M Prime One, an open and simple 3D printer

Posted by diegotrap

|

M Prime One, an open and simple 3D printer October 15, 2015 01:32PM |

Registered: 11 years ago Posts: 14 |

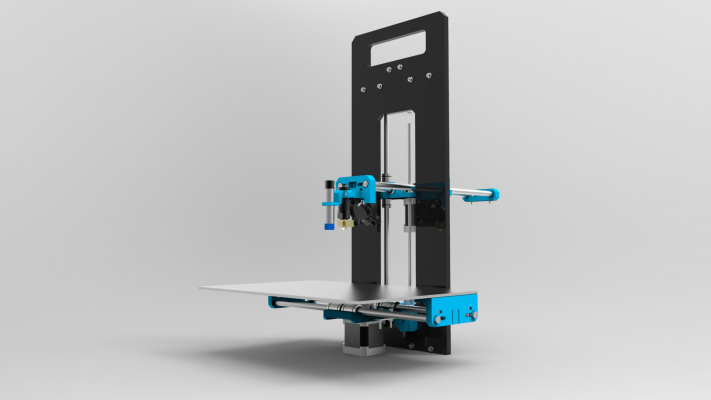

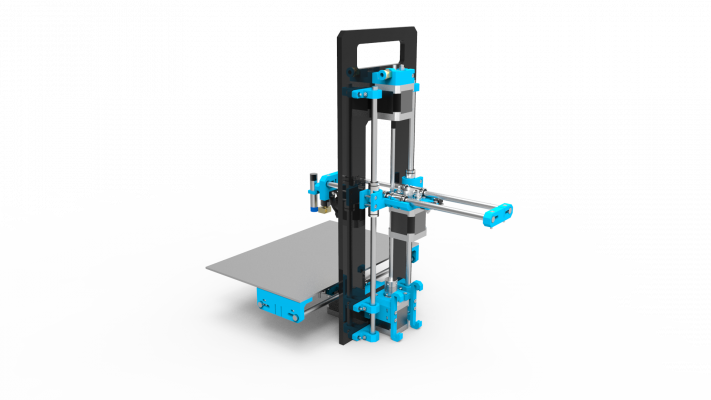

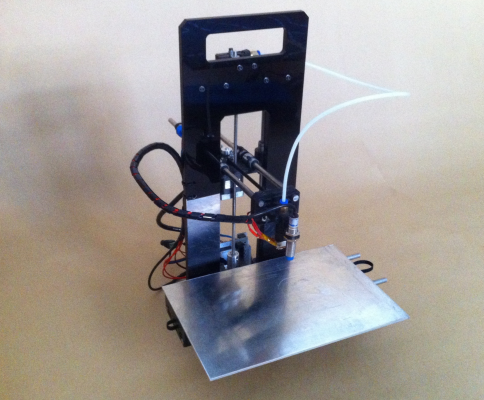

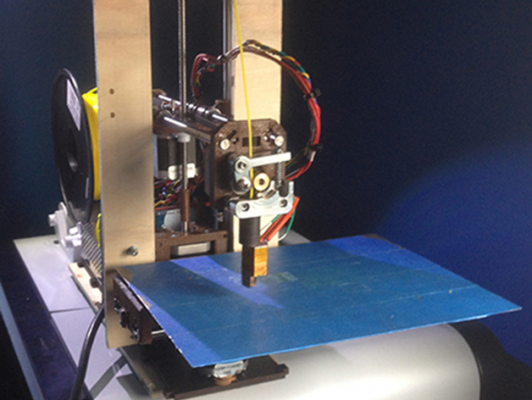

Hello! I've been developing a new 3D printer for a year now, and I want to introduce it to the RepRap forums. It is a machine inspired by the Smartrap and the Prusa i3, designed from scratch using free tools to be open, simple and economical. I've called it M Prime One.

I leave a couple of photos of the printer:

I think the best way for you to know the project a little bit better is to check the following links, where you can find the images, files and documentation of the printer:

Github repository: https://github.com/M-Prime/M_Prime_One

Reprap Wiki page: http://reprap.org/wiki/M_Prime_One

M Prime One page at thingiverse: http://www.thingiverse.com/thing:1058861

Online store: http://mprime.io

I'd love to hear any opinions, suggestions, doubts... about the printer. :-)

Edited 1 time(s). Last edit at 10/15/2015 01:38PM by diegotrap.

I leave a couple of photos of the printer:

I think the best way for you to know the project a little bit better is to check the following links, where you can find the images, files and documentation of the printer:

Github repository: https://github.com/M-Prime/M_Prime_One

Reprap Wiki page: http://reprap.org/wiki/M_Prime_One

M Prime One page at thingiverse: http://www.thingiverse.com/thing:1058861

Online store: http://mprime.io

I'd love to hear any opinions, suggestions, doubts... about the printer. :-)

Edited 1 time(s). Last edit at 10/15/2015 01:38PM by diegotrap.

|

Re: M Prime One, an open and simple 3D printer October 15, 2015 01:46PM |

Registered: 9 years ago Posts: 344 |

|

Re: M Prime One, an open and simple 3D printer October 29, 2015 09:23PM |

Registered: 16 years ago Posts: 80 |

|

Re: M Prime One, an open and simple 3D printer October 30, 2015 07:53AM |

Registered: 11 years ago Posts: 14 |

John, both axes move as you say, in a rack-and-pinion way. You can see it in the video of this prototype printing: https://www.youtube.com/watch?v=jsdfbjJOcaI

|

Re: M Prime One, an open and simple 3D printer November 06, 2015 06:24AM |

Registered: 9 years ago Posts: 21 |

Hi. This design is really charming. I have already printed the parts and laser cutted an acrylic sheet. I am waiting for the other parts to be delivered, and i have one question: what is the material of the bed? Is that steel? And what is the thickness and dimensions for it. Thank you for your graet design

|

Re: M Prime One, an open and simple 3D printer November 06, 2015 07:09AM |

Registered: 11 years ago Posts: 14 |

iran, I like you appreciate the design.

You'll need a bed that can be detected by the inductive sensor, so it should be metal. We use aluminium beds, with washers attached to the lower surface so the bed is attracted by the X axis magnets. It can also be Dibond/Alucobond..., which are commercial names for aluminium and plastic composite, basically a sandwich with a plastic core covered by two layers of thin aluminium. It has the advantage of being lighter than pure aluminium. The dimensions of the bed are 290x195x3mm. I hope this is enough information to solve your doubts, if you need anything else, please keep asking.

Keep us updated as your printer progresses, I always like to see other people building the printer! ;-)

You'll need a bed that can be detected by the inductive sensor, so it should be metal. We use aluminium beds, with washers attached to the lower surface so the bed is attracted by the X axis magnets. It can also be Dibond/Alucobond..., which are commercial names for aluminium and plastic composite, basically a sandwich with a plastic core covered by two layers of thin aluminium. It has the advantage of being lighter than pure aluminium. The dimensions of the bed are 290x195x3mm. I hope this is enough information to solve your doubts, if you need anything else, please keep asking.

Keep us updated as your printer progresses, I always like to see other people building the printer! ;-)

|

Re: M Prime One, an open and simple 3D printer November 06, 2015 08:19AM |

Registered: 9 years ago Posts: 21 |

Thank you. I think I know where to find some dibond. its vastly used in building facades. and what type of magnets should I buy which tolerate the movement and keep the bed in place?

پرینتر سه بعدی - چاپ سه بعدی

قطعات - فروش - آموزش

سایت رسمی رپرپ ایران

پرینتر سه بعدی - چاپ سه بعدی

قطعات - فروش - آموزش

سایت رسمی رپرپ ایران

|

Re: M Prime One, an open and simple 3D printer November 06, 2015 08:50AM |

Registered: 11 years ago Posts: 14 |

|

Re: M Prime One, an open and simple 3D printer November 27, 2015 06:51AM |

Registered: 8 years ago Posts: 13 |

Hi All,

first of all let me introduce myself - Juraj here, from Slovakia. This is my first post on these great forums...

I would like to thank Diego for nice design! This will be my very first reprap build "from scratches", and I have been in contact with Diego already through email. So one more thank you for the support in answering my noob questions

Since I have (and most probably will have) more questions regarding M Prime One I have decided to post them here so they can be of future reference to others building this printer. So- here comes the first one (and second, and third, and... as well):

What is the thickness of the acrylic frame please?

What material should I print the printed parts from? Can I use PLA for the parts? Or ABS?

Have you also designed an LCD display case / holder for the machine? Where is the display supposed to be on the printer (if though about already)?

Would it be possible to post a picture of the bed with the magnets and washers here - for my better understanding on how it is supposed to be done?

Thank you!

Juraj

Edited 1 time(s). Last edit at 11/27/2015 06:57AM by Brushie.

first of all let me introduce myself - Juraj here, from Slovakia. This is my first post on these great forums...

I would like to thank Diego for nice design! This will be my very first reprap build "from scratches", and I have been in contact with Diego already through email. So one more thank you for the support in answering my noob questions

Since I have (and most probably will have) more questions regarding M Prime One I have decided to post them here so they can be of future reference to others building this printer. So- here comes the first one (and second, and third, and... as well):

What is the thickness of the acrylic frame please?

What material should I print the printed parts from? Can I use PLA for the parts? Or ABS?

Have you also designed an LCD display case / holder for the machine? Where is the display supposed to be on the printer (if though about already)?

Would it be possible to post a picture of the bed with the magnets and washers here - for my better understanding on how it is supposed to be done?

Thank you!

Juraj

Edited 1 time(s). Last edit at 11/27/2015 06:57AM by Brushie.

|

Re: M Prime One, an open and simple 3D printer November 27, 2015 07:03AM |

Registered: 11 years ago Posts: 14 |

Thanks for posting in here, Juraj, and I have no problem in helping people build their M Prime Ones.

About the thickness of the acrylic, 8mm is the best, because the printer and accessories have been designed with a 8mm-thick frame in mind. You can use other thicknesses if you can't find 8mm, 6 to 10mm will work too, but it may require to change the bolt lengths or modify accessories like the spool holder.

Good luck with your printer, Juraj!

About the thickness of the acrylic, 8mm is the best, because the printer and accessories have been designed with a 8mm-thick frame in mind. You can use other thicknesses if you can't find 8mm, 6 to 10mm will work too, but it may require to change the bolt lengths or modify accessories like the spool holder.

Good luck with your printer, Juraj!

|

Re: M Prime One, an open and simple 3D printer November 30, 2015 05:02AM |

Registered: 8 years ago Posts: 13 |

Hi Diego,

thanks for your reply.

I am about to start printing the parts - can you advise on this a little bit please? Can they be printed with PLA or should I use ABS?

Regarding the mechanical endstops - in the BOM v1.8 is mentioned, neverhteless I can not find these anywhere. Ebay is full of v1.2 endstops - do you think these can be used?

Thanks,

Juraj

Edited 1 time(s). Last edit at 11/30/2015 09:26AM by Brushie.

thanks for your reply.

I am about to start printing the parts - can you advise on this a little bit please? Can they be printed with PLA or should I use ABS?

Regarding the mechanical endstops - in the BOM v1.8 is mentioned, neverhteless I can not find these anywhere. Ebay is full of v1.2 endstops - do you think these can be used?

Thanks,

Juraj

Edited 1 time(s). Last edit at 11/30/2015 09:26AM by Brushie.

|

Re: M Prime One, an open and simple 3D printer November 30, 2015 07:27AM |

Registered: 11 years ago Posts: 14 |

|

Re: M Prime One, an open and simple 3D printer November 30, 2015 05:08PM |

Registered: 8 years ago Posts: 13 |

|

Re: M Prime One, an open and simple 3D printer December 01, 2015 08:25AM |

Registered: 11 years ago Posts: 14 |

|

Re: M Prime One, an open and simple 3D printer December 02, 2015 05:48AM |

Registered: 8 years ago Posts: 13 |

So - I am working hard on getting all the components together. Am starting to print the parts over this weekend and sourcing other parts - from Diego, locally, as well as waiting for already ordered electronics from several sources...

I was wondering whether someone can help me to find a way how to attach LCD to the printer? I have ordered the classic LCD (used on most i3 designs) together with the electronics and would like to use it for his printer. Any ideas / suggestions?

Cheers

I was wondering whether someone can help me to find a way how to attach LCD to the printer? I have ordered the classic LCD (used on most i3 designs) together with the electronics and would like to use it for his printer. Any ideas / suggestions?

Cheers

|

Re: M Prime One, an open and simple 3D printer December 02, 2015 08:31AM |

Registered: 11 years ago Posts: 14 |

You can use the files in the github repository (https://github.com/M-Prime/M_Prime_One/tree/master/3D_model/printed_parts/lcd_adapters/smart_lcd_holder) if you have an Smart LCD controller.

For other designs, you can try to attach it to the frame or even the front part of the printer, but that would require that you design the appropriate parts. Being such a compact printer, it's not easy to find a spot to attach the LCD, so I think the "official" development will be more focused in making the printer wireless rather than designing many LCD adaptors. Unless we find a solution that truly pleases us.

For other designs, you can try to attach it to the frame or even the front part of the printer, but that would require that you design the appropriate parts. Being such a compact printer, it's not easy to find a spot to attach the LCD, so I think the "official" development will be more focused in making the printer wireless rather than designing many LCD adaptors. Unless we find a solution that truly pleases us.

|

Re: M Prime One, an open and simple 3D printer December 04, 2015 06:58AM |

Registered: 8 years ago Posts: 13 |

To be honest the LCD is still in the post somewhere between Hong-kong and Europe and I am not sure which type it is. Will wait once I have it in my hands to locate proper holder. May just end up having the LCD controller standing aside the printer...

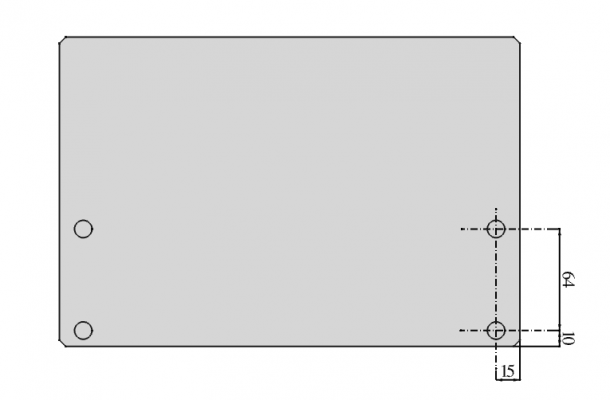

Neverhteless - Diego, can you please post a picture on how exactly you attach the bed to the printer (with the washer and magntets)?

Cheers.

Neverhteless - Diego, can you please post a picture on how exactly you attach the bed to the printer (with the washer and magntets)?

Cheers.

|

Re: M Prime One, an open and simple 3D printer December 09, 2015 09:49AM |

Registered: 11 years ago Posts: 14 |

Brushie,

First, the magnets. They are glued to the round pockets in the x_axis_end part. In the next iteration of the part, the magnets are screwed to the printed part.

Second, the washers. The are glued to the bottom of the bed. You'll need a strong bond, we have used cyanocrylate, epoxy and Loctite 638, I prefer the latter. Here you have the dimensions you have to take into account to place the washers on the bed:

Sorry about the delay in my answer, I am quite busy with the store and replying the support requests of the users. In order to do do it properly I need some time.

First, the magnets. They are glued to the round pockets in the x_axis_end part. In the next iteration of the part, the magnets are screwed to the printed part.

Second, the washers. The are glued to the bottom of the bed. You'll need a strong bond, we have used cyanocrylate, epoxy and Loctite 638, I prefer the latter. Here you have the dimensions you have to take into account to place the washers on the bed:

Sorry about the delay in my answer, I am quite busy with the store and replying the support requests of the users. In order to do do it properly I need some time.

|

Re: M Prime One, an open and simple 3D printer December 11, 2015 06:18AM |

Registered: 8 years ago Posts: 13 |

|

Re: M Prime One, an open and simple 3D printer March 03, 2016 10:16AM |

Registered: 8 years ago Posts: 18 |

I just finished my build and added a few "vitamins".

A great little printer (get it here: [www.thingiverse.com] ) created from bits and pieces of Printrbot Simple 1405 and QUBD 2 UP. Works better now than either of the originals lol.

Cheers,

Mark B

BTW...thats a DaVinci 2.0A converted to Mega/RAMPS 1.4 being used as the base for the M-Prime

Edited 1 time(s). Last edit at 03/04/2016 02:58PM by MarkBot.

A great little printer (get it here: [www.thingiverse.com] ) created from bits and pieces of Printrbot Simple 1405 and QUBD 2 UP. Works better now than either of the originals lol.

Cheers,

Mark B

BTW...thats a DaVinci 2.0A converted to Mega/RAMPS 1.4 being used as the base for the M-Prime

Edited 1 time(s). Last edit at 03/04/2016 02:58PM by MarkBot.

|

Re: M Prime One, an open and simple 3D printer June 09, 2020 10:15AM |

Registered: 11 years ago Posts: 12 |

|

Re: M Prime One, an open and simple 3D printer August 02, 2020 12:17PM |

Registered: 5 years ago Posts: 44 |

A bit late, sembot, but here goes [www.thingiverse.com]

Sorry, only registered users may post in this forum.