new Open x carriage. Thoughts?

Posted by Buback

|

Re: new Open x carriage. Thoughts? February 18, 2011 11:57AM |

Registered: 13 years ago Posts: 601 |

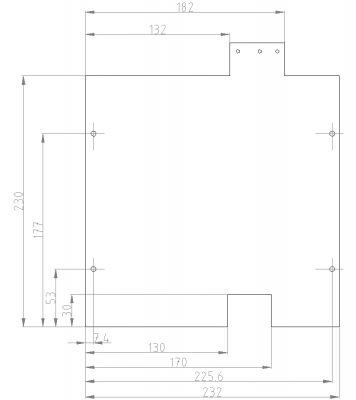

doh. these measurements aren't listed anywhere as far as I've seen. i guess i need to find out for certain before i print out any more arms.

---

it's an I2C connector, i think, which would allow you to connect something like a heated bed controller addon. it's only comms, though, no power. you COULD create a fan controller board, and connect it to the IC2 (it's a standard, i hear), and control when the fan turns on and off by adding code to the firmware, but that sounds like a lot of work, and you'd still need to get power to the fan by hooking up some leads to the 12 v source.

probably easier just to hook a 12V fan up to the source and have it always on. i think all you need to do is stick the leads into the screw terminals on the gen6

--

i attached some screenshots of the crossbar on the top. is this what you had in mind? this example is using a triangular RP crossmember, but the same idea could easily be done in other shapes, like for 8mm rod.

---

it's an I2C connector, i think, which would allow you to connect something like a heated bed controller addon. it's only comms, though, no power. you COULD create a fan controller board, and connect it to the IC2 (it's a standard, i hear), and control when the fan turns on and off by adding code to the firmware, but that sounds like a lot of work, and you'd still need to get power to the fan by hooking up some leads to the 12 v source.

probably easier just to hook a 12V fan up to the source and have it always on. i think all you need to do is stick the leads into the screw terminals on the gen6

--

i attached some screenshots of the crossbar on the top. is this what you had in mind? this example is using a triangular RP crossmember, but the same idea could easily be done in other shapes, like for 8mm rod.

|

Re: new Open x carriage. Thoughts? February 18, 2011 12:46PM |

Registered: 13 years ago Posts: 39 |

Of course, just wire up to the 12v from the laptop brick. Stupid.

About the Axle. All I really meant was imagine the pencil prototype you've built already, except the pencil is twice as long, and it tunnels through all three components on each runner. That way the runners are held more rigidly against their tendency to rotate around their bars due of the weight of the build plate. On reflection it's a marginal gain. And tear drop holes in those parts would eat up most of the plastic, wouldn't they. I hadn't thought about that. Your prototype is good, If you are worried about long term plastic sag then your plan to lay the axle along the top of all the parts is the best solution. Again, the axle makes up for poorly printed parts that have to be used in an emergency, because it holds them all together, in the same place. If not, then your prototype is good! It's very simple and clean.

Hope Camiel designs in the heated-bed controller sometime. I left the bread maker heating element on too long last night. All the solder that was improving the element's surface contact with my build plate melted off! Luckily it pooled in the kapton tape. Took the plate off, turned it upside down and remelted the solder back under the element and onto the build plate lol. Upshot is, I need an automatic thermostat controller.

Woodsmoke

r:-8

About the Axle. All I really meant was imagine the pencil prototype you've built already, except the pencil is twice as long, and it tunnels through all three components on each runner. That way the runners are held more rigidly against their tendency to rotate around their bars due of the weight of the build plate. On reflection it's a marginal gain. And tear drop holes in those parts would eat up most of the plastic, wouldn't they. I hadn't thought about that. Your prototype is good, If you are worried about long term plastic sag then your plan to lay the axle along the top of all the parts is the best solution. Again, the axle makes up for poorly printed parts that have to be used in an emergency, because it holds them all together, in the same place. If not, then your prototype is good! It's very simple and clean.

Hope Camiel designs in the heated-bed controller sometime. I left the bread maker heating element on too long last night. All the solder that was improving the element's surface contact with my build plate melted off! Luckily it pooled in the kapton tape. Took the plate off, turned it upside down and remelted the solder back under the element and onto the build plate lol. Upshot is, I need an automatic thermostat controller.

Woodsmoke

r:-8

|

Re: new Open x carriage. Thoughts? February 18, 2011 01:15PM |

Registered: 13 years ago Posts: 601 |

running the cross member through all the pieces is a bit tricky just because of how they are printed. the 210 bearing arm is no problem, as that 8mm hole would be along the z axis as it printed, but the other two arms would have to have teardrop holes. it's not out of the question, of course. and once it's published and out in the wild that may be the direction development goes.

edit: Ok, This image

from the heated bed build page shows that the holes are 218.2mm apart along the x and 124mm apart along the y. The wiki page says that they are exactly the same as the regular bed, so i went back and added them to the materials prep page in the mendel build instructions.

I'll make the changes to the files, but i don't want to print out the arms again. I print on a glass plate salvaged from an old xerox machine, held down by some scavenged hard drive magnets, so the mounting holes aren't important to me, as the glass sits above the screws anyway. I just want to test it out at this point, and i doubt a couple mm will effect the results of the tests.

Edited 1 time(s). Last edit at 02/18/2011 02:45PM by Buback.

edit: Ok, This image

from the heated bed build page shows that the holes are 218.2mm apart along the x and 124mm apart along the y. The wiki page says that they are exactly the same as the regular bed, so i went back and added them to the materials prep page in the mendel build instructions.

I'll make the changes to the files, but i don't want to print out the arms again. I print on a glass plate salvaged from an old xerox machine, held down by some scavenged hard drive magnets, so the mounting holes aren't important to me, as the glass sits above the screws anyway. I just want to test it out at this point, and i doubt a couple mm will effect the results of the tests.

Edited 1 time(s). Last edit at 02/18/2011 02:45PM by Buback.

|

Re: new Open x carriage. Thoughts? September 28, 2011 07:28AM |

Registered: 13 years ago Posts: 87 |

I experienced several problems getting this piece to work:

1) As I mentioned on Thingiverse my Herringbone extruder didn't fit. The gear for this extruder dips below the base of the main block and hits the carriage. I solved it by printing out a small 5mm riser, although I vaguely remember seeing somewhere that someone has released an alternate design with this modification built in?

2) The threads for my Adrian's hot end rubbed against the x-rails when installed. Again, this is a simple incompatibility with the Herringbone extruder. I solved it by drilling additional mounting holes in the carriage and riser about 1cm further back.

3) The belt keeps slipping off (my machine is a Mendel). I solved this with a couple of plastic ties, but I've lost the clip-on-clip-off which was why I wanted this piece in the first place. Will have to look at the belt clamp and see if that will work on a Mendel.

4) The adjustable arm has a tendency to slip if it's not secured very tight. I think I might need to add a rubber band or something here to keep the tension taught.

Now, that said, it's working really, really well! My x axis edges have all suddenly became perfectly straight and look very clean compared to my y axis edges. I'm in the middle of printing up an open-y carriage in the hope that it works just as well.

1) As I mentioned on Thingiverse my Herringbone extruder didn't fit. The gear for this extruder dips below the base of the main block and hits the carriage. I solved it by printing out a small 5mm riser, although I vaguely remember seeing somewhere that someone has released an alternate design with this modification built in?

2) The threads for my Adrian's hot end rubbed against the x-rails when installed. Again, this is a simple incompatibility with the Herringbone extruder. I solved it by drilling additional mounting holes in the carriage and riser about 1cm further back.

3) The belt keeps slipping off (my machine is a Mendel). I solved this with a couple of plastic ties, but I've lost the clip-on-clip-off which was why I wanted this piece in the first place. Will have to look at the belt clamp and see if that will work on a Mendel.

4) The adjustable arm has a tendency to slip if it's not secured very tight. I think I might need to add a rubber band or something here to keep the tension taught.

Now, that said, it's working really, really well! My x axis edges have all suddenly became perfectly straight and look very clean compared to my y axis edges. I'm in the middle of printing up an open-y carriage in the hope that it works just as well.

Sorry, only registered users may post in this forum.