Need to decide 5mm, 8mm or proper leadscrews

Posted by gordonendersby

|

Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 01:47PM |

Registered: 9 years ago Posts: 286 |

Im speccing up my new machine and Ive got to decide what to do about the Z-axis leadscrews.

On my Prusa I2 ive been happily using stainless steel M8x1.25 threaded rod and im getting great results.

Its very good stainless rod, its got properly cut threads unlike cheaper zinc coated formed threads and the threads are nice and snug in the nuts and x-ends.

With springs in the x-ends im getting very little backlash and very little z-banding.

Im going to build a P3Steel. [reprap.org]

Ive got the 3mm steel frame parts already and intend to weld the main frame sections for extra stiffness.

The frame I got came with 5mm threaded zinc coated rods and they look awful and very thin.

Most of the P3steel printed parts out there seem to be designed for the 5mm rods and I suppose I could replace those zinc coated rods with better quality properly cut 5mm threaded stainless rod.

Although there seem to be some x-ends on the reprap wiki for proper lead screw nuts so I should be able to use them also.

But I havnt a clue what to go for at the moment.

As ive said, ive had great results with good quality stainless 8mm.

Ive got some nasty 5mm zinc coated threaded rod.

Or do I splash out on some decent 8mm Fine 1.5mm lead screws and nuts.

Will I really see any benefit over my good quality stainless 8mm threaded rod.

Gordon

On my Prusa I2 ive been happily using stainless steel M8x1.25 threaded rod and im getting great results.

Its very good stainless rod, its got properly cut threads unlike cheaper zinc coated formed threads and the threads are nice and snug in the nuts and x-ends.

With springs in the x-ends im getting very little backlash and very little z-banding.

Im going to build a P3Steel. [reprap.org]

Ive got the 3mm steel frame parts already and intend to weld the main frame sections for extra stiffness.

The frame I got came with 5mm threaded zinc coated rods and they look awful and very thin.

Most of the P3steel printed parts out there seem to be designed for the 5mm rods and I suppose I could replace those zinc coated rods with better quality properly cut 5mm threaded stainless rod.

Although there seem to be some x-ends on the reprap wiki for proper lead screw nuts so I should be able to use them also.

But I havnt a clue what to go for at the moment.

As ive said, ive had great results with good quality stainless 8mm.

Ive got some nasty 5mm zinc coated threaded rod.

Or do I splash out on some decent 8mm Fine 1.5mm lead screws and nuts.

Will I really see any benefit over my good quality stainless 8mm threaded rod.

Gordon

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 05:07PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 05:13PM |

Registered: 9 years ago Posts: 977 |

Actually the P3Steel inherited its Z-axis 5mm threaded rods from the Prusa i3. And the reason most people, including myself, use them, is because they work fine, and you gain practically nothing from going to 8mm threaded rods. Of course lead screws are great but again, they are very expensive compared to the dirt-cheap 5mm threaded rods and the gain in precision is very small compared to the extra expense.

You'll also notice that in actual use, the zinc coated threaded rods works exactly the same as the slightly more expensive stainless steel threaded rods.

If you absolutely want to use 8mm threaded rods you'll need different X motor and idler ends.

You'll also notice that in actual use, the zinc coated threaded rods works exactly the same as the slightly more expensive stainless steel threaded rods.

If you absolutely want to use 8mm threaded rods you'll need different X motor and idler ends.

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 05:58PM |

Registered: 9 years ago Posts: 286 |

I thought the reason the i3 going for m5x1mm is the thread pitch and steps to pitch ratio.

Before that it was 8mmx1.25 threaded rod as per the i2 frame.

The zink coated threaded rods are formed with the thread undersized ready for the zinc coating.

The stainless are cut threads, smoother and more accurate.

M5 come as 1mm thread pitch.

M8 come as 1.25mm thread pitch.

The 8mm lead screw comes as fine 1.50mm pitch.

The 8mm lead screws standard is 2mm pitch.

So im trying to compare the pitches against the accuracy as much as anything.

Definetly want to ignore the zinc coated. Why have the rough zinc coating when stainless smooth cut threads are not much more.

So is it worth going on to the proper lead screws even though the pitch is lower.

Stick with m8 that i know Ive got good results from. Not a problem to import the files and change the x-ends to 13m hex heads.

Or will the 5mm x 1mm thread and pitch get me near to the proper lead screws anyway.

Gordon

Before that it was 8mmx1.25 threaded rod as per the i2 frame.

The zink coated threaded rods are formed with the thread undersized ready for the zinc coating.

The stainless are cut threads, smoother and more accurate.

M5 come as 1mm thread pitch.

M8 come as 1.25mm thread pitch.

The 8mm lead screw comes as fine 1.50mm pitch.

The 8mm lead screws standard is 2mm pitch.

So im trying to compare the pitches against the accuracy as much as anything.

Definetly want to ignore the zinc coated. Why have the rough zinc coating when stainless smooth cut threads are not much more.

So is it worth going on to the proper lead screws even though the pitch is lower.

Stick with m8 that i know Ive got good results from. Not a problem to import the files and change the x-ends to 13m hex heads.

Or will the 5mm x 1mm thread and pitch get me near to the proper lead screws anyway.

Gordon

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 06:15PM |

Registered: 9 years ago Posts: 286 |

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 07:02PM |

Registered: 11 years ago Posts: 5,780 |

The only concern with the pitch is how many steps does your motor need to make per mm. with 2mm pitch and a 200 step per rev motor you'll have 100 steps per mm. Since you'll probably be printing in 100-300 um layers, you'll have 10-30 steps per layer. It should be enough. You can use microstepping to get more steps per layer...

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 07:57PM |

Registered: 9 years ago Posts: 977 |

Quote

gordonendersby

I thought the reason the i3 going for m5x1mm is the thread pitch and steps to pitch ratio.

Before that it was 8mmx1.25 threaded rod as per the i2 frame.

The zink coated threaded rods are formed with the thread undersized ready for the zinc coating.

The stainless are cut threads, smoother and more accurate.

M5 come as 1mm thread pitch.

M8 come as 1.25mm thread pitch.

The 8mm lead screw comes as fine 1.50mm pitch.

The 8mm lead screws standard is 2mm pitch.

So im trying to compare the pitches against the accuracy as much as anything.

Definetly want to ignore the zinc coated. Why have the rough zinc coating when stainless smooth cut threads are not much more.

So is it worth going on to the proper lead screws even though the pitch is lower.

Stick with m8 that i know Ive got good results from. Not a problem to import the files and change the x-ends to 13m hex heads.

Or will the 5mm x 1mm thread and pitch get me near to the proper lead screws anyway.

Gordon

The pitch matters of course but in this case using 1mm or 2mm pitch is irrelevant. You have to reason around the stepper and the stepper driver microstepping and also the layer thickness you are trying to achieve.

For a 1.8 degrees stepper with 1/16th microstepping, you have 4000 steps per mm (iirc, check it for yourself please) for the Z axis on the standard Prusa i3 or P3Steel i.e. 0.25microns per step. Using a 8mm standard lead screw you would have 2000 steps per mm i.e. 0.5 microns per step. The thinnest layer you are likely to want to print is 100 microns, so as you can see, with either thread pitch you still have more than enough resolution.

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 08:28PM |

Registered: 9 years ago Posts: 286 |

I understood there were issues with calculations and rounding where the 1mm pitch helped.

Im running 1/32 microstepping on my prusa i2 as ive got drv8825's.

Im keeping it for small accurate prints as ive managed to get it very good at fine detail and tiny prints.

My finest layer height is 0.06mm with the 0.3mm nozzle.

The new machine is supposed to be more about giving me more height for printing.

So really theres no need for 1/32 stepping but it might be nice as they are smoother and less noisy.

I still keep looking at those skinny M5 rods. They just dont look substantial enough.

I think im leaning more to proper lead screws from the info you have all given me.

If im going to the trouble of welding the frame as well. I might as well go for the more substantial and accurately made lead screws.

I think ill try and go for the 8mm fine 1.5mm rather than the 2mm if its not overly expensive and available.

Thanks for the input.

Edited 1 time(s). Last edit at 04/25/2015 08:29PM by gordonendersby.

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

Im running 1/32 microstepping on my prusa i2 as ive got drv8825's.

Im keeping it for small accurate prints as ive managed to get it very good at fine detail and tiny prints.

My finest layer height is 0.06mm with the 0.3mm nozzle.

The new machine is supposed to be more about giving me more height for printing.

So really theres no need for 1/32 stepping but it might be nice as they are smoother and less noisy.

I still keep looking at those skinny M5 rods. They just dont look substantial enough.

I think im leaning more to proper lead screws from the info you have all given me.

If im going to the trouble of welding the frame as well. I might as well go for the more substantial and accurately made lead screws.

I think ill try and go for the 8mm fine 1.5mm rather than the 2mm if its not overly expensive and available.

Thanks for the input.

Edited 1 time(s). Last edit at 04/25/2015 08:29PM by gordonendersby.

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 25, 2015 09:47PM |

Registered: 9 years ago Posts: 977 |

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 01:33AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 05:30AM |

Registered: 9 years ago Posts: 286 |

Why weld the frame, because ive got a mig welder sitting in the garage.

Ive chosen the p3steel for its mass, helps with vibration and stiffness, its going to be the same shape every print.

Those little 3mm bolts holding it together are ok, but welding is better.

No mucking around checking its all done up tight and aligned properly regularly as you should do.

Ill bolt it together, check its alignment, do a few welding tacs, check the alignment.

Bang it a few times with a hammer.Then add a few strategic stitch welds.

Not sure about some of the other brackets and fittings as i may make changes later.

Once thats done the main frame isnt going anywhere and makes a very stable platform for everything else on top.

The whole reprap thing is about using what youve got access to.

When i built my prusa i2 i had access to 8mm stainless threaded rod for a good price.

It turned out to be a good decision. While stainless bends a little easier than mild steel rod. Its heavier.

My machine came out heavier than others ive seen.

I think this contributes to how well it prints very small parts and not a spec of rust.

Have i mentioned i just happen to have a mig welder sitting in the garage.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

Ive chosen the p3steel for its mass, helps with vibration and stiffness, its going to be the same shape every print.

Those little 3mm bolts holding it together are ok, but welding is better.

No mucking around checking its all done up tight and aligned properly regularly as you should do.

Ill bolt it together, check its alignment, do a few welding tacs, check the alignment.

Bang it a few times with a hammer.Then add a few strategic stitch welds.

Not sure about some of the other brackets and fittings as i may make changes later.

Once thats done the main frame isnt going anywhere and makes a very stable platform for everything else on top.

The whole reprap thing is about using what youve got access to.

When i built my prusa i2 i had access to 8mm stainless threaded rod for a good price.

It turned out to be a good decision. While stainless bends a little easier than mild steel rod. Its heavier.

My machine came out heavier than others ive seen.

I think this contributes to how well it prints very small parts and not a spec of rust.

Have i mentioned i just happen to have a mig welder sitting in the garage.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 06:02AM |

Registered: 9 years ago Posts: 977 |

Have you got the P3Steel frame already in your hands, and if so, did you assemble it? Because if/when you do, you'll notice that it doesn't need soldering, it's completely rigid just screwed together as it was designed to be.

I am saying this after having assembled more than a half dozen P3Steel frames (pictures of two of these frames are in the wiki, btw), but don't take my word for it, you can ask any P3Steel builder/user if he has ever felt that the frame was not stiff enough or needed any solder joints.

On the other hand, if you feel like using your mig soldering apparatus, go ahead and solder away. It's just like the lead screws, this is not at all required and won't change anything in the final performance of the printer, but if it makes you feel good, then why not?

BTW if you start soldering things midway in the build and then feel like you have to disassemble some part of the frame, what are you going to do? Unsolder?

I am saying this after having assembled more than a half dozen P3Steel frames (pictures of two of these frames are in the wiki, btw), but don't take my word for it, you can ask any P3Steel builder/user if he has ever felt that the frame was not stiff enough or needed any solder joints.

On the other hand, if you feel like using your mig soldering apparatus, go ahead and solder away. It's just like the lead screws, this is not at all required and won't change anything in the final performance of the printer, but if it makes you feel good, then why not?

BTW if you start soldering things midway in the build and then feel like you have to disassemble some part of the frame, what are you going to do? Unsolder?

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 09:48AM |

Registered: 9 years ago Posts: 286 |

Still flat packed at the moment. Ive got to fix the small defects that got it reduced price. Just a little hand filing.

I only inted to weld the main structure. But i may weld other bits. Ill decide later as i go.

Id like tomake each axis cartridge like for maintenance.

For example being able to remove the whole x-axis as a single unit. So its bolted in place.

Each z-axis tower as individual bolt on units.

The the bed to be able to be unbolted and lifted off including the guide rods.

Decided this after finding how fiddly it is just to replace the rods in situ on the i2.

The i3 style is more accesable but thats what im aiming for.

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

I only inted to weld the main structure. But i may weld other bits. Ill decide later as i go.

Id like tomake each axis cartridge like for maintenance.

For example being able to remove the whole x-axis as a single unit. So its bolted in place.

Each z-axis tower as individual bolt on units.

The the bed to be able to be unbolted and lifted off including the guide rods.

Decided this after finding how fiddly it is just to replace the rods in situ on the i2.

The i3 style is more accesable but thats what im aiming for.

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 10:19AM |

Registered: 11 years ago Posts: 5,780 |

These are all good ideas. I set my printer up with modular X and Y axes that are held in place by two screws/nuts each. The Z axis screws also bolt to the frame with two screws each. I can pull the X and Y assemblies off the frame in about 2 minutes (mostly to unscrew the screw terminals that I used for electrical connections), and I can put them back almost as quickly. The Z axis would take a little longer because the X axis bolts to it. My bed plate doesn't come off quite so easily, but the only thing it requires is occasional replacement of kapton tape which I can do with the bed in situ.

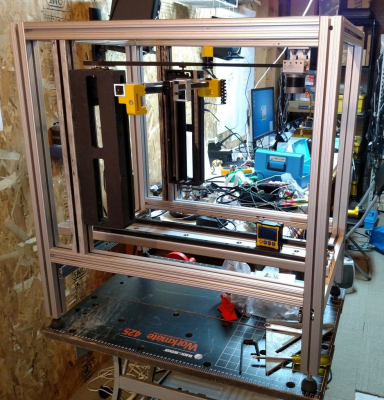

If you really want to go for quality printing and minimal maintenance/adjustment, replace end supported guide rails with fully supported rails or linear guides. I have linear guides in my X and Y axes and the bed is so solid I never have to relevel or zero it even after transporting the machine in my car laying on its side.

Edited 1 time(s). Last edit at 04/26/2015 10:22AM by the_digital_dentist.

If you really want to go for quality printing and minimal maintenance/adjustment, replace end supported guide rails with fully supported rails or linear guides. I have linear guides in my X and Y axes and the bed is so solid I never have to relevel or zero it even after transporting the machine in my car laying on its side.

Edited 1 time(s). Last edit at 04/26/2015 10:22AM by the_digital_dentist.

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 11:19AM |

Registered: 9 years ago Posts: 286 |

Ive seen the linear rails.

What have you got underneath tHem or are they able to span the length of the printer unsupported?

For some reason ive got the idea they need to be on some kind of bed or bar over there length for support.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

What have you got underneath tHem or are they able to span the length of the printer unsupported?

For some reason ive got the idea they need to be on some kind of bed or bar over there length for support.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Need to decide 5mm, 8mm or proper leadscrews April 26, 2015 11:56AM |

Registered: 11 years ago Posts: 5,780 |

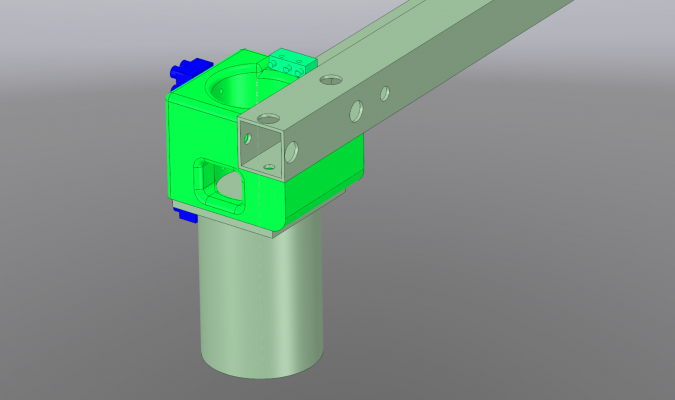

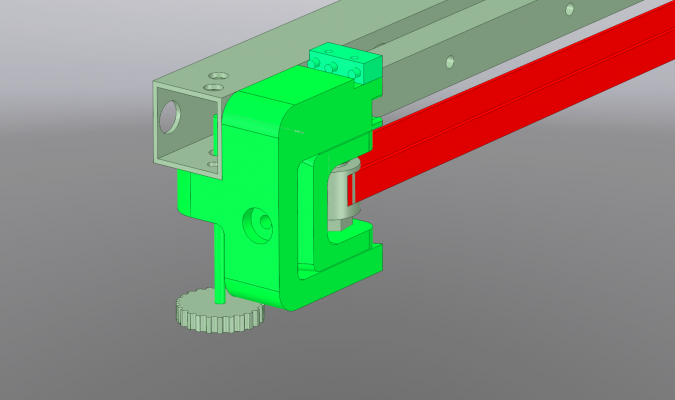

In my X-axis the linear guide is screwed to a 1" square x 1/8" wall tube. I suspect the X axis would have been OK without any extra support, but the tube makes it easy to attach other things like belt tensioners, limit switches, and motor mounts. The Y axis has a very heavy aluminum base plate. I think a much lighter rectangular tube would have been adequate, but the plate was offered to me cheaper than a tube would have cost, and there was no questioning the rigidity of the plate, so I used the plate.

The motor mount and and belt tensioner are both printed. I like the motor mount but would make a small change to the belt tensioner design. The the sliding part is a wedge design that was intended to keep the slide locked firmly into the fixed piece. The problem is the plastic flexes a bit when you put tension on the belt and the wedge tilts out a little. I think a simple ledge on the sliding part with corresponding grooves on the fixed part would have been less likely to distort under tension. I may eventually mill both pieces out of aluminum.

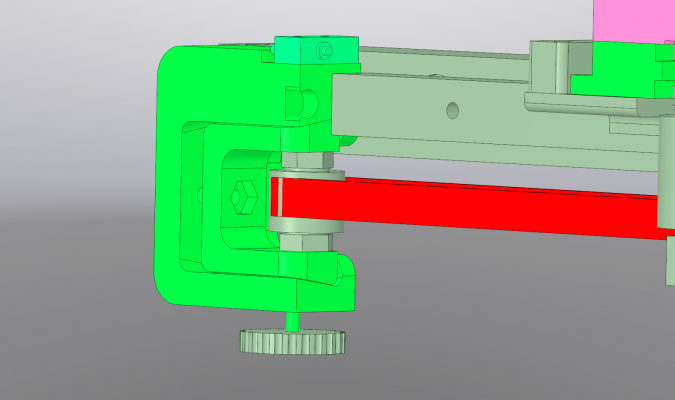

The thumbwheel at the bottom of the belt tensioner bumps a limit switch to set the zero position in the Z axis. I am considering going to an optical switch for better precision and will probably modify the design for it shortly. The limit switches on the belt tensioner and motor mount get bumped by the bearing block on the linear guide.

Edited 4 time(s). Last edit at 04/26/2015 12:24PM by the_digital_dentist.

The motor mount and and belt tensioner are both printed. I like the motor mount but would make a small change to the belt tensioner design. The the sliding part is a wedge design that was intended to keep the slide locked firmly into the fixed piece. The problem is the plastic flexes a bit when you put tension on the belt and the wedge tilts out a little. I think a simple ledge on the sliding part with corresponding grooves on the fixed part would have been less likely to distort under tension. I may eventually mill both pieces out of aluminum.

The thumbwheel at the bottom of the belt tensioner bumps a limit switch to set the zero position in the Z axis. I am considering going to an optical switch for better precision and will probably modify the design for it shortly. The limit switches on the belt tensioner and motor mount get bumped by the bearing block on the linear guide.

Edited 4 time(s). Last edit at 04/26/2015 12:24PM by the_digital_dentist.

|

Re: Need to decide 5mm, 8mm or proper leadscrews June 10, 2015 02:04AM |

Registered: 10 years ago Posts: 62 |

I'd start with the 5mm threaded rod it came with. Any printer is only going to be as good as the weakest part, and you won't know what that is until it's up and running. Once it's printing you can decide if it's worth the trouble of changing to 8mm threaded or lead screws, or spend the time/money upgrading other parts of it that bug you.

|

Re: Need to decide 5mm, 8mm or proper leadscrews June 10, 2015 08:34AM |

Registered: 11 years ago Posts: 5,780 |

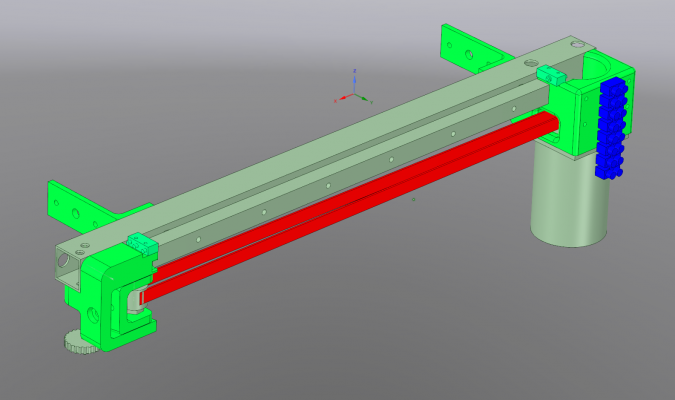

Here's a clear view of the plate that supports the Y axis linear guides in my printer:

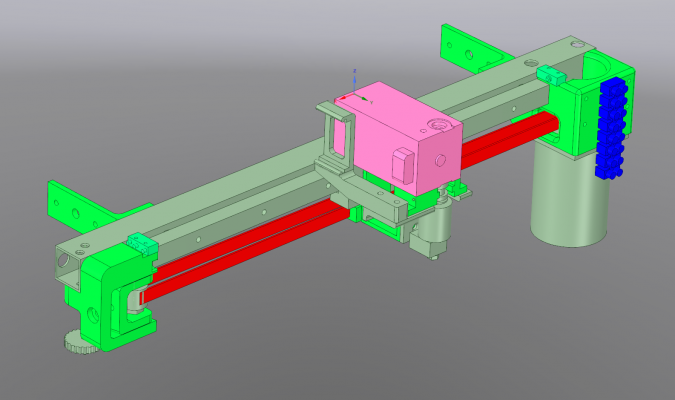

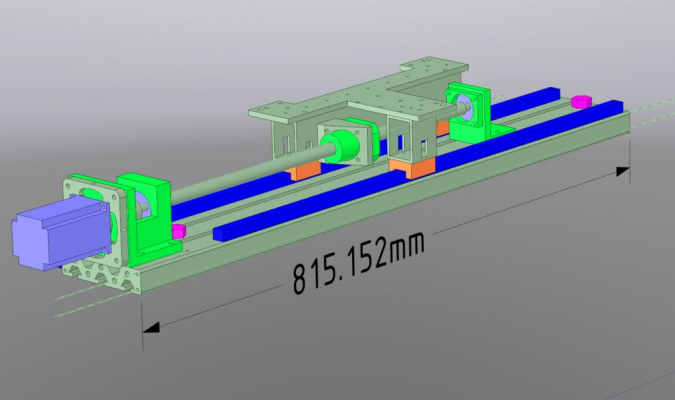

Here's a CAD drawing of Y axis as I actually finished it:

The two pink bolts are the screws that attach the Y axis to the machine's frame.

You can see the Y axis bolted to the frame here:

You can see the whole thing here: Son of MegaMax

Here's a CAD drawing of Y axis as I actually finished it:

The two pink bolts are the screws that attach the Y axis to the machine's frame.

You can see the Y axis bolted to the frame here:

You can see the whole thing here: Son of MegaMax

Sorry, only registered users may post in this forum.