[DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ?

Posted by ianmcmill

|

[DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? March 22, 2015 01:36PM |

Registered: 10 years ago Posts: 153 |

I'm in a dilemma. I'm building a Skeleton3D printer (link) but at a slightly larger scale. I want to use my 'basalt' heat bed from my old TwoUp. The original design of the Z axis is too weak for that build platform. It warps and bends, it wobbles and jiggles.

I started to construct my own design in Fusion360. I now have two designs at hand but I am not really sure about them. I am by no means a engineer nor a designer. I study Chemistry and English. So I can't tell what I am doing wrong and which prime principles I am offending. Please no stoning sentences.

Oh yeah and both designs take really long to print. 0.4mm nozzle, 0.2mm layer, average print speed 40mm/sec = 7-8 hours.

Long story short. Here are my designs.

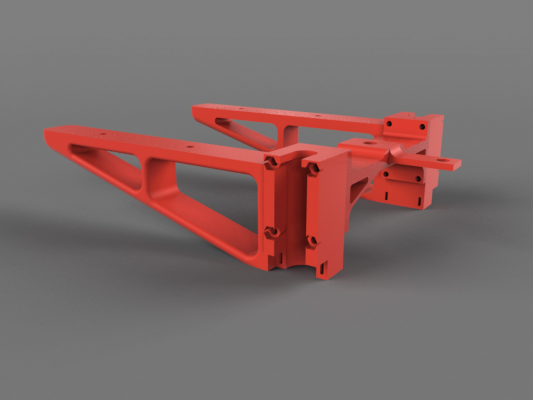

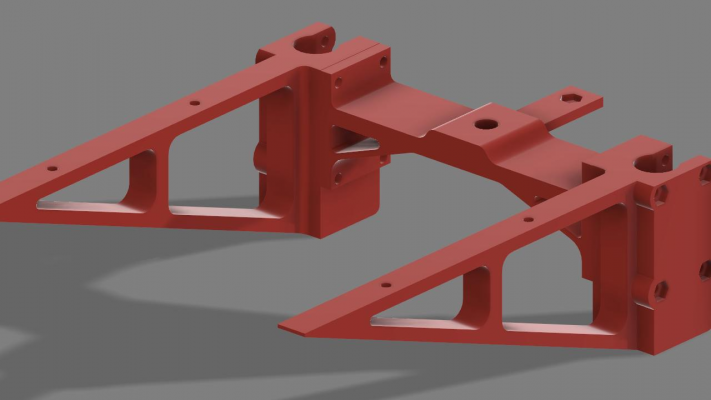

This one is made of three parts. They are connected via screws. Some really cool renders are on my blog. Including two 4k rendered orbiting videos. -> [capotexl.de]

Stl file #1

z_axis_support_v7_preview.stl

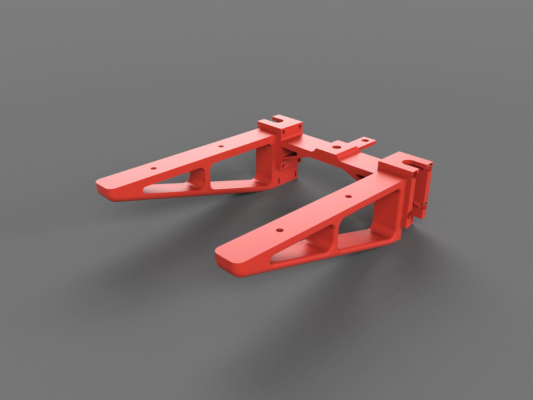

This one is a one-piece. No screws and therefore more rigid connections. I guess.

Some holes are still missing...

Stl file #2

bed_test_new.stl

I can post .iges files on demand.

Edited 3 time(s). Last edit at 03/22/2015 01:40PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

I started to construct my own design in Fusion360. I now have two designs at hand but I am not really sure about them. I am by no means a engineer nor a designer. I study Chemistry and English. So I can't tell what I am doing wrong and which prime principles I am offending. Please no stoning sentences.

Oh yeah and both designs take really long to print. 0.4mm nozzle, 0.2mm layer, average print speed 40mm/sec = 7-8 hours.

Long story short. Here are my designs.

This one is made of three parts. They are connected via screws. Some really cool renders are on my blog. Including two 4k rendered orbiting videos. -> [capotexl.de]

Stl file #1

z_axis_support_v7_preview.stl

This one is a one-piece. No screws and therefore more rigid connections. I guess.

Some holes are still missing...

Stl file #2

bed_test_new.stl

I can post .iges files on demand.

Edited 3 time(s). Last edit at 03/22/2015 01:40PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? March 23, 2015 08:27AM |

Registered: 10 years ago Posts: 153 |

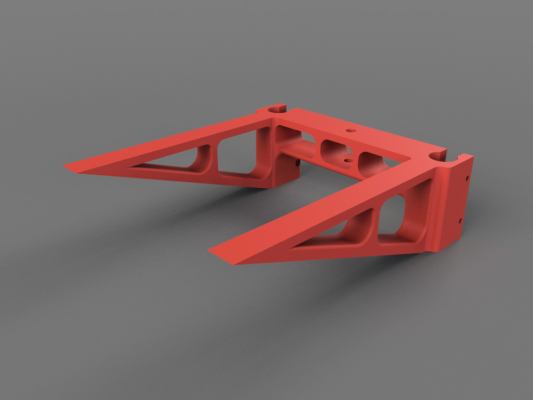

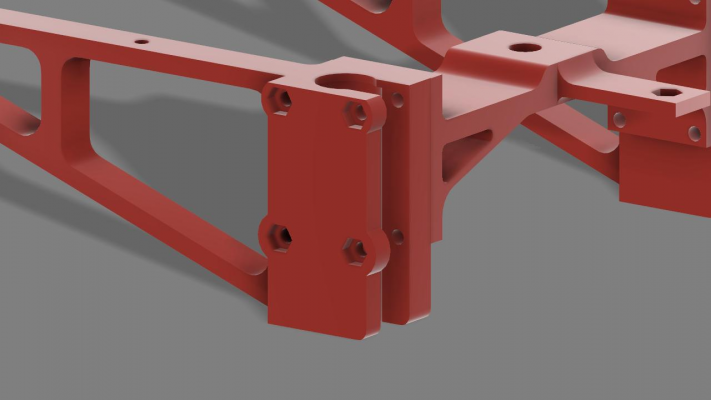

Okay so I reduced the width of the arms to 10 mm and rotated the bearing holder 90° so that the bearing can be clamped in with two screws.

The overall print time is now reduced to around 5 hours for both parts. I also increased the outer perimeter print speed to 45mm/sec from 30mm/sec.

stl

z_support_plate_left_v8.stl

z_support_plate_right_v8.stl

Edited 2 time(s). Last edit at 03/23/2015 08:31AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

The overall print time is now reduced to around 5 hours for both parts. I also increased the outer perimeter print speed to 45mm/sec from 30mm/sec.

stl

z_support_plate_left_v8.stl

z_support_plate_right_v8.stl

Edited 2 time(s). Last edit at 03/23/2015 08:31AM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? March 23, 2015 04:52PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? March 23, 2015 05:55PM |

Registered: 10 years ago Posts: 153 |

Yeah sure. Taking the upsize in consideratin it is not that tiny anymore. Transportable ? Clearly. 30cm cube.

I wanted to use the head bed but I already have removed the silicon head pad. Though as I don't have an aluminium plate around I thought I could go back to the basalt thing.

Anyways I have now come up with a support platform that is rigid enough. Thanks !

Edited 1 time(s). Last edit at 03/23/2015 05:55PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

I wanted to use the head bed but I already have removed the silicon head pad. Though as I don't have an aluminium plate around I thought I could go back to the basalt thing.

Anyways I have now come up with a support platform that is rigid enough. Thanks !

Edited 1 time(s). Last edit at 03/23/2015 05:55PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? March 24, 2015 03:20PM |

Registered: 10 years ago Posts: 153 |

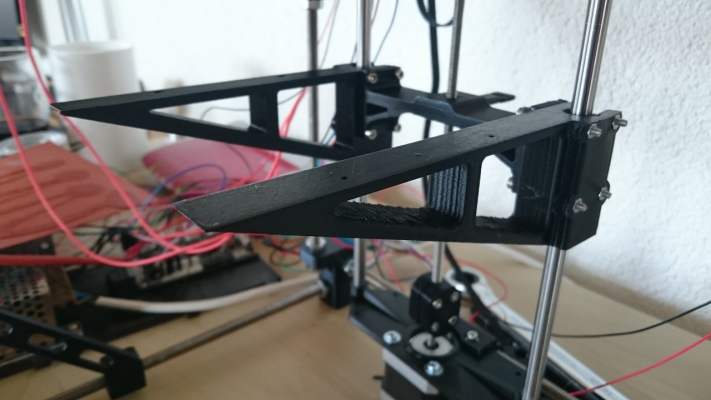

This becomes more of a buildlog than a resourceful help thread so here you go with more pictures and printed parts. I assembled them and they fit perfect. NOW the build platform, no matter if it is a thin aluminium plate or a 1cm thick wall tile, is stury. The original one really was not stiff at all. Even in tiny and transportable scale.

Maybe this one now is a bit overkill but rather over kill it than trying to fix it with zip ties and stuff later.

More pictures on [capotexl.de]

Edited 2 time(s). Last edit at 03/24/2015 03:22PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

Maybe this one now is a bit overkill but rather over kill it than trying to fix it with zip ties and stuff later.

More pictures on [capotexl.de]

Edited 2 time(s). Last edit at 03/24/2015 03:22PM by ianmcmill.

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? April 12, 2015 03:19AM |

Registered: 9 years ago Posts: 158 |

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? April 12, 2015 01:58PM |

Registered: 10 years ago Posts: 814 |

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? April 13, 2015 01:05PM |

Registered: 10 years ago Posts: 814 |

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? April 13, 2015 01:35PM |

Registered: 10 years ago Posts: 153 |

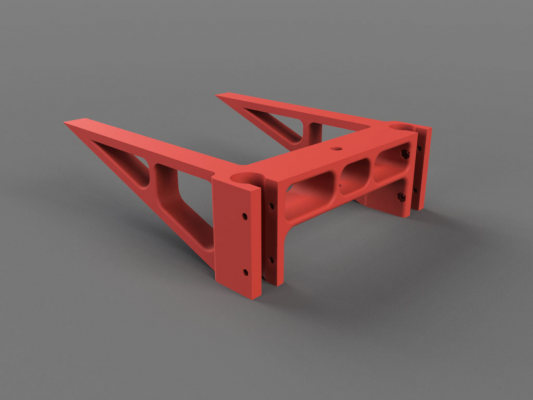

Okay so here is the complete Z axis. I hope I didn't forget anything.

These are the parts for building the support platform for a (generic) build platform but are especially made for a bigger version of the Skeleton3D.

I can add the parts that hold the smooth rods and the motor as well.

I also remodeled the X and Y motor holders to a much stronger version.

Also the pulley holders are remodeled to be more rigid (preview) No bending and warping when force of the timing belts are applied.

support_plateau_left_v12_lm8luu.stl

support_plateau_right_v12_lm8luu.stl

support_plate_link_v12.stl

Don't be confused about the LM8LUU naming. Two ordinary short LM8UU do fit it as well.

The bearing diameter is exactly 15.00 mm. No tolerance. So be sure to calibrate your extruder to print exact wall thickness. (Nice guide here)

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

These are the parts for building the support platform for a (generic) build platform but are especially made for a bigger version of the Skeleton3D.

I can add the parts that hold the smooth rods and the motor as well.

I also remodeled the X and Y motor holders to a much stronger version.

Also the pulley holders are remodeled to be more rigid (preview) No bending and warping when force of the timing belts are applied.

support_plateau_left_v12_lm8luu.stl

support_plateau_right_v12_lm8luu.stl

support_plate_link_v12.stl

Don't be confused about the LM8LUU naming. Two ordinary short LM8UU do fit it as well.

The bearing diameter is exactly 15.00 mm. No tolerance. So be sure to calibrate your extruder to print exact wall thickness. (Nice guide here)

Blog: Capotexl

Filament Factory - How to build your own cheap filament extruder

Frankenstein Laser Engraver

Make the world a better place

|

Re: [DESIGN QUESTION] Z axis table - Skeleton3D mod - Where are the Engineers ? April 14, 2015 04:41PM |

Registered: 10 years ago Posts: 814 |

Sorry, only registered users may post in this forum.