Kappa 3D printer - The next generation 3D printer

Posted by francis_regan

Kappa 3D printer - The next generation 3D printer  June 17, 2017 04:58PM |

Registered: 7 years ago Posts: 4 |

Hey Guys, my name is Regan and I'm based out of Singapore. For the past one year, my team and I have been working on a new style of 3D printer inspired from Scott Russell Kinematics also known as straight line mechanism.

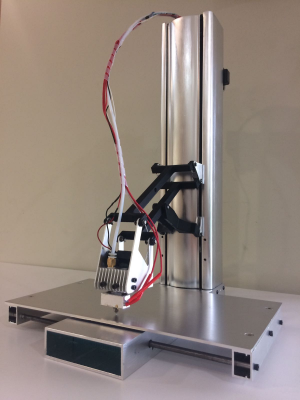

Fast forward to May 2016 and we were well into research and development on a Car Washing project. While on the project we stumbled across the idea on using the similar design for a 3D printer. 3 days later we came out with the first concept of the 3D printer based on Scott Russell Straight line mechanism. And it was really magical to see the idea in action, and we named it Kappa The very first video and picture of the machine.

The very first video and picture of the machine.

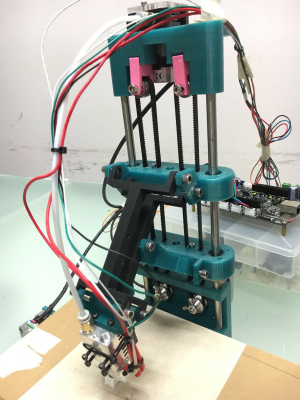

This is the very first prototype that we implemented and brought our our concept to life.

Concept behind the design - Scott russell straight line mechanism

Image courtesy: wikipedia

From the images above you can see that there are two types of arms,

- long arm (Moves along a straight line B and C are in the same plane)

- short arm (fixed)

The above shows one direction of motion along one plane. But how do we improve on this to a 3D printer?

Simple, make the bottom arm also movable

Movement in the bottom arm C along E, results in the movement of both Z and Y axis.

The last direction of motion X is separated from this design and a motor moves the platform left to right.

Here is a video of our printers Kappa in action

So whats new?

We wanted to redefine few features based on our bitter experiences with 3D printers. Some of the new features we introduced are

- Removable style PCB board (slot-able cassette style).

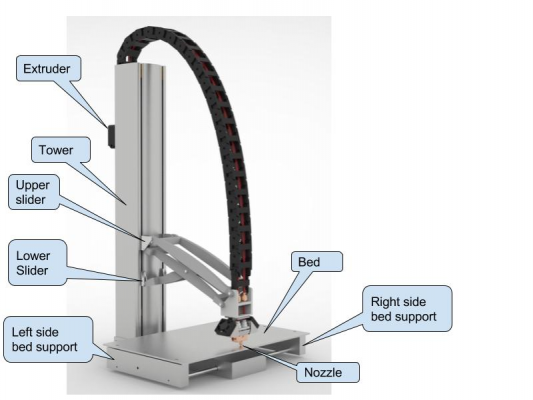

- Body is a slim aluminium tower which also acts as a heatsink.

- Foldable and removable arms for maximum space efficiency

- To hold the nozzle perpendicular to the platform, we use double long arms

- Compact assembly of parts inside the tower to optimise space

I'm attaching a rendered pic, which shows the parts of our printer.

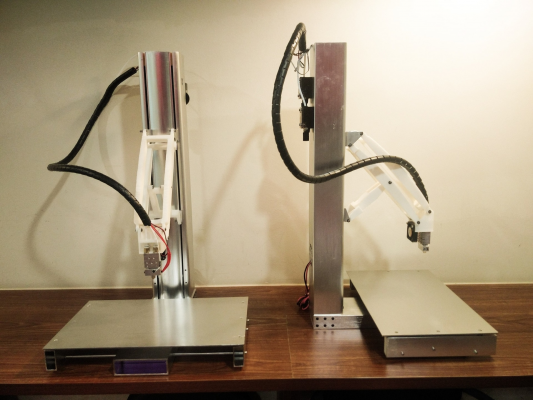

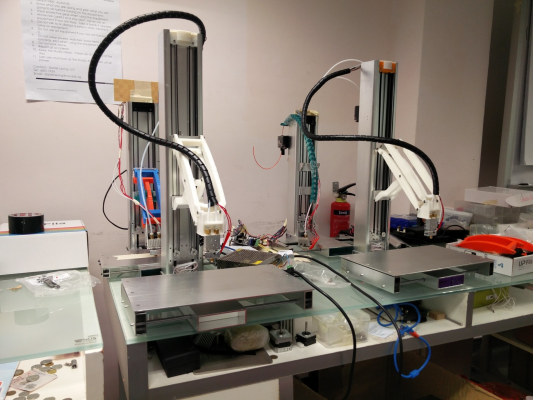

Few other variations of our printer

Few prototypes used for testing and analysis

Please let us know what you think of our new concept. Would love to share more information to you guys.

This project is completely bootstrapped by us, and we have tested and completed the printer end-to-end. We are launching soon in August 2017 via Kickstarter.

Please visit our FB pages and follow us on the new updates.

Also visit our website at www.ionic3dp.com

Edited 5 time(s). Last edit at 06/17/2017 05:15PM by francis_regan.

Fast forward to May 2016 and we were well into research and development on a Car Washing project. While on the project we stumbled across the idea on using the similar design for a 3D printer. 3 days later we came out with the first concept of the 3D printer based on Scott Russell Straight line mechanism. And it was really magical to see the idea in action, and we named it Kappa

The very first video and picture of the machine.

The very first video and picture of the machine.This is the very first prototype that we implemented and brought our our concept to life.

Concept behind the design - Scott russell straight line mechanism

Image courtesy: wikipedia

From the images above you can see that there are two types of arms,

- long arm (Moves along a straight line B and C are in the same plane)

- short arm (fixed)

The above shows one direction of motion along one plane. But how do we improve on this to a 3D printer?

Simple, make the bottom arm also movable

Movement in the bottom arm C along E, results in the movement of both Z and Y axis.

The last direction of motion X is separated from this design and a motor moves the platform left to right.

Here is a video of our printers Kappa in action

So whats new?

We wanted to redefine few features based on our bitter experiences with 3D printers. Some of the new features we introduced are

- Removable style PCB board (slot-able cassette style).

- Body is a slim aluminium tower which also acts as a heatsink.

- Foldable and removable arms for maximum space efficiency

- To hold the nozzle perpendicular to the platform, we use double long arms

- Compact assembly of parts inside the tower to optimise space

I'm attaching a rendered pic, which shows the parts of our printer.

Few other variations of our printer

Few prototypes used for testing and analysis

Please let us know what you think of our new concept. Would love to share more information to you guys.

This project is completely bootstrapped by us, and we have tested and completed the printer end-to-end. We are launching soon in August 2017 via Kickstarter.

Please visit our FB pages and follow us on the new updates.

Also visit our website at www.ionic3dp.com

Edited 5 time(s). Last edit at 06/17/2017 05:15PM by francis_regan.

Re: Kappa 3D printer - The next generation 3D printer  July 20, 2017 08:09AM |

Registered: 15 years ago Posts: 376 |

This is an excellent design. Is the 3D printed prototype open sourced as I would love to contribute to its development?

Because of the very narrow profile of the main upright, this machine seems the ideal configuration for a dual head. By extending the X axis by the width of the head, you could easily have dual print heads which are independant of each other.

I am not a big fan of moving the produced part, which is why I like deltas, but perhaps the main upright could be turned left and right to give a curved arc build envelope.

Helium Frog Website

Because of the very narrow profile of the main upright, this machine seems the ideal configuration for a dual head. By extending the X axis by the width of the head, you could easily have dual print heads which are independant of each other.

I am not a big fan of moving the produced part, which is why I like deltas, but perhaps the main upright could be turned left and right to give a curved arc build envelope.

Helium Frog Website

Re: Kappa 3D printer - The next generation 3D printer  September 07, 2017 07:52AM |

Registered: 9 years ago Posts: 1,035 |

No other responses from July ... strane. I find the design very interesting as you basically save one axis worth of linear guides/rails and also pretty compact. Personally I would have better liked a rotating X axis like the Polar3D so that the bed wouldn't stick too much out of the footprint but nevertheless this design is very welcomed. By not receiving a response I assume the design is not open sourced and the code is proprietary so I would like to know more about that aspect too.

Other than that, good luck with your project.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Other than that, good luck with your project.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: Kappa 3D printer - The next generation 3D printer  September 09, 2017 03:50PM |

Registered: 7 years ago Posts: 4 |

Dear martinprice2004,

I am extremely sorry that I missed out on your message. I checked my emails and did notice the notification from rep-rap mailer, but it slipped my notice.

We would love to share the 3D printed design of Kappa on the rep-rap community so people can contribute and improve on it.

When we made the first prototype, we realized that there could be a potential problem of rigidity and vibrations especially when moving the tower at high speeds.

So instead we kept the tower stable and the bed to move. We wanted the tower to be very stable and went ahead with aluminum extrusion and mounted all the motors inside it.

Helped save up space and also easy assembly during production.

We have several variations of the design and one idea would be to keep a U-shaped platform and the tower can rotate around printing on the platform.

Also to let you know, our team is launching on Kickstarter tomorrow and we really hope the rewards we get from the project can fund us moving forward with more R&D.

I'll be a bit busy over the following week due to Kickstarter activities and I will submit the files including source code, in a week or two.

It would be really wonderful if you can contribute to us by selecting a reward in Kickstarter.

Francis Regan,

www.ionic3dp.com

Edited 1 time(s). Last edit at 09/09/2017 04:07PM by francis_regan.

I am extremely sorry that I missed out on your message. I checked my emails and did notice the notification from rep-rap mailer, but it slipped my notice.

We would love to share the 3D printed design of Kappa on the rep-rap community so people can contribute and improve on it.

When we made the first prototype, we realized that there could be a potential problem of rigidity and vibrations especially when moving the tower at high speeds.

So instead we kept the tower stable and the bed to move. We wanted the tower to be very stable and went ahead with aluminum extrusion and mounted all the motors inside it.

Helped save up space and also easy assembly during production.

We have several variations of the design and one idea would be to keep a U-shaped platform and the tower can rotate around printing on the platform.

Also to let you know, our team is launching on Kickstarter tomorrow and we really hope the rewards we get from the project can fund us moving forward with more R&D.

I'll be a bit busy over the following week due to Kickstarter activities and I will submit the files including source code, in a week or two.

It would be really wonderful if you can contribute to us by selecting a reward in Kickstarter.

Francis Regan,

www.ionic3dp.com

Edited 1 time(s). Last edit at 09/09/2017 04:07PM by francis_regan.

|

Re: Kappa 3D printer - The next generation 3D printer September 09, 2017 04:05PM |

Registered: 7 years ago Posts: 4 |

Dear Realthor,

My apologies, I had missed out on the posts from this forum.

Yes we had patented the design of this machine in Singapore last year including other variants such as rotating table, rotating tower etc.

But after a lot of careful considerations, we have decided to open-source our invention so others can contribute and improve Kappa as well.

In the following weeks, I'll prepare all the necessary design files and source so anyone interested can work on it.

We are launching on Kickstarter tomorrow with over a year of development of our machine.

Please do watch out for us on Kickstarter and please do back us so we can contribute more in this project.

Our website is www.ionic3dp.com and my personal email address is regan@ionic3dp.com.

If you need any further information or clarification please feel free to contact me directly.

Francis Regan,

www.ionic3dp.com

My apologies, I had missed out on the posts from this forum.

Yes we had patented the design of this machine in Singapore last year including other variants such as rotating table, rotating tower etc.

But after a lot of careful considerations, we have decided to open-source our invention so others can contribute and improve Kappa as well.

In the following weeks, I'll prepare all the necessary design files and source so anyone interested can work on it.

We are launching on Kickstarter tomorrow with over a year of development of our machine.

Please do watch out for us on Kickstarter and please do back us so we can contribute more in this project.

Our website is www.ionic3dp.com and my personal email address is regan@ionic3dp.com.

If you need any further information or clarification please feel free to contact me directly.

Francis Regan,

www.ionic3dp.com

Re: Kappa 3D printer - The next generation 3D printer  September 10, 2017 02:47PM |

Registered: 10 years ago Posts: 14,672 |

Looks interesting! For best print quality I think you will need to apply the same techniques as used on the best delta printers, i.e. 0.9deg motors for YZ motion, and a segmentation-free step generation algorithm - which should be easy to implement because the movement equations appear to me to be quadratic. But perhaps you are doing these things already?

From a print speed perspective, I guess the main limitation will be the moving bed that implements the X axis.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

From a print speed perspective, I guess the main limitation will be the moving bed that implements the X axis.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Kappa 3D printer - The next generation 3D printer  September 11, 2017 11:57AM |

Registered: 7 years ago Posts: 4 |

Hey @dc42,

Thanks for the question. We are not using 0.9d motors nor segmentation-free algoithm.

We break each and every line into multiple segments.

For each segment we calculate the inverse kinematic and then motor will follow the inverse kinematic to move in the particular segment. This is similar to most deltas.

Thanks for the question. We are not using 0.9d motors nor segmentation-free algoithm.

We break each and every line into multiple segments.

For each segment we calculate the inverse kinematic and then motor will follow the inverse kinematic to move in the particular segment. This is similar to most deltas.

Re: Kappa 3D printer - The next generation 3D printer  September 19, 2017 03:28PM |

Registered: 6 years ago Posts: 1,007 |

Re: Kappa 3D printer - The next generation 3D printer  October 20, 2017 03:52AM |

Registered: 9 years ago Posts: 1,035 |

I believe the most difficulty -precision-wise- is when the arm is fully extended and the two sliding arms (a and b on your drawing above) are closest to each other. To avoid this a and b should be fairly long so that when fully extended (printing at the opposite extreme to the Z tower), there is a comfortable distance between the a and b arms' sliding ends. Have you measured or noticed anything when printing with arm fully extended?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.