MK3 Alu-Heatbed how to print with a hole in center.

Posted by Carlos Fellip

|

MK3 Alu-Heatbed how to print with a hole in center. January 15, 2015 12:44AM |

Registered: 9 years ago Posts: 8 |

Good day.

Some months ago i bought my first 3D printer (a Prusa i3 kit), since then i have done some awesome prints on PLA.

But as the heatbed could reach only 65ºC I was unable to print on ABS. Then i bought an Alu-Heatbed MK3 for printing on ABS and because it heats up faster than the MK2.

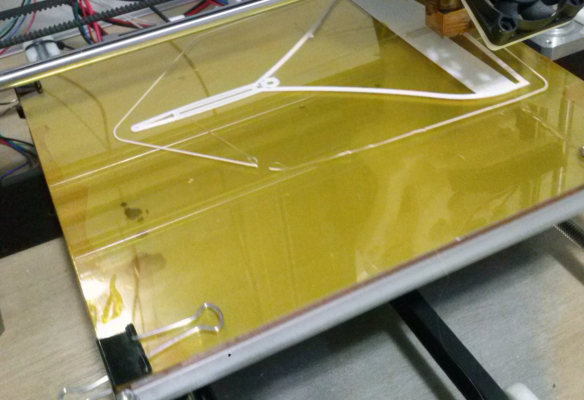

But there is a hole in the center so how can I print? Do i have to fill that hole? With what?

I'm not supposed to use a glass, with this heatbed. But can i use or it will be to heavy for the y-axis motor? Which size of binder clip shoud i use for the 3mm thick MK3 plus 3mm glass plate?

Regards

Carlos Fellip

Some months ago i bought my first 3D printer (a Prusa i3 kit), since then i have done some awesome prints on PLA.

But as the heatbed could reach only 65ºC I was unable to print on ABS. Then i bought an Alu-Heatbed MK3 for printing on ABS and because it heats up faster than the MK2.

But there is a hole in the center so how can I print? Do i have to fill that hole? With what?

I'm not supposed to use a glass, with this heatbed. But can i use or it will be to heavy for the y-axis motor? Which size of binder clip shoud i use for the 3mm thick MK3 plus 3mm glass plate?

Regards

Carlos Fellip

|

Re: MK3 Alu-Heatbed how to print with a hole in center. January 16, 2015 06:19AM |

Registered: 10 years ago Posts: 50 |

hey:

buy a glass => no hole and perfekt plane

buy a power extention => not needed but without MK3 headbed is just a joke

buy a roll of Bluetape => (what you realy need)and you pla will stick

for example here: [3d-druck-shop.youin3d.com]

buy a glass => no hole and perfekt plane

buy a power extention => not needed but without MK3 headbed is just a joke

buy a roll of Bluetape => (what you realy need)and you pla will stick

for example here: [3d-druck-shop.youin3d.com]

|

Re: MK3 Alu-Heatbed how to print with a hole in center. January 16, 2015 07:22AM |

Registered: 9 years ago Posts: 8 |

I already have a glass, but may i use it over a MK3 heatbed? If yes, which size of binder clip shoud i use because the binders i used with mk2+glass looks too small.

But i still think that MK3+Glass+y carriage would get too heavy wouldn't it?

Edited 1 time(s). Last edit at 01/16/2015 07:22AM by Carlos Fellip.

But i still think that MK3+Glass+y carriage would get too heavy wouldn't it?

Edited 1 time(s). Last edit at 01/16/2015 07:22AM by Carlos Fellip.

|

Re: MK3 Alu-Heatbed how to print with a hole in center. January 20, 2015 02:54AM |

Registered: 9 years ago Posts: 8 |

I'm testing a glass plate over the MK3 Heatbed, it worked pretty well on my first test.

Edited 1 time(s). Last edit at 01/20/2015 02:59AM by Carlos Fellip.

Edited 1 time(s). Last edit at 01/20/2015 02:59AM by Carlos Fellip.

|

Re: MK3 Alu-Heatbed how to print with a hole in center. January 20, 2015 05:44AM |

Registered: 10 years ago Posts: 14,672 |

Use 3mm or 4mm float glass on top of the aluminium bed. Get your local glass merchant to cut several plates of the right size, and smooth the sharp edges. Then you can start another print while you are waiting for the first one to cool so that you can remove it from the pate.

I recommend picture frame clips rather than foldback clips, they have a lower profile and don't get in the way of the head as much. See [forums.reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I recommend picture frame clips rather than foldback clips, they have a lower profile and don't get in the way of the head as much. See [forums.reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: MK3 Alu-Heatbed how to print with a hole in center. June 25, 2021 01:16PM |

Registered: 7 years ago Posts: 16 |

this reply is late kind of, but accordingly the center hole is intended for a thermistor !

[reprap.org]

so i'd guess if 'all else fails' one can perhaps get a thermistor to fill that hole (and maybe measure temperature?) ;/

i think as it is about 3mm, chances are that prints should bridge across it, but it is a heated bed so problem remains

but i had to say it is a lousy design, that hole creates a whole lot of problems. i'm thinking if aluminum foil and silicone caulk may solve it.

silicone caulk can take rather high temperatures and aluminum foil bridges the surface. but of course silicone caulk is *soft* that is a downside.

i'm thinking about soldering it but accordingly aluminum is hard to solder unless one managed to cut off air to the surface (i've read some success with using ordinary cooking oil for aluminium foil), but for such a thick piece, it won't be easy

i'd guess glass is popular, but i still prefer aluminum due to the much higher heat transfer rates, it heats up much faster than glass

Edited 3 time(s). Last edit at 06/25/2021 01:23PM by ag123.

[reprap.org]

so i'd guess if 'all else fails' one can perhaps get a thermistor to fill that hole (and maybe measure temperature?) ;/

i think as it is about 3mm, chances are that prints should bridge across it, but it is a heated bed so problem remains

but i had to say it is a lousy design, that hole creates a whole lot of problems. i'm thinking if aluminum foil and silicone caulk may solve it.

silicone caulk can take rather high temperatures and aluminum foil bridges the surface. but of course silicone caulk is *soft* that is a downside.

i'm thinking about soldering it but accordingly aluminum is hard to solder unless one managed to cut off air to the surface (i've read some success with using ordinary cooking oil for aluminium foil), but for such a thick piece, it won't be easy

i'd guess glass is popular, but i still prefer aluminum due to the much higher heat transfer rates, it heats up much faster than glass

Edited 3 time(s). Last edit at 06/25/2021 01:23PM by ag123.

Sorry, only registered users may post in this forum.