(Probably) a new CoreXY-based design

Posted by roman_savchuk

|

(Probably) a new CoreXY-based design January 08, 2019 07:50AM |

Registered: 5 years ago Posts: 3 |

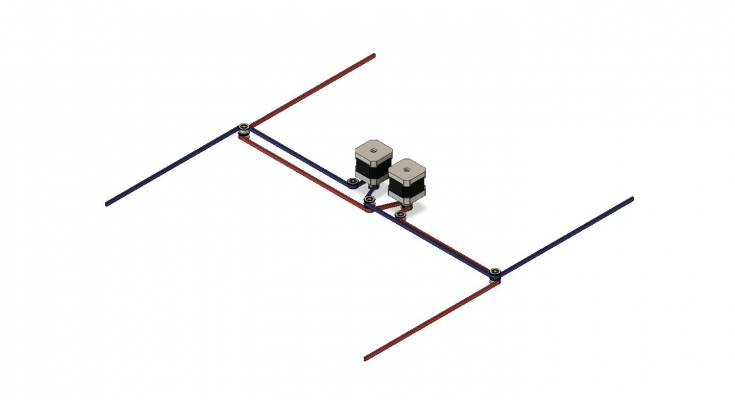

I wanted a small CNC router and at some point of researching my options decided to build shapeoko-like machine from scratch. I wanted it to be as simple as possible, and that brought me to mounting all of the machine motors on the X Carrier assembly, with xy belt drive arrangement like this.

Basically it's a non-crossing CoreXY like a D-bot used in some 3d printers, except for the belts are fixed and the motors are movable. I think it's a new design, but let me know if I'm wrong

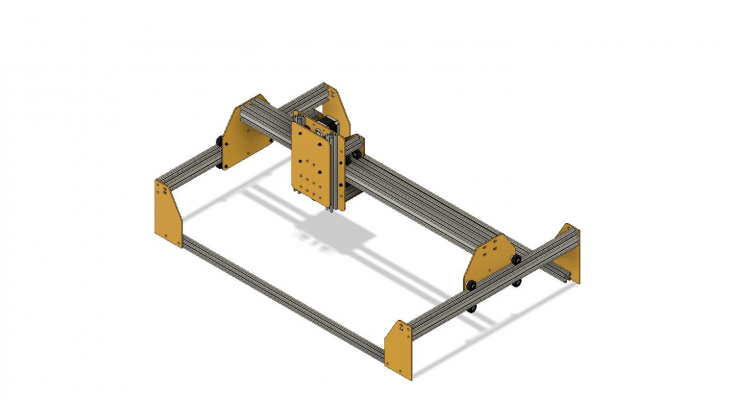

Rest of the machine in Fusion 360

Test-running an unfinshed prototype

[www.youtube.com]

P.S. Posted this to r/hobbycnc earlier today

Basically it's a non-crossing CoreXY like a D-bot used in some 3d printers, except for the belts are fixed and the motors are movable. I think it's a new design, but let me know if I'm wrong

Rest of the machine in Fusion 360

Test-running an unfinshed prototype

[www.youtube.com]

P.S. Posted this to r/hobbycnc earlier today

|

Re: (Probably) a new CoreXY-based design January 08, 2019 07:50AM |

Registered: 5 years ago Posts: 3 |

Ok, I should've explained the point of this design in the opening post.

The gantry is based on existing aluminium profile machines like shapeoko or x-carve. All of them already have motors mounted on carriers, i.e. 2 motors to make Y-axis movement, 1 motor to make X-axis movement. So, it's already removing the mass of 1 motor from the moving assemblies.

The biggest advantage is actually addressing cable management issues. All NEMA motors, endstops and mainboard are located on a single rigid X carrier assembly. The only moving cables are power cable to mainboard, usb cable (or none if wifi shield is used) and power cable to spindle. So you can completely eliminate cable chains and distributor boxes.

Edited 2 time(s). Last edit at 01/09/2019 04:32AM by roman_savchuk.

The gantry is based on existing aluminium profile machines like shapeoko or x-carve. All of them already have motors mounted on carriers, i.e. 2 motors to make Y-axis movement, 1 motor to make X-axis movement. So, it's already removing the mass of 1 motor from the moving assemblies.

The biggest advantage is actually addressing cable management issues. All NEMA motors, endstops and mainboard are located on a single rigid X carrier assembly. The only moving cables are power cable to mainboard, usb cable (or none if wifi shield is used) and power cable to spindle. So you can completely eliminate cable chains and distributor boxes.

Edited 2 time(s). Last edit at 01/09/2019 04:32AM by roman_savchuk.

|

Re: (Probably) a new CoreXY-based design January 08, 2019 12:34PM |

Registered: 6 years ago Posts: 1,007 |

New ideas in these machines are very rare but bad, unsuitable ideas being quickly forgotten are regularly reinvented !

The CoreXY has been "invented" to have the motors fixed. Here you have the complexity without this advantage.

Edited 1 time(s). Last edit at 01/08/2019 12:35PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The CoreXY has been "invented" to have the motors fixed. Here you have the complexity without this advantage.

Edited 1 time(s). Last edit at 01/08/2019 12:35PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: (Probably) a new CoreXY-based design January 08, 2019 12:40PM |

Registered: 7 years ago Posts: 363 |

|

Re: (Probably) a new CoreXY-based design January 09, 2019 03:41AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: (Probably) a new CoreXY-based design January 09, 2019 04:35AM |

Registered: 5 years ago Posts: 3 |

|

Re: (Probably) a new CoreXY-based design January 23, 2019 01:10PM |

Registered: 6 years ago Posts: 134 |

Nice idea to shorten belts. Also, you may place motors on Y carriages instead of X. It may save X from weight load of motors and complexity of design but will keep weight on Y.

[Update] I was too fast to jump to conclusions. It won't work on Y

Edited 1 time(s). Last edit at 01/24/2019 07:19PM by piper3d.

[Update] I was too fast to jump to conclusions. It won't work on Y

Edited 1 time(s). Last edit at 01/24/2019 07:19PM by piper3d.

|

Re: (Probably) a new CoreXY-based design January 29, 2019 05:53PM |

Registered: 10 years ago Posts: 150 |

Indeed, unless you consider that, in the provided drawing, the motors are still fixed, and that it is the whole belt and pulley system that moves (and remains lighter than the motors).Quote

MKSA

Here you have the complexity without this advantage.

Then, you have the benefit of shorting belts...

|

Re: (Probably) a new CoreXY-based design December 02, 2019 09:57AM |

Registered: 5 years ago Posts: 50 |

|

Re: (Probably) a new CoreXY-based design December 02, 2019 11:26AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

ruyvieira

The added weight should be a bonus for a CNC router, in my opinion. The toolhead will be gravity-assisted.

Except that the weight will not be on the toolhead but strictly on the axis.

http://www.marinusdebeer.nl/

|

Re: (Probably) a new CoreXY-based design December 02, 2019 11:29AM |

Registered: 5 years ago Posts: 50 |

Quote

Ohmarinus

Quote

ruyvieira

The added weight should be a bonus for a CNC router, in my opinion. The toolhead will be gravity-assisted.

Except that the weight will not be on the toolhead but strictly on the axis.

Drilling down creates a point load on the axis too, only in the opposite direction

Sorry, only registered users may post in this forum.