Bowden Tool Change Idea....Got a tool-change idea? Post it here! (Mendel)

Posted by Mdbaughman2

|

Bowden Tool Change Idea....Got a tool-change idea? Post it here! (Mendel) May 15, 2010 05:00PM |

Registered: 14 years ago Posts: 54 |

I've been playing with the idea of a tool-change setup... anyway its currently an idea that someone might be able to design/build on....

anyway in the time that I've been sitting here thinking, i had an idea for a tool-change setup for the Mendel. The idea is one I have read in several places on the wiki/forums. The idea is mounting multiple Bowden extruders (or other type tool-heads) inside the Mendel carriage. Like to have one for infill and one for border materials.

The idea i have is not an actual-tool change but more like a tool swap for two extruders or a cutter/extruder setup.... I figure this would be a good start on the road to multiple extruders!

anyway... here's my idea. (I'm not one with the artistic gift of CAD. (yet..) but give me a pen paper and a pair of scissors....) i guess its really more to prevent collisions between unused tool-head and prints... here goes!

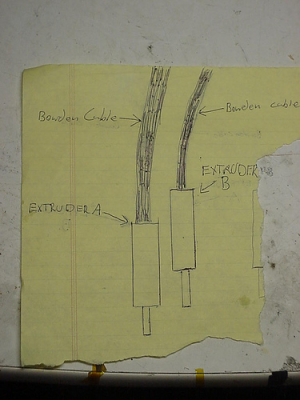

take two Bowden extruders...

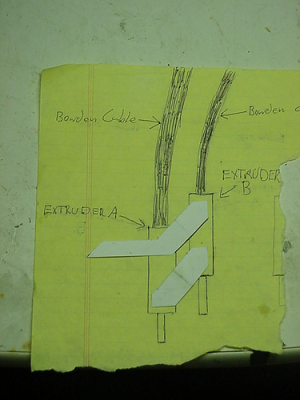

than do something like this.... here is position A. note the arm.. thats for a way to attach an actuator... the idea is to have a center pivot point between the tool-heads..

here is position B

anyway that's my idea... hopefully somebody can run-away with it and make something out of it... I might get-going on it in a few months... (like once i learn a free cad program i like) I would probably need someone "reprap software wise" to help make a tool changer happen... cheers

Edited 4 time(s). Last edit at 05/20/2010 01:10PM by Mdbaughman2.

anyway in the time that I've been sitting here thinking, i had an idea for a tool-change setup for the Mendel. The idea is one I have read in several places on the wiki/forums. The idea is mounting multiple Bowden extruders (or other type tool-heads) inside the Mendel carriage. Like to have one for infill and one for border materials.

The idea i have is not an actual-tool change but more like a tool swap for two extruders or a cutter/extruder setup.... I figure this would be a good start on the road to multiple extruders!

anyway... here's my idea. (I'm not one with the artistic gift of CAD. (yet..) but give me a pen paper and a pair of scissors....) i guess its really more to prevent collisions between unused tool-head and prints... here goes!

take two Bowden extruders...

than do something like this.... here is position A. note the arm.. thats for a way to attach an actuator... the idea is to have a center pivot point between the tool-heads..

here is position B

anyway that's my idea... hopefully somebody can run-away with it and make something out of it... I might get-going on it in a few months... (like once i learn a free cad program i like) I would probably need someone "reprap software wise" to help make a tool changer happen... cheers

Edited 4 time(s). Last edit at 05/20/2010 01:10PM by Mdbaughman2.

|

Re: Bowden Tool Change Idea.... (Mendel) May 15, 2010 05:27PM |

Registered: 15 years ago Posts: 332 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 15, 2010 05:42PM |

Registered: 13 years ago Posts: 52 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 15, 2010 05:43PM |

Registered: 14 years ago Posts: 54 |

to avoid collisions (second head hitting/moving a piece being printed... if you where to want to print several objects at once... or like you ponited out a dremel... or like one with PLA @.3mm for borders and one with ABS @.5 as filler.... there are a lot of uses....

or like you ponited out a dremel... or like one with PLA @.3mm for borders and one with ABS @.5 as filler.... there are a lot of uses....

hintss you beat me to it... lol

Edited 2 time(s). Last edit at 05/15/2010 06:00PM by Mdbaughman2.

or like you ponited out a dremel... or like one with PLA @.3mm for borders and one with ABS @.5 as filler.... there are a lot of uses....

or like you ponited out a dremel... or like one with PLA @.3mm for borders and one with ABS @.5 as filler.... there are a lot of uses....

hintss you beat me to it... lol

Edited 2 time(s). Last edit at 05/15/2010 06:00PM by Mdbaughman2.

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 02:24AM |

Registered: 13 years ago Posts: 52 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 03:15AM |

Admin Registered: 17 years ago Posts: 7,879 |

You could fix one nozzle and mount the rest on solenoids with a sprint to retract them.

Or put two or three side by side on a plate that swings on a pivot at the bottom to make any of three the lowest. The outer two would be a little higher than the middle one and angled slighly outwards.

You could mount many on a revolving turret like CNC machine do. They work like a multi-lens microscope. The objective lenses are mounted on an inclined disk and angled slightly outwards so one points straight down and the others are a bit higher. This has the advantage that the active one is always in the same place so you don't lose any x-travel.

[www.hydraraptor.blogspot.com]

Or put two or three side by side on a plate that swings on a pivot at the bottom to make any of three the lowest. The outer two would be a little higher than the middle one and angled slighly outwards.

You could mount many on a revolving turret like CNC machine do. They work like a multi-lens microscope. The objective lenses are mounted on an inclined disk and angled slightly outwards so one points straight down and the others are a bit higher. This has the advantage that the active one is always in the same place so you don't lose any x-travel.

[www.hydraraptor.blogspot.com]

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 04:14AM |

Registered: 14 years ago Posts: 54 |

NopeHead

You could fix one nozzle and mount the rest on solenoids with a sprint to retract them.

-----

sounds simple... could you explain more? (curious... whats a sprint?)

------------------------------------------------------------------

Or put two or three side by side on a plate that swings on a pivot at the bottom to make any of three the lowest. The outer two would be a little higher than the middle one and angled slighly outwards.

You could mount many on a revolving turret like CNC machine do. They work like a multi-lens microscope. The objective lenses are mounted on an inclined disk and angled slightly outwards so one points straight down and the others are a bit higher. This has the advantage that the active one is always in the same place so you don't lose any x-travel.

----

I like your two ideas however they seem a lil hard to engineer... in the aspect of how would things seal up? if you did the cnc tool change... how would you go about the locking and unlocking issues with the actual toolhead swap...

Thats the reason why i was thinking along the simpler lines.. like your first idea...

i didn't cover actuation because there are probably 100's of ways is could be done...

one way i was thinking was to setup a limit switch setup that (an idea..) to execute a tool change, you could have the run the Z up to the top and hit a switch that executes the tool change... (but the software is not knowing witch is witch..)

however being able to control the tool-change directly via (a pin or two) one of the boards would be better.. then the software will actually call up the proper extruder..

I purpose this idea due to the simplistic nature of the idea... however actuation control also needs to be discussed. What would be the best way to setup a tool change in the reprap software world? (Nopehead i know you use your own software setup..) what pin should be a default output? (that wont conflict with cooling, heated bed setup?)

also how would one go about fixing XYZ offset issues (between extruders) in the RepRap software world? (i haven't got that far in my research yet... it could already be done.. but not sure! I'v seen it in CNC machines..)

Edited 1 time(s). Last edit at 05/16/2010 04:19AM by Mdbaughman2.

You could fix one nozzle and mount the rest on solenoids with a sprint to retract them.

-----

sounds simple... could you explain more? (curious... whats a sprint?)

------------------------------------------------------------------

Or put two or three side by side on a plate that swings on a pivot at the bottom to make any of three the lowest. The outer two would be a little higher than the middle one and angled slighly outwards.

You could mount many on a revolving turret like CNC machine do. They work like a multi-lens microscope. The objective lenses are mounted on an inclined disk and angled slightly outwards so one points straight down and the others are a bit higher. This has the advantage that the active one is always in the same place so you don't lose any x-travel.

----

I like your two ideas however they seem a lil hard to engineer... in the aspect of how would things seal up? if you did the cnc tool change... how would you go about the locking and unlocking issues with the actual toolhead swap...

Thats the reason why i was thinking along the simpler lines.. like your first idea...

i didn't cover actuation because there are probably 100's of ways is could be done...

one way i was thinking was to setup a limit switch setup that (an idea..) to execute a tool change, you could have the run the Z up to the top and hit a switch that executes the tool change... (but the software is not knowing witch is witch..)

however being able to control the tool-change directly via (a pin or two) one of the boards would be better.. then the software will actually call up the proper extruder..

I purpose this idea due to the simplistic nature of the idea... however actuation control also needs to be discussed. What would be the best way to setup a tool change in the reprap software world? (Nopehead i know you use your own software setup..) what pin should be a default output? (that wont conflict with cooling, heated bed setup?)

also how would one go about fixing XYZ offset issues (between extruders) in the RepRap software world? (i haven't got that far in my research yet... it could already be done.. but not sure! I'v seen it in CNC machines..)

Edited 1 time(s). Last edit at 05/16/2010 04:19AM by Mdbaughman2.

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 04:26AM |

Registered: 15 years ago Posts: 332 |

hintss Wrote:

-------------------------------------------------------

> so if the unused extruder is on the right and

> you're printing from right to left, it dosen't hit

> the part. He says that that is the whole point of

> the pivot

On my reprap the nozzle does skim over what its already printed, without snagging it at all. Surely you could just print with the finest nozzle first, so that won't be an issue?

I like the idea of a microscope style rotating thing, A worm gear might be a good way to rotate it, because then you don't need to constantly power it to keep it in position, and you can use a fairly small and weak motor.

-------------------------------------------------------

> so if the unused extruder is on the right and

> you're printing from right to left, it dosen't hit

> the part. He says that that is the whole point of

> the pivot

On my reprap the nozzle does skim over what its already printed, without snagging it at all. Surely you could just print with the finest nozzle first, so that won't be an issue?

I like the idea of a microscope style rotating thing, A worm gear might be a good way to rotate it, because then you don't need to constantly power it to keep it in position, and you can use a fairly small and weak motor.

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 05:04AM |

Admin Registered: 17 years ago Posts: 7,879 |

sprint is a typo I meant spring.

You don't have any seals, you have a separate Bowden cable to each one and multiple drive units.

I will just add a new extruder controller for each extruder. Handling many is no problem in my hardware and software, neither is XYZ offsets. I will just add a few lines to my Pythons scripts.

[www.hydraraptor.blogspot.com]

You don't have any seals, you have a separate Bowden cable to each one and multiple drive units.

I will just add a new extruder controller for each extruder. Handling many is no problem in my hardware and software, neither is XYZ offsets. I will just add a few lines to my Pythons scripts.

[www.hydraraptor.blogspot.com]

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 05:23AM |

Admin Registered: 17 years ago Posts: 7,879 |

James,

My nozzle skims over objects but the problem with multiple nozzles is that they would to be exactly aligned in z, and stay aligned when they warm up. Also the nozzle not in use may ooze a little and that would get smeared into the object.

[www.hydraraptor.blogspot.com]

My nozzle skims over objects but the problem with multiple nozzles is that they would to be exactly aligned in z, and stay aligned when they warm up. Also the nozzle not in use may ooze a little and that would get smeared into the object.

[www.hydraraptor.blogspot.com]

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 05:23AM |

Registered: 14 years ago Posts: 54 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 04:02PM |

Registered: 15 years ago Posts: 96 |

I currently have a double headed extruder on my mendel. im not using both yet but having them at the same height hasnt been a issue yet. the oozing issue may become one once i have both heated simultaneously but... that will be for another day. Its posible that issue could be solved by cooling/stoping heat to the unused head though then you have to deal with heat up and cool down times. Im thinking that simply retracting the filament on the unused head might be sufficient though the active valve design ad4rian came up with a couple of years ago might also be a solution.

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 04:57PM |

Admin Registered: 17 years ago Posts: 7,879 |

Retracting ABS works very well but PLA tends to ooze slowly afterwards.

If you use PTFE insulators you have to be aware that they expand get about 0.1-0.2mm longer when they heat up.

I don't have a sketch but it is just the way a microscope works:

Imagine each objective lens is a nozzle.

I wouldn't use the turret design on a moving head machine like Mendel. I think moving table is the way to go.

[www.hydraraptor.blogspot.com]

If you use PTFE insulators you have to be aware that they expand get about 0.1-0.2mm longer when they heat up.

I don't have a sketch but it is just the way a microscope works:

Imagine each objective lens is a nozzle.

I wouldn't use the turret design on a moving head machine like Mendel. I think moving table is the way to go.

[www.hydraraptor.blogspot.com]

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 05:08PM |

Registered: 14 years ago Posts: 54 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 16, 2010 05:18PM |

Registered: 14 years ago Posts: 54 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 17, 2010 04:04PM |

Registered: 14 years ago Posts: 573 |

If you are using only extruders (You cannot have a bowdenn-mill or bowden-drill for obvious reasons),

there is not much need for a tool-change. Just make it a double- or

tripple-head. A bowden-head is leightweight enough that is makes no difference.

-------------------------------------------

* homeprototype free 3d design repository

* Blog

* Google+

there is not much need for a tool-change. Just make it a double- or

tripple-head. A bowden-head is leightweight enough that is makes no difference.

-------------------------------------------

* homeprototype free 3d design repository

* Blog

* Google+

|

Re: Bowden Tool Change Idea.... (Mendel) May 17, 2010 05:00PM |

Registered: 14 years ago Posts: 117 |

I think this is the idea thats most worth pursuing. Having two Bowden-driven hot-ends with two different sized nozzles (small for details, larger for filling) could speed up printing quite a bit.

Automated lowering of the active head should be easy enough with a servo.

I'm still on my way to a mendel but I'll try this sooner or later if nobody beats me to it.

Automated lowering of the active head should be easy enough with a servo.

I'm still on my way to a mendel but I'll try this sooner or later if nobody beats me to it.

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 01:57AM |

Registered: 13 years ago Posts: 52 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 02:53AM |

Registered: 14 years ago Posts: 54 |

I think that was the original tool change idea... just that the stored extruders are supposed to attach to the upper frame rails... that would work if we could figure out a lock/unlock mechanism... for the carriage and the storing points!

i was thinking on the upper side of the extruder, it would slide into its storage holder via the X axis... then unlock from carrage some-how, drop the z for disconnect....

just need to figure out the lock/unlock mechanism for the carrage...

this would work for 2 tool/head change-outs... by toolhead i mean

example:

one of these being a cluster of bowden extruders... (the 2 or 3 mounted on one tool mount..

the other... what ever you want.... now where talking up to 6 extruders.... do we want multi (6) colored builds like the commercial machines? I think we do!

Edited 1 time(s). Last edit at 05/18/2010 02:58AM by Mdbaughman2.

i was thinking on the upper side of the extruder, it would slide into its storage holder via the X axis... then unlock from carrage some-how, drop the z for disconnect....

just need to figure out the lock/unlock mechanism for the carrage...

this would work for 2 tool/head change-outs... by toolhead i mean

example:

one of these being a cluster of bowden extruders... (the 2 or 3 mounted on one tool mount..

the other... what ever you want.... now where talking up to 6 extruders.... do we want multi (6) colored builds like the commercial machines? I think we do!

Edited 1 time(s). Last edit at 05/18/2010 02:58AM by Mdbaughman2.

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 03:20AM |

Registered: 14 years ago Posts: 117 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 03:36AM |

Registered: 14 years ago Posts: 54 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 07:41PM |

Registered: 13 years ago Posts: 52 |

|

Re: Bowden Tool Change Idea.... (Mendel) May 18, 2010 08:14PM |

Registered: 14 years ago Posts: 54 |

the idea i see is, it to have a storage "place" on both the left and right of the upper frame rails... Leaving the center open...

tool change...

---printing

1 the carriage will raise off the print

2 the carriage will center, then the z will rise to the top of the frame..

3 the carriage will slide left... sliding toolhead into its holder...

4 carriage unlocks toolhead (to be figured out)

5 carriage drops till clear of toohead... leaving toolhead in Its holder

6 carriage slides right below 2nd toolhead

and basically the inverse... 5 4 3 2 1

the holder would be shaped like a c (or a claw) leaving the middle open between the upper frame studding (on the right or left)...

you get the idea?

tool change...

---printing

1 the carriage will raise off the print

2 the carriage will center, then the z will rise to the top of the frame..

3 the carriage will slide left... sliding toolhead into its holder...

4 carriage unlocks toolhead (to be figured out)

5 carriage drops till clear of toohead... leaving toolhead in Its holder

6 carriage slides right below 2nd toolhead

and basically the inverse... 5 4 3 2 1

the holder would be shaped like a c (or a claw) leaving the middle open between the upper frame studding (on the right or left)...

you get the idea?

|

Re: Bowden Tool Change Idea.... (Mendel) May 19, 2010 03:36AM |

I have been pondering toolchange for a while and considered the system old pen plotters use, a row of pens held in a station and the plotter picks them as needed,

in our case the pens would have the filament in place, (colour, material) and the drive engage with it on picking up the pen or head.

Skeinforge has an option, tower, to use this the heads need to clear, software to allow for combined stl files so that different areas within a single part, (like twin shot) would open up this area, once the software is available then multi head and therefore multi material and colour become possible.

This is only my opinion but I think that for fdm to achieve any sort of speed the heads need to move and the platform move only in Z, otherwise the part as it gets bigger is put under higher inertia.

P.S look under "turret" for cnc tool heads, as I write this it occurs to me that hpgl used by plotters handled the line colours and therefore pens, think I will have a look at HPGL.

in our case the pens would have the filament in place, (colour, material) and the drive engage with it on picking up the pen or head.

Skeinforge has an option, tower, to use this the heads need to clear, software to allow for combined stl files so that different areas within a single part, (like twin shot) would open up this area, once the software is available then multi head and therefore multi material and colour become possible.

This is only my opinion but I think that for fdm to achieve any sort of speed the heads need to move and the platform move only in Z, otherwise the part as it gets bigger is put under higher inertia.

P.S look under "turret" for cnc tool heads, as I write this it occurs to me that hpgl used by plotters handled the line colours and therefore pens, think I will have a look at HPGL.

|

Re: Bowden Tool Change Idea....Got a tool-change idea? Post it here! (Mendel) June 05, 2010 10:46PM |

Registered: 13 years ago Posts: 12 |

1. I think that the changing tool head (Pen plotters) are old and problematic technology. Many CNC machines use the carousel method for tool change as rotation can be easily controlled.

- Every time you change a tool there is an opportunity for an issue.

- With pen plotters the pens had an internal reservoir for ink, which is different for an extruder which has a continuous feedstock line running into it. Therefor you would need to be very careful not to cross the feedstock lines during extruder change out.

2. The idea of having fine and course extrusion heads is great as this would speed up printing but keep detail high at the object edges.

- It seems that at least one more head would be required for removable scaffold material, so that you remove the < 45 degree overhang constraint.

3. The microscope idea seems very strong

- As long as the turnstile only turns < 360 degrees then returns back the way it came. To remove the chance of getting the feedstock twisted up (after multiple rotations).

- Possibly one of the passes that the extruder heads could go through, before starting to print again, would be one that cuts off any oozed filament from the waiting heated head (if oozing material cannot be controlled).

All this talk is very exciting, I wish I had the technical skills to be of assistance.

J

- Every time you change a tool there is an opportunity for an issue.

- With pen plotters the pens had an internal reservoir for ink, which is different for an extruder which has a continuous feedstock line running into it. Therefor you would need to be very careful not to cross the feedstock lines during extruder change out.

2. The idea of having fine and course extrusion heads is great as this would speed up printing but keep detail high at the object edges.

- It seems that at least one more head would be required for removable scaffold material, so that you remove the < 45 degree overhang constraint.

3. The microscope idea seems very strong

- As long as the turnstile only turns < 360 degrees then returns back the way it came. To remove the chance of getting the feedstock twisted up (after multiple rotations).

- Possibly one of the passes that the extruder heads could go through, before starting to print again, would be one that cuts off any oozed filament from the waiting heated head (if oozing material cannot be controlled).

All this talk is very exciting, I wish I had the technical skills to be of assistance.

J

|

Re: Bowden Tool Change Idea.... (Mendel) June 08, 2010 02:14PM |

Registered: 14 years ago Posts: 105 |

I wouldn't be so quick to dismiss the idea. This is how CNC tooling addresses the issue, although things like lathes with a limited number of tools generally go with a rotating turret.

The biggest issue would be cable management. You may ultimately have to redesign the entire frame around the entanglement issue or come up with some sort of cable guides.

In either case: it's a viable approach and shouldn't be taken off the table.

The biggest issue would be cable management. You may ultimately have to redesign the entire frame around the entanglement issue or come up with some sort of cable guides.

In either case: it's a viable approach and shouldn't be taken off the table.

Sorry, only registered users may post in this forum.