Prusa i3 - stuck filament

Posted by corceling

|

Prusa i3 - stuck filament September 07, 2014 10:40AM |

Registered: 9 years ago Posts: 10 |

Hello,

I built my Prusa i3 about 2 months from now and I couldn't print a successful part since. The problem with my printer is that when it reaches about 15 minutes of the process the filament start to get stuck in the header. I tried a few things like change the e-motor voltage, tried some temperatures from 180 to 210°C (I'm printing with PLA) and change the feedrate and other small things on the slicer configuration. Detail that it only print with 0.35mm layer and 0.4mm (with 0.4mm nozzle), below that it doesn't print nothing. I don´t know if is something with the config or is my printer.

I can't find a solution on the internet for this problem, the filament get so stucked that I only can take it of heating directly on the oven, so it melts the filament.

It starts fine, but with the time the e-motor starts clicking and them stops extruding material.

I posted a vídeo, so the guys can take a look:

Video

Any thoughts?

I built my Prusa i3 about 2 months from now and I couldn't print a successful part since. The problem with my printer is that when it reaches about 15 minutes of the process the filament start to get stuck in the header. I tried a few things like change the e-motor voltage, tried some temperatures from 180 to 210°C (I'm printing with PLA) and change the feedrate and other small things on the slicer configuration. Detail that it only print with 0.35mm layer and 0.4mm (with 0.4mm nozzle), below that it doesn't print nothing. I don´t know if is something with the config or is my printer.

I can't find a solution on the internet for this problem, the filament get so stucked that I only can take it of heating directly on the oven, so it melts the filament.

It starts fine, but with the time the e-motor starts clicking and them stops extruding material.

I posted a vídeo, so the guys can take a look:

Video

Any thoughts?

|

Re: Prusa i3 - stuck filament September 07, 2014 07:49PM |

Registered: 10 years ago Posts: 477 |

|

Re: Prusa i3 - stuck filament September 08, 2014 08:42AM |

Registered: 9 years ago Posts: 10 |

Quote

SteveRoy

The heat from the nozzle is probably creeping up the extruder tube causing the filament to expand.

I see from the video you have 2 fans running, one looks like it cools the print, the other? does it cool the motor or tube? (if there is a tube - hard to tell)

Steve

One of the coolers is to cool the printed part and the other one to cool the motor and tube... Yesterday I tried some other stuff like envolving the extruder head with teflon and kaplan tape, I put some thermal paste between the coolers cold plate and the body where the tube goes thru, put I stucked the filament in less than 2 minutes...

One thing that you said about the filament expanding, I use a 1.75mm PLA fialment and one thing I noiticed is that the feeding tube have about 2.3mm in diameter... Can it be the cause of the jamming? Or seems to be more like a cooling problem? As I see, looks like the cooler is not working like it should, not making the region were the tube and filament pass cold as needed...

Other thing is that I think I screwup when it first jammed (i wasnt using the cooler at that time, silly me), I tried to clean with a drill and I think i damaged the inside walls of the tube...

I send some pictures from the feeder without the cooler, in the image is possible to see how is the system....

|

Re: Prusa i3 - stuck filament September 08, 2014 05:51PM |

Registered: 10 years ago Posts: 581 |

In between the heater element (the aluminium block above the nozzle) and the extruder, you should have a heat sink cooled by a fan directed at it. All the heat from the heater element is traveling up to the extruder and causing your filament to soften and expand. Your extruder won't be able to push the filament through. Take a look at the E3D hot end and you'll see what I mean.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 - stuck filament September 08, 2014 08:01PM |

Registered: 9 years ago Posts: 10 |

Quote

3dkarma

In between the heater element (the aluminium block above the nozzle) and the extruder, you should have a heat sink cooled by a fan directed at it. All the heat from the heater element is traveling up to the extruder and causing your filament to soften and expand. Your extruder won't be able to push the filament through. Take a look at the E3D hot end and you'll see what I mean.

I understand now... Probably is what you said... The model of my printer is exactly like this model:

MK8 Extruder

I trying to figure it out how to improve this system, since it is not working fine... Tomorrow I will talk to a local fabricador and see if he can make a new pipe from a m6 inox screw... I will try to fit a teflon tube inside it... I will try a different lenght too... I will change the cold plate to a non painted model and try to find a better fan too... If this doesn't work, I don't know what else should work, besides changing the hole extruder...

I thing I will try too is to make the inside hole of the pipe with a smaller diameter... Now is about 2.2 to 2.3mm, I will ask to make a 2.0mm... Probably the filament expand from the 1.75mm original, but with wich margin... thanks for the feedback...

|

Re: Prusa i3 - stuck filament September 09, 2014 02:59AM |

Registered: 10 years ago Posts: 581 |

If you do get a new pipe made, putting a teflon tube inside will limit the maximum temperature it will reach, but it will still be good for ABS temperatures. If you decide against a teflon tube, make sure the inside of the metal tube gets highly polished, otherwise filament will stick inside and you'll be back to your old problem.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 - stuck filament September 09, 2014 06:08PM |

Registered: 9 years ago Posts: 10 |

Quote

3dkarma

If you do get a new pipe made, putting a teflon tube inside will limit the maximum temperature it will reach, but it will still be good for ABS temperatures. If you decide against a teflon tube, make sure the inside of the metal tube gets highly polished, otherwise filament will stick inside and you'll be back to your old problem.

thanks for the tips... Tomorrow morning I will talk to the fabricator and see what he can do. I will make three variants for the tube... One with the teflon and two without, but with different lenghts... I will see which one works better and post the results here... I also bought two from dx.com, but I'm sure is goin to take more than a month to get here and until them I probably will be crazy

hehe...

hehe......

|

Re: Prusa i3 - stuck filament September 16, 2014 07:19PM |

Registered: 9 years ago Posts: 10 |

I was trying to fix my pipe, polishing the inside... So I bought valve grinding paste and a 5/64 inch drill... This time I think I mess it up more... hehe It did not sitck on the pipe like before, now i could unstuck heating the extruder up to 230°C... But still can't print... I posted a new vídeo if what happens:

Video

Here is some photos of the material I used... I think the grinding paste is a good call, but need take care of the inner diameter, I think I enlarged it a little bit more... The filament expanded too much (as in the picture)... I also changed the coller for a bigger one, more air flow and connected it directly to the power supply, so its always on... And the thermal paste doesn't seems to work either...

Video

Here is some photos of the material I used... I think the grinding paste is a good call, but need take care of the inner diameter, I think I enlarged it a little bit more... The filament expanded too much (as in the picture)... I also changed the coller for a bigger one, more air flow and connected it directly to the power supply, so its always on... And the thermal paste doesn't seems to work either...

|

Re: Prusa i3 - stuck filament September 16, 2014 07:51PM |

Registered: 10 years ago Posts: 477 |

|

Re: Prusa i3 - stuck filament September 17, 2014 02:59AM |

Registered: 10 years ago Posts: 581 |

Filament's definitely expanding too much. That grinding paste is for hardened valves, so it's going to tip into the barrel like it's butter.

Can't see in the pictures - where's that fan with the heat sink attached? It looks like it's got thermal compound on it.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

Can't see in the pictures - where's that fan with the heat sink attached? It looks like it's got thermal compound on it.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 - stuck filament September 18, 2014 09:00PM |

Registered: 9 years ago Posts: 10 |

Quote

3dkarma

Filament's definitely expanding too much. That grinding paste is for hardened valves, so it's going to tip into the barrel like it's butter.

Can't see in the pictures - where's that fan with the heat sink attached? It looks like it's got thermal compound on it.

I took it off to show how the motor clicks... As a matter of fact it goes in front off that piece of metal, that the filament goes true... Taking it to the side of thermology, if the filament doesn't touch the walls it doesn't exchange heat and the gap filled with air helps to create a worst scenario for the expansion of the filament... Tomorrow I will get the new pipes machining shop, them I tell if it works...

And Steve, if nothing of this works, I will easily think on buying a new head...

|

Re: Prusa i3 - stuck filament September 20, 2014 02:18PM |

Registered: 9 years ago Posts: 10 |

Really, now that I thought that I had fixed my printer, changing the pipe for a new one, the extruder motor began to act strange...

I don't know what happened, but I disassembled and conected the motor in other axis and the step motor is fine... I think is a drive problem...

Does it happened with someone?

Video

I don't know what happened, but I disassembled and conected the motor in other axis and the step motor is fine... I think is a drive problem...

Does it happened with someone?

Video

|

Re: Prusa i3 - stuck filament September 20, 2014 04:08PM |

Registered: 10 years ago Posts: 581 |

That definitely looks like a vref problem on the stepper driver; either that or the stepper driver board is fried. You say you tried plugging it into the driver for one of the axes? Did it move properly then?

Do you know how to check the vref for a stepper driver? If so, what reading do you get?

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

Do you know how to check the vref for a stepper driver? If so, what reading do you get?

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 - stuck filament September 20, 2014 05:14PM |

Registered: 9 years ago Posts: 10 |

Quote

3dkarma

That definitely looks like a vref problem on the stepper driver; either that or the stepper driver board is fried. You say you tried plugging it into the driver for one of the axes? Did it move properly then?

Do you know how to check the vref for a stepper driver? If so, what reading do you get?

Actually I let it seat for a while and it started to work again... But I still can't manage to print... Now looks like is the tip that is getting stucked...

How do i get this vref value? There is a g-code command that returns the value?

Other thing I just dircovered is that my nozzle tip isn't 0.4mm, it is 0.3mm or less... I tried to clean with a 0.4mm wire snd it didn't even get close to enter the hole...

|

Re: Prusa i3 - stuck filament September 20, 2014 06:52PM |

Registered: 10 years ago Posts: 581 |

You need a multimeter to check vref. Read the reprap wiki article and check back if you have questions.

If you let it sit for a while and it started working again, chances are the vref is too high and the stepper driver is overheating.

It is much harder to print with a 0.3mm nozzle than a 0.4mm. The pressure in the melt chamber is much higher and the chances of blocking or jamming are also higher.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

If you let it sit for a while and it started working again, chances are the vref is too high and the stepper driver is overheating.

It is much harder to print with a 0.3mm nozzle than a 0.4mm. The pressure in the melt chamber is much higher and the chances of blocking or jamming are also higher.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 - stuck filament September 27, 2014 09:40AM |

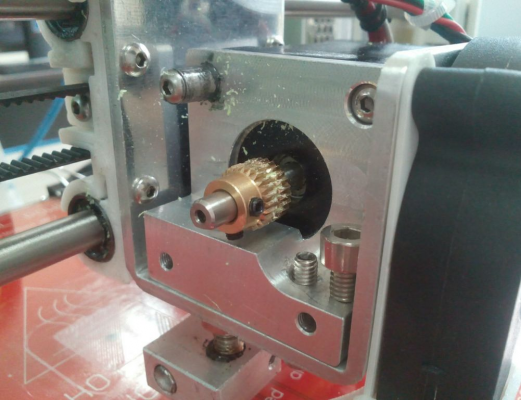

Registered: 9 years ago Posts: 10 |

Hello guys, I finally manage to fix my printing problems. I couldn't mesure the vref, but I changed the flow rate a little bit and now is working fine. My nozzle is 3mm, and now I can print with 0.1mm layer high with no problem. I thing I noticed too is that I was using the expert mode os Slic3r, so i changed to the basic and let it setup for me. I made some upgrades too to my printer head. I get a new pipe with exactly 2mm diameter, the old one was with 2.4mm, so the filament was buckling. The cooler always on to cool the extruder is a good call too.

I printed a filament oiler too, that you put a sponge and canoil oil inside. I thing this helps a lot too with you are using PLA. Other thing is that I thing the material I'm using is no that good, I found that this changes a lot the behavior of the printer too.

Here some pictures of my printer extruder and some parts I manage to print. Thanks guys for the help, If someone is having the same problem I had, this forum is perfect, it has a lot of informations on other posts too that can be added. Other thing is taht I'm printing PLA at 210°C, 120mm/min, 60mm/s perimeters and infill. One thing that I notice that is important is the retraction, it help prevent the filament to jam. It retracts 2mm each layer change.

I printed a filament oiler too, that you put a sponge and canoil oil inside. I thing this helps a lot too with you are using PLA. Other thing is that I thing the material I'm using is no that good, I found that this changes a lot the behavior of the printer too.

Here some pictures of my printer extruder and some parts I manage to print. Thanks guys for the help, If someone is having the same problem I had, this forum is perfect, it has a lot of informations on other posts too that can be added. Other thing is taht I'm printing PLA at 210°C, 120mm/min, 60mm/s perimeters and infill. One thing that I notice that is important is the retraction, it help prevent the filament to jam. It retracts 2mm each layer change.

|

Re: Prusa i3 - stuck filament October 30, 2014 03:53PM |

Registered: 9 years ago Posts: 2 |

Hello, corceling

We have the same printers that chapter and I had the same problem.

Will continue to have this problem even fusion that change.

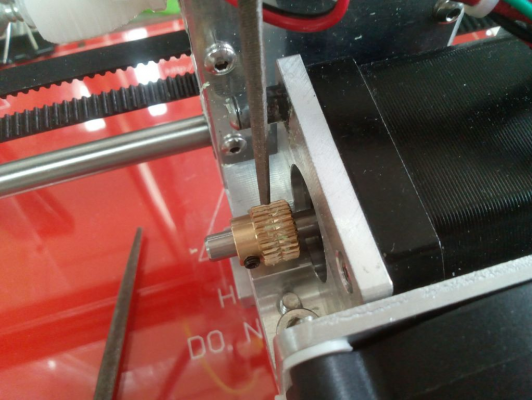

The real problem comes from the Brass Extruder Gear which is this>

This gear is not designed for Extruder. And instead must submit such material as it slides instead of 100 mm and it gives only 30 mm ..

Nothing to do with the heat and the other crap out there.

But there is another way to improve your gear. Sawing as mild depression. At the moment I have no photos but will do tomorrow and I'll get to look at how I did it.

Here are some photos of the gear corrected.

with round and sharpened Metal Filing Files I fixed gear . so I can filing correct use program for printer and typed to 200 mm extrude .

First with the tip Metal Filing Files and then lightly round. Then have each member of the unit must be sang with acute Metal Filing Files

Edited 1 time(s). Last edit at 10/31/2014 04:34AM by ddart.

We have the same printers that chapter and I had the same problem.

Will continue to have this problem even fusion that change.

The real problem comes from the Brass Extruder Gear which is this>

This gear is not designed for Extruder. And instead must submit such material as it slides instead of 100 mm and it gives only 30 mm ..

Nothing to do with the heat and the other crap out there.

But there is another way to improve your gear. Sawing as mild depression. At the moment I have no photos but will do tomorrow and I'll get to look at how I did it.

Here are some photos of the gear corrected.

with round and sharpened Metal Filing Files I fixed gear . so I can filing correct use program for printer and typed to 200 mm extrude .

First with the tip Metal Filing Files and then lightly round. Then have each member of the unit must be sang with acute Metal Filing Files

Edited 1 time(s). Last edit at 10/31/2014 04:34AM by ddart.

|

Re: Prusa i3 - stuck filament November 30, 2014 09:58AM |

Registered: 9 years ago Posts: 1 |

Hello, I've the same problem. The filament get stuck and I have to remove it. After two or three printings it get stuck again. I have a white pipe, I don't know if it is teflon, but I think its PVC. I don't know the outside diameter but the 3mm filament passes but it doesn't have to much room. What shall I do? Best. António

|

Re: Prusa i3 - stuck filament November 30, 2014 10:14AM |

Registered: 9 years ago Posts: 2 |

|

Re: Prusa i3 - stuck filament December 09, 2014 10:22AM |

Registered: 9 years ago Posts: 4 |

|

Re: Prusa i3 - stuck filament December 16, 2014 01:19AM |

Registered: 10 years ago Posts: 20 |

agventu, just like the OP your issue sounds like heat creep. You don't have a fan blowing on the heat-break (the stainless steel threaded tube), do you? If I try to print without my fan running (on my Prusa i3), I get a jam within the first layer or two every time! With the fan running, I've pushed out 2+ hour prints with no issues.

Like 3dkarma suggested, look into getting an E3D heat-sink for your hot-end. Works like a charm for me

Like 3dkarma suggested, look into getting an E3D heat-sink for your hot-end. Works like a charm for me

|

Re: Prusa i3 - stuck filament December 16, 2014 08:27AM |

Registered: 9 years ago Posts: 4 |

Sorry, only registered users may post in this forum.