On the Fly Powder Printing Bed

Posted by madscifi

|

On the Fly Powder Printing Bed February 26, 2011 09:21PM |

Registered: 14 years ago Posts: 196 |

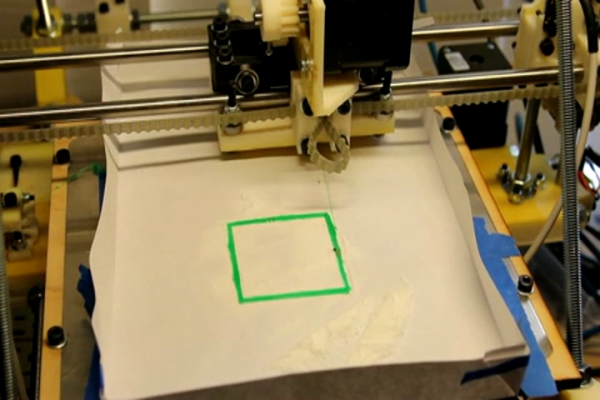

Now that I've finally completed the construction of a Sell's style Mendel I've used it to run a simple proof-of-concept experiment.

The idea is to take advantage of the fact that the RepRap can build the walls of a container one layer at a time. Then, between the construction of each layer of the container some powder can be dispensed, the surface smoothed, and the powder fused using a laser or inkjet. Repeat until done.

So far I've tried building a couple of layers of a container and manually dispensing and spreading some sugar after each layer of the container has been constructed. See this YouTube video.

The most serious concerns seemed to be that the plastic would not stick due to the powder, or that it would not be strong enough to allow the powder to be surfaced. These concerns appear to be manageable.

Johnrpm has suggested the design of a powder dispenser that uses a single roller to both dispense the powder and to surface the powder. The idea is that the roller protrudes below the dispenser and that there is essentially no gap between roller and the wall of the powder container on one side and a small gap between the roller and wall of the powder container on the other. The roller can be turned one direction to dispense powder, and turned the other direction to surface the dispensed powder without dispensing powder.

I'd encourage everyone else who is interested in designing a powder dispenser to please do so. My mechanical design and construction skills are pretty limited, but I think the idea is worth pursuing so I'm going to give it a try.

The idea is to take advantage of the fact that the RepRap can build the walls of a container one layer at a time. Then, between the construction of each layer of the container some powder can be dispensed, the surface smoothed, and the powder fused using a laser or inkjet. Repeat until done.

So far I've tried building a couple of layers of a container and manually dispensing and spreading some sugar after each layer of the container has been constructed. See this YouTube video.

The most serious concerns seemed to be that the plastic would not stick due to the powder, or that it would not be strong enough to allow the powder to be surfaced. These concerns appear to be manageable.

Johnrpm has suggested the design of a powder dispenser that uses a single roller to both dispense the powder and to surface the powder. The idea is that the roller protrudes below the dispenser and that there is essentially no gap between roller and the wall of the powder container on one side and a small gap between the roller and wall of the powder container on the other. The roller can be turned one direction to dispense powder, and turned the other direction to surface the dispensed powder without dispensing powder.

I'd encourage everyone else who is interested in designing a powder dispenser to please do so. My mechanical design and construction skills are pretty limited, but I think the idea is worth pursuing so I'm going to give it a try.

|

Re: On the Fly Powder Printing Bed February 27, 2011 06:11AM |

Registered: 13 years ago Posts: 406 |

|

Re: On the Fly Powder Printing Bed February 28, 2011 12:43AM |

Registered: 14 years ago Posts: 196 |

Johnrpm, I have a question about the powder dispenser: what would be a good range of RPMs to try out when turning the dispenser rod? I'll probably need to order a motor for that and I'm not certain what I should be looking for. I assume something relatively slow, but any idea just how slow? Also, what sort of diameter did you use?

|

Re: On the Fly Powder Printing Bed February 28, 2011 03:44AM |

Registered: 13 years ago Posts: 406 |

Madscifi,

Working from memory, (8 years or so) the roller was approx 20mm dia, smooth surface.

the rpm is dependent on the powder and velocity of travel, but if you have it variable rpm, I would try 0-200 rpm, this should cover your bases, bear in mind that the higher the rpm the better the balance, bearings must be, otherwise it may add vibrations to your rig, if you get a dc motor with epicyclic gearbox, they come in speed ranges, if you are faced with a choice, go for a little slower rather than faster, I hope I have not confused things.

Maybe this type of motor and gearbox, [www.rapidonline.com]

Edited 1 time(s). Last edit at 02/28/2011 03:48AM by johnrpm.

Random Precision

Working from memory, (8 years or so) the roller was approx 20mm dia, smooth surface.

the rpm is dependent on the powder and velocity of travel, but if you have it variable rpm, I would try 0-200 rpm, this should cover your bases, bear in mind that the higher the rpm the better the balance, bearings must be, otherwise it may add vibrations to your rig, if you get a dc motor with epicyclic gearbox, they come in speed ranges, if you are faced with a choice, go for a little slower rather than faster, I hope I have not confused things.

Maybe this type of motor and gearbox, [www.rapidonline.com]

Edited 1 time(s). Last edit at 02/28/2011 03:48AM by johnrpm.

Random Precision

|

Re: On the Fly Powder Printing Bed February 28, 2011 10:27PM |

Registered: 14 years ago Posts: 196 |

I just found a suggestion for this type of approach in a very early comment on this same Forum. So the credit, as far as I can tell, for the idea of making the walls on-the-fly belongs to RBisping.

Johnrpm - thanks, that makes sense.

Johnrpm - thanks, that makes sense.

|

Re: On the Fly Powder Printing Bed March 01, 2011 08:58AM |

Registered: 15 years ago Posts: 376 |

This is a nice idea building the wall with a reprap. The "sinking/rising box" in normal powder sintering machines isn't the easiest thing to engineer at home and I imagine would make the a desktop machine quite large.

With the current interest in multi head repraps this seems to be a realistic proposal.

I have had a few thoughts of depositing powder in strips of about 5mm wide, a bit like a tarmac laying machine see below. All tooling fastened to the head. Keeping the head narrow would control the powder deposition and rolling pressure much easier.

Imagine a smaller version of this machine mounted to the X axis of a reprap

As the head moves across a little powder is deposited, a roller follows it, then a heated plate only slightly above the powder which raises the temperature to the transition point. The heater could be 5mm wide in Y, but long in X so the powder has time to rise in temperature Behind the heated plate is a laser panning back and forth 5mm taking the powder where needed to the melting point.

The head then moves quickly back, index 5mm in Y and then begins another pass.

With the current interest in multi head repraps this seems to be a realistic proposal.

I have had a few thoughts of depositing powder in strips of about 5mm wide, a bit like a tarmac laying machine see below. All tooling fastened to the head. Keeping the head narrow would control the powder deposition and rolling pressure much easier.

Imagine a smaller version of this machine mounted to the X axis of a reprap

As the head moves across a little powder is deposited, a roller follows it, then a heated plate only slightly above the powder which raises the temperature to the transition point. The heater could be 5mm wide in Y, but long in X so the powder has time to rise in temperature Behind the heated plate is a laser panning back and forth 5mm taking the powder where needed to the melting point.

The head then moves quickly back, index 5mm in Y and then begins another pass.

|

Re: On the Fly Powder Printing Bed March 02, 2011 01:37PM |

Registered: 13 years ago Posts: 27 |

Quote

martinprice2004

As the head moves across a little powder is deposited, a roller follows it, then a heated plate only slightly above the powder which raises the temperature to the transition point. The heater could be 5mm wide in Y, but long in X so the powder has time to rise in temperature Behind the heated plate is a laser panning back and forth 5mm taking the powder where needed to the melting point.

I like the idea Martin. Using a roller to bring the temperature most of the way to the transition point would lower the amount of laser power you would need.

Question: without walls, how do you keep the powder stack rigid enough to add another layer?

|

Re: On the Fly Powder Printing Bed March 07, 2011 12:43AM |

Registered: 14 years ago Posts: 196 |

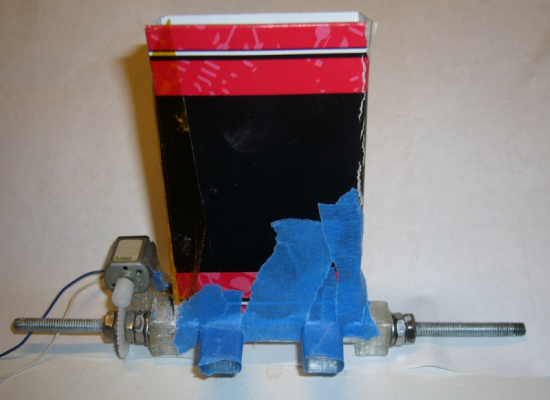

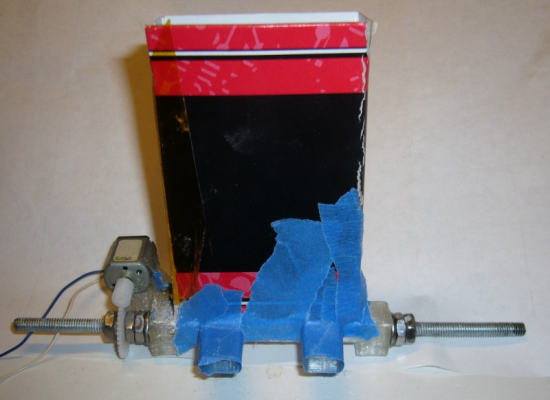

Here is my first attempt at a powder dispenser. It was constructed with a small dc motor that I collected years ago, a piece of 10-32 threaded rod, some thin cardboard, and a couple of tiny plastic gears of the "toy" variety. Consequently it is will not be very useful to anyone at this point. Besides, the motor turns, the threaded rod turns, but the hydroperm powder does is not ejected, except when I tap on the device.

powder-print-dispensor-3.scad

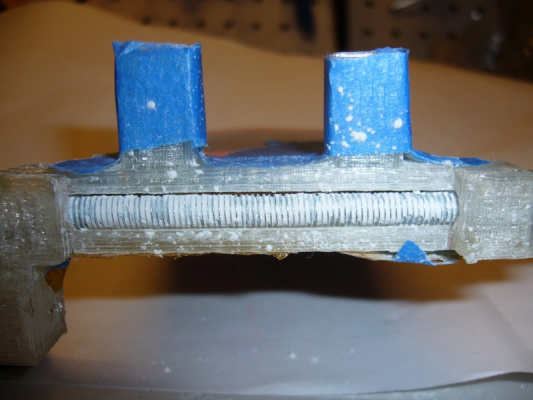

The threads appear to simply fill up with powder (I was hoping they would help eject the powder). Any suggestions on better approaches to the design of the device would be greatly appreciated. A couple of obvious things spring to my mind, mainly a rod with cuts running along the axis of the rod and possibly something to vibrate the powder container (piezo?), but at this point those are simply untested ideas.

powder-print-dispensor-3.scad

The threads appear to simply fill up with powder (I was hoping they would help eject the powder). Any suggestions on better approaches to the design of the device would be greatly appreciated. A couple of obvious things spring to my mind, mainly a rod with cuts running along the axis of the rod and possibly something to vibrate the powder container (piezo?), but at this point those are simply untested ideas.

|

Re: On the Fly Powder Printing Bed March 07, 2011 04:30AM |

Registered: 13 years ago Posts: 406 |

Are the blue tubes chutes where the powder emits?, maybe if they were shorter?, or better still cut of to keep the distance from roller to powder exit as short as possible, so that the powder does not have to push itself, I know that with powders some flow agents are added, glass etc, to be able to get thin layers and smooth finish, vibration can compact the powder which may make it flow initially but cause problems after a few minutes,

toner cartridges sometimes have a rotating spring to fluff up the toner and stop compaction, I am not familiar with hydroperm?

but it looks like it may not flow easily?, I do not have openscad on this PC so I may be talking rubbish.

P.S, I see you have your reprap running.

P.P.S spiral brick tie, about 6mm dia stainless steel 300mm long (approx)

Edited 2 time(s). Last edit at 03/07/2011 05:03AM by johnrpm.

Random Precision

toner cartridges sometimes have a rotating spring to fluff up the toner and stop compaction, I am not familiar with hydroperm?

but it looks like it may not flow easily?, I do not have openscad on this PC so I may be talking rubbish.

P.S, I see you have your reprap running.

P.P.S spiral brick tie, about 6mm dia stainless steel 300mm long (approx)

Edited 2 time(s). Last edit at 03/07/2011 05:03AM by johnrpm.

Random Precision

|

Re: On the Fly Powder Printing Bed March 07, 2011 10:30PM |

Registered: 14 years ago Posts: 196 |

Johnrpm - sorry about that. The images made perfect sense to me, but that is only because I've seen it in reality.

The first image is the front view. The blue tape covered tabs are just that, solid tabs. The cardboard defines the powder container and the powder is supposed to be dispensed by the threaded rod.

The second image is from the bottom.

Is the cross section of the brick tie a cross or a bar? I cannot find anything like that which is small enough to work for what I want, but I should be able to print something along those lines. Thanks!

The first image is the front view. The blue tape covered tabs are just that, solid tabs. The cardboard defines the powder container and the powder is supposed to be dispensed by the threaded rod.

The second image is from the bottom.

Is the cross section of the brick tie a cross or a bar? I cannot find anything like that which is small enough to work for what I want, but I should be able to print something along those lines. Thanks!

|

Re: On the Fly Powder Printing Bed March 09, 2011 03:29PM |

Registered: 13 years ago Posts: 406 |

My fault for not looking, I am no expert on powders but from working with powders, the main thing that characterises them is....... particle shape, rounded or sharp, and particle size distribution, not sure what's in an hour glass, maybe sand, but it flows through a small hole without lodgeing or blocking, the particles are probably Spherical, and uniform size, looking at hydroperm, it is gypsum with cement, both of these have some very fine particles, which may not help flow, one way would be to sieve it, but that may change its properties, would a shute at say 45degrees help, so that the powder runs down the surface of the hopper to avoid the lodgeing?.

Random Precision

Random Precision

Sorry, only registered users may post in this forum.