Ratcheting Z-Axis from X-Axis carriage extremes

Posted by mungewell

|

Ratcheting Z-Axis from X-Axis carriage extremes February 09, 2010 01:08PM |

With some more wild imagination being applied to the design of a repstrap, I came up with the idea of using the X-axis motor to ratchet the Z-axis. The idea would be to save the cost of the Z-axis motor/controller.

That is that moving to the extremes of the X-axis could push/pull a ratchet to raise or lower the Z-axis. With a M8 thread the pitch would be approx 1mm, so a 4 position ratchet would give 0.25mm steps and the extruded material would naturally slump to the surface anyhow.

Does the concept of having to move to the end of the X-axis screw with the laying of plastic? Can the extruder shut off/restart the material flow OK to have this happen?

Cheers,

Simon.

aka Mungewell.

That is that moving to the extremes of the X-axis could push/pull a ratchet to raise or lower the Z-axis. With a M8 thread the pitch would be approx 1mm, so a 4 position ratchet would give 0.25mm steps and the extruded material would naturally slump to the surface anyhow.

Does the concept of having to move to the end of the X-axis screw with the laying of plastic? Can the extruder shut off/restart the material flow OK to have this happen?

Cheers,

Simon.

aka Mungewell.

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 09, 2010 05:36PM |

Registered: 14 years ago Posts: 278 |

Interesting concept.

The issues that may need addressing with such a mechanism:

- ratchet may be more complex than simple motor. Good tradeoff, if it can be produced completely via printed parts.

- Path computation may become more complex if Z must be raised temporarily to enter areas surrounded by plastic printed at the current layer (E.G, outline, followed by infill.) May not be an issue.

- zeroing Z, how do you ensure Z axis zero position? Can a human to adjust the Z manually, easily?

- Designs limits multi-head printing options.

The issues that may need addressing with such a mechanism:

- ratchet may be more complex than simple motor. Good tradeoff, if it can be produced completely via printed parts.

- Path computation may become more complex if Z must be raised temporarily to enter areas surrounded by plastic printed at the current layer (E.G, outline, followed by infill.) May not be an issue.

- zeroing Z, how do you ensure Z axis zero position? Can a human to adjust the Z manually, easily?

- Designs limits multi-head printing options.

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 09, 2010 07:17PM |

Registered: 14 years ago Posts: 6 |

I played a little with the concept, and maybe a scheme like this would work:

In answer to BeagleFury's questions:

1) Should be 'printable + a couple of springs' (unless someone figures how to do these reliably in plastic), but the main concept for RepStrap is that you don't have a 3D printer at all so you would have to be able to make with hand tools.

2) Could end up with string everywhere. I have some other ideas would would involve 'messing' with the path/gcode anyhow.

3) Zeroing done with optical vane (if required). Manual setting could be via rotating threaded bar by hand, or just whacking the mechanism the appropriate amount of times.

Cheers,

Mungewell.

In answer to BeagleFury's questions:

1) Should be 'printable + a couple of springs' (unless someone figures how to do these reliably in plastic), but the main concept for RepStrap is that you don't have a 3D printer at all so you would have to be able to make with hand tools.

2) Could end up with string everywhere. I have some other ideas would would involve 'messing' with the path/gcode anyhow.

3) Zeroing done with optical vane (if required). Manual setting could be via rotating threaded bar by hand, or just whacking the mechanism the appropriate amount of times.

Cheers,

Mungewell.

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 09, 2010 10:36PM |

Registered: 14 years ago Posts: 387 |

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 10, 2010 12:24AM |

Registered: 14 years ago Posts: 6 |

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 11, 2010 03:55PM |

Registered: 14 years ago Posts: 6 |

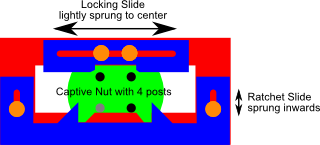

I 'played' some more and came up with this.

Any comments on the manufacturability of this would be welcome.

Cheers,

Mungewell

Any comments on the manufacturability of this would be welcome.

Cheers,

Mungewell

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 12, 2010 01:43AM |

Registered: 14 years ago Posts: 387 |

|

Re: Ratcheting Z-Axis from X-Axis carriage extremes February 12, 2010 01:36PM |

Registered: 14 years ago Posts: 6 |

Sorry, only registered users may post in this forum.

I don't see a very good way to do that.

I don't see a very good way to do that.