Thin sheet question

Posted by AgeingHippy

|

Thin sheet question June 11, 2010 11:04AM |

Registered: 13 years ago Posts: 482 |

Hello All

I am currently constructing my thin sheets and have a few questions....

1) I am using the aluminium from a cider can. This seems awfully flimsy. Has anyone had to change their thin sheet to some stiffer form of tin or am I overly concerned?

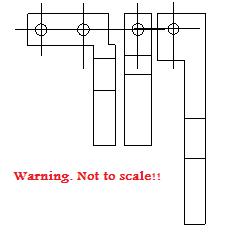

2) The template given by the dfx file accessed from here gives a different shape for the x-flag given in this jpg. Can anyone please clarify? Please see the attached shot of the template printed from the dfx file here.

Thanks people.

I am currently constructing my thin sheets and have a few questions....

1) I am using the aluminium from a cider can. This seems awfully flimsy. Has anyone had to change their thin sheet to some stiffer form of tin or am I overly concerned?

2) The template given by the dfx file accessed from here gives a different shape for the x-flag given in this jpg. Can anyone please clarify? Please see the attached shot of the template printed from the dfx file here.

Thanks people.

|

Re: Thin sheet question June 11, 2010 02:43PM |

Registered: 14 years ago Posts: 36 |

As long as you can bend it and it'll keep it's shape it will work fine. I'm still trying to think of something more ridgid, every one in a while you'll accidently bend it the wrong way and it'll crash. If you're careful and keep an eye on it while it's printing it'll be fine.

Either one should work. It looks like the dxf one just has an extra mounting point so it won't twist arround on the bolt. I'm using the single (jpg) one and it works just fine.

----------------------------------------------------

Build Progress Blog

Either one should work. It looks like the dxf one just has an extra mounting point so it won't twist arround on the bolt. I'm using the single (jpg) one and it works just fine.

----------------------------------------------------

Build Progress Blog

|

Re: Thin sheet question June 11, 2010 03:03PM |

Registered: 13 years ago Posts: 482 |

yea - I have used the 2 hole one and it sits fine. I needed to trim a little to clear the bearing in that corner...

I am concerned about the stiffness and having to replace it later will be a bit of an irritation...

well... gotta go visiting now although truth be told, I would rather continue building my printer

I am concerned about the stiffness and having to replace it later will be a bit of an irritation...

well... gotta go visiting now although truth be told, I would rather continue building my printer

|

Re: Thin sheet question June 11, 2010 07:54PM |

Registered: 14 years ago Posts: 75 |

For what it's worth, I made mine out of a Coke can and I've accidentally bumped it so many times (during construction - I'm not printing yet, but I do have the axes moving) that I'm convinced it is too flimsy and instead I should use some more stiff tin from a can of soup or something..

Another thin sheet problem I had was that the Y flag screw hole was in the wrong place, so the Y flag comes in at an angle and doesn't even reach the opto endstop.

--Jeff Keegan (Just Another RepRap blog)

Another thin sheet problem I had was that the Y flag screw hole was in the wrong place, so the Y flag comes in at an angle and doesn't even reach the opto endstop.

--Jeff Keegan (Just Another RepRap blog)

|

Re: Thin sheet question June 12, 2010 12:26AM |

Admin Registered: 16 years ago Posts: 476 |

Regarding change of x-flag shape: the svn log command is your friend. It says:

That commit changed the .dxf file, but not any derived files such as .jpg

Jonathan

r3597 | adrian-bowyer | 2010-05-27 08:15:39 -0700 (Thu, 27 May 2010) | 1 line

Minor change to X opto flag to give it two mounting holes (prevents rotation).

That commit changed the .dxf file, but not any derived files such as .jpg

Jonathan

|

Re: Thin sheet question June 12, 2010 05:57AM |

Registered: 13 years ago Posts: 482 |

|

Re: Thin sheet question June 12, 2010 07:52AM |

Registered: 14 years ago Posts: 3,742 |

Quote

Jeff Keegan

Another thin sheet problem I had was that the Y flag screw hole was in the wrong place, so the Y flag comes in at an angle and doesn't even reach the opto endstop.

How can the Y flag screw hole be in the wrong place, it is a simple rectangle?

If your Y flag is not matching up to the opto coupler on the Y motor bracket then you have either mounted it wrong (unlikely), or you don't have the Y motor bracket mounted in the proper position relative to the Y bars (more likely).

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Thin sheet question June 15, 2010 12:01AM |

Registered: 14 years ago Posts: 75 |

I mean I think the hole on my frog was in the wrong place, just a bit off to the side, so that when I screwed the rectangle Y flag to it, it's still coming in on the slanty part of the frog, so it's coming in at a bit of an angle. As a result, the flag is JUST short enough that it doesn't make a great connection with the opto switch. I'm planning on redoing them all with stiffer tin anyway, so I'll just make my new opto flag a little wider/longer or something. Maybe I'll post a picture later.

--Jeff Keegan (Just Another RepRap blog)

--Jeff Keegan (Just Another RepRap blog)

|

Re: Thin sheet question July 24, 2010 03:23AM |

Registered: 14 years ago Posts: 60 |

|

Re: Thin sheet question July 27, 2010 03:02AM |

Registered: 13 years ago Posts: 103 |

Using a beer can my approach to "flimsy" opt flags was to fold the metal over and use it double thickness. (Little bit of folding along the edges as well and they become less flimsy (I know doing sheet metal work at school would be useful). Not using the standard design for the thin sheet as my electronics are in different locations

David

David

|

Re: Thin sheet question July 27, 2010 04:52PM |

Registered: 14 years ago Posts: 75 |

Just a followup from me, I redid all of my endstops (as said above, they were originally from a Coke can) with a solid tin can of mandarin oranges, and now I'm extremely happy with them all. I had to redesign the Y one (either I drilled the hole in the wrong place on the frog, or I used the wrong hole, or something.. my new one looks a bit more like the others now).

Just buy a pair of tin snips at the hardware store, grab a can of soup or something, and cut them according to your paper cutouts.. Bend the folds with a pair of pliers, and you're good to go. Aluminum cans are a waste of time (at least without folding them, as davmj did, which I didn't try).

--Jeff Keegan (Just Another RepRap blog)

Just buy a pair of tin snips at the hardware store, grab a can of soup or something, and cut them according to your paper cutouts.. Bend the folds with a pair of pliers, and you're good to go. Aluminum cans are a waste of time (at least without folding them, as davmj did, which I didn't try).

--Jeff Keegan (Just Another RepRap blog)

|

Re: Thin sheet question August 05, 2010 07:50AM |

Registered: 14 years ago Posts: 75 |

One thing worth noting (as nophead just pointed out in another thread, which seems so far to have helped me) is to make sure your endflag isn't reflective either. I had some shiney tin can, which may have been what was giving me problems on my Y endstop every once in a while. In my case, a folding a piece of blue masking tape around the top and bottom seems to have fixed the problem. Black tape or paint is probably better, as long as it's not shiney.

--Jeff Keegan (Just Another RepRap blog)

--Jeff Keegan (Just Another RepRap blog)

Sorry, only registered users may post in this forum.