues. A mechanical issue could be the Z couplers compressing and expanding during the print and a configuration issue could be something like the layer height not being a multiple of the pitch of the Z lead screw. Those aren't the only causes of Z artifact but they are two that are fairly common.

Edited 1 time(s). Last edit at 08/13/2014 02:22PM by vegasloki.

|

Re: Help with low quality prints August 14, 2014 05:21PM |

Registered: 9 years ago Posts: 7 |

thanks for the help everyone. So we've been changing the extrusion mulitplier, but it hasn't done too much to help with the last bit of inaccuracy in our parts. But at least we can print something of decent quality

The two things we're running into now is that :

The two things we're running into now is that :

- The bed doesnt seem to level no matter how hard we calibrate the 4 corner screws. The center of the bed appears to be sunk in even though we have a metal bed

- We constantly clog the extruder so about every 3-4 prints we have to remove our J-nozzle and remove all the filament out. We seem to have a lot of solid filament getting stuck towards the top of the extruder, the cold end and we dont know why. Currently we're running black PLA at 175C .

Sorry, only registered users may post in this forum.