LaserCut Mendel by Tech Zone Remix

Posted by SebastienBailard

|

Re: LaserCut Mendel by Tech Zone Remix March 18, 2011 08:57PM |

Registered: 13 years ago Posts: 15 |

HI Nate I'll try again I wrote it all out and clicked preview and poof it dissappeared,

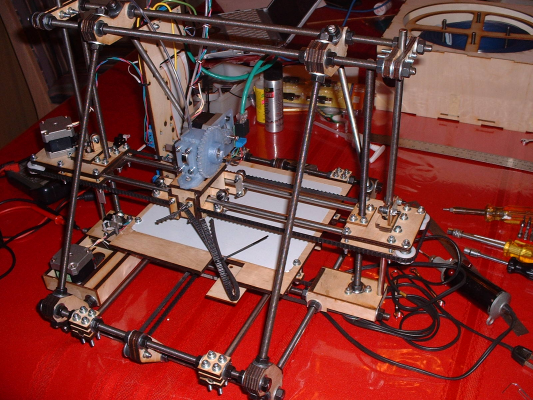

I use a single idler in the outside , farthest to the left on the plywood box for the z screw and I machined Plastic shell to go over the bearings rather than the large washer . You can just see the bolt head under the Z axis opto stop. You can see the plastic shells better on the right side of the X axis. If you still have problems let me know and I will take a picture of the underside for you.

|

Re: LaserCut Mendel by Tech Zone Remix March 18, 2011 09:29PM |

Ulrich-

If you could post a picture that would be nice. I'm a little disappointed in techzone. I sent two emails about this over the last week. I got one response saying they would send me pictures a couple of days ago.

People seem to have good things to say about the company but I'm not getting a particularly warm feeling about them or the kit they sold me... It not really a kit more of a bunch of parts that should need minimal modification to turn into a 3D printer...

Cheers,

NATE

If you could post a picture that would be nice. I'm a little disappointed in techzone. I sent two emails about this over the last week. I got one response saying they would send me pictures a couple of days ago.

People seem to have good things to say about the company but I'm not getting a particularly warm feeling about them or the kit they sold me... It not really a kit more of a bunch of parts that should need minimal modification to turn into a 3D printer...

Cheers,

NATE

|

Re: LaserCut Mendel by Tech Zone Remix March 19, 2011 02:45AM |

Registered: 13 years ago Posts: 15 |

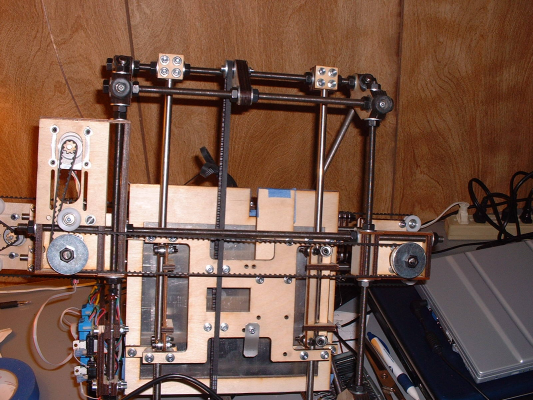

Hi Nate, Here is a picture of the bottom of my mendel hope it helps.

Ulrich

Ulrich

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 04:03AM |

Admin Registered: 17 years ago Posts: 7,879 |

The reprap host worked on XP last time I tried it (several years ago). What problem did you have running it?

Edited 1 time(s). Last edit at 03/19/2011 04:04AM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 03/19/2011 04:04AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 12:34PM |

Registered: 13 years ago Posts: 15 |

I can Open the Reprap Host with my windows XP I set the COM port to 4 , thats what it showed in device manager. I think that the Reprap.bat file is not right and I don't know how to fix it. here is a copy of my reprap.bat file: If you can help that would be very much appreciated.

Ulrich Glimm

.

rem reprap-host -- runs Reprap Java host code with an appropriate classpath

rem Amount of RAM to allow Java VM to use

set REPRAP_RAM_SIZE=1024M

rem reprap.jar file and stl file

set REPRAP_DIR=%ProgramFiles%\Reprap

rem Java3D and j3d.org libraries

rem set JAVA_LIBRARY_DIR=%ProgramFiles%\Reprap

rem cd so we can find the reprap-wv.stl file. Can we avoid this??

IF NOT EXIST reprap-wv.stl cd "%REPRAP_DIR%"

java -cp ".\reprap.jar;.\RXTXcomm.jar;.\j3dcore.jar;.\j3d-org-java3d-all.jar;.\j3dutils.jar;.\swing-layout-1.0.3.jar;.\vecmath.jar;." -Xmx%REPRAP_RAM_SIZE% org/reprap/Main

if ERRORLEVEL 1 pause

Ulrich Glimm

.

rem reprap-host -- runs Reprap Java host code with an appropriate classpath

rem Amount of RAM to allow Java VM to use

set REPRAP_RAM_SIZE=1024M

rem reprap.jar file and stl file

set REPRAP_DIR=%ProgramFiles%\Reprap

rem Java3D and j3d.org libraries

rem set JAVA_LIBRARY_DIR=%ProgramFiles%\Reprap

rem cd so we can find the reprap-wv.stl file. Can we avoid this??

IF NOT EXIST reprap-wv.stl cd "%REPRAP_DIR%"

java -cp ".\reprap.jar;.\RXTXcomm.jar;.\j3dcore.jar;.\j3d-org-java3d-all.jar;.\j3dutils.jar;.\swing-layout-1.0.3.jar;.\vecmath.jar;." -Xmx%REPRAP_RAM_SIZE% org/reprap/Main

if ERRORLEVEL 1 pause

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 01:53PM |

Admin Registered: 17 years ago Posts: 7,879 |

That is the same as the reprap.bat on my XP system and running it launches my old copy of the host. Why do you think it is wrong?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 02:23PM |

Registered: 13 years ago Posts: 15 |

It launches the host software,but it will not connect to my mendel,nothing moves, no heat, I think maybe that it is not reading the firmware on my Reprap mother board or extruder board. I have Gen 3. from Techzone laser cut Mendel kit.

I can run Repsnapper and it homes everything moves as it should, but I have trouble tring to understand the print setup in repsnapper.I think there is more help with the Reprap host software, thats why I want to try it.

I can run Repsnapper and it homes everything moves as it should, but I have trouble tring to understand the print setup in repsnapper.I think there is more help with the Reprap host software, thats why I want to try it.

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 02:40PM |

Admin Registered: 17 years ago Posts: 7,879 |

If it launches the java software then its job is done and it is working so the problem doesn't lie in the batch file.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 02:52PM |

Registered: 13 years ago Posts: 15 |

|

Re: LaserCut Mendel by Tech Zone March 19, 2011 02:56PM |

Registered: 13 years ago Posts: 1,780 |

The firmware that came with the electronics might not be compatible with the reprap host. Have you tried loading the firmware that came with the reprap host? But if you're using their thermocouple A-D board on your extruder, then the reprap host won't support that. If you use the 20100719 release, then I have posted a firmware that works with the thermocouple in this forum.

|

nmorriss

Re: LaserCut Mendel by Tech Zone Remix March 19, 2011 03:07PM |

Re: LaserCut Mendel by Tech Zone Remix  March 19, 2011 03:39PM |

Registered: 13 years ago Posts: 27 |

Update and a couple of questions. I got passed my BSOD problem with the USB port on the Windows XP machine. Updating the FTDI driver makes it work great.

I've gone through a few charred wooden blocks and extruder modifications, and now trying to print again. I'm trying to print the 40mm cube so I can measure and make calibration adjustments. When it lays down the first layer and goes to the second layer, the nozzle is running over the first layer and peeling it up. Is this a sign I'm putting too much plastic down, my Z home position is off, or Z axis steps are off?

Anyone else with Gen 3 electronics from TechZone. What settings are you using for:

- Z Home height from top of bed. I started with 2 pieces of paper between the nozzle tip and bed

- Extruder steps/mm in Configuration.h

- Z steps/mm in Configuration.h

Once I get an extruder design that works well, I'll post it here. The wooden block idea just doesn't last, and I'm tired of taking my extruder on and off my Mendel!

I've gone through a few charred wooden blocks and extruder modifications, and now trying to print again. I'm trying to print the 40mm cube so I can measure and make calibration adjustments. When it lays down the first layer and goes to the second layer, the nozzle is running over the first layer and peeling it up. Is this a sign I'm putting too much plastic down, my Z home position is off, or Z axis steps are off?

Anyone else with Gen 3 electronics from TechZone. What settings are you using for:

- Z Home height from top of bed. I started with 2 pieces of paper between the nozzle tip and bed

- Extruder steps/mm in Configuration.h

- Z steps/mm in Configuration.h

Once I get an extruder design that works well, I'll post it here. The wooden block idea just doesn't last, and I'm tired of taking my extruder on and off my Mendel!

Re: LaserCut Mendel by Tech Zone Remix  March 20, 2011 05:25PM |

Registered: 13 years ago Posts: 41 |

>>Anyone else with Gen 3 electronics from TechZone. What settings are you using for:

- Z Home height from top of bed. I started with 2 pieces of paper between the nozzle tip and bed

I haven't measured a home height explicitly, but I would guess that it's about .3-.4 mm. I find that it's fairly easy to tweak this by hand if you don't quite have it correct(as the z-axis isn't powered), and this will give you some idea about how you'll need to bump your zero around. If there is an explicit setting (i wasn't aware), then it's probably 0, with physical adjustments to the optoswitches for fine tuning.

- Extruder steps/mm in Configuration.h and Z steps/mm in Configuration.h

values depend on the Stepper motors you're using. If you have 0.9 degree motors rather than 1.8 degree, you'll need to double these values from what is generally passed around as techzone firmware.

Edited 1 time(s). Last edit at 03/20/2011 05:26PM by EtherDais.

- Z Home height from top of bed. I started with 2 pieces of paper between the nozzle tip and bed

I haven't measured a home height explicitly, but I would guess that it's about .3-.4 mm. I find that it's fairly easy to tweak this by hand if you don't quite have it correct(as the z-axis isn't powered), and this will give you some idea about how you'll need to bump your zero around. If there is an explicit setting (i wasn't aware), then it's probably 0, with physical adjustments to the optoswitches for fine tuning.

- Extruder steps/mm in Configuration.h and Z steps/mm in Configuration.h

values depend on the Stepper motors you're using. If you have 0.9 degree motors rather than 1.8 degree, you'll need to double these values from what is generally passed around as techzone firmware.

Edited 1 time(s). Last edit at 03/20/2011 05:26PM by EtherDais.

|

Re: LaserCut Mendel by Tech Zone March 28, 2011 01:20AM |

Registered: 13 years ago Posts: 15 |

Ulrich Glimm Wrote:

-------------------------------------------------------

> > Hi I have a Techzone Laser cut Mendel and I am

> having problems with it recognizing the reprap

> software. I can open it but nothing moves or

> works. I believe that it has the wrong reprap.bat

> file . If anybody out there has a techzone Mendel

> with gen3 boards and is using Windows XP please

> send me a copy of your reprap.bat file. Or share

> how you got yours going.

> The instructions are there, you have to hunt for

> them, for assembling the machine. I found a few

> pictures, and with trial and error I managed to

> get it assembled. All the mendels I have seen have

> 2 or 4 threaded rods going through the Z axis

> boxes, mine only has one.

> I wonder if Windows XP will run this Mendel or if

> I should be looking to run it on Linux.

> I can run the motors and extrude in Repsnapper but

> I cannot make it print anything,

-------------------------------------------------------

> > Hi I have a Techzone Laser cut Mendel and I am

> having problems with it recognizing the reprap

> software. I can open it but nothing moves or

> works. I believe that it has the wrong reprap.bat

> file . If anybody out there has a techzone Mendel

> with gen3 boards and is using Windows XP please

> send me a copy of your reprap.bat file. Or share

> how you got yours going.

> The instructions are there, you have to hunt for

> them, for assembling the machine. I found a few

> pictures, and with trial and error I managed to

> get it assembled. All the mendels I have seen have

> 2 or 4 threaded rods going through the Z axis

> boxes, mine only has one.

> I wonder if Windows XP will run this Mendel or if

> I should be looking to run it on Linux.

> I can run the motors and extrude in Repsnapper but

> I cannot make it print anything,

Re: LaserCut Mendel by Tech Zone Remix  March 28, 2011 06:52AM |

Hi, is there a way to increase the speed of the extruder stepper motor without editing configuration.h? I'm using repsnapper. Is there some setting on repsnapper that allows me to increase the speed of the motor to increase the flow rate? I want to do this because the ABS extrusion is too "thin" and my parts are coming out looking like wireframes.

Re: LaserCut Mendel by Tech Zone Remix  March 28, 2011 09:11AM |

Registered: 13 years ago Posts: 1,780 |

Click on the Printer Settings button in the Print options tab. There's a setting for Extrusion multiplier between the Extruded Material width and Layer Thickness. I think you need to increase the multiplier to increase flow rate. I haven't used Repsnapper to generate g-code in a while but I think that should do it. You should have set the E_steps_per_mm parameter in your firmware code to match your extruder first, then tweak your print using the multiplier.

Re: LaserCut Mendel by Tech Zone Remix  March 29, 2011 07:17AM |

Brnd, after trying repsnapper (prints are not so great), I've decided to try to generate gcode using skeinforge and then use repsnapper to print, just like what you're doing.

Question:

Skeinforge settings:

1) I'm using version 40. Can I just leave the settings as default? I tried but the extruder seems to be turning at an extremely slow speed.

2) Do you have to adjust flow rates (Extruder speeds)?

3) Would it be possible for you to send me your skeinforge settings (i.e. your standard profile for skeinforge)?

Repsnapper settings:

Do I need to do anything here? Any settings I need to change or just default?

Question:

Skeinforge settings:

1) I'm using version 40. Can I just leave the settings as default? I tried but the extruder seems to be turning at an extremely slow speed.

2) Do you have to adjust flow rates (Extruder speeds)?

3) Would it be possible for you to send me your skeinforge settings (i.e. your standard profile for skeinforge)?

Repsnapper settings:

Do I need to do anything here? Any settings I need to change or just default?

Re: LaserCut Mendel by Tech Zone Remix  March 29, 2011 07:32AM |

Registered: 14 years ago Posts: 3,742 |

See "Skeinforge 40 Changes to Dimension" in the Skeinforge forum.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Re: LaserCut Mendel by Tech Zone Remix  March 29, 2011 08:02AM |

Registered: 13 years ago Posts: 1,780 |

Repnapper seem to have communication issues with the reprap firmware on Gen 3. I'm only able to make it work with the one that came with the 20100719 64-bit version. But it freezes once in a while even with temp monitoring disabled. In fact, it seems that enabling temp monitoring helps to unfreeze it when leaving it unattended.

Since switching to Pololu microstepping controllers, I had more problems. So, I switched back to using the reprap host for sending the g-codes to the printer. No freeze so far over the weekend after running overnight everyday. I did see it pause once and then start on its own. One problem with the reprap host is that it won't run at speeds higher than 19200 baud. I found that repsnapper will still talk to the reprap up to 57600 baud.

Since switching to Pololu microstepping controllers, I had more problems. So, I switched back to using the reprap host for sending the g-codes to the printer. No freeze so far over the weekend after running overnight everyday. I did see it pause once and then start on its own. One problem with the reprap host is that it won't run at speeds higher than 19200 baud. I found that repsnapper will still talk to the reprap up to 57600 baud.

|

Can Anyone Tell Me Where to Start? March 31, 2011 12:30AM |

Registered: 13 years ago Posts: 27 |

I finally got back to my Mendel (TechZone with Gen 3 electronics and Wade's extruder). I figured out a way to make the hot end using a piece of 5/8" PTFE rod and eliminating the oak block. Finally seems to work well after about 10 iterations.

I printed the 40mm cube tonight to start my calibration and the photos show what I got. The good news is it measures 40 mm all around, so dimensionally I was pleased. The globs are where RepSnapper kept stopping and I had to click "Kick". Any ideas on this? Also, when just sitting there, the PLA does slowly drip out of the nozzle head, forming these globs.

As far as the infill goes, I'm assuming I need to work on E-Steps_mm in Config.H. Currently it is set to 3.0. It doesn't look like enough material is coming out. Should I be tweaking the values in RepSnapper to get a more solid fill? I left them at the defaults.

All ideas are appreciated.

I printed the 40mm cube tonight to start my calibration and the photos show what I got. The good news is it measures 40 mm all around, so dimensionally I was pleased. The globs are where RepSnapper kept stopping and I had to click "Kick". Any ideas on this? Also, when just sitting there, the PLA does slowly drip out of the nozzle head, forming these globs.

As far as the infill goes, I'm assuming I need to work on E-Steps_mm in Config.H. Currently it is set to 3.0. It doesn't look like enough material is coming out. Should I be tweaking the values in RepSnapper to get a more solid fill? I left them at the defaults.

All ideas are appreciated.

|

Re: Can Anyone Tell Me Where to Start? March 31, 2011 05:29AM |

Registered: 13 years ago Posts: 1,780 |

Skeinforge 40 for g-codes and reprap host to send to the printer is the most stable way I've found so far but it;s not without problems. Repsnapper seems to have major communication issues with the reprap firmware with the Techzone Gen 3 remix electronics.

There certainly needs to be better documentation on what's compatible with what. Unfortunately, the firmware is a mess since the protocol is not even documented well. Changes have been made in different releases but there are not enough documentation.

There certainly needs to be better documentation on what's compatible with what. Unfortunately, the firmware is a mess since the protocol is not even documented well. Changes have been made in different releases but there are not enough documentation.

Re: LaserCut Mendel by Tech Zone Remix  April 01, 2011 10:24PM |

Registered: 13 years ago Posts: 27 |

Thanks brnrd,

I am now trying Skeinforge 40 to generate the G-Code and RepRap Host to send the file. TechZone Gen 3 electronics. Wade's Extruder with 8mm hobbed bolt. Small gear has 11 teeth, large gear has 39 teeth. Stepper Motors are 1.8 deg.

I'm using a laptop with 32-bit Windows XP SP3. The RepRap Host communicates, but it doesn't want to move the axes properly. They move, but won't home. So I'm guessing I need to modify the firmware again. I've downloaded a fresh copy of the 20100719 version of the Five_DGcode firmware as I've seen you've recommended in other posts.

Here's what my Configuration.H looks like:

// These settings are mainly for a standard Mendel

#if MOTHERBOARD == 2

// Comment out the next line if you are running a Darwin with a MOTHERBOARD > 1

#define MENDEL 1

// Set to 1 if enable pins are inverting

// For RepRap stepper boards version 1.x the enable pins are *not* inverting.

// For RepRap stepper boards version 2.x and above the enable pins are inverting.

#define INVERT_ENABLE_PINS 1

// Set to one if the axis opto-sensor outputs inverting (ie: 1 means open, 0 means closed)

// RepRap opto endstops with H21LOI sensors are not inverting; ones with H21LOB

// are inverting.

#define X_ENDSTOP_INVERTING true

#define Y_ENDSTOP_INVERTING true

#define Z_ENDSTOP_INVERTING true

#define MY_NAME 'H' // Byte representing the name of this device

#define E0_NAME '0' // Byte representing the name of extruder 0

#define E1_NAME '1' // Byte representing the name of extruder 1

#define RS485_MASTER 1 // *RO

// Axis scaling in stepper-motor steps per mm of movement

#define X_STEPS_PER_MM 10.047

#define X_STEPS_PER_INCH (X_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_X_DIR 0

#define Y_STEPS_PER_MM 10.047

#define Y_STEPS_PER_INCH (Y_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_Y_DIR 0

#define Z_STEPS_PER_MM 833.398

#define Z_STEPS_PER_INCH (Z_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_Z_DIR 0

// Stepper-driven extruder

// E_STEPS_PER_MM is the number of steps needed to

// extrude 1mm out of the nozzle. E0 for extruder 0;

// E1 for extruder 1, and so on.

//#define E_STEPS_PER_MM 0.9 // NEMA 17 extruder 5mm diameter drive - empirically adjusted

//#define E0_STEPS_PER_MM 2.2 // NEMA 17 59/11 geared extruder 8mm diameter drive

//#define E1_STEPS_PER_MM 2.2 // NEMA 17 59/11 geared extruder 8mm diameter drive

#define E0_STEPS_PER_MM 85.365 // NEMA 17 59/11 geared extruder 8mm diameter drive SF 40 defines this based on feedstock

#define E1_STEPS_PER_MM 85.365 // NEMA 17 59/11 geared extruder 8mm diameter drive SF 40 defines this based on feedstock

#endif

Any guidance?

I am now trying Skeinforge 40 to generate the G-Code and RepRap Host to send the file. TechZone Gen 3 electronics. Wade's Extruder with 8mm hobbed bolt. Small gear has 11 teeth, large gear has 39 teeth. Stepper Motors are 1.8 deg.

I'm using a laptop with 32-bit Windows XP SP3. The RepRap Host communicates, but it doesn't want to move the axes properly. They move, but won't home. So I'm guessing I need to modify the firmware again. I've downloaded a fresh copy of the 20100719 version of the Five_DGcode firmware as I've seen you've recommended in other posts.

Here's what my Configuration.H looks like:

// These settings are mainly for a standard Mendel

#if MOTHERBOARD == 2

// Comment out the next line if you are running a Darwin with a MOTHERBOARD > 1

#define MENDEL 1

// Set to 1 if enable pins are inverting

// For RepRap stepper boards version 1.x the enable pins are *not* inverting.

// For RepRap stepper boards version 2.x and above the enable pins are inverting.

#define INVERT_ENABLE_PINS 1

// Set to one if the axis opto-sensor outputs inverting (ie: 1 means open, 0 means closed)

// RepRap opto endstops with H21LOI sensors are not inverting; ones with H21LOB

// are inverting.

#define X_ENDSTOP_INVERTING true

#define Y_ENDSTOP_INVERTING true

#define Z_ENDSTOP_INVERTING true

#define MY_NAME 'H' // Byte representing the name of this device

#define E0_NAME '0' // Byte representing the name of extruder 0

#define E1_NAME '1' // Byte representing the name of extruder 1

#define RS485_MASTER 1 // *RO

// Axis scaling in stepper-motor steps per mm of movement

#define X_STEPS_PER_MM 10.047

#define X_STEPS_PER_INCH (X_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_X_DIR 0

#define Y_STEPS_PER_MM 10.047

#define Y_STEPS_PER_INCH (Y_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_Y_DIR 0

#define Z_STEPS_PER_MM 833.398

#define Z_STEPS_PER_INCH (Z_STEPS_PER_MM*INCHES_TO_MM) // *RO

#define INVERT_Z_DIR 0

// Stepper-driven extruder

// E_STEPS_PER_MM is the number of steps needed to

// extrude 1mm out of the nozzle. E0 for extruder 0;

// E1 for extruder 1, and so on.

//#define E_STEPS_PER_MM 0.9 // NEMA 17 extruder 5mm diameter drive - empirically adjusted

//#define E0_STEPS_PER_MM 2.2 // NEMA 17 59/11 geared extruder 8mm diameter drive

//#define E1_STEPS_PER_MM 2.2 // NEMA 17 59/11 geared extruder 8mm diameter drive

#define E0_STEPS_PER_MM 85.365 // NEMA 17 59/11 geared extruder 8mm diameter drive SF 40 defines this based on feedstock

#define E1_STEPS_PER_MM 85.365 // NEMA 17 59/11 geared extruder 8mm diameter drive SF 40 defines this based on feedstock

#endif

Any guidance?

Re: LaserCut Mendel by Tech Zone Remix  April 02, 2011 12:52AM |

Registered: 13 years ago Posts: 1,780 |

Your e steps per mm will be different. There's a topic in the skeinforge forum about how to set this for skeinforge 40. The formula is (number of steps in a revolution)/(pi*pinch wheel diameter)*(#teeth in driver gear)/(#teeth in motor). But for the hobbed bolt, the diameter is going to be less than 8 mm. I haven't used that type of extruder so I don't know for sure what method works best to firgure out the diameter. It would be best to read through that discussion instead of repeating it here.

Re: LaserCut Mendel by Tech Zone Remix  April 05, 2011 06:50AM |

Re: LaserCut Mendel by Tech Zone Remix  April 05, 2011 08:13AM |

Registered: 14 years ago Posts: 3,742 |

Did you press the extrude button (once or more times) before starting the print?

With the RepRap Host doing this can cause the same problem.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

With the RepRap Host doing this can cause the same problem.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Re: LaserCut Mendel by Tech Zone Remix  April 05, 2011 01:53PM |

Registered: 13 years ago Posts: 27 |

I had it happen initially that it ran backwards every time. Simply reverse the wires from the motor into the stepper controller. If it's happening intermittently, did you accidentally hit the Reverse button before you started printing. The color change on the button when the Reverse is engaged isn't super apparent.

Tom

Tom

Re: LaserCut Mendel by Tech Zone Remix  April 08, 2011 01:44AM |

Registered: 14 years ago Posts: 13 |

Ok finally getting back to working on the reprap. I have all 3 axis moving smoothly and in the right directions now. Yeay! Using techzone Gen3 electronics with A/D thermocouple fyi. Just need to get the extruder working correctly now, it is heating and the motor is moving but not reporting anything for temperature.

Sounds like Skeinforge 40 to produce the gcode, reprap host software 20100729 and brnrds firmware is my best bet to get this printing. Anyone have better suggestion for tool chain? Have I missed any major caveats?

I am able to upload to my extruder firmware but having issues uploading to the MB. I keep getting:

"avrdude: Yikes! Invalid device signature.

Double check connections and try again, or use -F to override

this check."

Anyone seen this before? I did find this this. I was trying to upload with Arduino 0018 and I checked and the chip is a 644P. If nothing else I will try playing around with the signature codes in Arduino tomorrow.

Sounds like Skeinforge 40 to produce the gcode, reprap host software 20100729 and brnrds firmware is my best bet to get this printing. Anyone have better suggestion for tool chain? Have I missed any major caveats?

I am able to upload to my extruder firmware but having issues uploading to the MB. I keep getting:

"avrdude: Yikes! Invalid device signature.

Double check connections and try again, or use -F to override

this check."

Anyone seen this before? I did find this this. I was trying to upload with Arduino 0018 and I checked and the chip is a 644P. If nothing else I will try playing around with the signature codes in Arduino tomorrow.

Re: LaserCut Mendel by Tech Zone Remix  April 08, 2011 02:10PM |

Registered: 13 years ago Posts: 1,780 |

The firmware should load fine to your motherboard without any problems. You did pick Sanguino, right? Have you tried using the Serial Monitor in Arduino to make sure that the MB is communicating? Also, is the red led next to the green one blinking about twice a second?

Please note that I have been experiencing problems with the Techzone remix extruder and Thermocouple A-D combination. Once in a while, the extruder loses the temperature setting and the the tip, the bed or both would lose temperature and get cold during a print. The other issue that I've noticed is that I started getting a lot of timeout error in the host when trying to read the tip and bed temperature. I think that this is cause by the long time that it takes to read the AD since it's being done through a serial connection. A couple of days ago, I reluctantly switched back to using a thermistor on the tip. So far, the problem of losing temperature has not happened but there's no guarantee that it's realIy gone. I really want to use a thermocouple since I think it's much more reliable and accurate at the critical temperature range that we need for the extruder. Perhaps, the preamp option like the AD595 would be a better way.

Please note that I have been experiencing problems with the Techzone remix extruder and Thermocouple A-D combination. Once in a while, the extruder loses the temperature setting and the the tip, the bed or both would lose temperature and get cold during a print. The other issue that I've noticed is that I started getting a lot of timeout error in the host when trying to read the tip and bed temperature. I think that this is cause by the long time that it takes to read the AD since it's being done through a serial connection. A couple of days ago, I reluctantly switched back to using a thermistor on the tip. So far, the problem of losing temperature has not happened but there's no guarantee that it's realIy gone. I really want to use a thermocouple since I think it's much more reliable and accurate at the critical temperature range that we need for the extruder. Perhaps, the preamp option like the AD595 would be a better way.

Re: LaserCut Mendel by Tech Zone Remix  April 09, 2011 12:13AM |

Registered: 14 years ago Posts: 13 |

Thanks for the feedback.

Board: Sanguino

Serial Port: /dev/ttyUSB0

I can see the "start" on the serial monitor @ 19200 baud. But my attempts to send commands on the serial monitor winodw aren't working. But the terminal output of reprap shows messages like:

"comms: G-code: N43 G1 Y2.8 *98 dequeued and sent [107.478s/2ms]

comms: GCode acknowledged [107.489s/11ms]"

So I tried just echoing to and tailing from /dev/ttyUSB. And the motors move and I get replies back. So then I opened the monitor again and echoed another command and was able to see the response in Arduino's serial monitor. That doesn't make sense I can program the extruder just fine so the Arduino IDE is obviously capable of Txing.

FYI just heard back from techzone (Kurt Bidstrup) and he is suggesting RepSnapper.

Board: Sanguino

Serial Port: /dev/ttyUSB0

I can see the "start" on the serial monitor @ 19200 baud. But my attempts to send commands on the serial monitor winodw aren't working. But the terminal output of reprap shows messages like:

"comms: G-code: N43 G1 Y2.8 *98 dequeued and sent [107.478s/2ms]

comms: GCode acknowledged [107.489s/11ms]"

So I tried just echoing to and tailing from /dev/ttyUSB. And the motors move and I get replies back. So then I opened the monitor again and echoed another command and was able to see the response in Arduino's serial monitor. That doesn't make sense I can program the extruder just fine so the Arduino IDE is obviously capable of Txing.

FYI just heard back from techzone (Kurt Bidstrup) and he is suggesting RepSnapper.

Re: LaserCut Mendel by Tech Zone Remix  April 10, 2011 03:46AM |

Registered: 14 years ago Posts: 13 |

So I set: "build.verbose=true" and "upload.verbose=true". Think I only really needed the later. And then attempted to upload brnrds modified firmware. It failed due to the chip signature being 0x0000 but I then copied the command and added -F and the firmware appeared to upload.

Only remaining issue is that I am still not getting anything other than 2000 for the extruder temperature in the reprap host software. Seeing: "comms: GCodeWriter.waitForOK() - temperature reading: T:2000 B:0..." in the terminal. Double checked all the connections with multimeter. There was <1 Ohm on all the lines of all the cables from the A-D to Extruder and Extruder to MB. And about ~5 ohms across the thermo couple. AI will try digging into some of the info/code for the A-D.

Wishing I had recieved my new scope Would be nice to identify which board isn't returning a value. Any suggestions on how to debug A-D without a scope? Maybe I can borrow one for a couple days.

Only remaining issue is that I am still not getting anything other than 2000 for the extruder temperature in the reprap host software. Seeing: "comms: GCodeWriter.waitForOK() - temperature reading: T:2000 B:0..." in the terminal. Double checked all the connections with multimeter. There was <1 Ohm on all the lines of all the cables from the A-D to Extruder and Extruder to MB. And about ~5 ohms across the thermo couple. AI will try digging into some of the info/code for the A-D.

Wishing I had recieved my new scope Would be nice to identify which board isn't returning a value. Any suggestions on how to debug A-D without a scope? Maybe I can borrow one for a couple days.

Sorry, only registered users may post in this forum.