[project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver

Posted by Petrus

|

[project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver February 08, 2012 12:53PM |

Registered: 12 years ago Posts: 162 |

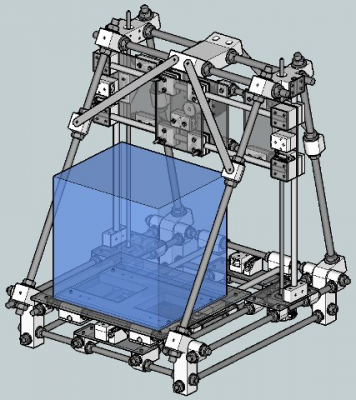

I already built a repstrap that is able to mill polycarbonate and engrave circuit board but it is too slow and not as rigid as I want. So I decided to make a new printer with the same abilities but stronger, faster and self-replicable. It will looks like this :

The design is inspired by the triangular frame of the reprap mendel.

Differences compared to the standard mendel :

- vertical X axis to quickly change the tool (extruder or spindle)

- M10 and M12 threaded rods instead of M8 for better frame stiffness

- 10mm smooth rods instead of 8mm for better axis stiffness

- Precision doubling belt configuration inspired by Madkite's design : [www.thingiverse.com]

- nema23 steppers for the X and Y axis instead of nema17

- Each axis will be equipped with 4 printed linear bearings : [www.thingiverse.com]

I will also try to use steel cables instead of timed belts for X and Y axis.

[edit]

picture update

Edited 3 time(s). Last edit at 03/13/2012 10:53AM by Petrus.

The design is inspired by the triangular frame of the reprap mendel.

Differences compared to the standard mendel :

- vertical X axis to quickly change the tool (extruder or spindle)

- M10 and M12 threaded rods instead of M8 for better frame stiffness

- 10mm smooth rods instead of 8mm for better axis stiffness

- Precision doubling belt configuration inspired by Madkite's design : [www.thingiverse.com]

- nema23 steppers for the X and Y axis instead of nema17

- Each axis will be equipped with 4 printed linear bearings : [www.thingiverse.com]

I will also try to use steel cables instead of timed belts for X and Y axis.

[edit]

picture update

Edited 3 time(s). Last edit at 03/13/2012 10:53AM by Petrus.

|

Re: [project]Self replicable 3Dprinter/mill/PCB engraver February 08, 2012 06:44PM |

Registered: 13 years ago Posts: 485 |

|

Re: [project] Havy mendel, a self replicating 3Dprinter/mill/PCB engraver March 13, 2012 09:47AM |

Registered: 12 years ago Posts: 162 |

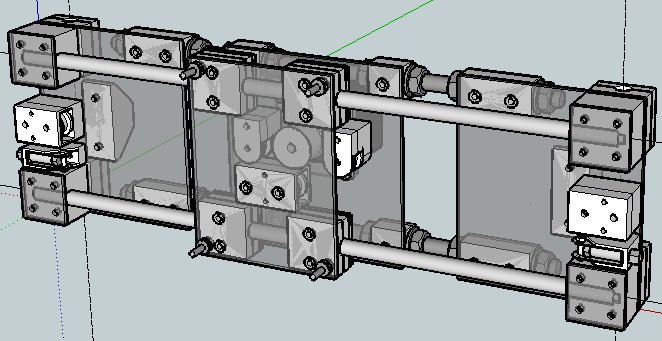

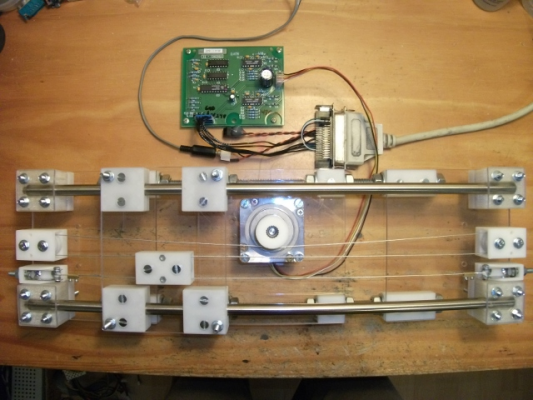

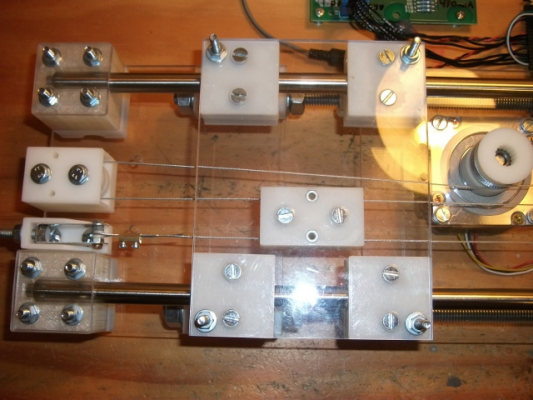

Here are the parts for the X axis :

It will looks like this once assembled :

The pulleys close to the motor are for the timed belt version aka plan B

Polycarbonate plate to threaded rod attachment :

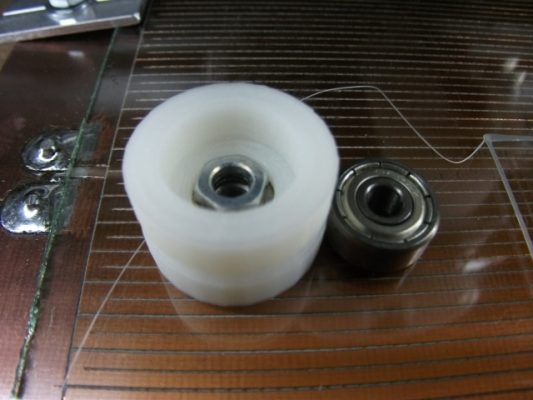

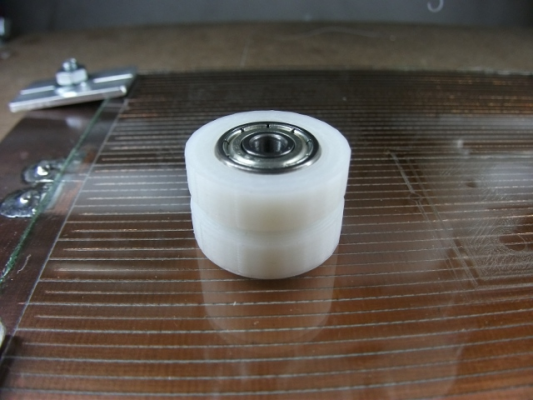

The pulleys are made with a printed cylinder, two 624ZZ bearings spaced by a drilled M4 nut :

I also improved the linear bearing design by inserting a captive nut:

It will looks like this once assembled :

The pulleys close to the motor are for the timed belt version aka plan B

Polycarbonate plate to threaded rod attachment :

The pulleys are made with a printed cylinder, two 624ZZ bearings spaced by a drilled M4 nut :

I also improved the linear bearing design by inserting a captive nut:

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver March 14, 2012 08:22PM |

Registered: 12 years ago Posts: 162 |

I finished the X axis assembly :

I don't have a powerful enough driver to test the acceleration and speed limits but it works well.

I don't have a powerful enough driver to test the acceleration and speed limits but it works well.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver March 15, 2012 01:18PM |

Registered: 13 years ago Posts: 485 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver March 15, 2012 02:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... if made correct, it's astonishing accurate!

My first three laserplotters were wire-driven - 0,3mm or 0.5mm thick steelwire with 19 fibres over Nylon-coated ball-bearings - image of the bearings atached ...

The working area was 400x300mm, with 0.025mm resoultion and similar repeatability ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My first three laserplotters were wire-driven - 0,3mm or 0.5mm thick steelwire with 19 fibres over Nylon-coated ball-bearings - image of the bearings atached ...

The working area was 400x300mm, with 0.025mm resoultion and similar repeatability ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver March 28, 2012 03:12PM |

Registered: 12 years ago Posts: 162 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver April 04, 2012 12:34PM |

Registered: 12 years ago Posts: 162 |

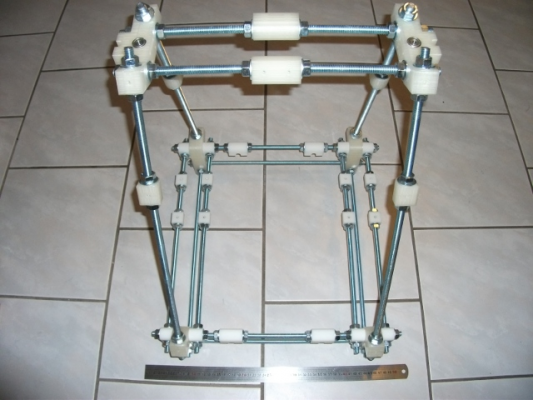

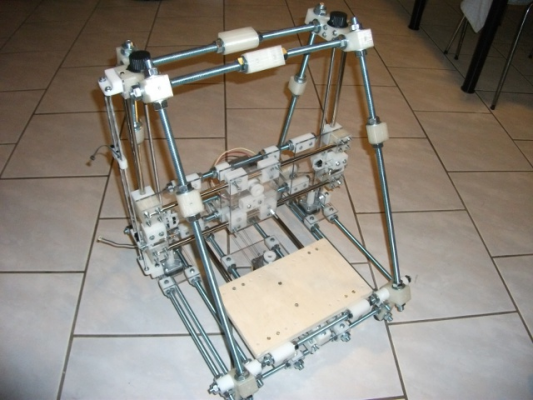

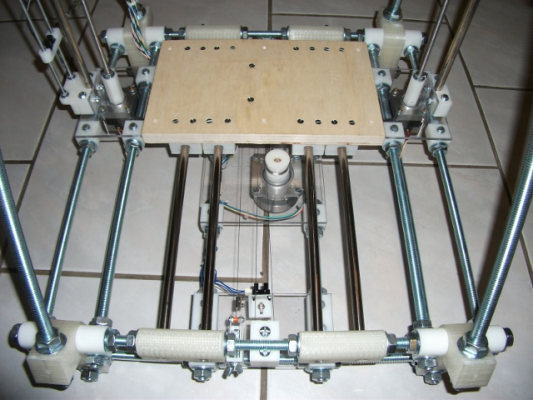

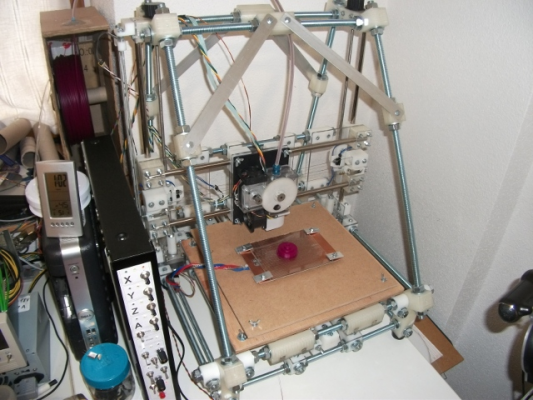

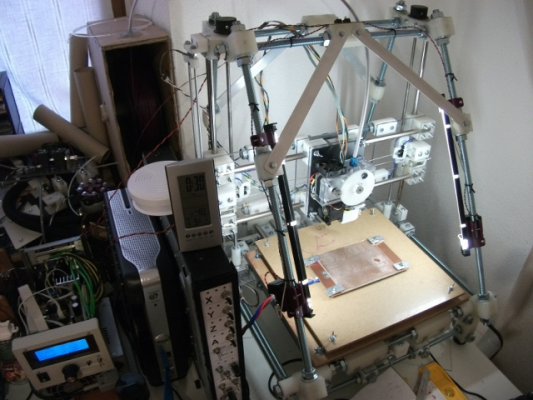

I assembled the frame :

Even without the diagonal bars, the structure is stiffer than my current printer.

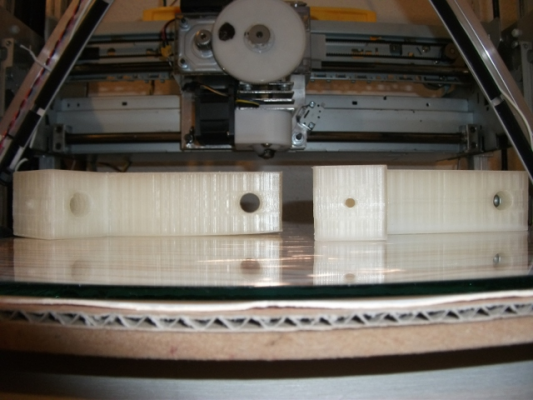

To print the large parts, I built a temporary heated bed with copper wire glued to a pizza cardboard, it works fine.

To improve the PLA adhesion, I aplied ABS juice (ABS dissolved in acetone):

Left : without ABS juice, right : with ABS juice

Even without the diagonal bars, the structure is stiffer than my current printer.

To print the large parts, I built a temporary heated bed with copper wire glued to a pizza cardboard, it works fine.

To improve the PLA adhesion, I aplied ABS juice (ABS dissolved in acetone):

Left : without ABS juice, right : with ABS juice

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver May 02, 2012 02:23PM |

Registered: 12 years ago Posts: 162 |

last advancements :

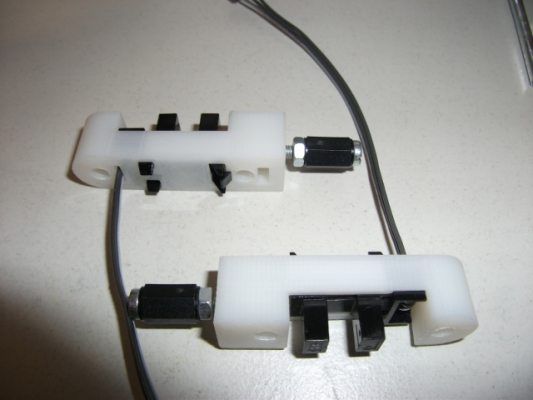

The opto end stops are salvaged from printers, I designed a support to clip them in :

The opto end stops are salvaged from printers, I designed a support to clip them in :

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver May 25, 2012 07:26PM |

Registered: 12 years ago Posts: 162 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver May 28, 2012 04:01PM |

Registered: 12 years ago Posts: 162 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver June 16, 2012 04:31PM |

Registered: 12 years ago Posts: 179 |

Quote

- Precision doubling belt configuration inspired by Madkite's design : [www.thingiverse.com]

You should test it with and without the block-and-tackle pulley design. The consensus in IRC is that the added complexity of the design, additional belt length, and increased friction, is likely to introduce more backlash than the added mechanical advantage will remove. So far, that's all just opinion, because I haven't seen anyone actually measure the difference between the two designs.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver June 24, 2012 01:37PM |

Registered: 12 years ago Posts: 162 |

I installed my repstrap's extruder on the heavy Mendel temporarily.

The speed is twice as fast as my last printer (60mm/s instead of 30mm/s)

I plan to improve the speed again using more powerful stepper drivers and maybe a bigger Y stepper motor.

I don't have backlash problems, as you can see, rounds are round.

The speed is twice as fast as my last printer (60mm/s instead of 30mm/s)

I plan to improve the speed again using more powerful stepper drivers and maybe a bigger Y stepper motor.

I don't have backlash problems, as you can see, rounds are round.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver June 29, 2012 06:56PM |

Registered: 12 years ago Posts: 162 |

I've uploaded the files on thingiverse :

Main/Frame : [www.thingiverse.com]

X Axis : [www.thingiverse.com]

Y Axis : [www.thingiverse.com]

Z Axis : [www.thingiverse.com]

Linear bearing : [www.thingiverse.com]

[edit]

I've also put the files on the wiki : [reprap.org]

Edited 1 time(s). Last edit at 06/30/2012 11:37AM by Petrus.

Main/Frame : [www.thingiverse.com]

X Axis : [www.thingiverse.com]

Y Axis : [www.thingiverse.com]

Z Axis : [www.thingiverse.com]

Linear bearing : [www.thingiverse.com]

[edit]

I've also put the files on the wiki : [reprap.org]

Edited 1 time(s). Last edit at 06/30/2012 11:37AM by Petrus.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver September 06, 2012 01:23PM |

Registered: 12 years ago Posts: 162 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver September 06, 2012 11:49PM |

Registered: 11 years ago Posts: 2 |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver October 05, 2012 06:20PM |

Registered: 12 years ago Posts: 162 |

I built a new chuck to make the next hot-ends :

The motor is a blushless motor salvaged from a laser printer.

Stl files are available on the heavy Mendel wiki page : [reprap.org]

The motor is a blushless motor salvaged from a laser printer.

Stl files are available on the heavy Mendel wiki page : [reprap.org]

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver October 12, 2012 10:10AM |

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver November 01, 2012 08:12PM |

Registered: 13 years ago Posts: 61 |

Petrus -

so you use braided steel wire? Does that stand up to the constant flexing well? I have seen similar things with solid wire and I have been trying to find out more info on what type of wire works best.

Also, I've been looking for some bearings like you have, with either nylon or rubber coatings on them. Can you give me any more info on where you got yours?

Thank you for posting this!

so you use braided steel wire? Does that stand up to the constant flexing well? I have seen similar things with solid wire and I have been trying to find out more info on what type of wire works best.

Also, I've been looking for some bearings like you have, with either nylon or rubber coatings on them. Can you give me any more info on where you got yours?

Thank you for posting this!

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver November 02, 2012 07:11PM |

Registered: 12 years ago Posts: 162 |

The wires are 0.69mm diameter, 49 strands stainless steel wire (fishing wire).

I tried with 7 strand galvanized wire, but it didn't pass the reliability test (100 cycles of this : [youtu.be]) the wire broke.

The bearings are standard 624ZZ bearing pushed inside an ABS printed part with a drilled nut inbetween as you can see on the pictures.

I tried with 7 strand galvanized wire, but it didn't pass the reliability test (100 cycles of this : [youtu.be]) the wire broke.

The bearings are standard 624ZZ bearing pushed inside an ABS printed part with a drilled nut inbetween as you can see on the pictures.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver November 05, 2012 06:32AM |

Admin Registered: 16 years ago Posts: 13,884 |

... in past I've built some laserplotters with 49strand-wires (assembled in 7x7) with diameters of 0.3, 0.5 and 0.7mm - ye smaller the diameter, the longer the lifetime ... but the more 'elasticity' in the wire too.

The min possible diameter (without to much wobble) depends mainly on the moved weights and overall length of the wire ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The min possible diameter (without to much wobble) depends mainly on the moved weights and overall length of the wire ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver January 20, 2013 10:08AM |

Registered: 12 years ago Posts: 162 |

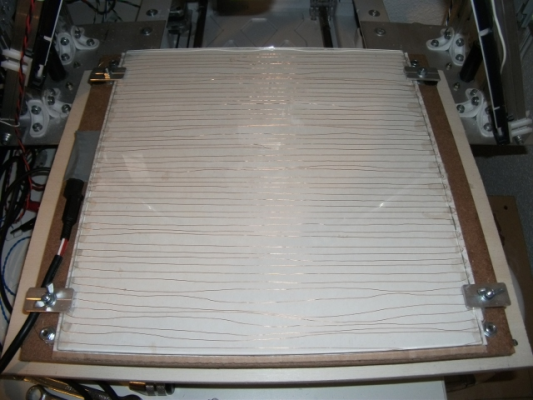

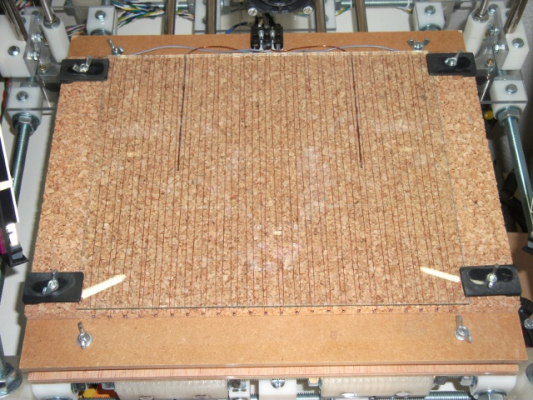

I made a cheap and easy to build large heated bed. The heated surface is 240 x 200mm :

It is built from 10mm thick cork, small nails, 0,25mm diameter copper wire from a stepper motor found in an old printer and 3mm glass on the top :

The bed didn't heat-up enough if I connect it on the two sides, so I made the connexion between the center and the sides. It heats-up to 120°C on 12V, maybe higher if I didn't set the safety cutoff temperature at 120°C.

It is built from 10mm thick cork, small nails, 0,25mm diameter copper wire from a stepper motor found in an old printer and 3mm glass on the top :

The bed didn't heat-up enough if I connect it on the two sides, so I made the connexion between the center and the sides. It heats-up to 120°C on 12V, maybe higher if I didn't set the safety cutoff temperature at 120°C.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver February 19, 2013 03:20PM |

Registered: 12 years ago Posts: 88 |

In the photos I can see a small heated bed etched on a PCB, is that right? Any info on that one?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver February 21, 2013 12:58PM |

Registered: 12 years ago Posts: 162 |

I made the small heated bed for my first printer : [forums.reprap.org] then reused it for the heavy Mendel. It was mechanically engraved by the printer itself (Yeah, I love the self replication aspect of the reprap project) I use it most of the time, it heats up much faster than the big one and why wasting energy with a big print bed if I have to print a small object ?

I put the drawing on the wiki.

I put the drawing on the wiki.

|

Re: [project] Heavy mendel, a self replicating 3Dprinter/mill/PCB engraver February 22, 2013 02:15PM |

Registered: 12 years ago Posts: 88 |

Petrus Wrote:

-------------------------------------------------------

> why wasting energy with a big print bed if I have to print a small object ?

Thanks Petrus. To save energy I cover most of the bed with insulation and leave exposed only what's needed for the print. It does help raise the temperature faster too.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> why wasting energy with a big print bed if I have to print a small object ?

Thanks Petrus. To save energy I cover most of the bed with insulation and leave exposed only what's needed for the print. It does help raise the temperature faster too.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Sorry, only registered users may post in this forum.