Laser for sintering of metal powder

Posted by Nathan_T

|

Laser for sintering of metal powder August 23, 2019 06:19AM |

Registered: 6 years ago Posts: 20 |

Hello everybody! I'm interesting about lasers for selective laser sintering of metal powder. I read that fiber lasers are good for this purpose. First of all I found second-hand fiber lasers on Ebay and that was nLIGHT's laser (this is not advert!):

How much power and length of wave should be laser for sintering of metal powder?

Edited 1 time(s). Last edit at 08/23/2019 06:41AM by Nathan_T.

How much power and length of wave should be laser for sintering of metal powder?

Edited 1 time(s). Last edit at 08/23/2019 06:41AM by Nathan_T.

|

Re: Laser for sintering of metal powder August 23, 2019 07:14AM |

Admin Registered: 16 years ago Posts: 13,884 |

... fiber-lasers are commonly used for metal sintering for their high power (some tens to thousands Watts CW or Megawatts pulsed) and superior focussing ability down to spot diameters of some ten microns.

The laser in your link is not a fiber laser, but a "fiber coupled" diode module without essential infos like power, wavelength or fiber diameter.

I have different "fiber coupled" laserdiodes and multi-diode modules with powers from 5Watt to 200Watts -- the here achievable spot diameters are 10x bigger or even more, so not comparable with fiber-lasers!

With my tests with fiber-lasers or laserdiodes I've got some rough numbers -- a fiberlaser (1064nm wavelength) will start to melt metal powder with even lowest powers from 2Watts on a spot of 0.03mm ... but you'll need more than 10 Watts to melt/fuse it to a solid metal surface beneath.

Laserdiodes (808nm to 975nm) on a spot of 0.2mm diameter will start melting metal powder at/above 20 Watts ... and fuse to solid metal at powers with more than 60 Watts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The laser in your link is not a fiber laser, but a "fiber coupled" diode module without essential infos like power, wavelength or fiber diameter.

I have different "fiber coupled" laserdiodes and multi-diode modules with powers from 5Watt to 200Watts -- the here achievable spot diameters are 10x bigger or even more, so not comparable with fiber-lasers!

With my tests with fiber-lasers or laserdiodes I've got some rough numbers -- a fiberlaser (1064nm wavelength) will start to melt metal powder with even lowest powers from 2Watts on a spot of 0.03mm ... but you'll need more than 10 Watts to melt/fuse it to a solid metal surface beneath.

Laserdiodes (808nm to 975nm) on a spot of 0.2mm diameter will start melting metal powder at/above 20 Watts ... and fuse to solid metal at powers with more than 60 Watts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 26, 2019 04:39AM |

Registered: 6 years ago Posts: 20 |

|

Re: Laser for sintering of metal powder August 26, 2019 10:11AM |

Admin Registered: 16 years ago Posts: 13,884 |

... search for some related threads here - [reprap.org]

Most of the "seriously" fusing tests was made in/for projects under NDA's (have one running actually too), so no images ... but did some more "free" tinkering on my own, what's shown in the threads

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Most of the "seriously" fusing tests was made in/for projects under NDA's (have one running actually too), so no images ... but did some more "free" tinkering on my own, what's shown in the threads

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 26, 2019 10:32AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Laser for sintering of metal powder August 26, 2019 11:59AM |

Admin Registered: 16 years ago Posts: 13,884 |

... oh, I did some "private" powder-sintering too and posted some hints and pics in the threads - but actually not the time to find them again (so it's not all hidden)

My hope was to motivate some others to do their own experiments ... even built and distributed some IR-diodemodules+drivers with 5Watt or 9Watts on a 0,1mm spot.

But either no feedback ... or they were used for kick-starting or such

Here some of the old related infos - [reprap.org]

And then, look through all the even older threads from 2007 on (my first related "work" from 1990, but not documented then), I've posted here and in other forums ...

Edited 1 time(s). Last edit at 08/26/2019 12:02PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My hope was to motivate some others to do their own experiments ... even built and distributed some IR-diodemodules+drivers with 5Watt or 9Watts on a 0,1mm spot.

But either no feedback ... or they were used for kick-starting or such

Here some of the old related infos - [reprap.org]

And then, look through all the even older threads from 2007 on (my first related "work" from 1990, but not documented then), I've posted here and in other forums ...

Edited 1 time(s). Last edit at 08/26/2019 12:02PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 29, 2019 06:55AM |

Registered: 6 years ago Posts: 20 |

Viktor, I found your posts about laser for sintering powder there

And there about plastic welding.

After that I found laserdiode like in your post - Jenoptik 20W

And this one - Rofin 50W

What can you say about these lasers?

|

Re: Laser for sintering of metal powder August 29, 2019 09:25AM |

Admin Registered: 16 years ago Posts: 13,884 |

... 20 Watts on a spot of roughly 0.4mm (some specs of the fiber exit?) is not sufficient for sintering metal powder - it will melt the powder, but not fusing it to previously solidified parts for lack of energy ... but should be more than enough for plastic powder or dark glass or mineralic dust!

50 Watts could be a first entry -- here you'll need the specs and datasheet of the diode - ist it meant for continuous mode or only pulsing? ... and you'll need a good cooling system ...

Edited 1 time(s). Last edit at 08/29/2019 09:27AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

50 Watts could be a first entry -- here you'll need the specs and datasheet of the diode - ist it meant for continuous mode or only pulsing? ... and you'll need a good cooling system ...

Edited 1 time(s). Last edit at 08/29/2019 09:27AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 31, 2019 04:36AM |

Registered: 5 years ago Posts: 155 |

Is it possible to multiplex laser diodes so they have enough power for metal melting? I have 808 nm 300 mW laser diodes: is there an idea to let them work together?

I thought of install them separately and focus to one point, but maybe you know another method like sending the laser beams into one common fiber to produce one beam.

I thought of install them separately and focus to one point, but maybe you know another method like sending the laser beams into one common fiber to produce one beam.

|

Re: Laser for sintering of metal powder August 31, 2019 05:32AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Laser for sintering of metal powder August 31, 2019 12:18PM |

Registered: 5 years ago Posts: 155 |

|

Re: Laser for sintering of metal powder August 31, 2019 02:14PM |

Admin Registered: 16 years ago Posts: 13,884 |

... "like stringing up on a chain, into one laser beam" -- not really practicable.

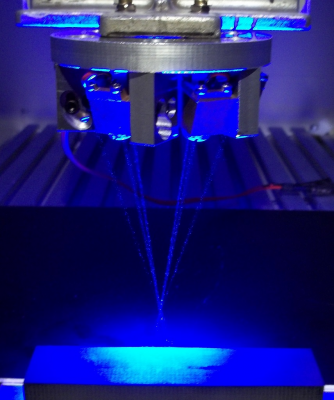

Here some "combiantion methodes", which are commonly used (the "blue death-star" is from me -- 0,3mm spot combined vs. 0,1mm spot single):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Here some "combiantion methodes", which are commonly used (the "blue death-star" is from me -- 0,3mm spot combined vs. 0,1mm spot single):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 31, 2019 02:23PM |

Registered: 5 years ago Posts: 155 |

|

Re: Laser for sintering of metal powder August 31, 2019 05:13PM |

Admin Registered: 16 years ago Posts: 13,884 |

... no - the 61 diodes are red 400mW ones, so combined only 20Watts -- and with a 0,7mm thick fiber-bundle will give a 0,6mm spot best ... not enough energy density

For metal melting/fusing I'm using IR-diodes with 200Watts on a spot of 0,4mm or CW-fiberlasers with 50 to 130 Watts on spots with 0,04mm (down to 0,01mm with beam-expander) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

For metal melting/fusing I'm using IR-diodes with 200Watts on a spot of 0,4mm or CW-fiberlasers with 50 to 130 Watts on spots with 0,04mm (down to 0,01mm with beam-expander) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder August 31, 2019 05:24PM |

Registered: 5 years ago Posts: 155 |

|

Re: Laser for sintering of metal powder September 26, 2019 01:30PM |

Registered: 6 years ago Posts: 20 |

|

Re: Laser for sintering of metal powder September 26, 2019 03:14PM |

Admin Registered: 16 years ago Posts: 13,884 |

... you'll need a constant current regulator, capable of this current - then you have to measure the voltage drop across the regulator and add some Volts more for "reserve" -- but the more "overvoltage", the more excessive heat at the driver ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder October 01, 2019 06:38PM |

Registered: 6 years ago Posts: 20 |

I found a well power supply company Mean Well RSP-320-2.5 (they have normal documentation at least):

[www.meanwell.com]

It is 2.5V, adjustable between 2.35-2.85V. Voltage tolerance ± 2% and ripple 0.1V. Should this error of 2% be taken into account? After all, this error will not affect the ripple?

To get into the range of 1.61V (emission voltage) and forward voltage of 1.73V, I think to lower voltage through Schottky diodes. For a current of 58.5 A, I'll need 30 pieces in parallel and so connect 2 times in series. Schottky Diodes 1N5820:

[ru.mouser.com]

The current on the diode will be: 58.5 / 30 = 1.95A according to the documentation, the drop will be 0.34V.

That is, with a minimum voltage of the power supply unit, the output will be 2.35 - 0.34 - 0.34 = 1.67V

And because of the ripple, the interval is from 1.57 to 1.77 V.

Is it possible to reduce ripple by placing a electrolyte and ceramic capacitors with a low ESR on output?

And of course it bothers me that the power supply is 60A. There is a NEL-400-2.8 power supply unit for 80A and a voltage of 2.8V, but it has ripples of 0.15V:

[www.mean-well.ru]

I understand that this is a non-specialized power supply, but special power supplies cost a lot of money:

[www.ebay.com]

[www.meanwell.com]

It is 2.5V, adjustable between 2.35-2.85V. Voltage tolerance ± 2% and ripple 0.1V. Should this error of 2% be taken into account? After all, this error will not affect the ripple?

To get into the range of 1.61V (emission voltage) and forward voltage of 1.73V, I think to lower voltage through Schottky diodes. For a current of 58.5 A, I'll need 30 pieces in parallel and so connect 2 times in series. Schottky Diodes 1N5820:

[ru.mouser.com]

The current on the diode will be: 58.5 / 30 = 1.95A according to the documentation, the drop will be 0.34V.

That is, with a minimum voltage of the power supply unit, the output will be 2.35 - 0.34 - 0.34 = 1.67V

And because of the ripple, the interval is from 1.57 to 1.77 V.

Is it possible to reduce ripple by placing a electrolyte and ceramic capacitors with a low ESR on output?

And of course it bothers me that the power supply is 60A. There is a NEL-400-2.8 power supply unit for 80A and a voltage of 2.8V, but it has ripples of 0.15V:

[www.mean-well.ru]

I understand that this is a non-specialized power supply, but special power supplies cost a lot of money:

[www.ebay.com]

|

Re: Laser for sintering of metal powder October 01, 2019 07:17PM |

Admin Registered: 16 years ago Posts: 13,884 |

... you'll need much more voltage for the current-regulating circuitry!

Calculate with 3 to 5 Volts more than your diodes forward voltage -- this depends on the current regulating circuitry ... the PSes for my "4V-diodes" have (needs) mostly 8-9 Volts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Calculate with 3 to 5 Volts more than your diodes forward voltage -- this depends on the current regulating circuitry ... the PSes for my "4V-diodes" have (needs) mostly 8-9 Volts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder October 02, 2019 04:40AM |

Registered: 6 years ago Posts: 20 |

|

Re: Laser for sintering of metal powder October 02, 2019 05:02AM |

Admin Registered: 16 years ago Posts: 13,884 |

... first select/build your constant current regulation and driving circuit -- only then, with known values for voltage-drop (and needed "reserves") you can select the PS ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder October 02, 2019 08:22PM |

Registered: 6 years ago Posts: 20 |

I think to connect laser diode according this scheme.

Using two parallel mosfets IRLB3034PbF:

[www.mouser.com]

Using two parallel mosfets IRLB3034PbF:

[www.mouser.com]

|

Re: Laser for sintering of metal powder October 03, 2019 01:31AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Nathan_T

I think to connect laser diode according this scheme.

Using two parallel mosfets IRLB3034PbF:

[www.mouser.com]

For sure you will get powerful sparks of light but not from the laser diode !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Laser for sintering of metal powder October 03, 2019 03:09AM |

Admin Registered: 16 years ago Posts: 13,884 |

... you still have no current regulation!!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder October 03, 2019 04:43AM |

Registered: 6 years ago Posts: 20 |

Quote

MKSA

For sure you will get powerful sparks of light but not from the laser diode !

Can you recommend scheme for control laser diode?

Quote

VDX

... you still have no current regulation!!

What can you say about this power supply with adjustable current?

[www.ebay.com]

|

Re: Laser for sintering of metal powder October 03, 2019 05:49AM |

Registered: 10 years ago Posts: 14,672 |

In view of the high forward current, my first thought was to operate the laser in pulsed mode so that it can be driven via a high frequency transformer. But unfortunately the datasheet doesn't specify a maximum reverse voltage; so we can't assume that would be safe to do.

My next thought is to use a transformer still, this time with a centre-tapped output and 2 mosfets or banks of mosfets to do synchronous rectification. Mosfets will dissipate much less power than Schottky diodes would. The voltage supplied to the inverter feeding the primary of the transformer can be varied to adjust the laser current, and the laser current sensed by a sense resistor in series with it, to provide feedback to the voltage regulator.

How much do these diode lasers cost?

EDIT: instead of a current sense resistor, a Hall current sensor would probably be more suitable.

EDIT 2: having now looked up the datasheet for those 60A Meanwell supplies, a simpler solution (but potentially less efficient) would be to use one of them with a bank of mosfets connected in series with the diode to control the current. I would choose the 3.3v PSU because the maximum forward voltage of the laser diode is about 2V, and it should be possible to keep the voltage drop of the mosfet bank and wiring below 1.3V. Using the 2.5V PSU might be possible but doesn't leave as much margin for error. Again, use a Hall current sensor in series with the laser diode.

Edited 5 time(s). Last edit at 10/03/2019 06:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

My next thought is to use a transformer still, this time with a centre-tapped output and 2 mosfets or banks of mosfets to do synchronous rectification. Mosfets will dissipate much less power than Schottky diodes would. The voltage supplied to the inverter feeding the primary of the transformer can be varied to adjust the laser current, and the laser current sensed by a sense resistor in series with it, to provide feedback to the voltage regulator.

How much do these diode lasers cost?

EDIT: instead of a current sense resistor, a Hall current sensor would probably be more suitable.

EDIT 2: having now looked up the datasheet for those 60A Meanwell supplies, a simpler solution (but potentially less efficient) would be to use one of them with a bank of mosfets connected in series with the diode to control the current. I would choose the 3.3v PSU because the maximum forward voltage of the laser diode is about 2V, and it should be possible to keep the voltage drop of the mosfet bank and wiring below 1.3V. Using the 2.5V PSU might be possible but doesn't leave as much margin for error. Again, use a Hall current sensor in series with the laser diode.

Edited 5 time(s). Last edit at 10/03/2019 06:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Laser for sintering of metal powder October 03, 2019 11:56AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Laser for sintering of metal powder October 03, 2019 01:25PM |

Admin Registered: 16 years ago Posts: 13,884 |

... simply switching the PS (even with ther "PS-current" adjusted) directly across the diode could damage it pretty fast with spikes or transients while switching ON ... but even faster, when switching OFF!!

Had some problems when switching with MOSFETS, current controlled by OpAmps and shunts without proper "filtering" -- when switching from 0 to 20 Amps, some of the spikes were like 40-50 Amps for some ten nanoseconds, what's not directly killing the diode ... but the "negative" spikes, when switching OFF, while "only" 10 Amps, did this after some seconds !!!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Had some problems when switching with MOSFETS, current controlled by OpAmps and shunts without proper "filtering" -- when switching from 0 to 20 Amps, some of the spikes were like 40-50 Amps for some ten nanoseconds, what's not directly killing the diode ... but the "negative" spikes, when switching OFF, while "only" 10 Amps, did this after some seconds !!!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser for sintering of metal powder October 03, 2019 05:21PM |

Registered: 6 years ago Posts: 20 |

Quote

MKSA

On the proposed schematic, The Mosfets are mounted to short circuit the power supply !

It was late and I mistaked. I attached correct scheme to this post.

Quote

dc42

How much do these diode lasers cost?

Laser cost is 290$ US.

Quote

VDX

Had some problems when switching with MOSFETS, current controlled by OpAmps and shunts without proper "filtering" -- when switching from 0 to 20 Amps, some of the spikes were like 40-50 Amps for some ten nanoseconds, what's not directly killing the diode ... but the "negative" spikes, when switching OFF, while "only" 10 Amps, did this after some seconds !!!

Could you give a laser diode control circuit through MOSFET transistors with filtering from current spikes?

|

Re: Laser for sintering of metal powder October 03, 2019 06:05PM |

Admin Registered: 16 years ago Posts: 13,884 |

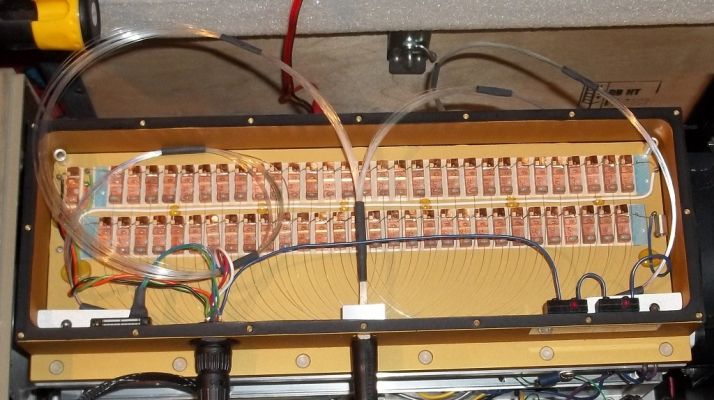

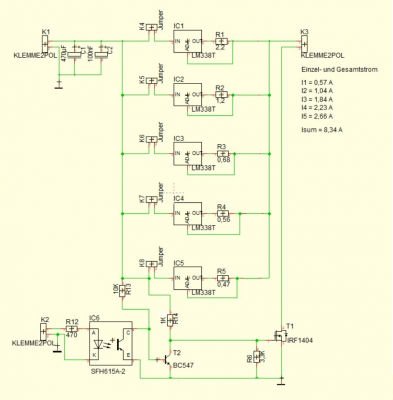

... my adjustable MOSFET constant current drivers aren't OS - but you can use more LM338 parallel in "constant current configuration", in the same way, as I've sketched here, in "4. power-source:"

[reprap.org]

*** EDIT *** - attached a more actual schematics of one of my old 5xLM338-drivers - you can define them for 3Amps per LM338 and then even more of them for higher currents:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[reprap.org]

*** EDIT *** - attached a more actual schematics of one of my old 5xLM338-drivers - you can define them for 3Amps per LM338 and then even more of them for higher currents:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.