|

What Z-corp ink is made of April 30, 2008 05:25PM |

Registered: 16 years ago Posts: 174 |

I think I just figured out what Z-Corp ink is made of. Apparently, they list out most of the ingredients in the MSDS's for the powder and ink. Turn out Z-Corp powder is just overpriced plaster and Z-Corp binder is water with pigments in it.

Binder

[www.tech.plymouth.ac.uk]

Powder

[www.tech.plymouth.ac.uk]

Sulfate salt is probably Calcium Sulfate. Vinyl polymer is probably polyvinyl alcohol or polyvinyl acetate, which are substances used in glues.

Binder

[www.tech.plymouth.ac.uk]

Powder

[www.tech.plymouth.ac.uk]

Sulfate salt is probably Calcium Sulfate. Vinyl polymer is probably polyvinyl alcohol or polyvinyl acetate, which are substances used in glues.

|

Re: What Z-corp ink is made of May 01, 2008 11:30PM |

Registered: 16 years ago Posts: 29 |

Thank Gene, the information you linked is very interesting.

Recently I have been experimenting along these lines.

I have an old inkjet setup to print on layers of powder.

Adding layers of powder is a manual process and I can only print 1/8 inch x 1/8 inch x 3 inches for now.

My setup in pretty limited but I have been able to test quite a few powder configurations.

Water and plaster (plaster of paris) is not enough to make the setup work I have been working on finding an adhesive in either powder form (that will not shrink and curl) to add to the plaster or in liquid form that can be applied using an inkjet head.

I have an old inkjet hp printer that has no problem printing water or ammonia. Anything more exotic seems to clog the head immediately. I plan to try printing some adhesives with an epson head (piezo inkjet technology) in the future.

I have not yet tried adding PVA powder to the plaster...

Scorch

Recently I have been experimenting along these lines.

I have an old inkjet setup to print on layers of powder.

Adding layers of powder is a manual process and I can only print 1/8 inch x 1/8 inch x 3 inches for now.

My setup in pretty limited but I have been able to test quite a few powder configurations.

Water and plaster (plaster of paris) is not enough to make the setup work I have been working on finding an adhesive in either powder form (that will not shrink and curl) to add to the plaster or in liquid form that can be applied using an inkjet head.

I have an old inkjet hp printer that has no problem printing water or ammonia. Anything more exotic seems to clog the head immediately. I plan to try printing some adhesives with an epson head (piezo inkjet technology) in the future.

I have not yet tried adding PVA powder to the plaster...

Scorch

|

Re: What Z-corp ink is made of May 02, 2008 01:42PM |

Registered: 16 years ago Posts: 174 |

Cool, do you have any details of your printing set up? I am thinking about building my own inkjet based 3d printer. Could you provide details of your experiments? Have you been able to get the plaster to stick together, even loosely?

Here's where you can get some PVA powder:

[shop2.chemassociates.com]

You can also obtain polyvinyl alcohol from slime making kits.

You might also try sifting in this or other powdered water soluble adhesives to the plaster:

[www.jamestowndistributors.com]

Epson print heads might present a problem, as they aren't replaceable as far as I know. Epson printer cartridges contain ink only, other printer cartridges contain ink and a disposable nozzle. Hewlett Packard's print heads might also present a problem, they heat up the ink to shoot it out, which means if you're using water, that most of it could evaporate before it hits the plaster.

Here's where you can get some PVA powder:

[shop2.chemassociates.com]

You can also obtain polyvinyl alcohol from slime making kits.

You might also try sifting in this or other powdered water soluble adhesives to the plaster:

[www.jamestowndistributors.com]

Epson print heads might present a problem, as they aren't replaceable as far as I know. Epson printer cartridges contain ink only, other printer cartridges contain ink and a disposable nozzle. Hewlett Packard's print heads might also present a problem, they heat up the ink to shoot it out, which means if you're using water, that most of it could evaporate before it hits the plaster.

|

Re: What Z-corp ink is made of May 02, 2008 07:49PM |

Registered: 16 years ago Posts: 29 |

My setup is pretty rudimentary. It is an old HP printer with the paper feeding mechanism ripped out. I made a small (flat) platform to place the powder on when I am printing. The print head is ~1/8 inch wide so that is as wide as I can print without moving the powder. I am holding off on doing anything elaborate to get bigger print area until I am confident I can get the powder to hold together fairly well.

I have tried a bunch of different powders. The best results I have had so far is a 50% - 50% mix of Weldwood Plastic Resin Glue (which you linked above) and Durahm's Water Putty [www.waterputty.com] (this stuff is mostly plaster but it seems to work a little better than straight plaster of paris.

I had looked at PVA powder previously and decided against spending the money on it because I read that it is not readily mixed with water at room temperature.

(I will probably get some eventually)

You are correct Epson printers do not get a new print head when the ink is replaced. I have two Epson C80's that I am sacrificing to the cause (that is two printers with four colors each. That gives me 8 individual piezo inkjet heads to experiment with.)

I get pretty good results with water in the HP. It is actually amazing how far the HP print head will spray water. I have tried using multiple passed on each layer of powder to increase the water volume. Multiple passes of water gives mixed results depending on the powder. (my best results have been with a single print pass per powder layer.)

If you are interested in this stuff here is a link to a guy who has a more elaborate setup.

[www.indoor.flyer.co.uk]

He has not updated his site in months. I e-mailed him once and didn't get a response. The page I linked is not even mentioned/linked on his main page.

I will try to make a list of things I have tried and summarize the results later.

Scorch

Edited 1 time(s). Last edit at 05/02/2008 07:51PM by Scorch.

I have tried a bunch of different powders. The best results I have had so far is a 50% - 50% mix of Weldwood Plastic Resin Glue (which you linked above) and Durahm's Water Putty [www.waterputty.com] (this stuff is mostly plaster but it seems to work a little better than straight plaster of paris.

I had looked at PVA powder previously and decided against spending the money on it because I read that it is not readily mixed with water at room temperature.

(I will probably get some eventually)

You are correct Epson printers do not get a new print head when the ink is replaced. I have two Epson C80's that I am sacrificing to the cause (that is two printers with four colors each. That gives me 8 individual piezo inkjet heads to experiment with.)

I get pretty good results with water in the HP. It is actually amazing how far the HP print head will spray water. I have tried using multiple passed on each layer of powder to increase the water volume. Multiple passes of water gives mixed results depending on the powder. (my best results have been with a single print pass per powder layer.)

If you are interested in this stuff here is a link to a guy who has a more elaborate setup.

[www.indoor.flyer.co.uk]

He has not updated his site in months. I e-mailed him once and didn't get a response. The page I linked is not even mentioned/linked on his main page.

I will try to make a list of things I have tried and summarize the results later.

Scorch

Edited 1 time(s). Last edit at 05/02/2008 07:51PM by Scorch.

|

Re: What Z-corp ink is made of May 03, 2008 08:40PM |

Registered: 16 years ago Posts: 174 |

|

Re: What Z-corp ink is made of May 03, 2008 11:46PM |

Registered: 16 years ago Posts: 29 |

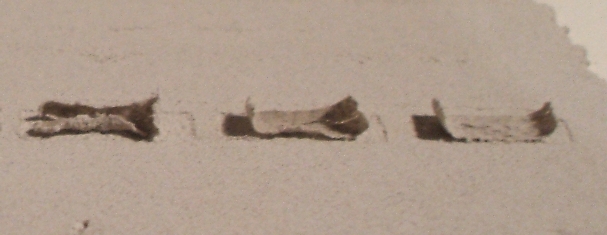

Here is a pic of some small pieces I made using 50-50 mix of water putty and weldwood. These are pics of pieces that started out twice as long as they are. I broke them in half testing the strength. I did not optimize the mix ratio, 1:1 is the first ratio I tried. I think less weldwood might be better.

(The ruler in the pic is has inch increments)

Here is a pic of me squeezing one of the pieces between my thumb and finger.

I can crush them if I try.

Adding cyanoacrylate might be an interesting chemistry experiment. Cyanoacrylate does not play nice with some materials (I am thinking about the weldwood).

The shape of the pieces shown above is not perfect, they should be bricks with square corners I noticed even at this small scale the bottom surface was warped.

Scorch

(The ruler in the pic is has inch increments)

Here is a pic of me squeezing one of the pieces between my thumb and finger.

I can crush them if I try.

Adding cyanoacrylate might be an interesting chemistry experiment. Cyanoacrylate does not play nice with some materials (I am thinking about the weldwood).

The shape of the pieces shown above is not perfect, they should be bricks with square corners I noticed even at this small scale the bottom surface was warped.

Scorch

|

Re: What Z-corp ink is made of May 05, 2008 10:37PM |

Registered: 16 years ago Posts: 29 |

Here is my data dump of the main combinations I have tried. Below is a picture of a bad case of "curl" so you have an idea what I am referring to when I note curl below. (Curling is really just shrinking. More shrinking on the side the liquid was sprayed results in a curling effect.)

Here are the powders I have tried. If I list two components they are 50/50.

-Portland Cement (Curled)

-Portland Cement / Powdered Sugar (did not curl, multiple print passes increased adhesion)

-Bentonite Clay (poor adhesion)

-Plaster of paris (multiple print passes increased adhesion, loose adhesion)

-Water Putty (slightly better than plaster of paris)

-Weldwood (curled)

-Water putty / Weldwood (did not curl with one print pass. curled with multiple print passes per layer.)

-Corn starch (poor adhesion; difficult to spread layers evenly)

-Powdered sugar (seemed to dissolve more readily than most other powders)

-Flour (curled)

-Four / powdered sugar (did not curl, loose adhesion)

-Casein (curled)

-Casein with Ammonia inkjet (curled)

-Casein / Borax (curled)

-Casein / Lime (curled)

-Casein / Baking Soda (curled)

(I would really like to get a Casein mix to work. Mixing Casein and ammonia or other base (high PH) produces a hard plastic. It would be nice to be able to print with a material with these properties.)

-Methyl Cellulose (curled)

-Methyl cellulose based wall paper paste (curled)

-Wheat based wallpaper paste (curled)

Things I have tried in HP inkjet (HP540):

- Water (I have just been using local tap water, City well water)

- Household ammonia (Ammonium Hydroxide)

- Acrylic bonding additive for concrete (clogged HP head immediately)

- 20:1 solution of water and Elmer

Here are the powders I have tried. If I list two components they are 50/50.

-Portland Cement (Curled)

-Portland Cement / Powdered Sugar (did not curl, multiple print passes increased adhesion)

-Bentonite Clay (poor adhesion)

-Plaster of paris (multiple print passes increased adhesion, loose adhesion)

-Water Putty (slightly better than plaster of paris)

-Weldwood (curled)

-Water putty / Weldwood (did not curl with one print pass. curled with multiple print passes per layer.)

-Corn starch (poor adhesion; difficult to spread layers evenly)

-Powdered sugar (seemed to dissolve more readily than most other powders)

-Flour (curled)

-Four / powdered sugar (did not curl, loose adhesion)

-Casein (curled)

-Casein with Ammonia inkjet (curled)

-Casein / Borax (curled)

-Casein / Lime (curled)

-Casein / Baking Soda (curled)

(I would really like to get a Casein mix to work. Mixing Casein and ammonia or other base (high PH) produces a hard plastic. It would be nice to be able to print with a material with these properties.)

-Methyl Cellulose (curled)

-Methyl cellulose based wall paper paste (curled)

-Wheat based wallpaper paste (curled)

Things I have tried in HP inkjet (HP540):

- Water (I have just been using local tap water, City well water)

- Household ammonia (Ammonium Hydroxide)

- Acrylic bonding additive for concrete (clogged HP head immediately)

- 20:1 solution of water and Elmer

|

Re: What Z-corp ink is made of May 06, 2008 02:44AM |

Registered: 16 years ago Posts: 270 |

This is what i love about RepRap all the experimentation, excellent work.

Ian

[www.bitsfrombytes.com]

Ian

[www.bitsfrombytes.com]

|

Re: What Z-corp ink is made of May 06, 2008 03:44PM |

Registered: 16 years ago Posts: 174 |

You might try controlling the humidity inside the print chamber and see if it effects curl. You might also try distilled water with some glycerol, instead of tap water and see if it makes a difference. Heating the print chamber is another thing too, Z-corp printers have a mysterious temperature control thing. Z-corp printers also have a some sort of wash sequence.

|

Re: What Z-corp ink is made of May 14, 2008 08:52PM |

Registered: 16 years ago Posts: 113 |

A little time travelling brings back the original Z Corp binder ZB7 and powder z100:

Binder:

[www.mae.carleton.ca]

Powder:

[www.mae.carleton.ca]

Plaster, sugar, a few other things. Shows what they evolved from.

Also of use is this:

[www.freepatentsonline.com]

Aparently this patent is someone trying to duplicate the Z Corp system with commodity equipment. Of special note is that the system they inspected used a large format, low resolution HP print head,

Binder:

[www.mae.carleton.ca]

Powder:

[www.mae.carleton.ca]

Plaster, sugar, a few other things. Shows what they evolved from.

Also of use is this:

[www.freepatentsonline.com]

Aparently this patent is someone trying to duplicate the Z Corp system with commodity equipment. Of special note is that the system they inspected used a large format, low resolution HP print head,

|

Re: What Z-corp ink is made of May 14, 2008 09:27PM |

Registered: 16 years ago Posts: 174 |

I found two things funny about this: Z-corp uses food coloring and this quote "The Z Corporation adopts a printer-head made by HP and solely develops its own control card for controlling the quantity of deposited binders because the powder needs a large portion of binders in its composition." In other words, Z Corp doesn't make their own nozzles and probably uses nozzles from commercial printers.

I am surprised that they were even able to get that patent, they pretty much copied Z-Corp.

Carbohydrate might be dextran, a common water soluble adhesive.

[en.wikipedia.org]

Glycol ether, I haven't a clue.

[en.wikipedia.org]

I am surprised that they were even able to get that patent, they pretty much copied Z-Corp.

Carbohydrate might be dextran, a common water soluble adhesive.

[en.wikipedia.org]

Glycol ether, I haven't a clue.

[en.wikipedia.org]

|

Re: What Z-corp ink is made of May 14, 2008 10:33PM |

Registered: 16 years ago Posts: 29 |

This is great stuff guys, keep it coming...

I think I will add dextrin to my short list of things to try:

- Liquid PVA (diluted in Epson print head)

- PVA powder mixed with plaster (or Water putty)

- Dextrin mixed with plaster (or Water putty)

Not much progress on this lately. The weather has been too nice in the garage. When it heats up this summer working in the basement will be more appealing.

Scorch

I think I will add dextrin to my short list of things to try:

- Liquid PVA (diluted in Epson print head)

- PVA powder mixed with plaster (or Water putty)

- Dextrin mixed with plaster (or Water putty)

Not much progress on this lately. The weather has been too nice in the garage. When it heats up this summer working in the basement will be more appealing.

Scorch

|

Re: What Z-corp ink is made of June 02, 2008 10:13PM |

Registered: 16 years ago Posts: 174 |

|

Re: What Z-corp ink is made of June 03, 2008 12:38AM |

Registered: 16 years ago Posts: 29 |

Gene, I will put something together for you in the next few days...

What I have is very limited and requires manual addition of powder to the build. You should be able to recreate what I have in one or two days.

I will be interested in how the Epson works for you.

Which Epson model do you have?

Scorch

What I have is very limited and requires manual addition of powder to the build. You should be able to recreate what I have in one or two days.

I will be interested in how the Epson works for you.

Which Epson model do you have?

Scorch

|

Re: What Z-corp ink is made of June 04, 2008 02:42PM |

Registered: 16 years ago Posts: 293 |

Gene Hacker Wrote:

-------------------------------------------------------

...

> I am surprised that they were even able to get

> that patent, they pretty much copied Z-Corp.

I thought US patents were given if they are valid according to some rules, not if they were fair... In Europe there are more cases where a patent office would reject a patent. But correct me if I'm wrong...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

-------------------------------------------------------

...

> I am surprised that they were even able to get

> that patent, they pretty much copied Z-Corp.

I thought US patents were given if they are valid according to some rules, not if they were fair... In Europe there are more cases where a patent office would reject a patent. But correct me if I'm wrong...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: What Z-corp ink is made of June 05, 2008 05:20PM |

Registered: 16 years ago Posts: 174 |

|

Re: What Z-corp ink is made of June 06, 2008 02:23AM |

Registered: 16 years ago Posts: 29 |

This video should help answer some of the questions you have about my setup.

[www.youtube.com]

I just switched ink cartridges so I left the black ink in for the video. Usually I run it with water. (I have switched to distilled water with the new cartridge).

At the end of the video one of the rectangular tubes is a little deformed. When I picked it up for the video I crushed it a bit. Before they dry they are soft.

Scorch

[www.youtube.com]

I just switched ink cartridges so I left the black ink in for the video. Usually I run it with water. (I have switched to distilled water with the new cartridge).

At the end of the video one of the rectangular tubes is a little deformed. When I picked it up for the video I crushed it a bit. Before they dry they are soft.

Scorch

|

Re: What Z-corp ink is made of June 06, 2008 03:47PM |

Registered: 16 years ago Posts: 270 |

|

Re: What Z-corp ink is made of June 07, 2008 04:03AM |

Registered: 16 years ago Posts: 293 |

Wow, awesome manual method. The result is also pretty good. Video is also done real nice

I can imagine that you could remove manual steps from the equation, one by one. Making the platform lower itself is pretty easy, smoothing out the new powder could also be, but probably requires various design iterations to get right (since it's tricky to see what you do right with your hands without thinking about it).

I've always found powder based techniques and SLS interesting as well, since the overhang problem would be solved. On the other hand, this allows mostly one material to be used (although the 'ink' could be different colors or perhaps conductive?)

I wonder what the strength is...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

I can imagine that you could remove manual steps from the equation, one by one. Making the platform lower itself is pretty easy, smoothing out the new powder could also be, but probably requires various design iterations to get right (since it's tricky to see what you do right with your hands without thinking about it).

I've always found powder based techniques and SLS interesting as well, since the overhang problem would be solved. On the other hand, this allows mostly one material to be used (although the 'ink' could be different colors or perhaps conductive?)

I wonder what the strength is...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: What Z-corp ink is made of June 07, 2008 03:30PM |

Registered: 16 years ago Posts: 29 |

I am not finished exploring different materials yet. I put the video together with the best material combination that I have found so far so Gene, et al, could see what I was up to.

I am holding off on automating until I know what materials I want to use. I might switch to an Epson printer to take advantage of the piezo print head. I don't want to spend a few months getting an HP to work then decide I should have used another printer.

The finished product using the materials in the video are not terribly strong. However, I have tried a lot of things that are not nearly as strong.

(I have some concerns about the chemicals in the Weldwood glue. I surely wouldn't make a child's toy using this material)

Scorch

I am holding off on automating until I know what materials I want to use. I might switch to an Epson printer to take advantage of the piezo print head. I don't want to spend a few months getting an HP to work then decide I should have used another printer.

The finished product using the materials in the video are not terribly strong. However, I have tried a lot of things that are not nearly as strong.

(I have some concerns about the chemicals in the Weldwood glue. I surely wouldn't make a child's toy using this material)

Scorch

|

Re: What Z-corp ink is made of June 09, 2008 06:42AM |

Registered: 17 years ago Posts: 304 |

Impressive demonstration!

I wonder if the Epson piezzoelectric cartridges would work with UV-resins. They have the consistency of syrup, so maybe they would clog the very fine nozzles, what do you think?

Also, for this setup one could consider air drying resins, which should be easier to get by than UV photoinitiator mixes, although they are slower at catalyzing.

Another very easy option would be to use regular 2 component resins and mix a small amount of Benzoinperoxyde (it's a solid) in the powder mix. Then print the resin component over that and voila!

I wonder if the Epson piezzoelectric cartridges would work with UV-resins. They have the consistency of syrup, so maybe they would clog the very fine nozzles, what do you think?

Also, for this setup one could consider air drying resins, which should be easier to get by than UV photoinitiator mixes, although they are slower at catalyzing.

Another very easy option would be to use regular 2 component resins and mix a small amount of Benzoinperoxyde (it's a solid) in the powder mix. Then print the resin component over that and voila!

|

Re: What Z-corp ink is made of June 09, 2008 09:53AM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi Fernando,

AFAIK Objet ( [www.2objet.com] ) use UV-hardening resins, but with bigger nozzles.

Normal ink is fluid as water (as it's mostly water indeed ), so it wouldn work with liquids more viscous ...

), so it wouldn work with liquids more viscous ...

Viktor

AFAIK Objet ( [www.2objet.com] ) use UV-hardening resins, but with bigger nozzles.

Normal ink is fluid as water (as it's mostly water indeed

), so it wouldn work with liquids more viscous ...

), so it wouldn work with liquids more viscous ...Viktor

|

Re: What Z-corp ink is made of June 09, 2008 09:30PM |

Registered: 16 years ago Posts: 29 |

MSDS for Epson ink: Viscosity < 5 mPa-s

MSDS for HP ink: Viscocity > 2 mPa-s

Water is about .7-.9 mPa-s

(The HP print head prints water without any problem.)

I have not been able to get the Epson to print anything other than Epson ink consistently. (I plan to try matching viscosity)

Fernando,

Do any of the UV resins have a viscosity this low? You say the resins are syrup like in consistency. Can the resins be thinned with water or other solvent?

A flammable solvent might involve some risk...Flame throwing inkjet printer?

Scorch

Edited 1 time(s). Last edit at 06/09/2008 09:37PM by Scorch.

MSDS for HP ink: Viscocity > 2 mPa-s

Water is about .7-.9 mPa-s

(The HP print head prints water without any problem.)

I have not been able to get the Epson to print anything other than Epson ink consistently. (I plan to try matching viscosity)

Fernando,

Do any of the UV resins have a viscosity this low? You say the resins are syrup like in consistency. Can the resins be thinned with water or other solvent?

A flammable solvent might involve some risk...Flame throwing inkjet printer?

Scorch

Edited 1 time(s). Last edit at 06/09/2008 09:37PM by Scorch.

|

Re: What Z-corp ink is made of June 10, 2008 12:58AM |

Admin Registered: 17 years ago Posts: 1,791 |

Here's an interesting approach:

[www.soligen.com]

It's powder-bed 3D printing, where they spray colloidal silica onto an alumina bed. (I assume the silica is suspeneded in water.) They then remove the printed object and use that as a refractory mold, pouring in metal and ending up with a cast metal object.

Possibly relevant:

[www.emeraldinsight.com]

[www.soligen.com]

It's powder-bed 3D printing, where they spray colloidal silica onto an alumina bed. (I assume the silica is suspeneded in water.) They then remove the printed object and use that as a refractory mold, pouring in metal and ending up with a cast metal object.

Possibly relevant:

[www.emeraldinsight.com]

|

Re: What Z-corp ink is made of June 10, 2008 04:50AM |

|

Re: What Z-corp ink is made of June 10, 2008 05:07AM |

Registered: 17 years ago Posts: 304 |

@Scorch

I have been thinking along the same lines, try to reduce the viscosity to the lowest possible values. There are two solutions I see here:

1) Find the safest thinner possible for Polyester resins. The logical choice for a thinner would be Styrene (viscosity 0.7 mPa-s).

2) Forget about Polyester and work with Methylmetacrylate and/or Butylmethacrylate, which have an extremely low viscosity (viscosity 0.6 mPa-s). The only catch being that you can't get these resins as easily as Polyester resins, which are sold practically in every DIY shop.

Any of these two solutions would be flammable though. My question is, do the nozzles get very hot? Enough to ignite the resin?

I have been thinking along the same lines, try to reduce the viscosity to the lowest possible values. There are two solutions I see here:

1) Find the safest thinner possible for Polyester resins. The logical choice for a thinner would be Styrene (viscosity 0.7 mPa-s).

2) Forget about Polyester and work with Methylmetacrylate and/or Butylmethacrylate, which have an extremely low viscosity (viscosity 0.6 mPa-s). The only catch being that you can't get these resins as easily as Polyester resins, which are sold practically in every DIY shop.

Any of these two solutions would be flammable though. My question is, do the nozzles get very hot? Enough to ignite the resin?

|

Re: What Z-corp ink is made of June 10, 2008 10:45PM |

Registered: 16 years ago Posts: 29 |

The Soligen process looks great. I know that a few of people that roam these forums, including myself, do some aluminum casting. Printing molds would be very useful.

I wonder if they use straight colloidal silica or if they have other additives in the binder. It looks like they also fire the printed object in the alumina powder before it is removed.

Fernando,

The print heads that don't use piezo technology actually boil the ink to produce small bubbles (cannon calls it bubblejet). I have little hope for anything but water based products in this type of printer. Externally these head stay cool because of the ink flowing through them. When the ink does not flow they do get warm.

The piezo heads use physical expansion of a piezoelectric material to eject the ink. Externally these seem cool unless the ink is not flowing then they do feel warm. Internally I am unsure of the heat generated in the piezo head.

I have had tried a couple flammable liquids in my HP. They didn't explode ...they didn't print either

...they didn't print either .

.

I wonder if they use straight colloidal silica or if they have other additives in the binder. It looks like they also fire the printed object in the alumina powder before it is removed.

Fernando,

The print heads that don't use piezo technology actually boil the ink to produce small bubbles (cannon calls it bubblejet). I have little hope for anything but water based products in this type of printer. Externally these head stay cool because of the ink flowing through them. When the ink does not flow they do get warm.

The piezo heads use physical expansion of a piezoelectric material to eject the ink. Externally these seem cool unless the ink is not flowing then they do feel warm. Internally I am unsure of the heat generated in the piezo head.

I have had tried a couple flammable liquids in my HP. They didn't explode

...they didn't print either

...they didn't print either .

.

|

Re: What Z-corp ink is made of June 11, 2008 04:41AM |

Registered: 17 years ago Posts: 304 |

Hmmmm... I see this resin printing calls for more experimentation.

I wonder if for Epson printers the liquid has to be hidrophylic...

I will soon take a vacation and I should be able to look into it.

First I will see what's the best solution as a printing resin.

I suppose acrylic is the way to go. I will get me an used Epson printer and try to print some stuff (itching that ever present experimentalists scratch)

Edited 1 time(s). Last edit at 06/11/2008 04:45AM by Fernando.

I wonder if for Epson printers the liquid has to be hidrophylic...

I will soon take a vacation and I should be able to look into it.

First I will see what's the best solution as a printing resin.

I suppose acrylic is the way to go. I will get me an used Epson printer and try to print some stuff (itching that ever present experimentalists scratch)

Edited 1 time(s). Last edit at 06/11/2008 04:45AM by Fernando.

|

Re: What Z-corp ink is made of June 11, 2008 05:30AM |

Admin Registered: 16 years ago Posts: 13,886 |

... i think for resins with higher viscosisty we should look more in the direction of dispensers ...

Beside the motor-driven ones (as in f@h) i'm thinking of a sort of peristaltic pump where at least four solenoids are pressing on a soft elastic hose in an alterated sequence (1000>1100>0110>0011>1001>1100>...)

So the fluid concealed in the hose between the collapsed solenoids is transported to one side with good and adjustable accuracy.

When you stop the sequence, then the transport stops too ...

Viktor

Beside the motor-driven ones (as in f@h) i'm thinking of a sort of peristaltic pump where at least four solenoids are pressing on a soft elastic hose in an alterated sequence (1000>1100>0110>0011>1001>1100>...)

So the fluid concealed in the hose between the collapsed solenoids is transported to one side with good and adjustable accuracy.

When you stop the sequence, then the transport stops too ...

Viktor

|

Re: What Z-corp ink is made of June 11, 2008 05:50AM |

Registered: 17 years ago Posts: 304 |

Different types of resins for different types of applications indeed.

I think the inkjet is easier for me to build on, plus I have a 1liter bottle of Methylmetacrylate plus Benzoylperoxide lying around wich I don't know what to do with, so I will try this.

The more viscous resins would be perfect for persitaltic pumps. That pump would work well with filler charged resins too, wich is a great advantage. I'll be curious to see how you solve the pulsing nature of the flow from those pumps though.

I think the inkjet is easier for me to build on, plus I have a 1liter bottle of Methylmetacrylate plus Benzoylperoxide lying around wich I don't know what to do with, so I will try this.

The more viscous resins would be perfect for persitaltic pumps. That pump would work well with filler charged resins too, wich is a great advantage. I'll be curious to see how you solve the pulsing nature of the flow from those pumps though.

Sorry, only registered users may post in this forum.