DIY printhead

Posted by johnrpm

|

Re: DIY printhead December 14, 2010 10:46PM |

Registered: 14 years ago Posts: 196 |

Details are here: [reprap.org]

The "obvious in hindsight" but I certainly never thought of that solution to the problem of defining a leak proof chamber by simply using an o-ring to both seal and define the chamber is wonderful.

I would suggest using a piece of transparent plastic for the nozzle plate so that it is possible to see into the chamber easily. That will make extracting the air bubbles a bit easier.

The "obvious in hindsight" but I certainly never thought of that solution to the problem of defining a leak proof chamber by simply using an o-ring to both seal and define the chamber is wonderful.

I would suggest using a piece of transparent plastic for the nozzle plate so that it is possible to see into the chamber easily. That will make extracting the air bubbles a bit easier.

|

Re: DIY printhead December 15, 2010 04:45AM |

Registered: 14 years ago Posts: 356 |

madscifi Wrote:

-------------------------------------------------------

> Details are here:

>

> The "obvious in hindsight" but I certainly never

> thought of that solution to the problem of

> defining a leak proof chamber by simply using an

> o-ring to both seal and define the chamber is

> wonderful.

>

> I would suggest using a piece of transparent

> plastic for the nozzle plate so that it is

> possible to see into the chamber easily. That will

> make extracting the air bubbles a bit easier.

I think Adrian approach is beautiful, because it's very quick, easy and cheap to 3D print, mainly because he (and most of us) already have a 3D printer.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Details are here:

>

> The "obvious in hindsight" but I certainly never

> thought of that solution to the problem of

> defining a leak proof chamber by simply using an

> o-ring to both seal and define the chamber is

> wonderful.

>

> I would suggest using a piece of transparent

> plastic for the nozzle plate so that it is

> possible to see into the chamber easily. That will

> make extracting the air bubbles a bit easier.

I think Adrian approach is beautiful, because it's very quick, easy and cheap to 3D print, mainly because he (and most of us) already have a 3D printer.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead December 15, 2010 05:43AM |

Registered: 13 years ago Posts: 406 |

|

Re: DIY printhead June 20, 2011 03:39PM |

This thread has been inactive for some time, but I hope someone will see this. I'm trying to jet a solution out of a DX4 head. There are 21 contacts on the ribbon, and each channel has 180 nozzles. How do the contacts correlate to the nozzles? For example, if I send current to 3 contacts, how many nozzles will fire?

What I need is to be able to constantly fire about 30-50 nozzles. If I understand it correctly, the volume/droplet size will vary based on the voltage applied.

What is the voltage range I should apply to each contact?

Thanks in advance.

What I need is to be able to constantly fire about 30-50 nozzles. If I understand it correctly, the volume/droplet size will vary based on the voltage applied.

What is the voltage range I should apply to each contact?

Thanks in advance.

|

Re: DIY printhead June 26, 2011 12:58PM |

Registered: 14 years ago Posts: 196 |

|

Re: DIY printhead July 29, 2011 04:24PM |

madscifi,

Have you complete any more movement on this project or is the project on hiatus?

Nevertheless, good to see some movement in the direction of a totally DIY printhead!

Pearce,

Another possibility is to modify the firmware on the printer. This has been suggested by Henry on other threads and on the DIY 3d Printer Yahoo Group. I know of no one yet who has actually reverse engineered a printer by modifying a piezo inkjet printer's firmware.

-Frak

Have you complete any more movement on this project or is the project on hiatus?

Nevertheless, good to see some movement in the direction of a totally DIY printhead!

Pearce,

Another possibility is to modify the firmware on the printer. This has been suggested by Henry on other threads and on the DIY 3d Printer Yahoo Group. I know of no one yet who has actually reverse engineered a printer by modifying a piezo inkjet printer's firmware.

-Frak

|

Re: DIY printhead July 29, 2011 09:35PM |

Registered: 14 years ago Posts: 196 |

I've pretty much stalled for the moment on this project. I have things I'd like to try out, but I'm not certain when that will I'll get back to it.

I'm not aware of any other ongoing work by anyone else on the subject at the moment. Hopefully I'm wrong and someone will correct me.

On a related issue Johnrpm has been working on a powderbed design.

I'm not aware of any other ongoing work by anyone else on the subject at the moment. Hopefully I'm wrong and someone will correct me.

On a related issue Johnrpm has been working on a powderbed design.

|

Re: DIY printhead December 13, 2011 05:02PM |

|

Re: DIY printhead December 16, 2011 07:05PM |

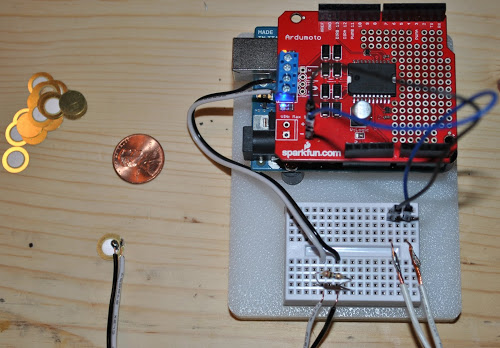

Just got twenty 10mm piezoelectric transducers off of ebay from zinky86. Hopefully tomorrow I will try powering them with my arduino and sparkfun ardumoto shield. I think it should work at powering the piezos. The delays, rise and fall times are in the micro second range, however that is with a resister. It will be something along the lines of what casainho has done.

|

Re: DIY printhead December 16, 2011 11:24PM |

Registered: 14 years ago Posts: 196 |

Welcome aboard and good luck.

Some comments about things that might not be clear from reading this thread:

1) 30-40 volts or so is good for driving the piezos (I don't know if you can use such a voltage with the board you have listed or not). Higher voltages might be useful just while starting out, but the higher voltages damage the piezos rather quickly.

2) Piezos on thinner plates seemed to work better than piezos on thicker plates (I believe they bend more for a given voltage than the piezos on thicker plates).

3) Any significant bubbles in the chamber make it almost impossible to eject drops.

4) Don't worry too much about rise and fall times. A simple single transistor or FET driver worked fine for me.

5) Controlling the amount of static water pressure above the nozzle is important. Too much and the nozzle leaks, too little and it is difficult to create drops.

6) I had the best luck with nozzles created by simply drilling a small hole through a thin piece of plastic (the more hydrophobic the plastic the better).

I am certain that I'm not the only one that is very interested in reading about any progress or problems you run into.

Some comments about things that might not be clear from reading this thread:

1) 30-40 volts or so is good for driving the piezos (I don't know if you can use such a voltage with the board you have listed or not). Higher voltages might be useful just while starting out, but the higher voltages damage the piezos rather quickly.

2) Piezos on thinner plates seemed to work better than piezos on thicker plates (I believe they bend more for a given voltage than the piezos on thicker plates).

3) Any significant bubbles in the chamber make it almost impossible to eject drops.

4) Don't worry too much about rise and fall times. A simple single transistor or FET driver worked fine for me.

5) Controlling the amount of static water pressure above the nozzle is important. Too much and the nozzle leaks, too little and it is difficult to create drops.

6) I had the best luck with nozzles created by simply drilling a small hole through a thin piece of plastic (the more hydrophobic the plastic the better).

I am certain that I'm not the only one that is very interested in reading about any progress or problems you run into.

|

Re: DIY printhead December 17, 2011 12:33PM |

Thanks madscifi for the summary! I have read through all nine pages of this thread and have learned valuable information.

The way I understand the function of these print heads is that the surface tension of the fluid you are trying to print is critical to keeping fluid from leaking through he nozzle. i.e. water has a high surface tension allowing for larger diameter nozzles.

My friend has a laser cutter so we are going to try to make a print head out of acrylic with the smallest diameter hole his laser can "drill" through acrylic. He seems to think that he could drill a hole on the order of .1 mm or less. We are also targeting a small reservoir, on the order of 10mm diameter circle, 1/16" thick. After looking a commercial print head designs, the reservoirs are extremely small with the piezoelectric element deforming most of the reservoir. Hopefully this will allow for a higher pressure wave to reach the nozzle, overcoming the surface tension of the fluid, and allowing a drop to be ejected. Finally we are going to try to continuously flow fluid through the reservoir to "sweep" out any air bubbles that can come back into the reservoir when the piezoelectric element retracts.

Check out this video http://www.xaar.com/videos/Xaar1001v3.wmv

Let me know what you think.

The way I understand the function of these print heads is that the surface tension of the fluid you are trying to print is critical to keeping fluid from leaking through he nozzle. i.e. water has a high surface tension allowing for larger diameter nozzles.

My friend has a laser cutter so we are going to try to make a print head out of acrylic with the smallest diameter hole his laser can "drill" through acrylic. He seems to think that he could drill a hole on the order of .1 mm or less. We are also targeting a small reservoir, on the order of 10mm diameter circle, 1/16" thick. After looking a commercial print head designs, the reservoirs are extremely small with the piezoelectric element deforming most of the reservoir. Hopefully this will allow for a higher pressure wave to reach the nozzle, overcoming the surface tension of the fluid, and allowing a drop to be ejected. Finally we are going to try to continuously flow fluid through the reservoir to "sweep" out any air bubbles that can come back into the reservoir when the piezoelectric element retracts.

Check out this video http://www.xaar.com/videos/Xaar1001v3.wmv

Let me know what you think.

|

Re: DIY printhead December 19, 2011 03:30AM |

Registered: 13 years ago Posts: 406 |

Welcome onlyjus,

Glad to see you are doing some work on this, Madscifi has a lot of experience and his advise is good, I like your idea of constant flow to remove bubbles, keep at it, I shall follow your progress with interest.

P.S the video is good, explains the shear mode well.

Random Precision

Glad to see you are doing some work on this, Madscifi has a lot of experience and his advise is good, I like your idea of constant flow to remove bubbles, keep at it, I shall follow your progress with interest.

P.S the video is good, explains the shear mode well.

Random Precision

|

Re: DIY printhead December 19, 2011 08:24PM |

Check it out, got the arduino/ardumoto powering the 10mm piezoelectric element. Depending on the power supply I can provide +18 to -18 volts. I can feel and hear the vibrations. Now I need to build a housing for it...

Got a question though, any tricks to solder wires to these? I broke two of them (third times the charm!), the piezo material seemed to de-laminate from the brass.

Got a question though, any tricks to solder wires to these? I broke two of them (third times the charm!), the piezo material seemed to de-laminate from the brass.

|

Re: DIY printhead December 20, 2011 05:00AM |

Registered: 14 years ago Posts: 356 |

I love to see pictures :-) -- thanks for sharing and good luck on this project. I would like to say I am monitoring this thread, for the development.

Edited 1 time(s). Last edit at 12/20/2011 05:01AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

Edited 1 time(s). Last edit at 12/20/2011 05:01AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead December 20, 2011 05:31AM |

Registered: 13 years ago Posts: 406 |

I use a hot iron with a tinned wire and solder as quick as possible, a softer more flexible wire may have less tendency to

pull off, some piezo buzzers can stand a fair bit of abuse, whilst others die at the least excuse.

Edit: I use lead solder, can not get on with unleaded.

Edited 1 time(s). Last edit at 12/20/2011 06:23AM by johnrpm.

Random Precision

pull off, some piezo buzzers can stand a fair bit of abuse, whilst others die at the least excuse.

Edit: I use lead solder, can not get on with unleaded.

Edited 1 time(s). Last edit at 12/20/2011 06:23AM by johnrpm.

Random Precision

|

Re: DIY printhead December 23, 2011 01:41AM |

Registered: 14 years ago Posts: 196 |

If you can know the manufacturer of the specific disks you can probably find their recommended soldering instructions.

Here is a link to the instructions provided by PUI Audio: [www.digikey.com]

A link to Murata's instructions: [www.murata.com]

Here is a link to the instructions provided by PUI Audio: [www.digikey.com]

A link to Murata's instructions: [www.murata.com]

|

Re: DIY printhead December 25, 2011 04:14PM |

Registered: 12 years ago Posts: 24 |

|

onlyjus

Re: DIY printhead January 03, 2012 09:41PM |

2shedsJackson Wrote:

-------------------------------------------------------

> There are some new MEMS Industrial Printheads with

> ~30pL drops and 16 nozzles for ~$100. I'll try and

> see about availability for DIY and how to publish

> specs on controlling them. They might fire at up

> to 50khz and handle fluids in the 8cps to 20cps

> range.

Any updates? I am extremely interested in this.

My buddy got several sheets of poly-carbonate that we will soon be using to fabricate a print head.

-------------------------------------------------------

> There are some new MEMS Industrial Printheads with

> ~30pL drops and 16 nozzles for ~$100. I'll try and

> see about availability for DIY and how to publish

> specs on controlling them. They might fire at up

> to 50khz and handle fluids in the 8cps to 20cps

> range.

Any updates? I am extremely interested in this.

My buddy got several sheets of poly-carbonate that we will soon be using to fabricate a print head.

|

Re: DIY printhead January 28, 2012 09:02AM |

I was able to develop a 10um nozzel even smaller than epson printhead nozzel at home just in 1$. Would like to help any one for diy printhead. Contact me at awasoft@hotmail.com

|

Re: DIY printhead January 28, 2012 09:28AM |

Registered: 13 years ago Posts: 226 |

Hi Awais - I think the whole community would find that extremely interesting. Would you consider creating a page on the wiki?

Maybe under the category Extruders? [reprap.org]

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

Maybe under the category Extruders? [reprap.org]

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: DIY printhead January 30, 2012 01:27PM |

Idea is very simple i used a polished steel plate (Actuly my broken piezo) and the sharpest needle available in the market. First of all i made a thin film of some oil ( May be Auto mobiloil but i prefer u use some oil with lowest viscosity) on plate n needle n cleared excess oil using some tissue paper just leaving a a thin film. Then made a big hole in my print head using 1m drill bit. Then roughen the surface of head. Placed a drop of epoxy on steeel plate and placed head on it in the way that some epoxy is coming out of print head hole. Then i placed needle in that hole n let it dry. Thats it after several hours u just remove steel plate n needle with care n u will get a micro hole. For pics or info u can contact me at awasoft@hotmail.com

|

DIY Micro Nozzle January 31, 2012 03:49AM |

Here is my wiki where i described that how you can make a (10um) micro hole in just 1$

[diywax3d.wikispaces.com]

[diywax3d.wikispaces.com]

|

Re: DIY Micro Nozzle January 31, 2012 06:30AM |

Registered: 13 years ago Posts: 226 |

Aweseome, thanks Awais!

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: DIY printhead February 13, 2012 07:23AM |

|

Re: DIY nozzle February 13, 2012 11:13AM |

|

Re: DIY printhead April 01, 2012 06:06PM |

Hi guys,

I just found this murata piezo device, the MZB100 microblower

[www.murata.com]

[www.murata.com]

I just found this murata piezo device, the MZB100 microblower

[www.murata.com]

[www.murata.com]

|

ChiKung

Re: DIY printhead May 04, 2012 01:39AM |

|

martino

Re: DIY printhead June 25, 2012 04:58AM |

Hello all,

I just add my personal experiments to this collective research..

I'm interested in making an actual plotter / printer without using existing cartridges..

Therefore I'm trying a setup stacking more piezos in vertical. I'm using 35mm piezos.

The resolution I obtain is 0,25 mm drops, which means around 100 dpi. It is fine for me as I want to use it for large format printing for now.

I'm using the facilities of the Fablab Amsterdam, so I have access to nice set of tools. In this prototype I used as a nozzle a copper foil used in general to cut circuits from and drilled the hole with a 1/100 inch.

The body is made of transparent PMMA (Acrylic) which I drilled holes into, so I could see what's going on in the head (ink level etc).

The problem I'm facing now is that when the piezos are vertical, the pressure from gravity is too high and the head just starts making big drops out of the nozzle. Only with a negative pressure in the ink chamber I'm able to make proper drops with the piezo.

That's a common problem that inkjets manifacturers have to solve as well.. I know HP uses a membrane in their cartridge which contains the ink and a sponge like structure, therefore this sponge pushes the sides of the membrane creating the negative pressure. I should open a commercial cartridge to check how they do it.

In the mean time I'm constructing a big bulky mechanical system with stuff laying around, to set the pressure in the meantime to do tests. It is basically a stepper motor pushing and pulling the plunger of a syringe connected to the ink system. When it pulls out it sets a negative pressure and viceversa.

I'm also gonna get hold of a pressure sensor so I can calculate what negative pressure I need and then try to find a cheaper and simplier system to set it.

Hope the broken english reading was interesting and maybe to get some tips on how to achieve the pressure.

ciao!

I just add my personal experiments to this collective research..

I'm interested in making an actual plotter / printer without using existing cartridges..

Therefore I'm trying a setup stacking more piezos in vertical. I'm using 35mm piezos.

The resolution I obtain is 0,25 mm drops, which means around 100 dpi. It is fine for me as I want to use it for large format printing for now.

I'm using the facilities of the Fablab Amsterdam, so I have access to nice set of tools. In this prototype I used as a nozzle a copper foil used in general to cut circuits from and drilled the hole with a 1/100 inch.

The body is made of transparent PMMA (Acrylic) which I drilled holes into, so I could see what's going on in the head (ink level etc).

The problem I'm facing now is that when the piezos are vertical, the pressure from gravity is too high and the head just starts making big drops out of the nozzle. Only with a negative pressure in the ink chamber I'm able to make proper drops with the piezo.

That's a common problem that inkjets manifacturers have to solve as well.. I know HP uses a membrane in their cartridge which contains the ink and a sponge like structure, therefore this sponge pushes the sides of the membrane creating the negative pressure. I should open a commercial cartridge to check how they do it.

In the mean time I'm constructing a big bulky mechanical system with stuff laying around, to set the pressure in the meantime to do tests. It is basically a stepper motor pushing and pulling the plunger of a syringe connected to the ink system. When it pulls out it sets a negative pressure and viceversa.

I'm also gonna get hold of a pressure sensor so I can calculate what negative pressure I need and then try to find a cheaper and simplier system to set it.

Hope the broken english reading was interesting and maybe to get some tips on how to achieve the pressure.

ciao!

|

martino

Re: DIY printhead June 25, 2012 12:22PM |

|

Re: DIY printhead July 17, 2012 01:49AM |

Registered: 11 years ago Posts: 7 |

Hi John !

Regular maintenance for printheads. If you use your printer once in awhile, you will probably get ink buildup inside the printhead which will eventually clog the head or cause nozzle deflections. If you use your printer constantly, you will probably get some buildup on the inside of the head and more buildup on the outside which you need to remove from time to time to keep your printer from leaving messy droplets and streaks on your prints.

Thanking you !

Regular maintenance for printheads. If you use your printer once in awhile, you will probably get ink buildup inside the printhead which will eventually clog the head or cause nozzle deflections. If you use your printer constantly, you will probably get some buildup on the inside of the head and more buildup on the outside which you need to remove from time to time to keep your printer from leaving messy droplets and streaks on your prints.

Thanking you !

Sorry, only registered users may post in this forum.