a T Slot mendel frame

Posted by Buback

|

a T Slot mendel frame March 10, 2011 02:19PM |

Registered: 13 years ago Posts: 601 |

it's something i want to work on. My plan is to design RP parts to connect the t slot, instead of buying connectors. the t slot itself it relatively cheap. slightly more than steel studding, maybe, but potentially more rigid. it might even be very easy to get it pre-cut to size.

I'm basing the RP parts around the mendel style equilateral triangle, so that the axes remain relatively unchanged.

the key is going to be getting the pieces to print, and how it's assembled, i think.

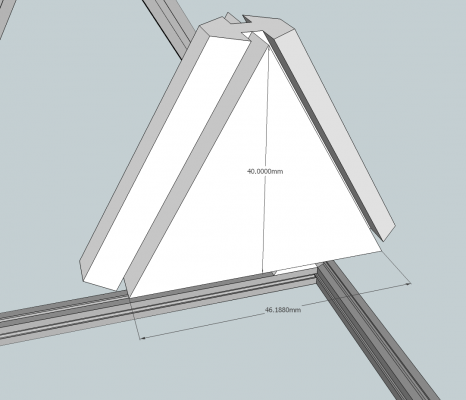

the triangle piece looks like this:

if printed this way, the overhang would be 60 degrees, which i think would be ok as long as your printer is printing well. the other option is to slice it in half down the middle of the T (so that the side facing you in the above picture would be the top) and screw them together.

The bottom would be similar, but at 45 degrees overhanging, which i don't think would be printable as one piece.

I'm basing the RP parts around the mendel style equilateral triangle, so that the axes remain relatively unchanged.

the key is going to be getting the pieces to print, and how it's assembled, i think.

the triangle piece looks like this:

if printed this way, the overhang would be 60 degrees, which i think would be ok as long as your printer is printing well. the other option is to slice it in half down the middle of the T (so that the side facing you in the above picture would be the top) and screw them together.

The bottom would be similar, but at 45 degrees overhanging, which i don't think would be printable as one piece.

|

Re: a T Slot mendel frame March 10, 2011 04:55PM |

Registered: 13 years ago Posts: 485 |

The equilateral triangle arrangement gives up some Z travel when the extruder gets near the top bar. What about opening it up into a trapezoid? The axes' mechanisms would still be similar, and you'd get 70mm+ more Z axis travel. If the top of the trapezoid is just wide enough to pass the extruder, you might not need to add a second extrusion at the top. This would also open up the angles of your corner pieces so you have less overhang.

Or, you could abandon each side triangle for an inverted "T" with a diagonal brace. You would still be able to use most of the existing axes' design, but with nothing above the extruder to get in the way. I think you'd have to print the corners as two pieces, but you might get more efficient use of your vitamins.

How do you plan to fix the corners to the extrusion?

Or, you could abandon each side triangle for an inverted "T" with a diagonal brace. You would still be able to use most of the existing axes' design, but with nothing above the extruder to get in the way. I think you'd have to print the corners as two pieces, but you might get more efficient use of your vitamins.

How do you plan to fix the corners to the extrusion?

|

Re: a T Slot mendel frame March 10, 2011 05:41PM |

Registered: 13 years ago Posts: 601 |

I think the triangle shape is easier to transport, and I've had to move my Mendel around quite a bit. the top bar is a natural handle.

you are certainly right about the build height. On the other hand, i don't know if i really want to build any taller. tall builds take a long time, and if something goes wrong, it's all ruined. i'd rather print in stages.

I'm more concerned with making the frame more rigid, which i think will improve print quality. I'm not sure that RP parts will undermine the rigidity of the tslot, but I'm gonna try.

all that said, i think moving the top member to the outside of the frame, instead of at the apex, would probably move it out of the way of most extruders. but i think this could be a quick mod in the case that you need the extra height for a particular print.

---

ill probably use captive nuts inside the RP part that goes in the channel.

I was also thinking about the plastic drywall screw thingys that expand when you screw a wood screw into them. i was thinking that you could make the RP T profile expand into the aluminum channel with a screw. I feel that this might fail too quickly though, but i'll print something out and try it to see how it holds.

edit: i know this is really confusing. it's hard to explain. i'll post a picture eventually

the last option is drilling holes in the extrusion. I'd like to avoid that at all costs.

Edited 1 time(s). Last edit at 03/10/2011 05:43PM by Buback.

you are certainly right about the build height. On the other hand, i don't know if i really want to build any taller. tall builds take a long time, and if something goes wrong, it's all ruined. i'd rather print in stages.

I'm more concerned with making the frame more rigid, which i think will improve print quality. I'm not sure that RP parts will undermine the rigidity of the tslot, but I'm gonna try.

all that said, i think moving the top member to the outside of the frame, instead of at the apex, would probably move it out of the way of most extruders. but i think this could be a quick mod in the case that you need the extra height for a particular print.

---

ill probably use captive nuts inside the RP part that goes in the channel.

I was also thinking about the plastic drywall screw thingys that expand when you screw a wood screw into them. i was thinking that you could make the RP T profile expand into the aluminum channel with a screw. I feel that this might fail too quickly though, but i'll print something out and try it to see how it holds.

edit: i know this is really confusing. it's hard to explain. i'll post a picture eventually

the last option is drilling holes in the extrusion. I'd like to avoid that at all costs.

Edited 1 time(s). Last edit at 03/10/2011 05:43PM by Buback.

|

Re: a T Slot mendel frame March 10, 2011 06:49PM |

Registered: 13 years ago Posts: 485 |

|

Re: a T Slot mendel frame March 13, 2011 10:25PM |

Registered: 13 years ago Posts: 27 |

Buback,

I've been thinking about a similar approach for my 2nd Mendel. I have to get my 1st one printing the way I want it first.

I've been thinking about building a larger Mendel, one that might make parts 12" x 12" x 4" (or something like that), and I've read the threaded studding doesn't support it, so aluminum extrusion is the way to go.

Keep us updated on the progress. I'll be anxious to see how it goes. Since mine is "sort of" printing now, I hope yours isn't making good parts before mine. I'll feel REALLY stupid then.

I've been thinking about a similar approach for my 2nd Mendel. I have to get my 1st one printing the way I want it first.

I've been thinking about building a larger Mendel, one that might make parts 12" x 12" x 4" (or something like that), and I've read the threaded studding doesn't support it, so aluminum extrusion is the way to go.

Keep us updated on the progress. I'll be anxious to see how it goes. Since mine is "sort of" printing now, I hope yours isn't making good parts before mine. I'll feel REALLY stupid then.

|

Re: a T Slot mendel frame March 14, 2011 01:49PM |

Registered: 13 years ago Posts: 601 |

I've got a couple pieces of this at home which is what I'm planing on using:

80/20 30 SERIES 30-3030 30mm X 30mm T-SLOTTED EXTRUSION x 610mm

at 610mm per side it'll be bigger than the mendel. these are nice because they're accurately precut.

I was thinking a 20 mm^2 extrusion would be better for a mendel-sized model. (I'm not very familiar with extrusions, so if anybody has suggestions for a preferred size extrusion, I'm all ears)

One thing i've found with the test pieces i've printed: you need to have ALL your axes calibrated properly. my z axis is a bit off, which makes the triangular printed pieces not equilateral! on the other hand, i think it's probably a great way to calibrate your z axis.

---

Right now, i'm working on basic stuff, like making sure the printed T fits inside the channel snugly. next is to select a prefered way of tightening the plastic in place.

so, what size extrusion should i be designing for?

80/20 30 SERIES 30-3030 30mm X 30mm T-SLOTTED EXTRUSION x 610mm

at 610mm per side it'll be bigger than the mendel. these are nice because they're accurately precut.

I was thinking a 20 mm^2 extrusion would be better for a mendel-sized model. (I'm not very familiar with extrusions, so if anybody has suggestions for a preferred size extrusion, I'm all ears)

One thing i've found with the test pieces i've printed: you need to have ALL your axes calibrated properly. my z axis is a bit off, which makes the triangular printed pieces not equilateral! on the other hand, i think it's probably a great way to calibrate your z axis.

---

Right now, i'm working on basic stuff, like making sure the printed T fits inside the channel snugly. next is to select a prefered way of tightening the plastic in place.

so, what size extrusion should i be designing for?

|

Re: a T Slot mendel frame March 14, 2011 02:29PM |

Registered: 13 years ago Posts: 818 |

Hello

I have almost done another 30x60mm aluminium t-slot repstrap. And I have just started building it's little brother with 20mm x 20mm t-slot frame. It's strong and light. I would say use 20mm it will be more than strong enough for a Mendel clone.

[richrap.blogspot.com]

I have almost done another 30x60mm aluminium t-slot repstrap. And I have just started building it's little brother with 20mm x 20mm t-slot frame. It's strong and light. I would say use 20mm it will be more than strong enough for a Mendel clone.

[richrap.blogspot.com]

|

Re: a T Slot mendel frame March 14, 2011 05:34PM |

Registered: 13 years ago Posts: 601 |

ok thanks. i don't have any yet, but didn't want to order anything to test with without some input. The channels are pretty narrow on 20x20 mm, and i am wondering if there will be enough plastic in a printed piece to keep the frame rigid.

the trunk of the T is what i'm most concerned about.

the trunk of the T is what i'm most concerned about.

|

Re: a T Slot mendel frame March 15, 2011 04:55PM |

Registered: 13 years ago Posts: 601 |

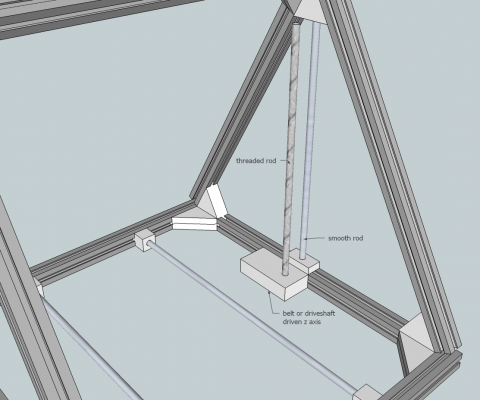

Is this design workable? I don't like the extension of the x axis outside of the triangle frame. there are many times when i would like to turn the frame on it's side to get to the underside or take pictures, instead of turning the machine on it's back. there various reasons, such as not having to mess with the filament, or electronics placement makes turning the machine on it's back dangerous.

the main issue is how the belts run. the motor for the x axis would probably need to be mounted inside as well, and if that is the case, then the x belt would have to be run like in a prusa, instead of like a sells, since the x bars will likely extend out to the smooth z bar. the a Sells x belt were moved down about 10 mm in the z direction, it would run perpendicularly underneath the x bars, and might have some advantages, but that would just cause problems with compatibility. I think the Prusa arrangement is a simpler and likely better design, anyway.

|

Re: a T Slot mendel frame March 17, 2011 07:01AM |

Registered: 13 years ago Posts: 818 |

It looks a good start, the 20mm T-slot frame provides quite a good slot size (size6) so should be enough.

I have often wondered about printing my own T-nuts for frame construction, I may try some to print some nuts and frame connectors when I'm back up and printing again.

Are you planning 2 motors for the Z drive?

Designing the parts so they can be printed without support material should be interesting. Due to the T-slot most will need to be printed on their end, and you may find that the parts are tight in the slot?

You could design the X axis to be vertical rather than horizontal, it may help with X-belt routing and motor mounting.

And how about using the T-slot as the runner instead of using round bar, PLA should slide well on/in the Aluminium channels?

Rich.

[richrap.blogspot.com]

I have often wondered about printing my own T-nuts for frame construction, I may try some to print some nuts and frame connectors when I'm back up and printing again.

Are you planning 2 motors for the Z drive?

Designing the parts so they can be printed without support material should be interesting. Due to the T-slot most will need to be printed on their end, and you may find that the parts are tight in the slot?

You could design the X axis to be vertical rather than horizontal, it may help with X-belt routing and motor mounting.

And how about using the T-slot as the runner instead of using round bar, PLA should slide well on/in the Aluminium channels?

Rich.

[richrap.blogspot.com]

|

Re: a T Slot mendel frame March 17, 2011 09:16AM |

Registered: 13 years ago Posts: 39 |

Nice one Buback,

Just got a break from college to print your open X carriage and you're already onto the next project. I must admit I like Richrap's idea for using the tslot for your runners somehow. It makes elegant use of the most highly engineered part of the printer. But your point about containing all the RP parts inside the frame so you might service all sides with peace of mind is a sound one as well. It's a pity combining both ideas leaves you nowhere suitable for placing the parts!

Isn't the issue though, that you want a larger print area. As a result you have had to upgrade from 8mm bar to tslot. But in order to keep the frame outermost, you have to employ 8mm bar again for the runners. My own y axis runners have a clear >1mm rise over the run of the build plate because they are not perfectly straight. Going up to 600mm gives the bars even more reason to sag, bow or vibrate.

Right, time to get printing now!

Woodsmoke

Just got a break from college to print your open X carriage and you're already onto the next project. I must admit I like Richrap's idea for using the tslot for your runners somehow. It makes elegant use of the most highly engineered part of the printer. But your point about containing all the RP parts inside the frame so you might service all sides with peace of mind is a sound one as well. It's a pity combining both ideas leaves you nowhere suitable for placing the parts!

Isn't the issue though, that you want a larger print area. As a result you have had to upgrade from 8mm bar to tslot. But in order to keep the frame outermost, you have to employ 8mm bar again for the runners. My own y axis runners have a clear >1mm rise over the run of the build plate because they are not perfectly straight. Going up to 600mm gives the bars even more reason to sag, bow or vibrate.

Right, time to get printing now!

Woodsmoke

|

Re: a T Slot mendel frame March 17, 2011 10:56AM |

Registered: 13 years ago Posts: 601 |

Yeah i think anything larger than the Mendel should probably go to 12mm round bars. it seems like it's pretty easy to get cheap linear bearings at 12mm ID. Forrest Higgs found some good examples.

Richrap:

For some reason, i prefer the belt drive of the sells mendel over the two motors of the prusa, so i'm designing it around belts. I'm also thinking about being able to use a worm gear/driveshaft driven z axis, so having a clear place to run the driveshaft is something i want to build into this design, even if it never happens.

I think making the x axis vertical is a larger job than i want to tackle right now.

and aluminum is not ideal for runners/rails. perhaps for the z axis, since it doesn't move very much, but i think the x or y would wear a channel into the aluminum. but as the link says, it might last the lifetime of the machine, which is long enough. it should be easy to integrate, being tslot, but you'd have to redo all the carriages, which is something i don't want to do right now.

Richrap:

For some reason, i prefer the belt drive of the sells mendel over the two motors of the prusa, so i'm designing it around belts. I'm also thinking about being able to use a worm gear/driveshaft driven z axis, so having a clear place to run the driveshaft is something i want to build into this design, even if it never happens.

I think making the x axis vertical is a larger job than i want to tackle right now.

and aluminum is not ideal for runners/rails. perhaps for the z axis, since it doesn't move very much, but i think the x or y would wear a channel into the aluminum. but as the link says, it might last the lifetime of the machine, which is long enough. it should be easy to integrate, being tslot, but you'd have to redo all the carriages, which is something i don't want to do right now.

Sorry, only registered users may post in this forum.