diegudios printer - looking for economical strength

Posted by diegudio

|

diegudios printer - looking for economical strength January 07, 2013 07:25PM |

Registered: 11 years ago Posts: 7 |

Hi there! My name is Diego, an argentinean in Austria and I'm new to the forum and to the 3D printing world...

I've been thinking in having my own CNC almost since the beginning of time, but due to space, noise and dirt reasons I keep it in stand by for the future... until I discovered the RepRap world and the possibility of having my own DIY printer and the dream of CNC came back again.

One part of me was saying "go for the safe, buy a kit", and the other said "no man, do-it-yourself"... as you can imagine, the DIY won the battle and here I'm presenting my own design called "diegudios_printer".

... and yes, it's still a design, but the general idea of the printer is there, and it's 100% oriented to finding a strong, robust frame with the less money investment possible.

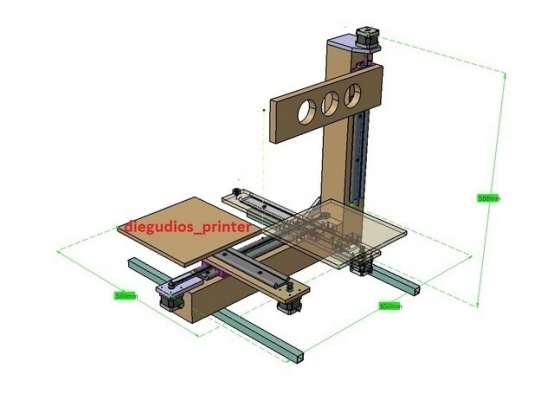

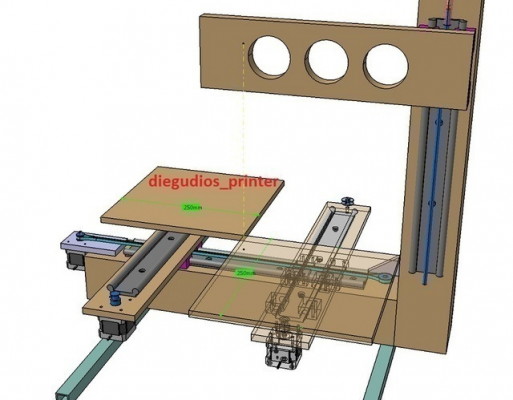

As you can see in the pictures, the design is more similar to those of the home-made CNC machines. I don't know if there is an "official" RepRap name to this kind of configuration. In case not, maybe I´m creating a new now

Some characteristics:

- The frame is based in a L-shape done with (probably) two pieces of 80x80 wood.

- The support bed (heated) is sliding in X & Y direction (horizontal plane)

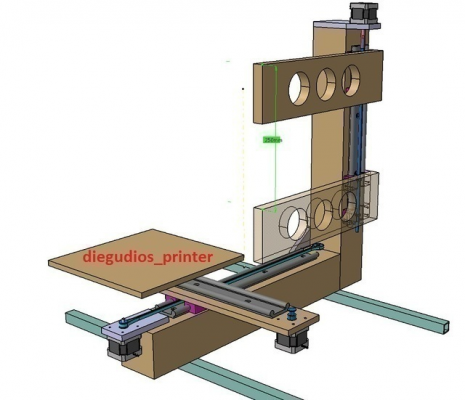

- The hotend will be located in the Z-sliding-arm, that will slide along the vertical part of the L-frame.

- The extruder will be static (as in some Rokstock configurations) - only the hotend will move.

- X & Y transmission is done with T2.5 belts, Z transmission is done by threaded shaft (M6 or M8)

- All 3 axis sliding devices are IGUS DryLin® W double-rail, with non-lubricated skids.

The idea of using this configuration is to reduce the "suspended masses" --> By moving the bed in X & Y directions (instead of only X or Y as in Mendel types), I reduce the components that must be displaced in the Z direction. Even more, with the fixed position of the extruder, the only mass moved in Z is the hotend, reducing bending of the Z-sliding-arm.

The stiffness of the bed when displaced outwards the frame (Y direction) is guarantee by the igus rail, which is an aluminium profile and gives extra-strength to the 10mm-thick-wooden base in which it's located.

The rails and the skids are quite cheap, easy to mantain and (I guess) they will provide a good strength for the suspended masses (Y-transmission motor).

As the speed in Z direction is not a priority, I decided to use a threaded shaft for the displacement instead of the belt, so I can get a better precission, and at the same time I reduce the total price by saving in belts, belt pulley and bearings. I don't need to "align" the threaded shaft because the Z-sliding-arm is aligned by the igus profile.

In addition, my configuration has the advantage of using 4 stepper motors instead of 5, saving some money there.

Of course, I won't see if all this assuptions are true until I put this to work...

The next step is to define the electronics (I have an Arduino board at home, so I'll find a configuration to use the arduino and save some more money)...

Finally, if this works, I'm open to share my design (including the 3D model) to whoever is interested.

Well, I've wrote such a big story here... I would appreciate your comments/suggestions and thanks to all of you in advance!!!

Edited 2 time(s). Last edit at 01/07/2013 07:29PM by diegudio.

___________

##diegudio##

I've been thinking in having my own CNC almost since the beginning of time, but due to space, noise and dirt reasons I keep it in stand by for the future... until I discovered the RepRap world and the possibility of having my own DIY printer and the dream of CNC came back again.

One part of me was saying "go for the safe, buy a kit", and the other said "no man, do-it-yourself"... as you can imagine, the DIY won the battle and here I'm presenting my own design called "diegudios_printer".

... and yes, it's still a design, but the general idea of the printer is there, and it's 100% oriented to finding a strong, robust frame with the less money investment possible.

As you can see in the pictures, the design is more similar to those of the home-made CNC machines. I don't know if there is an "official" RepRap name to this kind of configuration. In case not, maybe I´m creating a new now

Some characteristics:

- The frame is based in a L-shape done with (probably) two pieces of 80x80 wood.

- The support bed (heated) is sliding in X & Y direction (horizontal plane)

- The hotend will be located in the Z-sliding-arm, that will slide along the vertical part of the L-frame.

- The extruder will be static (as in some Rokstock configurations) - only the hotend will move.

- X & Y transmission is done with T2.5 belts, Z transmission is done by threaded shaft (M6 or M8)

- All 3 axis sliding devices are IGUS DryLin® W double-rail, with non-lubricated skids.

The idea of using this configuration is to reduce the "suspended masses" --> By moving the bed in X & Y directions (instead of only X or Y as in Mendel types), I reduce the components that must be displaced in the Z direction. Even more, with the fixed position of the extruder, the only mass moved in Z is the hotend, reducing bending of the Z-sliding-arm.

The stiffness of the bed when displaced outwards the frame (Y direction) is guarantee by the igus rail, which is an aluminium profile and gives extra-strength to the 10mm-thick-wooden base in which it's located.

The rails and the skids are quite cheap, easy to mantain and (I guess) they will provide a good strength for the suspended masses (Y-transmission motor).

As the speed in Z direction is not a priority, I decided to use a threaded shaft for the displacement instead of the belt, so I can get a better precission, and at the same time I reduce the total price by saving in belts, belt pulley and bearings. I don't need to "align" the threaded shaft because the Z-sliding-arm is aligned by the igus profile.

In addition, my configuration has the advantage of using 4 stepper motors instead of 5, saving some money there.

Of course, I won't see if all this assuptions are true until I put this to work...

The next step is to define the electronics (I have an Arduino board at home, so I'll find a configuration to use the arduino and save some more money)...

Finally, if this works, I'm open to share my design (including the 3D model) to whoever is interested.

Well, I've wrote such a big story here... I would appreciate your comments/suggestions and thanks to all of you in advance!!!

Edited 2 time(s). Last edit at 01/07/2013 07:29PM by diegudio.

___________

##diegudio##

Attachments:

open | download - diegudios_printer_dimensions.jpg (152 KB)

open | download - diegudios_printer_front.jpg (50.1 KB)

open | download - diegudios_printer_hotbed.jpg (166 KB)

open | download - diegudios_printer_lateral.jpg (62.3 KB)

open | download - diegudios_printer_top.jpg (56 KB)

open | download - diegudios_printer_Z-axis.jpg (123.3 KB)

open | download - diegudios_printer_dimensions.jpg (152 KB)

open | download - diegudios_printer_front.jpg (50.1 KB)

open | download - diegudios_printer_hotbed.jpg (166 KB)

open | download - diegudios_printer_lateral.jpg (62.3 KB)

open | download - diegudios_printer_top.jpg (56 KB)

open | download - diegudios_printer_Z-axis.jpg (123.3 KB)

|

Re: diegudios printer - looking for economical strength January 08, 2013 06:33AM |

Registered: 13 years ago Posts: 7,616 |

Looks really good, Diego. Make sure the connection between these two big bars is really stiff ... or complete it to a triangle.

Regarding electronics: Gen7 can be made DIY. The only usable part on the Arduino is the ATmega its self, so there's not much reason to make a plug-in board featuring everything, but not the ATmega.

Regarding electronics: Gen7 can be made DIY. The only usable part on the Arduino is the ATmega its self, so there's not much reason to make a plug-in board featuring everything, but not the ATmega.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: diegudios printer - looking for economical strength January 08, 2013 05:49PM |

Registered: 11 years ago Posts: 7 |

Thanks Traumflug!...

Yes, the two bars of the frame are wooden profiles, and will be glued and reinforced with a metallic L on one of the sides to keep the structure stable.

I need to inform myself a little better about electronics... The idea that I had was to use the Arduino and add the 4 motor controllers, but I'm not sure if this is possible. I imagine that the Gen6 that you mentioned is a motor controller based in the ATMega processor... so perhaps somebody else have already tried with something like the Gen6 but split in two pieces: in one side the ATMega (in my case the Arduino) and the motor controllers in other side...

But probably is cheaper (and easier) to buy the Gen6 directly instead of buying 4 motor controllers and adapting everything together with the Arduino...

I was today in a local store to search for some possible materials for the frame and I find out one very strong and well polished 1m-length 50x50mm profile that would fit... I will update the design to the new profile dimensions to see how it will look like...

The only thing that I'm still deciding is the igus guides... the package of 3 guides and the skids (12) cost 90€ including cutting and delivery... It would be great to find something cheaper...

___________

##diegudio##

Yes, the two bars of the frame are wooden profiles, and will be glued and reinforced with a metallic L on one of the sides to keep the structure stable.

I need to inform myself a little better about electronics... The idea that I had was to use the Arduino and add the 4 motor controllers, but I'm not sure if this is possible. I imagine that the Gen6 that you mentioned is a motor controller based in the ATMega processor... so perhaps somebody else have already tried with something like the Gen6 but split in two pieces: in one side the ATMega (in my case the Arduino) and the motor controllers in other side...

But probably is cheaper (and easier) to buy the Gen6 directly instead of buying 4 motor controllers and adapting everything together with the Arduino...

I was today in a local store to search for some possible materials for the frame and I find out one very strong and well polished 1m-length 50x50mm profile that would fit... I will update the design to the new profile dimensions to see how it will look like...

The only thing that I'm still deciding is the igus guides... the package of 3 guides and the skids (12) cost 90€ including cutting and delivery... It would be great to find something cheaper...

___________

##diegudio##

|

Re: diegudios printer - looking for economical strength January 09, 2013 07:27AM |

Registered: 13 years ago Posts: 7,616 |

Quote

I imagine that the Gen6 that you mentioned

I mentioner Gen7, not Gen6. Gen7 is DIY-able, Gen6 is designed for industry production.

Quote

the package of 3 guides and the skids (12) cost 90€ including cutting and delivery... It would be great to find something cheaper...

That's actually cheaper than I expected. I had a similar idea once, but didn't manage to squeeze the threaded rod between the rail and the carriage.

The about cheapest solution are drawer slides: [www.amazon.de]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: diegudios printer - looking for economical strength January 09, 2013 10:58AM |

Registered: 11 years ago Posts: 251 |

|

Re: diegudios printer - looking for economical strength January 09, 2013 01:09PM |

Registered: 11 years ago Posts: 7 |

Quote

I mentioner Gen7, not Gen6. Gen7 is DIY-able, Gen6 is designed for industry production.

Oh, you are right... sorry!... I've just got confused after reading information about Gen6 and Gen7.

But in any case, apart of the Gen7 board I will always need the 4 motor controllers, right? I mean, the Gen7 is not controlling the motors directly?

I reformulate my question: is there any all-in-one-controller, including stepper motor & hotend controller?

Quote

Drawer slides are surprisingly good if you restrict their movement. They have two sets of linear bearings forming a telescopic structure, the larger set are good, the smaller set I found are not stiff enough so you need to fix them relative to the large bearing.

Yeah, I've seen a very nice 40mm wide drawer slide in my local "construction" store (Baumax), but they costed 24€ each... The problem that I see with those slides are that the "0" position of the slide only allows you to move in one direction, and I don't mean in 1 axis (which is a fact) but in, for example, x "positive" but not negative, because they are blocked in the other direction. This means that I need to install the slide in such a way that the "0" position of the slide is one of the maximum displaced position of, for example, the x-y table... mmm, I don't know, I will think about it, this will radically change my design, but after seing them I agree that you can get a quite interesting precission...

Of course, I won't pay 24€ each because then I'm close to the 90€ of the igus guides, which are the "preferred" solution...

Thanks for answering!!!

|

Re: diegudios printer - looking for economical strength January 09, 2013 01:19PM |

Registered: 11 years ago Posts: 7 |

My worry with the drawer slides is what you can see in these two pictures:

PHOTO 1

PHOTO 2

When the sliding cart is in one extreme, everything is OK, but when it goes to the other extreme, you need extra space for the slides that are "poping out" from the frame... Either you do this, or you put the slides in such a way that you distribute this "poping-out" material in both sides...

Edited 1 time(s). Last edit at 01/09/2013 01:21PM by diegudio.

PHOTO 1

PHOTO 2

When the sliding cart is in one extreme, everything is OK, but when it goes to the other extreme, you need extra space for the slides that are "poping out" from the frame... Either you do this, or you put the slides in such a way that you distribute this "poping-out" material in both sides...

Edited 1 time(s). Last edit at 01/09/2013 01:21PM by diegudio.

|

Re: diegudios printer - looking for economical strength January 10, 2013 04:30AM |

Registered: 11 years ago Posts: 251 |

diegudio Wrote:

-------------------------------------------------------

> My worry with the drawer slides is what you can

> see in these two pictures:

>

> PHOTO 1

>

> PHOTO 2

>

> When the sliding cart is in one extreme,

> everything is OK, but when it goes to the other

> extreme, you need extra space for the slides that

> are "poping out" from the frame... Either you do

> this, or you put the slides in such a way that you

> distribute this "poping-out" material in both

> sides...

Yes this can be an issue if you want a compact machine. They are not space efficient and have relatively high friction.

Another problem with draw sliders is the ball bearings gradually move about and can be in such a position that reaching the extremes of travel requires extra force. Therefore the actual usable travel on even quite long sliders is depressingly short.

I have had great success using stainless steel rods (not precision ground, just good quality) and removing the centres from normal bearings to use as bushings. I just make sure there is always a big blob of grease trapped between each pair of bearings on a slider.

-------------------------------------------------------

> My worry with the drawer slides is what you can

> see in these two pictures:

>

> PHOTO 1

>

> PHOTO 2

>

> When the sliding cart is in one extreme,

> everything is OK, but when it goes to the other

> extreme, you need extra space for the slides that

> are "poping out" from the frame... Either you do

> this, or you put the slides in such a way that you

> distribute this "poping-out" material in both

> sides...

Yes this can be an issue if you want a compact machine. They are not space efficient and have relatively high friction.

Another problem with draw sliders is the ball bearings gradually move about and can be in such a position that reaching the extremes of travel requires extra force. Therefore the actual usable travel on even quite long sliders is depressingly short.

I have had great success using stainless steel rods (not precision ground, just good quality) and removing the centres from normal bearings to use as bushings. I just make sure there is always a big blob of grease trapped between each pair of bearings on a slider.

|

Re: diegudios printer - looking for economical strength January 10, 2013 08:47AM |

Registered: 13 years ago Posts: 7,616 |

Friction of drawer slides higly depends on the batch you get. They aren't exactly precision instruments, so you sometimes get ones with noticeable friction, sometimes ones with play.

Watch out for the WolfStrap in the wiki, it's a design using such slides.

You shouldn't compare high priced local stores with internet shops.

Watch out for the WolfStrap in the wiki, it's a design using such slides.

Quote

I've seen a very nice 40mm wide drawer slide in my local "construction" store (Baumax), but they costed 24€ each

You shouldn't compare high priced local stores with internet shops.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: diegudios printer - looking for economical strength January 10, 2013 01:54PM |

Registered: 11 years ago Posts: 7 |

Quote

I have had great success using stainless steel rods (not precision ground, just good quality) and removing the centres from normal bearings to use as bushings. I just make sure there is always a big blob of grease trapped between each pair of bearings on a slider.

Interesting...

I was thinking also in using rods with linear bearings (like LM8UU) that are not so expensive... I was afraid of how to align properly the two rods for each axis (you gotta think that I don't have another printer to create plastic supports)... and I'm not sure that I will get the appropiate precision if I do it manually on wood...

|

Re: diegudios printer - looking for economical strength January 12, 2013 06:31PM |

Registered: 11 years ago Posts: 7 |

I have some news...

1) reading and reading I figured out the most economical configuration for the electronics. As I already had a Arduino Mega, I will buy the kit for mounting the RAMPS 1.4 and 4 motor controllers. I'm not sure if this configuration is better than Gen7, but if both uses ATMega chips, I guess that the softwared uploaded to the chip should be similar (or even the same). I haven't red anything about software yet.

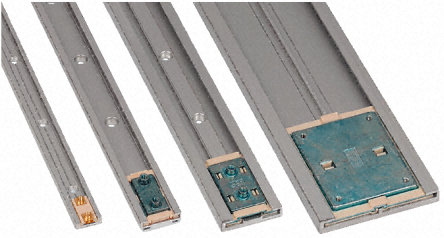

2) I decided for the IGUS linear guides, but instead of the DryLin W I will use the DryLin N, which for less price I get a bigger guide (80mm wide). It seems that the in the W is easier to attach something because the drills in the N are not so deep, but I don't think that it will be a problem.

IGUS DryLin N (the 80mm-wide is the bigger one)

IGUS DryLIn W

Now I need to define the hotend... I bought already the resistor and I also have some NiCrome wire at home, but I'm more worried about the thermal isolation than anything else. I can't find a PTFE bar or rod cheap to use as isolator, so I will need to think about it a little bit more or look for further info in the web... any idea?

1) reading and reading I figured out the most economical configuration for the electronics. As I already had a Arduino Mega, I will buy the kit for mounting the RAMPS 1.4 and 4 motor controllers. I'm not sure if this configuration is better than Gen7, but if both uses ATMega chips, I guess that the softwared uploaded to the chip should be similar (or even the same). I haven't red anything about software yet.

2) I decided for the IGUS linear guides, but instead of the DryLin W I will use the DryLin N, which for less price I get a bigger guide (80mm wide). It seems that the in the W is easier to attach something because the drills in the N are not so deep, but I don't think that it will be a problem.

IGUS DryLin N (the 80mm-wide is the bigger one)

IGUS DryLIn W

Now I need to define the hotend... I bought already the resistor and I also have some NiCrome wire at home, but I'm more worried about the thermal isolation than anything else. I can't find a PTFE bar or rod cheap to use as isolator, so I will need to think about it a little bit more or look for further info in the web... any idea?

Sorry, only registered users may post in this forum.