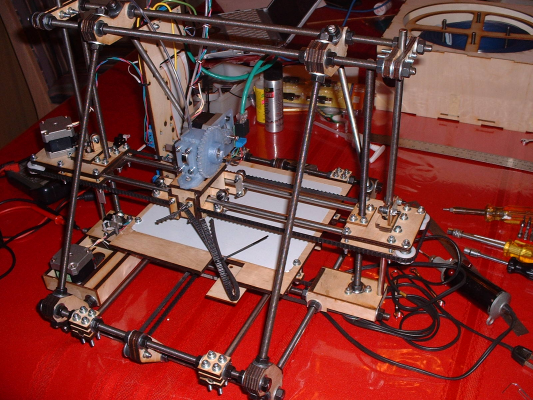

LaserCut Mendel by Tech Zone Remix

Posted by SebastienBailard

Re: LaserCut Mendel by Tech Zone Remix  March 06, 2011 09:31PM |

brnrd - So you're using a Mac eh? Are you running on Snow Leopard?

Thanks for the pointers, why are you not using repsnapper to convert to gcode? Also, can you send me your settings file for repsnapper?

EtherDais:

Thanks very much for sending the repsnapper xml file, I'll try and use some of your settings and see if it helps.

In reply to your questions:

1) z axis appears to move normally when I jog it. It doesn't seem to be a problem from what I can see. What do you mean by how freely does it move?

2) Will try changing the z axis travel speed. What do you mean by "step z heights"?

3) Yes, I have tried generating gcode for quite a few different parts from the thingverse. I can't tell if it's fine or not as I've not actually had a successful print. Although I did compare the gcode generated on repsnapper with gcode generated with replicatorG. The one from replicatorG seems to be much longer, a whole lot more gcode. Not too sure why but I'm guessing again it's something to do with the settings.

Thanks for the pointers, why are you not using repsnapper to convert to gcode? Also, can you send me your settings file for repsnapper?

EtherDais:

Thanks very much for sending the repsnapper xml file, I'll try and use some of your settings and see if it helps.

In reply to your questions:

1) z axis appears to move normally when I jog it. It doesn't seem to be a problem from what I can see. What do you mean by how freely does it move?

2) Will try changing the z axis travel speed. What do you mean by "step z heights"?

3) Yes, I have tried generating gcode for quite a few different parts from the thingverse. I can't tell if it's fine or not as I've not actually had a successful print. Although I did compare the gcode generated on repsnapper with gcode generated with replicatorG. The one from replicatorG seems to be much longer, a whole lot more gcode. Not too sure why but I'm guessing again it's something to do with the settings.

|

Stepper Motor for extruder March 07, 2011 04:12AM |

I'm having problems with my extruder. The stepper motor slips when I run it resulting in it's inability to push out the melted (ABS) filament.

I'm not sure if this is because there's something wrong with the motor. Is it supposed to "slip" so easily? Anyone have any problems with their stepper motors?

I'm not sure if this is because there's something wrong with the motor. Is it supposed to "slip" so easily? Anyone have any problems with their stepper motors?

|

Re: Help needed for Techzone Laser Cut Mendel March 07, 2011 04:24AM |

EtherDais: I used your xml file and noticed that my settings are very similar to yours, only a difference in the temperature setting. By the way, I assume this temperature setting is in degrees centigrade.

When I hit the print button, I'm still facing the problem of prints running for a few seconds, and then pausing. It will only start printing again when I hit the "pause" button again. Any idea what's the reason for this? It seems to be running a few lines of gcode at a time instead of printing the whole file.

When I hit the print button, I'm still facing the problem of prints running for a few seconds, and then pausing. It will only start printing again when I hit the "pause" button again. Any idea what's the reason for this? It seems to be running a few lines of gcode at a time instead of printing the whole file.

Re: LaserCut Mendel by Tech Zone Remix  March 07, 2011 07:49AM |

Registered: 13 years ago Posts: 1,780 |

I'm on Leopard. The compiled repsnapper that I got doesn't do retract/restart well for ooze control and it also is not as good as Skeinforge in generating g-code.

When printing, turn off termperature update in the Interactive control panel in the Print tab. Then go into the communications log, errors/warning and monitor the errors. Are you getting a lot of checksum errors? If so, try plugging your pc and the mendel electronics on the same power strip if they're not. And try running a ground wire between the motherboard and extruder controller.

When printing, turn off termperature update in the Interactive control panel in the Print tab. Then go into the communications log, errors/warning and monitor the errors. Are you getting a lot of checksum errors? If so, try plugging your pc and the mendel electronics on the same power strip if they're not. And try running a ground wire between the motherboard and extruder controller.

Re: LaserCut Mendel by Tech Zone Remix  March 07, 2011 09:09AM |

Brnrd, thanks for your reply. I've added the ground wire between the motherboard and extruder controller. It does seem to be helping a little bit, the printer runs for slightly longer before pausing (and needing to be "kicked" before resuming). But it's still far from ideal where i expect to just hit run, and have it print all the way to completion.

Will try turning off temperature update and also monitoring for checksum errors. Both the mendel and PC are plugged into the same powerstrip (along with some other devices....would that cause problems?)

Would it be possible for you to send over your repsnapper.xml configuration file?

I also checked/compared gcode files generated by replicatorG and repsnapper from an identical stl file. The replicatorG version has about 5x more code. What's the deal with that?

lastly, is there any way to increase the torque on the stepper extruder motor? Mine keeps slipping and seems to be extremely week. Is there a way to adjust this?

Will try turning off temperature update and also monitoring for checksum errors. Both the mendel and PC are plugged into the same powerstrip (along with some other devices....would that cause problems?)

Would it be possible for you to send over your repsnapper.xml configuration file?

I also checked/compared gcode files generated by replicatorG and repsnapper from an identical stl file. The replicatorG version has about 5x more code. What's the deal with that?

lastly, is there any way to increase the torque on the stepper extruder motor? Mine keeps slipping and seems to be extremely week. Is there a way to adjust this?

Re: LaserCut Mendel by Tech Zone Remix  March 07, 2011 10:06AM |

Registered: 13 years ago Posts: 1,780 |

Re: LaserCut Mendel by Tech Zone Remix  March 07, 2011 10:37AM |

Re: LaserCut Mendel by Tech Zone Remix  March 07, 2011 08:27PM |

Registered: 13 years ago Posts: 1,780 |

I only use repsnapper to send g-code files to the printer. For that, you don't need to tweak the settings file in repsnapper.

In skeinforge, you have to turn on the Dimensions option to use a stepper motor extruder. If this option if off, your g-codes won't include E codes. You should also set the retract/restart to about 1 mm of feed and 0 mm, respectively. In the skeinforge before 040, you would enter around 36 mm since it is specified in extruded filament length. In 040, just enter 1 mm since it is now specified in mm of feed.

In skeinforge, you have to turn on the Dimensions option to use a stepper motor extruder. If this option if off, your g-codes won't include E codes. You should also set the retract/restart to about 1 mm of feed and 0 mm, respectively. In the skeinforge before 040, you would enter around 36 mm since it is specified in extruded filament length. In 040, just enter 1 mm since it is now specified in mm of feed.

Re: LaserCut Mendel by Tech Zone Remix  March 08, 2011 04:03PM |

Registered: 13 years ago Posts: 27 |

Extruder Controller Question:

I'm to the point that my Mendel homes out and is calibrated.

Now I want to turn on the extruder to melt some plastic. I have the TechZone Gen 3 electronics.

Do I or Don't I need to upload firmware to the extruder controller. And if so, what file?

I'm using RepSnapper. I can connect to the printer, home it out, move it however I want and it works great. I can run the extruder motor and reverse it. I click "Switch Heat On" and I get nothing heating up, no matter how long I wait. The current temp reads 0, so that tells me something isn't configured/wired correctly. I measured voltage at the nichrome wire connections and get 0V, so it must not be getting a signal. I've switched the leads on the thermocouple and nothing changes.

I'm to the point that my Mendel homes out and is calibrated.

Now I want to turn on the extruder to melt some plastic. I have the TechZone Gen 3 electronics.

Do I or Don't I need to upload firmware to the extruder controller. And if so, what file?

I'm using RepSnapper. I can connect to the printer, home it out, move it however I want and it works great. I can run the extruder motor and reverse it. I click "Switch Heat On" and I get nothing heating up, no matter how long I wait. The current temp reads 0, so that tells me something isn't configured/wired correctly. I measured voltage at the nichrome wire connections and get 0V, so it must not be getting a signal. I've switched the leads on the thermocouple and nothing changes.

Re: LaserCut Mendel by Tech Zone Remix  March 08, 2011 08:15PM |

Registered: 13 years ago Posts: 1,780 |

According to an e-mail that I received a few weeks ago from Lambert, that the extruder controller comes preloaded with Techzone's firmware that uses their thermocouple A-D board. I think you need to load the firmware to the extruder controller to use the thermistor. Make sure that you select the right table in the temperature.h file.

Re: LaserCut Mendel by Tech Zone Remix  March 08, 2011 10:31PM |

Registered: 13 years ago Posts: 27 |

Re: LaserCut Mendel by Tech Zone Remix  March 08, 2011 10:59PM |

Registered: 13 years ago Posts: 1,780 |

Please read my forum message here. There's a bug in the techzone firmware that can either burn up your tip and emit lots of fumes or maybe even cause a fire. This will happen if the temperature reading goes above 255 C.

I have a modified firmware based on the reprap 20100719 firmware that includes support for a heated bed with a thermistor. I encountered the bug today while calibrating the thermocouple reading and fixed it. You can download the code in the link.

But, I don't understand why you're not getting a reading. The only time that you will get a reading of 0 with that firmware is if your extruder controller doesn't have power. I suppose it would also happen if you didn't connect the RS485 wires correctly. If the AD board is plugged in correctly, but the thermocouple is not, then you would get a reading of 2000. This shuts the heater off to avoid a disaster.

I have a modified firmware based on the reprap 20100719 firmware that includes support for a heated bed with a thermistor. I encountered the bug today while calibrating the thermocouple reading and fixed it. You can download the code in the link.

But, I don't understand why you're not getting a reading. The only time that you will get a reading of 0 with that firmware is if your extruder controller doesn't have power. I suppose it would also happen if you didn't connect the RS485 wires correctly. If the AD board is plugged in correctly, but the thermocouple is not, then you would get a reading of 2000. This shuts the heater off to avoid a disaster.

Re: LaserCut Mendel by Tech Zone Remix  March 11, 2011 12:44AM |

Registered: 13 years ago Posts: 27 |

SUCCESS!

I printed my first part tonight! My extruder not heating up was a wiring issue. I didn't have the RS485 cable in the right position and orientation on the motherboard. While my first part isn't perfect, it's progress. Now it's on to tweaking the settings in RepSnapper to produce better parts.

Thanks everyone for your support and help along the way.

I haven't given a plug for TechZone, but Lambert at TechZone has been VERY helpful through this whole build.

Tom

I printed my first part tonight! My extruder not heating up was a wiring issue. I didn't have the RS485 cable in the right position and orientation on the motherboard. While my first part isn't perfect, it's progress. Now it's on to tweaking the settings in RepSnapper to produce better parts.

Thanks everyone for your support and help along the way.

I haven't given a plug for TechZone, but Lambert at TechZone has been VERY helpful through this whole build.

Tom

|

Re: Stepper Motor for extruder March 11, 2011 01:00AM |

Registered: 13 years ago Posts: 15 |

Re: LaserCut Mendel by Tech Zone Remix  March 13, 2011 09:02PM |

Registered: 13 years ago Posts: 27 |

OK - as some wise people on this board predicted, eventually the oak block insulator part of the wade's extruder design from TechZone will burn up. It happened. I'll spare the rest of the problems I ran into making another one.

So, this made me look at some of the alternative designs, and question, why wouldn't the following design work?

- 5/8" Diameter x 1 1/2" Long PTFE/PEEK Rod, crossdrilled in 2 plcs at the top to connect to the extruder base (like the "tip adapter" does now)

- Drill 7/64" thru for the filament to go through

- Drill and tap the bottom 1/4-28 UNF x 1/2" Deep for brass nozzle to thread into

(Of course you could do the above in equivalent metric units)

Since PTFE/PEEK can handle 250 degrees C and are insulators, this would eliminate the oak block altogether.

Does the oak block provide rigidity?

I'm really new to this and naive, so please help me see my wayward ways.

Tom

So, this made me look at some of the alternative designs, and question, why wouldn't the following design work?

- 5/8" Diameter x 1 1/2" Long PTFE/PEEK Rod, crossdrilled in 2 plcs at the top to connect to the extruder base (like the "tip adapter" does now)

- Drill 7/64" thru for the filament to go through

- Drill and tap the bottom 1/4-28 UNF x 1/2" Deep for brass nozzle to thread into

(Of course you could do the above in equivalent metric units)

Since PTFE/PEEK can handle 250 degrees C and are insulators, this would eliminate the oak block altogether.

Does the oak block provide rigidity?

I'm really new to this and naive, so please help me see my wayward ways.

Tom

Re: LaserCut Mendel by Tech Zone Remix  March 13, 2011 10:20PM |

Registered: 13 years ago Posts: 27 |

A little more searching just proved my naivety. It looks like what I described is exactly what the original Adrian extruder uses.

Does anyone have experience with this? What are the drawbacks?

I'm just not seeing the advantages of the extra parts (and the oak block especially). Some of the other variations on the Wiki, look much like the oak block, although they use different materials.

Anyways, I ordered a 5/8" diameter PTFE rod that I'm going to experiment with.

Again - anyway that knows I'm about to run off the edge of the cliff, please let me know before I burn my house down!

Tom

Does anyone have experience with this? What are the drawbacks?

I'm just not seeing the advantages of the extra parts (and the oak block especially). Some of the other variations on the Wiki, look much like the oak block, although they use different materials.

Anyways, I ordered a 5/8" diameter PTFE rod that I'm going to experiment with.

Again - anyway that knows I'm about to run off the edge of the cliff, please let me know before I burn my house down!

Tom

Re: LaserCut Mendel by Tech Zone Remix  March 14, 2011 01:18AM |

Registered: 13 years ago Posts: 24 |

My TechZone Huxley kit shipped with a PTFE cylinder instead of the oak block. TechZone doesn't have the PTFE block listed on their order site at the moment. But, they may be able to give you more info about it. There is also a printed part that holds the cylinder into the x carriage.

I'm still putting my machine together and I haven't tested the hot end yet. But, the construction specs sound similar to what you described.

I'm still putting my machine together and I haven't tested the hot end yet. But, the construction specs sound similar to what you described.

|

Re: LaserCut Mendel by Tech Zone March 14, 2011 03:30PM |

Registered: 13 years ago Posts: 15 |

Hi I have a Techzone Laser cut Mendel and I am having problems with it recognizing the reprap software. I can open it but nothing moves or works. I believe that it has the wrong reprap.bat file . If anybody out there has a techzone Mendel with gen3 boards and is using Windows XP please send me a copy of your reprap.bat file. Or share how you got yours going.

The instructions are there, you have to hunt for them, for assembling the machine. I found a few pictures, and with trial and error I managed to get it assembled. All the mendels I have seen have 2 or 4 threaded rods going through the Z axis boxes, mine only has one.

I wonder if Windows XP will run this Mendel or if I should be looking to run it on Linux.

I can run the motors and extrude in Repsnapper but I cannot make it print anything,

|

Re: LaserCut Mendel by Tech Zone March 14, 2011 03:49PM |

Registered: 13 years ago Posts: 27 |

Ulrich,

I have the exact same setup as you have from Techzone, although I am running Windows 7. I've had problems with the Reprap software working intermittently and then hanging up. I switched to RepSnapper and didn't have any problems.

The one pc I have with Windows XP won't work with either software. When I have RepRap or RepSnapper up and plug in the USB cable, it gives me the blue screen of death. I think it's the USB to serial converter driver, but haven't found one that works.

Do you have a pc with Windows 7 that you could try just to see if it's XP or something else wrong?

Tom

I have the exact same setup as you have from Techzone, although I am running Windows 7. I've had problems with the Reprap software working intermittently and then hanging up. I switched to RepSnapper and didn't have any problems.

The one pc I have with Windows XP won't work with either software. When I have RepRap or RepSnapper up and plug in the USB cable, it gives me the blue screen of death. I think it's the USB to serial converter driver, but haven't found one that works.

Do you have a pc with Windows 7 that you could try just to see if it's XP or something else wrong?

Tom

|

Re: LaserCut Mendel by Tech Zone March 14, 2011 07:23PM |

Registered: 13 years ago Posts: 49 |

If the USB-serial cable uses the FTDI chip (I think it does), and it uses the stock FTDI driver, and you're not using the latest one, try it. FTDI just fixed a BSOD bug in the driver in last month that was affecting us at work -- we use their 4-serial-port chip, but I'm pretty sure the driver fix affected both.

|

Re: LaserCut Mendel by Tech Zone March 15, 2011 12:57AM |

Registered: 13 years ago Posts: 27 |

Thanks PatBob,

That seemed to work for my BSOD problem. I had updated the driver about 1-2 days before this last release came out and it didn't work. You're right, this one specifically targeted the BSOD problem. Now I can use my Windows XP machine which I intended to all along. The RepRap software is still hanging, but I'll figure that out later. RepSnapper is now working fine.

That seemed to work for my BSOD problem. I had updated the driver about 1-2 days before this last release came out and it didn't work. You're right, this one specifically targeted the BSOD problem. Now I can use my Windows XP machine which I intended to all along. The RepRap software is still hanging, but I'll figure that out later. RepSnapper is now working fine.

|

Re: LaserCut Mendel by Tech Zone March 15, 2011 02:04AM |

Registered: 13 years ago Posts: 15 |

When I use repsnapper I can home and move all the axis, I can heat the extruder and extrude plastic, the heater is very finiky some times it shows that the temp is 2000 and the heater will not turn on. Every time I open repsnapper I have to tell it to use COM4 and turn it on it does not seem to read the mother board or the extruder board but rather sends right through them. I tried to load a file but I could not make it print. It doesn't seem to know where it is ,maybe it just me , I'm not the sharpest knife in the drawer. This program is not user freindly and were are the help files?

|

Re: LaserCut Mendel by Tech Zone March 15, 2011 07:53AM |

Registered: 13 years ago Posts: 27 |

A couple of things:

- When the extruder reads 2000, typically it's because the wiring isn't right. Maybe you have a short. Double-check the connections and continuity. If you unplug the "one-wire" (ethernet cable) you'll get that 2000 reading every time, it's a safety feature because it's not reading the thermocouple. Did you check continuity across the 2 wires on your thermocouple? If there is some resistance there, that could be causing the problem. It's a known problem with the thermocouple wires.

- As far as the software goes, you need to change the repsnapper.xml file to: m_sPortName="COM4". Make sure it resides in the same directory the repsnapper applicatoin does.

- When the extruder reads 2000, typically it's because the wiring isn't right. Maybe you have a short. Double-check the connections and continuity. If you unplug the "one-wire" (ethernet cable) you'll get that 2000 reading every time, it's a safety feature because it's not reading the thermocouple. Did you check continuity across the 2 wires on your thermocouple? If there is some resistance there, that could be causing the problem. It's a known problem with the thermocouple wires.

- As far as the software goes, you need to change the repsnapper.xml file to: m_sPortName="COM4". Make sure it resides in the same directory the repsnapper applicatoin does.

|

Re: LaserCut Mendel by Tech Zone March 15, 2011 10:46AM |

Registered: 13 years ago Posts: 1,780 |

Note that unless you fixed the bug in the firmware, your extruder will overheat if your temperature ever goes above 255 C. I have a message in the firmware forum on this and how to fix it.

I haven't tested this but I think if you search in extruder_class.pde for "tmpRead=readDS2760(useWire)" and replace tmpRead with tempC, then it would fix the bug. The problem is that tmpRead is a byte so anything above 255 wraps back to 0, 1, 2, ... and turns the heat to on 100% of the time.

Edited 1 time(s). Last edit at 03/15/2011 11:13AM by brnrd.

I haven't tested this but I think if you search in extruder_class.pde for "tmpRead=readDS2760(useWire)" and replace tmpRead with tempC, then it would fix the bug. The problem is that tmpRead is a byte so anything above 255 wraps back to 0, 1, 2, ... and turns the heat to on 100% of the time.

Edited 1 time(s). Last edit at 03/15/2011 11:13AM by brnrd.

|

Re: LaserCut Mendel by Tech Zone March 16, 2011 01:34PM |

Registered: 13 years ago Posts: 41 |

While we're talking about strange temperature readings, I thought i'd describe a problem i'm fighting that I haven't found discussed anywhere else.

So, i've got a printed mendel, with Gen 3 Techzone electronics, printed using a similar electrical setup (Gen3, etc.) on a TZ Wooden Mendel. The new printed mendel is working great (motors driving, etc), with the exception of misbehavior on the part of the heater tip. It reads temperatures from the type K thermocouple used in the wooden one sitting next to it. It heats very responsively. I typically start out new tips by heating to a relatively low temp (say, 100C), in doing this, I realized that this tip will regularly underheat the tip by 20 degrees C. So If I ask it to heat to 140C, it will hover around 120C, 120C yields 100C, etc. This is of course, unless I ask it to heat to 150C or greater, in which case it starts to overdrive the heater and go into 'thermal overrun' mode, as brnrd has been so gracious as to describe and fix. The temperatures are still being read fairly consistantly in this time (in the 150-250C range), with an intermittant 2000C somewhere in this overheating process.

But wait, it gets better. IF i take that tip assembly (including the A-D converter) and plug in the Cat5 from the Wooden Mendel's extruder electronics, that can heat and regulate the tip without any issues at all. The code on both sets of Gen3 electronics is the same, aside from changes in terms of the opto flag states, and steps/mm, with no difference in the extruder code or the temp readout code. So it would seem that the wiring of the tip itself is fine, and the thermocouples are not obviously borked. I've Checked the Cat5 on the new printed mendel and it is properly wired, with no shorts or crossovers.

I'd love to hear if anyone has any suggestions. It's painfully on the cusp of behaving properly (as it does read temperature and heat, and the cartesian bot is solid). I don't know why a change in firmware would be required when the system is so similar, but I'd be willing to try one. I can't seem to trace down any physically significant difference between the two, yet clearly something is amiss.

So, i've got a printed mendel, with Gen 3 Techzone electronics, printed using a similar electrical setup (Gen3, etc.) on a TZ Wooden Mendel. The new printed mendel is working great (motors driving, etc), with the exception of misbehavior on the part of the heater tip. It reads temperatures from the type K thermocouple used in the wooden one sitting next to it. It heats very responsively. I typically start out new tips by heating to a relatively low temp (say, 100C), in doing this, I realized that this tip will regularly underheat the tip by 20 degrees C. So If I ask it to heat to 140C, it will hover around 120C, 120C yields 100C, etc. This is of course, unless I ask it to heat to 150C or greater, in which case it starts to overdrive the heater and go into 'thermal overrun' mode, as brnrd has been so gracious as to describe and fix. The temperatures are still being read fairly consistantly in this time (in the 150-250C range), with an intermittant 2000C somewhere in this overheating process.

But wait, it gets better. IF i take that tip assembly (including the A-D converter) and plug in the Cat5 from the Wooden Mendel's extruder electronics, that can heat and regulate the tip without any issues at all. The code on both sets of Gen3 electronics is the same, aside from changes in terms of the opto flag states, and steps/mm, with no difference in the extruder code or the temp readout code. So it would seem that the wiring of the tip itself is fine, and the thermocouples are not obviously borked. I've Checked the Cat5 on the new printed mendel and it is properly wired, with no shorts or crossovers.

I'd love to hear if anyone has any suggestions. It's painfully on the cusp of behaving properly (as it does read temperature and heat, and the cartesian bot is solid). I don't know why a change in firmware would be required when the system is so similar, but I'd be willing to try one. I can't seem to trace down any physically significant difference between the two, yet clearly something is amiss.

|

Re: LaserCut Mendel by Tech Zone March 16, 2011 11:10PM |

Registered: 13 years ago Posts: 15 |

I think that Reprap software uses "C" and Repsnapper uses "F" during experimenting I managed to overheat my Oak block. When I tried to print in Repsnapper the g code I was using was in "C" my tip cooled off and the extruder pushed the brass barrel right out of the oak block. I managed to reverse the oak block and reattach the heater wires,no easy task.

I am still tring to find the "reprap.bat" file for the Reprap software that will work with Windows XP, I think it may be more user freindly than Repsnapper.

So always check your g-code for temp "C" or "F".

I am still tring to find the "reprap.bat" file for the Reprap software that will work with Windows XP, I think it may be more user freindly than Repsnapper.

So always check your g-code for temp "C" or "F".

|

Re: LaserCut Mendel by Tech Zone March 16, 2011 11:26PM |

Registered: 13 years ago Posts: 1,780 |

No offense to Adrian Bowyer but I think RepSnapper is more user-friendly than the Reprap host.

I'm not aware of any options in the G-codes supported by the reprap host firmware to set the termperature units to F instead of C. You may have encountered the bug that I mentioned if you're using the thermocouple AD.

I'm not aware of any options in the G-codes supported by the reprap host firmware to set the termperature units to F instead of C. You may have encountered the bug that I mentioned if you're using the thermocouple AD.

|

Re: LaserCut Mendel by Tech Zone March 18, 2011 04:07PM |

Registered: 13 years ago Posts: 16 |

@EtherDais i do think you are having comparator issues, are you sure you have the offsets on the setting set to the same values? also, i would check your voltage from the regulator, no two are exactly the same, so maybe the voltage of the two differ slightly, i would first get a multimeter and start probing.

|

Re: LaserCut Mendel by Tech Zone March 18, 2011 07:02PM |

Registered: 13 years ago Posts: 15 |

I have played around tring to make Repsnapper work, the default heat setting when I start the program is 200 "C" or "F" ???

I have to set it to about 230 and when the temp comes up it shows about 209- 215 then the extruder seems to work ok , If it drops to 190 the stepper stalls.

I hooked a light to the heater becauce sometimes I have to turn it on 2 or 3 times before it will come back on. Then it sometimes shows 0 and the tip is overheating, sometimes it shows 2000 and nothing happens. I have checked the thermo coupler and heater for opens and shorts and it checks out OK. I still would like to get Reprap software to work in windows XP. Is there anybody out there that is using Reprap software on Windows XP??? There seems to be more information on Reprap and help files.

I have to set it to about 230 and when the temp comes up it shows about 209- 215 then the extruder seems to work ok , If it drops to 190 the stepper stalls.

I hooked a light to the heater becauce sometimes I have to turn it on 2 or 3 times before it will come back on. Then it sometimes shows 0 and the tip is overheating, sometimes it shows 2000 and nothing happens. I have checked the thermo coupler and heater for opens and shorts and it checks out OK. I still would like to get Reprap software to work in windows XP. Is there anybody out there that is using Reprap software on Windows XP??? There seems to be more information on Reprap and help files.

|

Re: LaserCut Mendel by Tech Zone Remix March 18, 2011 08:18PM |

Sorry, only registered users may post in this forum.