Mendel Build Height

Posted by brnrd

|

Mendel Build Height January 29, 2011 11:08AM |

Registered: 13 years ago Posts: 1,780 |

The Mendel wiki (http://reprap.org/wiki/Mendel) specifies a build envelope with a height of 140 mm. But with Adrian's geared extruder, I found that I can only go a little over 70 mm before the gear hits one of the frame bars. I don't know how high you can go with Wade's extruder but it looks like the gear which is rotated 90 degrees would also hit. Is anyone working on a solution to increase the height by either redesigning the extruder or the frame?

|

Re: Mendel Build Height January 29, 2011 04:14PM |

Admin Registered: 17 years ago Posts: 7,879 |

The motor hits the frame with Wade's. I only get 35mm, but that is because I have lost 23mm with my heated bed and about 10mm with my extruder's heatsink. That would give about 70mm with Wade's and I always assumed Adrian's would go higher because the gear does not stick out as far as the motor does on Wade's.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Mendel Build Height February 01, 2011 03:46PM |

Registered: 14 years ago Posts: 80 |

This is true. I beleive that you can get ~140mm without anything mounted on the carriage. To maximize your build height, you would probably want to move towards an Bowden Extruder setup like you find on a Ultimaker (http://blog.ultimaker.com/) This way you do not limit the Z height by the extruder height.

I am using a Stepper Extruder from Makergear (http://www.Makergear.com/) and i am able to max out safely at ~100mm travel in Z. This could be improved by compressing the springs on your print bed as much as possible while still remaining level.

I would still say that Bowden Extruder(http://reprap.org/wiki/Erik's_Bowden_Extruder) is the way to go.

I am using a Stepper Extruder from Makergear (http://www.Makergear.com/) and i am able to max out safely at ~100mm travel in Z. This could be improved by compressing the springs on your print bed as much as possible while still remaining level.

I would still say that Bowden Extruder(http://reprap.org/wiki/Erik's_Bowden_Extruder) is the way to go.

|

Re: Mendel Build Height February 03, 2011 08:40AM |

Registered: 13 years ago Posts: 1,780 |

The Bowden extruder is a good idea. Aside from the increased height, it's also easier to fit multiple extruders. One problem is the hysteresis resulting from the long filament and the sleeve between the gear and the hot end. Perhaps there are better cable guides out there using different materials or having metal lining like the cable guides in bikes.

Instead of a bowden cable, how about keeping the gear right above the hot end and driving it with a remote motor through a flex shaft like this?

[www.amazon.com]

This would have the same advantage and might be better in terms of hysteresis.

Instead of a bowden cable, how about keeping the gear right above the hot end and driving it with a remote motor through a flex shaft like this?

[www.amazon.com]

This would have the same advantage and might be better in terms of hysteresis.

|

Re: Mendel Build Height February 03, 2011 08:57AM |

Registered: 13 years ago Posts: 482 |

Since that item you linked is designed to work with a dremel I would imagine that it would not be stiff enough to predict the exact result when turning the stepper a few steps one way or the other.

Would the mechanism that allows the shaft to be flexible not also allow it to twist independant of the drive to some degree...?

I guess only experimentation would tell.

Thing is you are simply removing the motor but still need the gearing... erm actually I guess you would have the gearing with the motor and connect this directly to the filament feed...

Would the mechanism that allows the shaft to be flexible not also allow it to twist independant of the drive to some degree...?

I guess only experimentation would tell.

Thing is you are simply removing the motor but still need the gearing... erm actually I guess you would have the gearing with the motor and connect this directly to the filament feed...

|

Re: Mendel Build Height February 03, 2011 10:15AM |

Registered: 13 years ago Posts: 485 |

Instead of the flex shaft, you could use something like a spline shaft to move the motor to the end of the X axis. The spline shaft would lie parallel to the X axis, and the pinion gear would slide along it to maintain contact with the main gear on the extruder. Of course, you don't need a proper spline shaft for this application. You could maybe use a small rectangular aluminum extrusion for the shaft, or perhaps some spur gear shaft.

I like the aluminum box tube a little better than the gear shaft. I think it will be easier to mate parts to. This idea will add a little drag to the X axis, but it also moves the stepper off the carriage while avoiding the issues of the bowden extruder. It would add a little weight for the Z axis to lift, but it shouldn't be much.

Or, you could just rework the frame vertices to get more vertical space, instead of constraining the already complex extruder design with requirements dictated by an inconvenient static structure.

Edited 1 time(s). Last edit at 02/03/2011 10:20AM by Dale Dunn.

I like the aluminum box tube a little better than the gear shaft. I think it will be easier to mate parts to. This idea will add a little drag to the X axis, but it also moves the stepper off the carriage while avoiding the issues of the bowden extruder. It would add a little weight for the Z axis to lift, but it shouldn't be much.

Or, you could just rework the frame vertices to get more vertical space, instead of constraining the already complex extruder design with requirements dictated by an inconvenient static structure.

Edited 1 time(s). Last edit at 02/03/2011 10:20AM by Dale Dunn.

|

Re: Mendel Build Height February 04, 2011 07:20PM |

Registered: 13 years ago Posts: 1,780 |

AgeingHippy Wrote:

-------------------------------------------------------

> Since that item you linked is designed to work

> with a dremel I would imagine that it would not be

> stiff enough to predict the exact result when

> turning the stepper a few steps one way or the

> other.

>

> Would the mechanism that allows the shaft to be

> flexible not also allow it to twist independant of

> the drive to some degree...?

I used the dremel flex shaft just as example. You're right. I checked the one that I have and there is significant play between the two ends. I don't know if there are any that would be flexible enough so that the extruder can move relative to the motor and still be rigid enough to prevent twisting. Unless there is such a thing, the Bowden extruder might still be better.

-------------------------------------------------------

> Since that item you linked is designed to work

> with a dremel I would imagine that it would not be

> stiff enough to predict the exact result when

> turning the stepper a few steps one way or the

> other.

>

> Would the mechanism that allows the shaft to be

> flexible not also allow it to twist independant of

> the drive to some degree...?

I used the dremel flex shaft just as example. You're right. I checked the one that I have and there is significant play between the two ends. I don't know if there are any that would be flexible enough so that the extruder can move relative to the motor and still be rigid enough to prevent twisting. Unless there is such a thing, the Bowden extruder might still be better.

|

Re: Mendel Build Height February 04, 2011 07:32PM |

Registered: 13 years ago Posts: 1,780 |

Dale Dunn Wrote:

-------------------------------------------------------

> Instead of the flex shaft, you could use something

> like a spline shaft to move the motor to the end

> of the X axis. The spline shaft would lie parallel

...

This is also a good idea and would make it possible to mount multiple extruders. I thought about a splined shaft too but I was concerned about the additional friction on the X-axis. I also thought it would be difficult to line up the shaft with the gears over the full range of the X-axis. But your idea of using a rectangular rod might work.

-------------------------------------------------------

> Instead of the flex shaft, you could use something

> like a spline shaft to move the motor to the end

> of the X axis. The spline shaft would lie parallel

...

This is also a good idea and would make it possible to mount multiple extruders. I thought about a splined shaft too but I was concerned about the additional friction on the X-axis. I also thought it would be difficult to line up the shaft with the gears over the full range of the X-axis. But your idea of using a rectangular rod might work.

|

Re: Mendel Build Height February 04, 2011 09:53PM |

Registered: 13 years ago Posts: 485 |

|

Re: Mendel Build Height February 05, 2011 09:08AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel Build Height February 13, 2011 10:10PM |

Registered: 13 years ago Posts: 1,780 |

Has anyone tried using hypocycloid gear reduction in place of the gears in either Wade's or Adrian's geared extruders? This looks like a practical way to increase build height by eliminating the large driven gear in those extruders. In this page, the author used a two-stage gear for the challenge but one stage should be enough for the extruder.

|

Re: Mendel Build Height February 13, 2011 11:20PM |

Registered: 16 years ago Posts: 1,094 |

I and a few others have investigated differential hypocycloids, will experiment when my reprap is printing!

Check out this and this

-----------------------------------------------

Wooden Mendel

Teacup Firmware

Check out this and this

-----------------------------------------------

Wooden Mendel

Teacup Firmware

|

Re: Mendel Build Height February 18, 2011 04:02AM |

Registered: 13 years ago Posts: 486 |

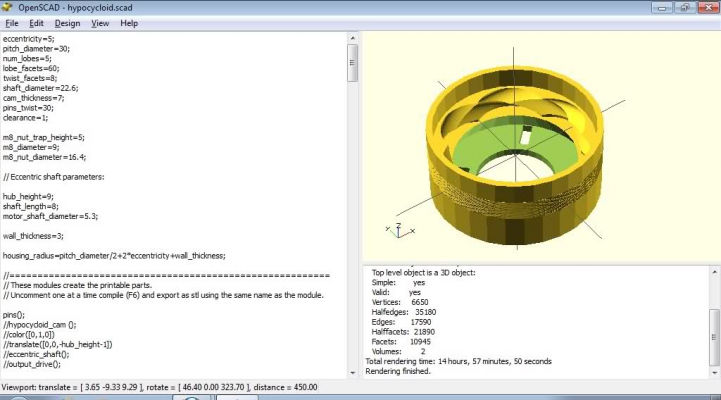

Im working on a parametric herringbone hypocycloid speed reducer design in openscad (wow thats a mouthful!)

I have some issues at the moment though: note the render time!

I have some issues at the moment though: note the render time!

|

Re: Mendel Build Height February 18, 2011 04:31AM |

Registered: 14 years ago Posts: 3,742 |

Greg Frost Wrote:

-------------------------------------------------------

> I have some issues at the moment though: note the render time!

Looks like you need a more powerful PC.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

-------------------------------------------------------

> I have some issues at the moment though: note the render time!

Looks like you need a more powerful PC.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Mendel Build Height February 18, 2011 06:38AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel Build Height February 18, 2011 08:18AM |

Registered: 16 years ago Posts: 438 |

Maybe submit your file to the openscad guys as a bug report? That's a really unreasonable compile render time.

--

I'm building it with Baling Wire

--

I'm building it with Baling Wire

|

Re: Mendel Build Height February 18, 2011 08:49AM |

Registered: 14 years ago Posts: 3,742 |

How about posting your hypocycloid.scad file, maybe it can be optimized for speed...

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Mendel Build Height February 18, 2011 04:23PM |

Admin Registered: 15 years ago Posts: 1,470 |

Triffid_Hunter Wrote:

-------------------------------------------------------

> I and a few others have investigated differential

> hypocycloids, will experiment when my reprap is

> printing!

>

> Check out this and this

Your youtube links don't work. I've noticed that before as well.

-------------------------------------------------------

> I and a few others have investigated differential

> hypocycloids, will experiment when my reprap is

> printing!

>

> Check out this and this

Your youtube links don't work. I've noticed that before as well.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Sorry, only registered users may post in this forum.