DIY printhead

Posted by johnrpm

|

Re: DIY printhead August 31, 2010 04:14PM |

Admin Registered: 17 years ago Posts: 7,879 |

Since the voltages you are talking about are well within the range of high voltage transistors, and the current is very low, I think you will get best control response by making a high voltage rail and using something like a long tailed pair to drive the piezo. It would be similar to the deflection plate driver in an analogue scope. If you drive it from a DAC you can apply an arbitrary waveform from DC to megahertz. A lot easier than using a transformer, which will tend to limit the waveform shapes you can get.

The high voltage rail can be done with a simple boost converter, or perhaps a Cockroft multiplier. I have seen the latter driven from a pair of PIC output pins to generate about 15V from 5V to make a piezo sounder loud enough for an alarm.

A transformer might be a cheaper option once you know what waveform you need, but the above scheme would be far more useful for experimenting.

Edited 1 time(s). Last edit at 08/31/2010 04:27PM by nophead.

[www.hydraraptor.blogspot.com]

The high voltage rail can be done with a simple boost converter, or perhaps a Cockroft multiplier. I have seen the latter driven from a pair of PIC output pins to generate about 15V from 5V to make a piezo sounder loud enough for an alarm.

A transformer might be a cheaper option once you know what waveform you need, but the above scheme would be far more useful for experimenting.

Edited 1 time(s). Last edit at 08/31/2010 04:27PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: DIY printhead August 31, 2010 05:16PM |

Registered: 13 years ago Posts: 406 |

Thank you for the usefull advise, I will try to digest it, I have never heard of a long tailed pair so would need some help with resistor values etc, do you think that low energy lights, or the inverter inside would be of use, I am trying to find common items that most people can use, not sure about the USA versions though.

P.S I see your update caused problems, mine disabled the sound card, not compatible for some reason, why after all this time I don't know.

Random Precision

P.S I see your update caused problems, mine disabled the sound card, not compatible for some reason, why after all this time I don't know.

Random Precision

|

Re: DIY printhead September 01, 2010 10:02AM |

Registered: 14 years ago Posts: 356 |

madscifi Wrote:

-------------------------------------------------------

> Speaking of standard power supply transformers, I

> tried using one to drive the piezo with a simple

> transistor circuit and it unsurprisingly did not

> work well. It boosts the voltage just fine, but

> the pulses became triangles after passing through

> the transformer.

Ok, we have that problem, a square wave on primary (or other wave shape) will loose his shape on secondary.

Maybe we can still have fast rise times on secondary/120 volts, if we rectify to DC voltage, using a cheap diode and capacitor, then we can try to switch that 120V again with a transistor like this one that costs 0.1€.

johnrpm Wrote:

-------------------------------------------------------

put simply a long suck time and

> short squirt time, the arduino can do this but

> would it take much to have a circuit relieve the

> arduino of the task and receive a logic high or

> low and produce the signal profile, with some

> presets for fine tuning,

> or is the arduino capable of running the reprap as

> well as the printhead.

Actual RepRap board code do the XYZ + (E) Extruder stepper motor impulse signals. The extruder board have another AVR microcontroller which is not need!! -- because that AVR is just "forwarding" the stepper motor impulses coming from main board and is controlling the heater which is very slow - needs low power processing.

However, Arduino is slow for RepRap and is relative old technology. Because of this, I am working with a friend to develop and commercialize a board using new 32bits ARM Cortex @ 100MHz, we would love that such board could be a kind of "Arduino" for RepRap world, were we could build 3D printers, 2D printers with this inkjet head, laser cutters, etc.

I would love to help make an "shield" for that board to work with this inkjet print head that we are developing here :-)

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Speaking of standard power supply transformers, I

> tried using one to drive the piezo with a simple

> transistor circuit and it unsurprisingly did not

> work well. It boosts the voltage just fine, but

> the pulses became triangles after passing through

> the transformer.

Ok, we have that problem, a square wave on primary (or other wave shape) will loose his shape on secondary.

Maybe we can still have fast rise times on secondary/120 volts, if we rectify to DC voltage, using a cheap diode and capacitor, then we can try to switch that 120V again with a transistor like this one that costs 0.1€.

johnrpm Wrote:

-------------------------------------------------------

put simply a long suck time and

> short squirt time, the arduino can do this but

> would it take much to have a circuit relieve the

> arduino of the task and receive a logic high or

> low and produce the signal profile, with some

> presets for fine tuning,

> or is the arduino capable of running the reprap as

> well as the printhead.

Actual RepRap board code do the XYZ + (E) Extruder stepper motor impulse signals. The extruder board have another AVR microcontroller which is not need!! -- because that AVR is just "forwarding" the stepper motor impulses coming from main board and is controlling the heater which is very slow - needs low power processing.

However, Arduino is slow for RepRap and is relative old technology. Because of this, I am working with a friend to develop and commercialize a board using new 32bits ARM Cortex @ 100MHz, we would love that such board could be a kind of "Arduino" for RepRap world, were we could build 3D printers, 2D printers with this inkjet head, laser cutters, etc.

I would love to help make an "shield" for that board to work with this inkjet print head that we are developing here :-)

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 01, 2010 03:46PM |

Admin Registered: 17 years ago Posts: 1,791 |

However, Arduino is slow for RepRap and is relative old technology. Because of this, I am working with a friend to develop and commercialize a board using new 32bits ARM Cortex @ 100MHz, we would love that such board could be a kind of "Arduino" for RepRap world, were we could build 3D printers, 2D printers with this inkjet head, laser cutters, etc.

Sounds cool, casainho.

http://reprap.org/wiki/Generation_8_Electronics ?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Sounds cool, casainho.

http://reprap.org/wiki/Generation_8_Electronics ?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: DIY printhead September 01, 2010 04:19PM |

Registered: 14 years ago Posts: 356 |

SebastienBailard Wrote:

-------------------------------------------------------

> Sounds cool, casainho.

> http:// reprap.org/ wiki/ Generation_8_Electronics ?

Sounds ugly that name scheme -- we will market with other name for sure. We are working for the prototype, in the end, or we will be able to commercialize it and so people will have access to working and tested electronics or we will publish anyway the work.

Edited 1 time(s). Last edit at 09/01/2010 04:20PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Sounds cool, casainho.

> http:// reprap.org/ wiki/ Generation_8_Electronics ?

Sounds ugly that name scheme -- we will market with other name for sure. We are working for the prototype, in the end, or we will be able to commercialize it and so people will have access to working and tested electronics or we will publish anyway the work.

Edited 1 time(s). Last edit at 09/01/2010 04:20PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 02, 2010 02:24AM |

Registered: 14 years ago Posts: 196 |

I agree with Nopehead, the easiest way to test a large variety of different pulse profiles is by using a fast high-voltage linear amplifier of some sort. In the end it may turn out to be unnecessary, as a simple pulse might be all that is needed, but it will still be an interesting exercise. Besides, if all we ever build is simple pulse circuits, we might miss something really useful.

There is good reason to believe that different pulse profiles can be used to good effect. For example, Generation of Monodisperse Micron-Sized Droplets using Free Adjustable Signals shows how, given a tubular style dropper, a pulse profile with small stairsteps can be used to generate 8 um diameter drops from a 40 um noozle (normally the drop diameter is somewhere between 1/2 and 2 times the nozzle diameter).

We have good specifications for the pulse requirements needed by tubular dropper designs, but I have not been able to find equivalent detailed information concerning the pulse profiles used for the bimorph disk dropper designs. I do know that the pulse widths mentioned in most papers concerning the bimorph designs discuss widths in the milliseconds, as opposed to microseconds for the tubular designs. What I don't have a good feeling for is a lower bound on the rise/fall times that would be most useful.

Anyway, here some circuits that I've tracked down that might work well with the bimorphs:

Fast high–voltage amplifiers for driving electro-optic modulators has three different designs. The paper discusses the designs in reference to piezos in the 100pf range, but the designs might be useful with the bimorphs regardless. One design will handle 500 Vpp, but the piezo must be floating. I think it would be better from a safety point of view if the piezo is referenced to ground, but I'd really like to hear from someone how knows a lot more about this topic than I do. The other two designs only go up to 60 Vpp, which may not be enough to be really useful, at least until there is an efficient head design.

A fast high-voltage amplifier for driving piezoelectric positioners is specifically designed for for piezos in the 10s of nanofards, which is exactly the range in which the bimorphs fall. Assuming all of the parts are obtainable (or suitable replacements can be found), this looks to be the "best" design from the standpoint of high speed and high voltage. However, it does not look like some of the parts are easily obtainable, so substitute parts will need to be found.

1-kV Piezo Amplifier Keeps Cost, Noise Low is really not a high speed driver. It clocks in with rise/fall times of about 1/2 to 2 V/us. However, it is a very simple design that can handle up to 1000 volts. An very similar (essentially the same approach but with better protections built into the circuit) design is on page 169 of The Art of Electronics. If the slower rise/fall times turn out to be fast enough, this is an easy to build design.

Op Amp Booster Designs has a design for a 120 Volt bipolar amp. Based on some other comments about the design on various web sites it is unclear if the design really works or not.

I'm currently hoping to build some variation of the design in The Art of Electronics in the near future since it can be easily adapted to readily available parts for a lower voltage implementation. If I can track down suitable replacements for the unubtainable parts, I'd like to see if I can also build the design from A fast high-voltage amplifier for driving piezoelectric positioners at some point in the future.

There is good reason to believe that different pulse profiles can be used to good effect. For example, Generation of Monodisperse Micron-Sized Droplets using Free Adjustable Signals shows how, given a tubular style dropper, a pulse profile with small stairsteps can be used to generate 8 um diameter drops from a 40 um noozle (normally the drop diameter is somewhere between 1/2 and 2 times the nozzle diameter).

We have good specifications for the pulse requirements needed by tubular dropper designs, but I have not been able to find equivalent detailed information concerning the pulse profiles used for the bimorph disk dropper designs. I do know that the pulse widths mentioned in most papers concerning the bimorph designs discuss widths in the milliseconds, as opposed to microseconds for the tubular designs. What I don't have a good feeling for is a lower bound on the rise/fall times that would be most useful.

Anyway, here some circuits that I've tracked down that might work well with the bimorphs:

Fast high–voltage amplifiers for driving electro-optic modulators has three different designs. The paper discusses the designs in reference to piezos in the 100pf range, but the designs might be useful with the bimorphs regardless. One design will handle 500 Vpp, but the piezo must be floating. I think it would be better from a safety point of view if the piezo is referenced to ground, but I'd really like to hear from someone how knows a lot more about this topic than I do. The other two designs only go up to 60 Vpp, which may not be enough to be really useful, at least until there is an efficient head design.

A fast high-voltage amplifier for driving piezoelectric positioners is specifically designed for for piezos in the 10s of nanofards, which is exactly the range in which the bimorphs fall. Assuming all of the parts are obtainable (or suitable replacements can be found), this looks to be the "best" design from the standpoint of high speed and high voltage. However, it does not look like some of the parts are easily obtainable, so substitute parts will need to be found.

1-kV Piezo Amplifier Keeps Cost, Noise Low is really not a high speed driver. It clocks in with rise/fall times of about 1/2 to 2 V/us. However, it is a very simple design that can handle up to 1000 volts. An very similar (essentially the same approach but with better protections built into the circuit) design is on page 169 of The Art of Electronics. If the slower rise/fall times turn out to be fast enough, this is an easy to build design.

Op Amp Booster Designs has a design for a 120 Volt bipolar amp. Based on some other comments about the design on various web sites it is unclear if the design really works or not.

I'm currently hoping to build some variation of the design in The Art of Electronics in the near future since it can be easily adapted to readily available parts for a lower voltage implementation. If I can track down suitable replacements for the unubtainable parts, I'd like to see if I can also build the design from A fast high-voltage amplifier for driving piezoelectric positioners at some point in the future.

|

Re: DIY printhead September 02, 2010 04:00AM |

Admin Registered: 16 years ago Posts: 13,884 |

... i have some piezo-motors with drivers, where an alumina-tip is moved by two PZT-actuators to perform an elliptic path, that will move an atached surface. This parts can be used for other displacement too, but the moving range is in some ten microns only ... and i can give away one of the motors and a driver if needed.

Then i have a PZT-driven gripper, which actuates a solid-state tweezer made from steel, so that the bending tip has a moving range o 0.3mm with some kHz actuating speed - when shorting the tweezer, it can run faster with a smaller moving range ... but this 'toy' isn't free for experimenting with ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Then i have a PZT-driven gripper, which actuates a solid-state tweezer made from steel, so that the bending tip has a moving range o 0.3mm with some kHz actuating speed - when shorting the tweezer, it can run faster with a smaller moving range ... but this 'toy' isn't free for experimenting with ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DIY printhead September 02, 2010 08:38AM |

Registered: 13 years ago Posts: 406 |

looking on the steminc site here piezo transformer

it says a step up ratio of 40,Am I right in thinking that they are what they say they are, ie, a transformer, interesting.

I have ordered one of these to see if it will drive the spark units, cheaper than buying the components.

Edited 1 time(s). Last edit at 09/02/2010 10:58AM by johnrpm.

Random Precision

it says a step up ratio of 40,Am I right in thinking that they are what they say they are, ie, a transformer, interesting.

I have ordered one of these to see if it will drive the spark units, cheaper than buying the components.

Edited 1 time(s). Last edit at 09/02/2010 10:58AM by johnrpm.

Random Precision

|

Re: DIY printhead September 02, 2010 10:53PM |

Registered: 14 years ago Posts: 196 |

Viktor, thank you for the offer, but I for one have no idea how one would utilize a piezo motor. They sound like something that would be better utilized as the stage for an STM or something similar. Maybe someone else has a good idea?

Out of curiosity, may I ask what the piezo tweezer is used for?

Johnrpm, if the power supply works for powering the spark units then I agree that the price is pretty unbeatable.

Edited 1 time(s). Last edit at 09/02/2010 10:56PM by madscifi.

Out of curiosity, may I ask what the piezo tweezer is used for?

Johnrpm, if the power supply works for powering the spark units then I agree that the price is pretty unbeatable.

Edited 1 time(s). Last edit at 09/02/2010 10:56PM by madscifi.

|

Re: DIY printhead September 03, 2010 02:58AM |

Admin Registered: 16 years ago Posts: 13,884 |

... i have two different types of piezo-motors: - the simpler one is built with two bulk PZT-blocks atached in a V-groove 90 deg scewed, with a piece of alumna between them. The driver activates them with some phase-shifting, so the alumna-piece performs an elliptic move, which will accelerate an atached surface. But i think this can be disassembled and driven in single mode, so they will act as normal PZT-actuators for single-shots or constant oszillation.

The others are the "Piezo-legs", which have a more complex structure ... and are much more expensive

With the PZT-activated tweezer i've built an assembling system for inserting tungsten-pins in the sockets of Osram-bulbs ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The others are the "Piezo-legs", which have a more complex structure ... and are much more expensive

With the PZT-activated tweezer i've built an assembling system for inserting tungsten-pins in the sockets of Osram-bulbs ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DIY printhead September 03, 2010 05:21AM |

Registered: 13 years ago Posts: 406 |

I ordered some trigger transformers but noticed the cold cathode supply and thought for the price it was worth a try,

last night I wired up a trigger transformer salvaged some time ago whilst waiting for the order to arrive.

the input voltage was 10 volts from the function generator and at the bimorph 80 volts from the trigger transformer, with no other componants in circuit.

It powered the buzzer and produced audible output, I noticed two things that may be of interest,

the voltage on the scope increased at certain frequencies, as if it has harmonics, in between these "harmonics" the voltage slightly reduced.

If I applied a small force on the bimorph the voltage reduced on the scope.

This may have implications on the way the disc is clamped, with O rings at the very edge to allow maximum deflection?,

also is the disc adding to the energy in some way from its own output?.

Maybe those with better elecronics experiance can shed some light.

a simple pulse might be all that is needed, but it will still be an interesting exercise. Besides, if all we ever build is simple pulse circuits, we might miss something really useful.

I fully agree, its good that you are working on this, my electronics skills are not sufficient to design and research this area, so I will concentrate for now on simple step up devices to power the spark units, and then nick your ideas when you have done all the work, at least this way we are covering more area.

Random Precision

last night I wired up a trigger transformer salvaged some time ago whilst waiting for the order to arrive.

the input voltage was 10 volts from the function generator and at the bimorph 80 volts from the trigger transformer, with no other componants in circuit.

It powered the buzzer and produced audible output, I noticed two things that may be of interest,

the voltage on the scope increased at certain frequencies, as if it has harmonics, in between these "harmonics" the voltage slightly reduced.

If I applied a small force on the bimorph the voltage reduced on the scope.

This may have implications on the way the disc is clamped, with O rings at the very edge to allow maximum deflection?,

also is the disc adding to the energy in some way from its own output?.

Maybe those with better elecronics experiance can shed some light.

a simple pulse might be all that is needed, but it will still be an interesting exercise. Besides, if all we ever build is simple pulse circuits, we might miss something really useful.

I fully agree, its good that you are working on this, my electronics skills are not sufficient to design and research this area, so I will concentrate for now on simple step up devices to power the spark units, and then nick your ideas when you have done all the work, at least this way we are covering more area.

Random Precision

|

Re: DIY printhead September 03, 2010 05:30AM |

Registered: 14 years ago Posts: 356 |

johnrpm Wrote:

-------------------------------------------------------

> If I applied a small force on the bimorph the

> voltage reduced on the scope.

> This may have implications on the way the disc is

> clamped, with O rings at the very edge to allow

> maximum deflection?,

> also is the disc adding to the energy in some way

> from its own output?.

Maybe if you change the deflection it will change his impedance and so the reduced voltage.

If the transformer you are using have higher resistance output, small variations of bimorph impedance will make that voltage changes. This means that bimorph may need more current than the one your transformer can give.

Edited 1 time(s). Last edit at 09/03/2010 05:34AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> If I applied a small force on the bimorph the

> voltage reduced on the scope.

> This may have implications on the way the disc is

> clamped, with O rings at the very edge to allow

> maximum deflection?,

> also is the disc adding to the energy in some way

> from its own output?.

Maybe if you change the deflection it will change his impedance and so the reduced voltage.

If the transformer you are using have higher resistance output, small variations of bimorph impedance will make that voltage changes. This means that bimorph may need more current than the one your transformer can give.

Edited 1 time(s). Last edit at 09/03/2010 05:34AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 03, 2010 06:05AM |

Registered: 13 years ago Posts: 406 |

I do not know enough to know the answer, but if we tap a bimorph we get a voltage output, and as we are tapping it electronicaly I thought that its own output may be adding to the signal, if you know what I mean, as in the piezo transformers.

Edit, If I try it with a bigger transformer would that tell us something???.

Edited 1 time(s). Last edit at 09/03/2010 06:09AM by johnrpm.

Random Precision

Edit, If I try it with a bigger transformer would that tell us something???.

Edited 1 time(s). Last edit at 09/03/2010 06:09AM by johnrpm.

Random Precision

|

Re: DIY printhead September 03, 2010 06:11AM |

Registered: 14 years ago Posts: 356 |

johnrpm Wrote:

-------------------------------------------------------

> I do not know enough to know the answer, but if we

> tap a bimorph we get a voltage output, and as we

> are tapping it electronicaly I thought that its

> own output may be adding to the signal, if you

> know what I mean, as in the piezo transformers.

Yes, I know and I registered that signal when kicking my piezo.

We don't have to know everything about piezos nor electronics to make this print head -- as example the extruder, I believe there is a lot to learn about temperature/energy on extruder but by experimentation we got something that worked for start and then and now people are getting more knowledge about it while using it.

Do you have some head you can send me? can I send you my address?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> I do not know enough to know the answer, but if we

> tap a bimorph we get a voltage output, and as we

> are tapping it electronicaly I thought that its

> own output may be adding to the signal, if you

> know what I mean, as in the piezo transformers.

Yes, I know and I registered that signal when kicking my piezo.

We don't have to know everything about piezos nor electronics to make this print head -- as example the extruder, I believe there is a lot to learn about temperature/energy on extruder but by experimentation we got something that worked for start and then and now people are getting more knowledge about it while using it.

Do you have some head you can send me? can I send you my address?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 03, 2010 06:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think in the same way a motor generates an EMF that reduces the current it takes, the piezo will generate an EMF when it bends that subtracts from the applied voltage, reducing the current. If you prevent it from bending it will not generate the opposing EMF, so will take more current, just like when you stop a motor rotating.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: DIY printhead September 03, 2010 09:21AM |

Registered: 13 years ago Posts: 406 |

Thanks Nophead, that makes sense and would explain why when adding a clamp to the disc I had to drive it harder to make it work.

Do you have some head you can send me? can I send you my address?

I am hatching another cunning plan, will post tonight now I have recieved a PM.

P.S I ordered the cold cathode drive and trigger transformers from Rapid at 4pm yesterday, they arrived at 10;30 this morning,credit where it is due.

Random Precision

Do you have some head you can send me? can I send you my address?

I am hatching another cunning plan, will post tonight now I have recieved a PM.

P.S I ordered the cold cathode drive and trigger transformers from Rapid at 4pm yesterday, they arrived at 10;30 this morning,credit where it is due.

Random Precision

|

Re: DIY printhead September 03, 2010 02:29PM |

Registered: 13 years ago Posts: 406 |

Untill now piezo print heads have been the domain of university researchers and commercial companies, but if you would like to take of your shoes and socks, and paddle in the sea of piezo here is a way.

Here is a thread about nozzles, they are fundamental to the head and can be a major drawback to people without machines of any kind to make them, also the body would need a lathe or miller available, as you can see from the thread we need ten people interested in buying a nozzle, if you sign up to this I will supply a body to a proven design made from acrylic as well as a 20mm bimorph at no cost, all I ask is that you cover the cost of postage for me to send it to you.

I will sign up, so we only need 9.

You will need to supply a reservoir the feed tube and connection fittings, and of course a drive unit which will involve some electronics, also it would be good if you added to the forum or wiki.

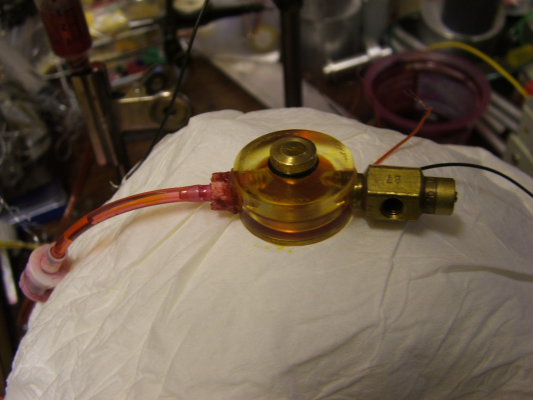

this is what the body looks like when ready to run

tha advantage with acrylic is you can see if air bubbles are present, the drawback is that solvents would damage it, but it may be best to start with refill ink, but thats up to you the developer.

Random Precision

Here is a thread about nozzles, they are fundamental to the head and can be a major drawback to people without machines of any kind to make them, also the body would need a lathe or miller available, as you can see from the thread we need ten people interested in buying a nozzle, if you sign up to this I will supply a body to a proven design made from acrylic as well as a 20mm bimorph at no cost, all I ask is that you cover the cost of postage for me to send it to you.

I will sign up, so we only need 9.

You will need to supply a reservoir the feed tube and connection fittings, and of course a drive unit which will involve some electronics, also it would be good if you added to the forum or wiki.

this is what the body looks like when ready to run

tha advantage with acrylic is you can see if air bubbles are present, the drawback is that solvents would damage it, but it may be best to start with refill ink, but thats up to you the developer.

Random Precision

|

Re: DIY printhead September 03, 2010 03:39PM |

Registered: 14 years ago Posts: 356 |

johnrpm Wrote:

-------------------------------------------------------

> Here is a thread about nozzles, they are

> fundamental to the head and can be a major

> drawback to people without machines of any kind to

> make them, also the body would need a lathe or

> miller available, as you can see from the thread

> we need ten people interested in buying a nozzle,

> if you sign up to this I will supply a body to a

> proven design made from acrylic as well as a 20mm

> bimorph at no cost, all I ask is that you cover

> the cost of postage for me to send it to you.

This is the way to go!! ask for help of others who are being helping he community to get the nozzles for RepRap. I bought my "Reprap Machined Extruder Parts Kit" from reifsnyderb and I like it a lot. Also he provides at a good price, which I believe is fair. Right now I will buy another extruder kit from him because broke the other.

However I don't agree with this deal of 10 units/developers for this print nozzle. What if the nozzle do not work? will be good to have 10 unhappy developers? (I am sure we even aren't 10 developers...)

johnrpm, your offer is very good however looks to me is to risky to make 10 nozzles/$150. Why not test better actual design and make this investment later with less risk? -- do you have any nozzle working? what size can you do and test?

And why not ask reifsnyderb if he have any idea to make the same nozzle for a cheap price or less units, even if the hole be a little bigger?

reifsnyderb seems to be a fair person and available to help, I think we should take advantage (on a positive way I mean). And you can remember reifsnyderb that later he can start to sell this nozzles and is a possibility to earn even more with RepRap community.

Edited 3 time(s). Last edit at 09/03/2010 03:41PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Here is a thread about nozzles, they are

> fundamental to the head and can be a major

> drawback to people without machines of any kind to

> make them, also the body would need a lathe or

> miller available, as you can see from the thread

> we need ten people interested in buying a nozzle,

> if you sign up to this I will supply a body to a

> proven design made from acrylic as well as a 20mm

> bimorph at no cost, all I ask is that you cover

> the cost of postage for me to send it to you.

This is the way to go!! ask for help of others who are being helping he community to get the nozzles for RepRap. I bought my "Reprap Machined Extruder Parts Kit" from reifsnyderb and I like it a lot. Also he provides at a good price, which I believe is fair. Right now I will buy another extruder kit from him because broke the other.

However I don't agree with this deal of 10 units/developers for this print nozzle. What if the nozzle do not work? will be good to have 10 unhappy developers? (I am sure we even aren't 10 developers...)

johnrpm, your offer is very good however looks to me is to risky to make 10 nozzles/$150. Why not test better actual design and make this investment later with less risk? -- do you have any nozzle working? what size can you do and test?

And why not ask reifsnyderb if he have any idea to make the same nozzle for a cheap price or less units, even if the hole be a little bigger?

reifsnyderb seems to be a fair person and available to help, I think we should take advantage (on a positive way I mean). And you can remember reifsnyderb that later he can start to sell this nozzles and is a possibility to earn even more with RepRap community.

Edited 3 time(s). Last edit at 09/03/2010 03:41PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 03, 2010 05:47PM |

Registered: 13 years ago Posts: 406 |

|

Re: DIY printhead September 03, 2010 05:52PM |

Registered: 14 years ago Posts: 356 |

Can't we get a cheaper way to make the holes? the nozzle? -- or can't the holes be larger than 0.05mm?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 03, 2010 06:12PM |

Admin Registered: 17 years ago Posts: 1,791 |

Sorry, I thought I was helping the community, I did not look forward to spending hours on the lathe and all the hastle of postage etc.

You are, very much so.

Casainho, please be gentle, , open source hardware has painful spiky bits compared to open source software; it costs more to ship via UPS than via ftp, and it is more work to copy something using a lathe than with a computer

, open source hardware has painful spiky bits compared to open source software; it costs more to ship via UPS than via ftp, and it is more work to copy something using a lathe than with a computer

And so on.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

You are, very much so.

Casainho, please be gentle,

, open source hardware has painful spiky bits compared to open source software; it costs more to ship via UPS than via ftp, and it is more work to copy something using a lathe than with a computer

, open source hardware has painful spiky bits compared to open source software; it costs more to ship via UPS than via ftp, and it is more work to copy something using a lathe than with a computerQuote

%cp old_nozzle.brass new_nozzle.brass

And so on.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: DIY printhead September 03, 2010 08:57PM |

Registered: 15 years ago Posts: 537 |

Hello,

Since there is some question regarding the 10 nozzle quote for $150.00, I figured I would stop by and offer an explanation.

One way to look at this is from the perspective of a typical machine shop hourly cost. If a machine shop were to make a single nozzle, it would probably take around 1 hour and cost $60.00 to $100.00. They would probably add tooling costs, as well.

What I am offering to do is to make 10 nozzles for $150.00. In order to this I'll have to make one nozzle as a master. Then I'll tool up my turret lathe and run off 10 more. There is probably at least 3 hours involved up to this point and I believe that I have all of the tooling in order to get to this point. (Without the turret lathe, it would probably take a lot longer.)

The orifice hole is the real trick and the primary reason for the expense. The drill bits are $14.64, each, and I will probably need at least 2 as I really don't expect them to last that long. Another issue is that a drill bit that small will have to be spun up at a very high RPM. Due to the size of the drill bit, it will probably be best to drill it out on my mini milling machine. The current top speed, of my mini mill, is 2800 RPMs. I have my doubts that this will be fast enough. The solution is to buy this: [www.sherlinedirect.com] It is a set of pulleys that will increase the top speed to 10,000 RPMs. Since I don't have any real use for this speed other than to drill these holes, there is a reasonable chance I will use these pulleys ten times and then set them aside. Including machine setup time, drilling the orifice holes will probably take an additional hour.

So, in summary, what I am offering to do is to spend around 4 hours making 10 nozzles, plus a master to assist with the turret lathe setup. I will have to purchase $30.00 worth of drill bits, probably have to purchase the high speed pulley set for $80.00 (that I doubt I will use any time soon unless I make more of these nozzles), and pay shipping and handling. If the total shipping and handling is $10.00 (it will probably be more), I will have an outlay of $120.00. This leaves $30.00. If we stop here, I am working for $7.50 per hour. But, it really doesn't stop here as I have not included the costs of a pretty nicely equipped machine shop. (Yes, I am using the machine shop to make other parts; but, in two years I have yet to break even. I am really doing this more for fun than anything else.)

Regards,

Brian

Since there is some question regarding the 10 nozzle quote for $150.00, I figured I would stop by and offer an explanation.

One way to look at this is from the perspective of a typical machine shop hourly cost. If a machine shop were to make a single nozzle, it would probably take around 1 hour and cost $60.00 to $100.00. They would probably add tooling costs, as well.

What I am offering to do is to make 10 nozzles for $150.00. In order to this I'll have to make one nozzle as a master. Then I'll tool up my turret lathe and run off 10 more. There is probably at least 3 hours involved up to this point and I believe that I have all of the tooling in order to get to this point. (Without the turret lathe, it would probably take a lot longer.)

The orifice hole is the real trick and the primary reason for the expense. The drill bits are $14.64, each, and I will probably need at least 2 as I really don't expect them to last that long. Another issue is that a drill bit that small will have to be spun up at a very high RPM. Due to the size of the drill bit, it will probably be best to drill it out on my mini milling machine. The current top speed, of my mini mill, is 2800 RPMs. I have my doubts that this will be fast enough. The solution is to buy this: [www.sherlinedirect.com] It is a set of pulleys that will increase the top speed to 10,000 RPMs. Since I don't have any real use for this speed other than to drill these holes, there is a reasonable chance I will use these pulleys ten times and then set them aside. Including machine setup time, drilling the orifice holes will probably take an additional hour.

So, in summary, what I am offering to do is to spend around 4 hours making 10 nozzles, plus a master to assist with the turret lathe setup. I will have to purchase $30.00 worth of drill bits, probably have to purchase the high speed pulley set for $80.00 (that I doubt I will use any time soon unless I make more of these nozzles), and pay shipping and handling. If the total shipping and handling is $10.00 (it will probably be more), I will have an outlay of $120.00. This leaves $30.00. If we stop here, I am working for $7.50 per hour. But, it really doesn't stop here as I have not included the costs of a pretty nicely equipped machine shop. (Yes, I am using the machine shop to make other parts; but, in two years I have yet to break even. I am really doing this more for fun than anything else.)

Regards,

Brian

|

Re: DIY printhead September 03, 2010 09:42PM |

Registered: 14 years ago Posts: 196 |

Johnrpm, your offer is really quite generous - thank you. Requiring those getting an acrylic head from you to purchase a nozzle from reifsnyderb is a good way to get some "buy-in" on the part of whomever gets a head from you without getting into the issue of selling of materials. I like it.

Reifsnyderb, you really don't need to defend your pricing at all. You've quoted what is a very low price for a small number of completely custom parts.

Casainho, at this point the print heads are not even experimental, they are under development. No one has show so much as a drop of ink from a print head attached to a reprap. As such, the entire concept is a risk. While $150 is not an insubstantial amount of money, $15 for a single custom machined nozzle is really cheap. If you want to eliminate all the risk you will need to wait until someone has worked out a complete design, shown it working on a reprap, and then wait some more for someone to reproduce a working copy from the design. Only then will the risk be minimal. Anyone getting a print head from Johnrpm at this point would be expected to understand that this might all be for naught, at least as far as its use on the reprap is concerned.

It is interesting that this is exactly the problem that the reprap hopefully will one day solve. We need a small number of custom components for a prototype. It is not really cost effective to have them made and shipped all around the world, as the minimum quantity makes the total price seem too large, and there are currently not enough people interested in purchasing the part to make even a minimal run. If only the nozzle could be printed on a reprap someone would simply upload a design and we could all print our own copies for pennies.

Reifsnyderb, you really don't need to defend your pricing at all. You've quoted what is a very low price for a small number of completely custom parts.

Casainho, at this point the print heads are not even experimental, they are under development. No one has show so much as a drop of ink from a print head attached to a reprap. As such, the entire concept is a risk. While $150 is not an insubstantial amount of money, $15 for a single custom machined nozzle is really cheap. If you want to eliminate all the risk you will need to wait until someone has worked out a complete design, shown it working on a reprap, and then wait some more for someone to reproduce a working copy from the design. Only then will the risk be minimal. Anyone getting a print head from Johnrpm at this point would be expected to understand that this might all be for naught, at least as far as its use on the reprap is concerned.

It is interesting that this is exactly the problem that the reprap hopefully will one day solve. We need a small number of custom components for a prototype. It is not really cost effective to have them made and shipped all around the world, as the minimum quantity makes the total price seem too large, and there are currently not enough people interested in purchasing the part to make even a minimal run. If only the nozzle could be printed on a reprap someone would simply upload a design and we could all print our own copies for pennies.

|

Re: DIY printhead September 04, 2010 05:25AM |

Registered: 14 years ago Posts: 356 |

I think is unrealistic waiting for 10 developers that want to join for make such buy for that 10 nozzles, because we are not 10 and also because that nozzles are not proved to work.

I am sure we can get much more traction when we have a print head fully working BUT even if with low quality. We need the print head + control board to work with RepRap Mendel electronics + software.

As I said before, I am sure I can help with control board and put it working with RepRap Mendel, if control board for piezo is simple.

For software I know also how to use Skeinforge to generate GCode from a image BMP/JPG file.

So, the difficult here is getting a print head + control board. I believe we need to go simple and cheap, because cheap is import for us and others who will start replicating, and the success of the project depends a lot from this replication, from getting critical mass of community.

Brian (reifsnyderb), what is the small hole you can do with your actual tools you use to produce extruder nozzles? (maybe that size can be enough for a start).

Do you have any ideas how to make "small" holes more cheap, maybe other then drilling? -- in this topic, people were talking about some alternatives to drilling. Can we find some ready cheap solution on market?

johnrpm, a hole of 0.1mm would work? what do you think is the minimum size?

Edited 1 time(s). Last edit at 09/04/2010 05:28AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

I am sure we can get much more traction when we have a print head fully working BUT even if with low quality. We need the print head + control board to work with RepRap Mendel electronics + software.

As I said before, I am sure I can help with control board and put it working with RepRap Mendel, if control board for piezo is simple.

For software I know also how to use Skeinforge to generate GCode from a image BMP/JPG file.

So, the difficult here is getting a print head + control board. I believe we need to go simple and cheap, because cheap is import for us and others who will start replicating, and the success of the project depends a lot from this replication, from getting critical mass of community.

Brian (reifsnyderb), what is the small hole you can do with your actual tools you use to produce extruder nozzles? (maybe that size can be enough for a start).

Do you have any ideas how to make "small" holes more cheap, maybe other then drilling? -- in this topic, people were talking about some alternatives to drilling. Can we find some ready cheap solution on market?

johnrpm, a hole of 0.1mm would work? what do you think is the minimum size?

Edited 1 time(s). Last edit at 09/04/2010 05:28AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: DIY printhead September 04, 2010 10:16AM |

Registered: 15 years ago Posts: 537 |

Hello,

The smallest hole that can be made with my current tooling is 0.25mm.

I really don't know of any way to make a smaller hole for cheaper. Other cutting methods require much more sophisticated, and expensive, equipment than a drill bit. i.e. waterjet (I don't know if waterjet can just drill a hole.)

Regards,

Brian

casainho Wrote:

-------------------------------------------------------

> I think is unrealistic waiting for 10 developers

> that want to join for make such buy for that 10

> nozzles, because we are not 10 and also because

> that nozzles are not proved to work.

>

> I am sure we can get much more traction when we

> have a print head fully working BUT even if with

> low quality. We need the print head + control

> board to work with RepRap Mendel electronics +

> software.

>

> As I said before, I am sure I can help with

> control board and put it working with RepRap

> Mendel, if control board for piezo is simple.

>

> For software I know also how to use Skeinforge to

> generate GCode from a image BMP/JPG file.

>

> So, the difficult here is getting a print head +

> control board. I believe we need to go simple and

> cheap, because cheap is import for us and others

> who will start replicating, and the success of the

> project depends a lot from this replication, from

> getting critical mass of community.

>

> Brian (reifsnyderb), what is the small hole you

> can do with your actual tools you use to produce

> extruder nozzles? (maybe that size can be enough

> for a start).

>

> Do you have any ideas how to make "small" holes

> more cheap, maybe other then drilling? -- in this

> topic, people were talking about some alternatives

> to drilling. Can we find some ready cheap solution

> on market?

>

> johnrpm, a hole of 0.1mm would work? what do you

> think is the minimum size?

The smallest hole that can be made with my current tooling is 0.25mm.

I really don't know of any way to make a smaller hole for cheaper. Other cutting methods require much more sophisticated, and expensive, equipment than a drill bit. i.e. waterjet (I don't know if waterjet can just drill a hole.)

Regards,

Brian

casainho Wrote:

-------------------------------------------------------

> I think is unrealistic waiting for 10 developers

> that want to join for make such buy for that 10

> nozzles, because we are not 10 and also because

> that nozzles are not proved to work.

>

> I am sure we can get much more traction when we

> have a print head fully working BUT even if with

> low quality. We need the print head + control

> board to work with RepRap Mendel electronics +

> software.

>

> As I said before, I am sure I can help with

> control board and put it working with RepRap

> Mendel, if control board for piezo is simple.

>

> For software I know also how to use Skeinforge to

> generate GCode from a image BMP/JPG file.

>

> So, the difficult here is getting a print head +

> control board. I believe we need to go simple and

> cheap, because cheap is import for us and others

> who will start replicating, and the success of the

> project depends a lot from this replication, from

> getting critical mass of community.

>

> Brian (reifsnyderb), what is the small hole you

> can do with your actual tools you use to produce

> extruder nozzles? (maybe that size can be enough

> for a start).

>

> Do you have any ideas how to make "small" holes

> more cheap, maybe other then drilling? -- in this

> topic, people were talking about some alternatives

> to drilling. Can we find some ready cheap solution

> on market?

>

> johnrpm, a hole of 0.1mm would work? what do you

> think is the minimum size?

|

Re: DIY printhead September 04, 2010 05:24PM |

Admin Registered: 16 years ago Posts: 13,884 |

... my smallest drillbits have 0.1mm, but i have no fitting for the millhead and it has only 25.000rpm, so not really perfect for drilling with them

Another possibility could be burning with my fiber-laser - i measured the actual spot with a single lens at 0.03mm, what can be reduced, when ataching the beamexpander prior to focussing ... then i'll receive around 0.01mm.

I think i can engrave a series of circles stepping deeper in the material, but i have to test how acurate the inner surface and the resulting throughhole comes out.

The best method would be small dishes with the hole through, inserted in or glued or welded to the printing head ...

What materials and thickness is interesting?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Another possibility could be burning with my fiber-laser - i measured the actual spot with a single lens at 0.03mm, what can be reduced, when ataching the beamexpander prior to focussing ... then i'll receive around 0.01mm.

I think i can engrave a series of circles stepping deeper in the material, but i have to test how acurate the inner surface and the resulting throughhole comes out.

The best method would be small dishes with the hole through, inserted in or glued or welded to the printing head ...

What materials and thickness is interesting?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DIY printhead September 05, 2010 12:43AM |

Registered: 14 years ago Posts: 196 |

Viktor,

The nozzles are commonly made of glass, metal, silicon, and various jewel bearing materials.

The various papers that have been referenced earlier in this discussion talk about the following types of nozzles:

Microdrop Generation has a lot of information about nozzles. The book, however, specifically covers tubular style drop generators and I've already been caught out once by assuming that the details are applicable to the style of drop generator that Johnrpm and I have been working with so far. That said, I'll go ahead and assume that the nozzle information is applicable and provide an overview below:

The example micro-machined silicon nozzle shown in the book is constructed from a 2mm diameter disk that is 0.5 mm thick. The hole is 35 um in diameter, and it passes through a landing that is 40 um thick. Surrounding the hole the landing is 120 um wide. The opening then proceeds to enlarge until it is about 800 um at the top surface of the disk.

Teflon, if it can be safely lasered and if it will hold up machanically, might be a very good choice of material in that it has a very high contact angle with any liquid we would likely be using. Delrin would be a good second choice from this point of view, not as good as teflon but much better than glass, for example. On the other hand I have not seen any discussions of nozzles made of plastic so plastics in general might simply be too flexible to work well. Or, maybe nobody has tried.

The concentric engraving you mention would be a first approximation to the ideal conical profile, so that might actually be a very good thing.

I, for one, would be very happy to try out any nozzle of any material you would care to produce. At this point any material that will hold up to water and inkjet ink would be useful. A 2 mm diameter disk is possibly too small, as it would be difficult for me to glue to a carrier without accidentally plugging the hole. Something larger, 5 to 10 mm, would be easier to work with i think.

Casainho, glass nozzles win from the point of view of low cost (from the point of view of someone constructing one at home) and ability to be fabricated using simple tools. On the other hand, making a consistent and good glass nozzle is likely to be rather difficult. Microdrop Generation has a lot of information concerning their construction and suggestions on how to approach the problem. It is something that I hope to look at in detail sometime soon.

Update 2010-09-05: I wonder if shrinky dinks could be used to make a nozzle (idea borrowed from this article).

Edited 2 time(s). Last edit at 09/05/2010 02:08PM by madscifi.

The nozzles are commonly made of glass, metal, silicon, and various jewel bearing materials.

The various papers that have been referenced earlier in this discussion talk about the following types of nozzles:

- Glass (made by drawing out a capillary tube) and commerical sapphire nozzles. The opening diameters used varied from 125 um to 250 um. The paper states that "...a nozzle with a short, smoth transistion section followed by a short, round passage is the most desirable in order to prevent the formation of unwanted satellite droplets."

- A commercial 1.2954 mm sapphire nozzle.

- 1.25, 1.00, and 0.40 mm diameter nozzles made in 0.787mm and 0.102mm thick stainless steel.

Microdrop Generation has a lot of information about nozzles. The book, however, specifically covers tubular style drop generators and I've already been caught out once by assuming that the details are applicable to the style of drop generator that Johnrpm and I have been working with so far. That said, I'll go ahead and assume that the nozzle information is applicable and provide an overview below:

- "An ideal ejection aperture hole would have a tapered cross section ending up in a short cylindrical hole with an aspect ration of about one-to-one." A long untapered hole has a high impedance to the pressure pulse, and a short hole passing through a flat thin film tends to let air in every time a drop is generated.

- The most common range of nozzle diameters discussed is the range from 10 um to 100 um.

- There is discussion of the fact that anti-wetting coatings on the nozzle can be useful to help counteract the tendency of the liquid to build up around the bottom of the nozzle (which interferes with drop generation).

The example micro-machined silicon nozzle shown in the book is constructed from a 2mm diameter disk that is 0.5 mm thick. The hole is 35 um in diameter, and it passes through a landing that is 40 um thick. Surrounding the hole the landing is 120 um wide. The opening then proceeds to enlarge until it is about 800 um at the top surface of the disk.

Teflon, if it can be safely lasered and if it will hold up machanically, might be a very good choice of material in that it has a very high contact angle with any liquid we would likely be using. Delrin would be a good second choice from this point of view, not as good as teflon but much better than glass, for example. On the other hand I have not seen any discussions of nozzles made of plastic so plastics in general might simply be too flexible to work well. Or, maybe nobody has tried.

The concentric engraving you mention would be a first approximation to the ideal conical profile, so that might actually be a very good thing.

I, for one, would be very happy to try out any nozzle of any material you would care to produce. At this point any material that will hold up to water and inkjet ink would be useful. A 2 mm diameter disk is possibly too small, as it would be difficult for me to glue to a carrier without accidentally plugging the hole. Something larger, 5 to 10 mm, would be easier to work with i think.

Casainho, glass nozzles win from the point of view of low cost (from the point of view of someone constructing one at home) and ability to be fabricated using simple tools. On the other hand, making a consistent and good glass nozzle is likely to be rather difficult. Microdrop Generation has a lot of information concerning their construction and suggestions on how to approach the problem. It is something that I hope to look at in detail sometime soon.

Update 2010-09-05: I wonder if shrinky dinks could be used to make a nozzle (idea borrowed from this article).

Edited 2 time(s). Last edit at 09/05/2010 02:08PM by madscifi.

|

Re: DIY printhead September 05, 2010 04:42PM |

Admin Registered: 16 years ago Posts: 13,884 |

... actually i'm busy with two other tasks, but i'll try with different materials (black POM, white PTFE, steel and brass) and post the results.

On the other hand i have some sample plates made from glass and silicon with arrays of tapered holes in different sizes ... here all holes except one could be stuffed, so only one stays for testing with

Another idea could be interesting for you: salvage empty inkjet-cartridges - in some old HP-cartridges i found metallic plates with holes in diametres from 19 to 25 microns (BW or colour heads) ... newer ones have plates made from etched silicone ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

On the other hand i have some sample plates made from glass and silicon with arrays of tapered holes in different sizes ... here all holes except one could be stuffed, so only one stays for testing with

Another idea could be interesting for you: salvage empty inkjet-cartridges - in some old HP-cartridges i found metallic plates with holes in diametres from 19 to 25 microns (BW or colour heads) ... newer ones have plates made from etched silicone ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: DIY printhead September 05, 2010 10:17PM |

Registered: 14 years ago Posts: 196 |

Viktor, thank you and take your time, we are not going anywhere.

Salvaging nozzles is a very good idea. Johnrpm had mentioned the possibility of salvaging nozzles from HP inkjet cartridges a while back but I had forgotten about idea. I only have access to used epson and canon cartridges which, of course, are of no use. Fortunately refurbished HP units are for sale rather cheaply on amazon. I've ordered one and will see what I can find. Amazingly there are even people selling empty used ones, but they generally cost more than the "refurbished" ones.

Salvaging nozzles is a very good idea. Johnrpm had mentioned the possibility of salvaging nozzles from HP inkjet cartridges a while back but I had forgotten about idea. I only have access to used epson and canon cartridges which, of course, are of no use. Fortunately refurbished HP units are for sale rather cheaply on amazon. I've ordered one and will see what I can find. Amazingly there are even people selling empty used ones, but they generally cost more than the "refurbished" ones.

|

Re: DIY printhead September 05, 2010 11:49PM |

Registered: 14 years ago Posts: 196 |

Micro-liter disposable pipette tips. Now that I have your attention, can anyone point to a scale drawing or provide any information concerning their construction? I'm wondering if they might not work as a ready made nozzle but I have not been able to find any dimensional information about them on the web. They are dirt cheap by the piece, but usually come in boxes of 100 or more so I'm hesitant to buy a box without some idea of how they are constructed. Thanks.

Sorry, only registered users may post in this forum.