Project log: Air 2 upgrade

Posted by Ohmarinus

|

Project log: Air 2 upgrade March 25, 2019 09:28AM |

Admin Registered: 11 years ago Posts: 3,096 |

So finally, I've picked up my first 3D printer from my cabinet and put it on my workbench.

[reprap.org]

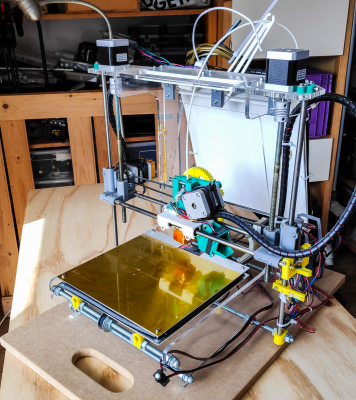

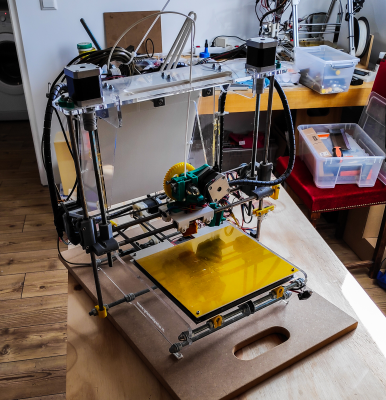

This is what it looks like today:

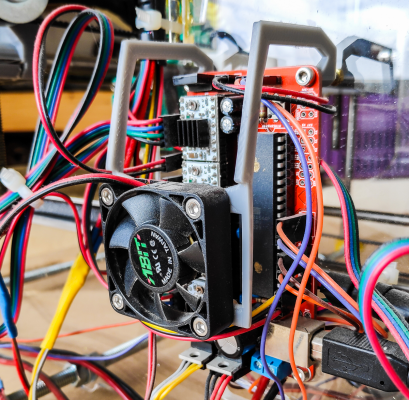

Sanguino-LOL-u (not the best board)

It's a very old DIY model that I can't seem to find much info about anymore. I bought it back in 2012 or so, it being a total ripoff because the guy selling it to me had printed the parts in horrible quality and supplied a homemade hotend and a Sanguinololu board. Nothing worked, I hated the machine, the rods were made of MILD steel and the LM8UU bearings were rusty and 2nd hand. To top it off, most screws were missing and the ones that were in the package weren't all metric (HOW?!?).

Anyway, I managed to turn it into a somewhat functional machine and have printed at least 2 huge bags full of trash (and some useful prints, but nothing stellar).

After one year I had created a second printer, the MendelMax 1.5, with some minor changes, a vertically placed X-stage and a self-designed heatbed system with aluminium plates. This machine still works today without having to have it configured in four years. Not even after moving into my new home two years ago. The machine still works wonderfully but the quality of the plastic parts is currently rapidly decreasing. I see cracks forming and I really have to start replacing the plastic parts of the printer because I use it for work.

Here an old image of that MendelMax 1.5

Currently I'm trying to get back into the latest techniques that I have access to in DIY 3D-printing. I am still doubting to get trapezoid rods for the Z-axis and a proximity-style bed leveling sensor.

My current plan for the Air 2 printer is as follows:

- Take the machine apart completely

- Clean the frame and mechanical parts

- Add 20x20 aluminium extrusions to the sides of the acrylic frame to make it sturdy for 3D-printing (the frame flexes left and right when the X-carriage moves around)

- Rebuild the base frame minus the X and Z axes and make sure it's squared

- Mount new hard chromed rods with new LM8UU bearings

- Convert from Sanguinololu to Ramps 1.4 with SD-support

- Print the new parts I want on the MendelMax 1.5 (including vertical X-axis)

- Mount a new bowden extruder with a 1.75mm hotend instead of the 3mm it has now (the MendelMax also works with 1.75mm)

- Add new pulleys and stepper motors with flat ends instead of round ends

- Convert the belts from T2 to GT2

The biggest obstacle I'm facing is that the OpenSCAD files that I used in the past for the MendelMax 1.5 parts do not work with the new version of OpenSCAD and I would really like to use the same kind of X and Z axes as I do on the MendelMax so that if one part breaks, I can still borrow it from the other printer. So I would have to figure out how to gain access to my old OpenSCAD files.

This post will mostly be a log of my progress with converting the printer to working condition with improvements/upgrades but I am very curious if anyone has ever had an Air2 and what they thought of it. Also curious how the Air2 can be improved on. The frame is terrible since the flex kind of makes it useless. I hope that adding the aluminium extrusions helps in fixating parts of the machine.

http://www.marinusdebeer.nl/

[reprap.org]

This is what it looks like today:

Sanguino-LOL-u (not the best board)

It's a very old DIY model that I can't seem to find much info about anymore. I bought it back in 2012 or so, it being a total ripoff because the guy selling it to me had printed the parts in horrible quality and supplied a homemade hotend and a Sanguinololu board. Nothing worked, I hated the machine, the rods were made of MILD steel and the LM8UU bearings were rusty and 2nd hand. To top it off, most screws were missing and the ones that were in the package weren't all metric (HOW?!?).

Anyway, I managed to turn it into a somewhat functional machine and have printed at least 2 huge bags full of trash (and some useful prints, but nothing stellar).

After one year I had created a second printer, the MendelMax 1.5, with some minor changes, a vertically placed X-stage and a self-designed heatbed system with aluminium plates. This machine still works today without having to have it configured in four years. Not even after moving into my new home two years ago. The machine still works wonderfully but the quality of the plastic parts is currently rapidly decreasing. I see cracks forming and I really have to start replacing the plastic parts of the printer because I use it for work.

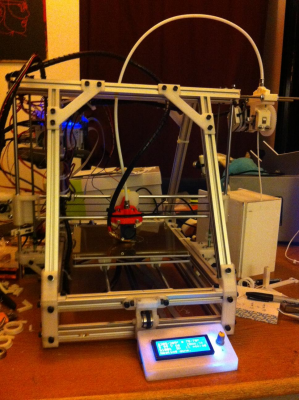

Here an old image of that MendelMax 1.5

Currently I'm trying to get back into the latest techniques that I have access to in DIY 3D-printing. I am still doubting to get trapezoid rods for the Z-axis and a proximity-style bed leveling sensor.

My current plan for the Air 2 printer is as follows:

- Take the machine apart completely

- Clean the frame and mechanical parts

- Add 20x20 aluminium extrusions to the sides of the acrylic frame to make it sturdy for 3D-printing (the frame flexes left and right when the X-carriage moves around)

- Rebuild the base frame minus the X and Z axes and make sure it's squared

- Mount new hard chromed rods with new LM8UU bearings

- Convert from Sanguinololu to Ramps 1.4 with SD-support

- Print the new parts I want on the MendelMax 1.5 (including vertical X-axis)

- Mount a new bowden extruder with a 1.75mm hotend instead of the 3mm it has now (the MendelMax also works with 1.75mm)

- Add new pulleys and stepper motors with flat ends instead of round ends

- Convert the belts from T2 to GT2

The biggest obstacle I'm facing is that the OpenSCAD files that I used in the past for the MendelMax 1.5 parts do not work with the new version of OpenSCAD and I would really like to use the same kind of X and Z axes as I do on the MendelMax so that if one part breaks, I can still borrow it from the other printer. So I would have to figure out how to gain access to my old OpenSCAD files.

This post will mostly be a log of my progress with converting the printer to working condition with improvements/upgrades but I am very curious if anyone has ever had an Air2 and what they thought of it. Also curious how the Air2 can be improved on. The frame is terrible since the flex kind of makes it useless. I hope that adding the aluminium extrusions helps in fixating parts of the machine.

http://www.marinusdebeer.nl/

|

Re: Project log: Air 2 upgrade April 03, 2019 11:46AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, the next step has been made. It got turned around completely.

The Air 2 frame was too flexible and most parts were broken by old age (and UV influence....).

So what happened? I bought an old original Prusa i3 MK2S frame to build my printer on. I had planned on putting all my parts on the frame but then I discovered that my old heatbed wouldn't fit on the Prusa frame so in the end I ordered new parts for over €200,- to build a completely new machine. It was the best decision I think. Slowly parts are starting to arrive.

Among the parts are a new printbed from the MK2S upgrade to 2.5 so this means: removable magnetic heatbed made of spring steel with a PEI surface (very modern), E3D v6 hotend (the one with the newer type of cartridge thermistor) with an additional 0.5mm nozzle (I don't do small prints at all, it's mostly mechanical and constructive parts that I design and make to work with 'vitamins' to keep it in oldschool terms), both a BLtouch and a P.I.N.D.A.2 sensor, I'll just have to see which one I like most on this new machine and the other probe can be used on my older MendelMax and last but not least a couple of new rolls of PLA filament to print out all the new parts of the new printer with quality plastics from FormFutura.

Besides that the printer will have a filament dry box with a bowden tube guiding the filament into the printer.

http://www.marinusdebeer.nl/

The Air 2 frame was too flexible and most parts were broken by old age (and UV influence....).

So what happened? I bought an old original Prusa i3 MK2S frame to build my printer on. I had planned on putting all my parts on the frame but then I discovered that my old heatbed wouldn't fit on the Prusa frame so in the end I ordered new parts for over €200,- to build a completely new machine. It was the best decision I think. Slowly parts are starting to arrive.

Among the parts are a new printbed from the MK2S upgrade to 2.5 so this means: removable magnetic heatbed made of spring steel with a PEI surface (very modern), E3D v6 hotend (the one with the newer type of cartridge thermistor) with an additional 0.5mm nozzle (I don't do small prints at all, it's mostly mechanical and constructive parts that I design and make to work with 'vitamins' to keep it in oldschool terms), both a BLtouch and a P.I.N.D.A.2 sensor, I'll just have to see which one I like most on this new machine and the other probe can be used on my older MendelMax and last but not least a couple of new rolls of PLA filament to print out all the new parts of the new printer with quality plastics from FormFutura.

Besides that the printer will have a filament dry box with a bowden tube guiding the filament into the printer.

http://www.marinusdebeer.nl/

|

Re: Project log: Air 2 upgrade April 03, 2019 12:14PM |

Admin Registered: 13 years ago Posts: 7,002 |

|

Re: Project log: Air 2 upgrade April 03, 2019 03:02PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Dust

If you dump the ramp and get a RAMBo min + a 2004 lcd you can use prusa firmware binaries and the mk2.5 profiles included with slic3rPE

Yes! I had thought about that, but it would set me back at least another €60 at least and it means I have to redo all the cable connectors. And honestly, what would be the benefits? I have a nice crystal LCD left over and a lot of Ramps electronics. Am I missing some unique features? Sorry

http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.