lasers for DMLS, and their properties- what would we need to make one on the cheap?

Posted by nubnubbud

|

lasers for DMLS, and their properties- what would we need to make one on the cheap? April 19, 2021 04:58AM |

Registered: 2 years ago Posts: 11 |

TL;DR: I feel we might be able to achieve DMLS properties with newer, high-powered laser diodes, and the reason companies aren't exploiting it is possibly shyness to invest in untested(rarely theorized) applications. or maybe I'm just dumb and missed something.

alright, I want to preface this by saying, if this turns out promising according to a number of people here, or if someone with a 5.5w laser or above is willing to run some tests, I may make a prototype DMLS printer.

I've been curious about all of this for quite a while, and I've been following trends in lasers for a bit, researching their properties and uses, etc, and was entranced by the use of lasers in DMLS printing from the first video I saw ( [www.youtube.com] )... essentially: A 1064nm laser from 100w-400w can be used to melt metal dust at 600-6000mm/s using a galvo-head.

then a couple years later, I saw other videos pop up, you know the ones. "absolutely new technology affordable metal 3D printing, request a quote for your multi-million dollar business now." and so on, where I thought "new? I've known about this for years as a consumer, and you don't ask for a quote if it's affordable, or call it a desktop printer if it's the size of a refrigerator..."

more recently (two years ago, in 2019) ( [www.youtube.com] ) came out, basically outing a few industry secrets... but let's break down their secrets too because 50k USD is still too much!

but also- take a quick look at that machine shown- or more accurately- the windows. They're green. from someone who's studied a lot about laser safety, that is a lot of information! there are only two common tints of laser protective plastic that color- and both have their best protection around the 410nm and below, and 1064nm and above wavelengths. but they said themselves- they're using a more common wavelength than industry standard, which are high power 1064nm or 980nm wavelength. They also said they're using a fiber system, and made it, at least partially, themselves. I believe they're using a blue or UV wavelength fiber laser, seeing as the other most likely 808nm, near-infrared, is only partially protected by the green shields. Why is it not orange, which is even better for those wavelengths? I don't know, but I'll reason it out later.. As well, blue lasers, now that engravers are common, are cheap by sheer production quantity, and getting stronger, as every company wants to boast the ability to punch through a centimeter of wood at some point. alright, moving on- take a close look at the print head- and you'll notice something strange. it's got two pipes going to it... and a number of noctua or similar cpu coolers on the back of the case. I believe this means, that the print head itself needs cooling, and badly. I can't be completely sure if it's a liquid cooling or air cooling, because fans in a box of superfine metal dust is not a good time... but I think it's liquid cooling. if it was air, you could just vent it in one side and out the other more efficiently. I'm not versed on cooling of fiber laser heads, but if someone could give me a reason why the fiber end needs to be cooled, I'd appreciate it! Now, this isn't their final design, but look at the market, and you'll see that 50-60w red lasers dominate the upper end of the market for price efficiency- and I can bet you their device doesn't exceed 10k USD in parts, meaning they could accord two fiber lasers at that price, bringing them to 100w comfortably. now look closely- they're not using a galvo-head, but a normal cartesian print-head moving at 10-75mm/s. If 100w infrared can melt metal at 600mm/s, they could feasibly be using lasers as low as 30w total power.

So, let's figure this out they're probably using a 380nm-425nm fiber coupled laser with liquid cooling to cut costs, and even then, they seem to have a reason not to use industry standard red lasers.

whew! that was a lot of thinking over a year to put into one wall of text! but that last little bit is the crux of my argument. I think they're using blue lasers for melting metal, and to back up that assumption, I've posted a number of attached graphs. Now, most are small, but companies throw these around like soundcloud rappers pitch their mixtapes, and a lot of them vary plenty... but look closely. almost all of them from sellers have steel leave the chart, conveniently just about at the wavelength the industry standard fiber cutting laser is- 1064nm. The research paper results seem to be a little more fair, showing the trend of steel being more receptive to lower wavelengths- even 50% absorptive at UV wavelengths, and significantly higher heat-to-material at more cost effective 410nm wavelengths than industry standard fiber lasers, which, if run at only 10-20mm/s, could potentially give enough energy to the powder to fuse it- or at the very least, sinter it, in a vacuum where heat losses to air could be negated.

[reprap.org] is another topic, and if you put the information of stainless steel powder into their calculator. I know it's probably not perfectly accurate, but as a rough guide, it seems to follow reality based on the industry standard result:

------at optimal settings and conditions, (thermal conductivity of 12w/mK, beam diameter of .2mm, layer height of .1mm, extra melt depth of .03mm, .006g/mm^3 powder density, and 20mm/s move speed) it quoted about 19W of optical power needed to melt a line.

------at very suboptimal settings and conditions, (thermal conductivity of 24w/mK, beam diameter of .4mm, layer height of .12mm, extra melt depth of .1mm, .00785g/mm^3 powder density, and 30mm/s move speed) it quoted about 99W of optical power needed to melt a line.

------at suboptimal conditions but precise settings, (thermal conductivity of 24w/mK, beam diameter of .15mm, layer height of .05mm, extra melt depth of .03mm, .00785g/mm^3 powder density, and 15mm/s move speed) it quoted about 31W of optical power needed to melt a line.

------at industry standard settings and conditions, (thermal conductivity of 12w/mK, beam diameter of .2mm, layer height of .05mm, extra melt depth of .03mm, .00785g/mm^3 powder density, and 1000mm/s move speed) it quoted about 103W of optical power needed to melt a line.

it's clear that the easiest and cheapest way to lower the laser power needed is precise focus with good optics, using better wavelengths than industry standard, and exceedingly precise bed and powder control, and perhaps by using a de-focused sub-laser to heat the powder just before the main laser passes over it. The biggest issue once power and focus are achieved will likely be stopping excessive "blobbing" as the melt pool attracts nearby particles.

So, tell me why I'm wrong. I have a feeling that all things considered, a large company surely should have figured this out by now and preempted me if I'm right. What am I missing? or, if no one knows, are you willing to help me test? I'm mostly just thirsty for information, and science needs to happen before engineering can make it functional, but if this can somehow, by chance, get off the ground, I'd be overjoyed.

Edited 1 time(s). Last edit at 04/19/2021 05:05AM by nubnubbud.

alright, I want to preface this by saying, if this turns out promising according to a number of people here, or if someone with a 5.5w laser or above is willing to run some tests, I may make a prototype DMLS printer.

I've been curious about all of this for quite a while, and I've been following trends in lasers for a bit, researching their properties and uses, etc, and was entranced by the use of lasers in DMLS printing from the first video I saw ( [www.youtube.com] )... essentially: A 1064nm laser from 100w-400w can be used to melt metal dust at 600-6000mm/s using a galvo-head.

then a couple years later, I saw other videos pop up, you know the ones. "absolutely new technology affordable metal 3D printing, request a quote for your multi-million dollar business now." and so on, where I thought "new? I've known about this for years as a consumer, and you don't ask for a quote if it's affordable, or call it a desktop printer if it's the size of a refrigerator..."

more recently (two years ago, in 2019) ( [www.youtube.com] ) came out, basically outing a few industry secrets... but let's break down their secrets too because 50k USD is still too much!

but also- take a quick look at that machine shown- or more accurately- the windows. They're green. from someone who's studied a lot about laser safety, that is a lot of information! there are only two common tints of laser protective plastic that color- and both have their best protection around the 410nm and below, and 1064nm and above wavelengths. but they said themselves- they're using a more common wavelength than industry standard, which are high power 1064nm or 980nm wavelength. They also said they're using a fiber system, and made it, at least partially, themselves. I believe they're using a blue or UV wavelength fiber laser, seeing as the other most likely 808nm, near-infrared, is only partially protected by the green shields. Why is it not orange, which is even better for those wavelengths? I don't know, but I'll reason it out later.. As well, blue lasers, now that engravers are common, are cheap by sheer production quantity, and getting stronger, as every company wants to boast the ability to punch through a centimeter of wood at some point. alright, moving on- take a close look at the print head- and you'll notice something strange. it's got two pipes going to it... and a number of noctua or similar cpu coolers on the back of the case. I believe this means, that the print head itself needs cooling, and badly. I can't be completely sure if it's a liquid cooling or air cooling, because fans in a box of superfine metal dust is not a good time... but I think it's liquid cooling. if it was air, you could just vent it in one side and out the other more efficiently. I'm not versed on cooling of fiber laser heads, but if someone could give me a reason why the fiber end needs to be cooled, I'd appreciate it! Now, this isn't their final design, but look at the market, and you'll see that 50-60w red lasers dominate the upper end of the market for price efficiency- and I can bet you their device doesn't exceed 10k USD in parts, meaning they could accord two fiber lasers at that price, bringing them to 100w comfortably. now look closely- they're not using a galvo-head, but a normal cartesian print-head moving at 10-75mm/s. If 100w infrared can melt metal at 600mm/s, they could feasibly be using lasers as low as 30w total power.

So, let's figure this out they're probably using a 380nm-425nm fiber coupled laser with liquid cooling to cut costs, and even then, they seem to have a reason not to use industry standard red lasers.

whew! that was a lot of thinking over a year to put into one wall of text! but that last little bit is the crux of my argument. I think they're using blue lasers for melting metal, and to back up that assumption, I've posted a number of attached graphs. Now, most are small, but companies throw these around like soundcloud rappers pitch their mixtapes, and a lot of them vary plenty... but look closely. almost all of them from sellers have steel leave the chart, conveniently just about at the wavelength the industry standard fiber cutting laser is- 1064nm. The research paper results seem to be a little more fair, showing the trend of steel being more receptive to lower wavelengths- even 50% absorptive at UV wavelengths, and significantly higher heat-to-material at more cost effective 410nm wavelengths than industry standard fiber lasers, which, if run at only 10-20mm/s, could potentially give enough energy to the powder to fuse it- or at the very least, sinter it, in a vacuum where heat losses to air could be negated.

[reprap.org] is another topic, and if you put the information of stainless steel powder into their calculator. I know it's probably not perfectly accurate, but as a rough guide, it seems to follow reality based on the industry standard result:

------at optimal settings and conditions, (thermal conductivity of 12w/mK, beam diameter of .2mm, layer height of .1mm, extra melt depth of .03mm, .006g/mm^3 powder density, and 20mm/s move speed) it quoted about 19W of optical power needed to melt a line.

------at very suboptimal settings and conditions, (thermal conductivity of 24w/mK, beam diameter of .4mm, layer height of .12mm, extra melt depth of .1mm, .00785g/mm^3 powder density, and 30mm/s move speed) it quoted about 99W of optical power needed to melt a line.

------at suboptimal conditions but precise settings, (thermal conductivity of 24w/mK, beam diameter of .15mm, layer height of .05mm, extra melt depth of .03mm, .00785g/mm^3 powder density, and 15mm/s move speed) it quoted about 31W of optical power needed to melt a line.

------at industry standard settings and conditions, (thermal conductivity of 12w/mK, beam diameter of .2mm, layer height of .05mm, extra melt depth of .03mm, .00785g/mm^3 powder density, and 1000mm/s move speed) it quoted about 103W of optical power needed to melt a line.

it's clear that the easiest and cheapest way to lower the laser power needed is precise focus with good optics, using better wavelengths than industry standard, and exceedingly precise bed and powder control, and perhaps by using a de-focused sub-laser to heat the powder just before the main laser passes over it. The biggest issue once power and focus are achieved will likely be stopping excessive "blobbing" as the melt pool attracts nearby particles.

So, tell me why I'm wrong. I have a feeling that all things considered, a large company surely should have figured this out by now and preempted me if I'm right. What am I missing? or, if no one knows, are you willing to help me test? I'm mostly just thirsty for information, and science needs to happen before engineering can make it functional, but if this can somehow, by chance, get off the ground, I'd be overjoyed.

Edited 1 time(s). Last edit at 04/19/2021 05:05AM by nubnubbud.

Attachments:

open | download - ss_laser-marking-central_s_m_metal_017_1924187.png (6.8 KB)

open | download - The-absorption-of-laser-output-at-different-wavelengths-varies-according-to-the-materials.png (79.1 KB)

open | download - Wavelength-dependence-of-the-absorption-rate-of-different-metals-13-14.jpg (34.5 KB)

open | download - LCG_AJ_Wavelength_EN.png (23.9 KB)

open | download - a-Theoretical-absorption-as-a-function-of-wavelength-for-a-range-of-common-metals.png (44.3 KB)

open | download - ss_laser-marking-central_s_m_metal_017_1924187.png (6.8 KB)

open | download - The-absorption-of-laser-output-at-different-wavelengths-varies-according-to-the-materials.png (79.1 KB)

open | download - Wavelength-dependence-of-the-absorption-rate-of-different-metals-13-14.jpg (34.5 KB)

open | download - LCG_AJ_Wavelength_EN.png (23.9 KB)

open | download - a-Theoretical-absorption-as-a-function-of-wavelength-for-a-range-of-common-metals.png (44.3 KB)

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 19, 2021 05:55AM |

Admin Registered: 16 years ago Posts: 13,884 |

... its not only sheer power, you have to look on -- it's more the availability and price per wavelength+watt and the energy-density (power per square-mm), what's limiting.

NIR-laserdiodes are common, as they are used for pumping high-power solid state lasers ... and when you look at the absorption-rates for Aluminum, then 808nm and 975nm are even better than the 1064nm from fiberlasers!

For comparison -- I've bought several NIR-laserdiodes with 975nm and 200W or 270W on a spot of 0,2mm for 300 Euros ... compare this with common UV lasers or laserdiodes ,,,

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

NIR-laserdiodes are common, as they are used for pumping high-power solid state lasers ... and when you look at the absorption-rates for Aluminum, then 808nm and 975nm are even better than the 1064nm from fiberlasers!

For comparison -- I've bought several NIR-laserdiodes with 975nm and 200W or 270W on a spot of 0,2mm for 300 Euros ... compare this with common UV lasers or laserdiodes ,,,

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 19, 2021 05:14PM |

Registered: 2 years ago Posts: 11 |

while that's true about the aluminum (and I noticed that!), blue lasers can work on copper and silver, which I consider a more important consideration. aluminum is nice, but at the scales a desktop printer would be good for, you won't get the full use of aluminum as a light structural metal. I'd prefer aluminum printing in half-meter and above sizes. As well, I'd gladly take steel's extra 4-8% sensitivity to it as well. we're definitely working at the very limits when it comes to the temps needed for steel, so everything counts. blue lasers' wavelengths was something I preferred!

I'm curious where you're getting those, though! I'm not seeing anywhere near that- closer to 500-1000 (400-800euros) for fiber laser diodes, unless it's just the raw diode array or a used 40w FAP800 from ebay for $100. please note that I'm mostly considering the prices of new hardware, as that's what I would need to use if I were to produce them in any middling amount, but if you get them in the right place, these diode banks can be cheaper new in bulk than used on ebay! I haven't seen that from a fiber laser diode, but I'm totally open to used ones for testing if you really are finding them at 100w+ for under $300

personally, I'm seeing 75w to 100w collimated 455nm diode banks for 200-300USD (165-250 euros), and if you can get them focused down, they should give NIR lasers a run for their money, especially on steel, where blue gets a 5% bonus to effective power. the issue is focusing well enough. at least they're pre-collimated into a nice square, but it's not quite what you get from a fiber laser, it's true.

I'm curious where you're getting those, though! I'm not seeing anywhere near that- closer to 500-1000 (400-800euros) for fiber laser diodes, unless it's just the raw diode array or a used 40w FAP800 from ebay for $100. please note that I'm mostly considering the prices of new hardware, as that's what I would need to use if I were to produce them in any middling amount, but if you get them in the right place, these diode banks can be cheaper new in bulk than used on ebay! I haven't seen that from a fiber laser diode, but I'm totally open to used ones for testing if you really are finding them at 100w+ for under $300

personally, I'm seeing 75w to 100w collimated 455nm diode banks for 200-300USD (165-250 euros), and if you can get them focused down, they should give NIR lasers a run for their money, especially on steel, where blue gets a 5% bonus to effective power. the issue is focusing well enough. at least they're pre-collimated into a nice square, but it's not quite what you get from a fiber laser, it's true.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 20, 2021 12:42AM |

Admin Registered: 16 years ago Posts: 13,884 |

... where did you see the collimated 445nm-laserdiode-banks with 100W output power for 300 USD? - be aware, that chinese seller give not optical output, but electric draw, what's only 1/4 optical (so a "100Watt-laser" will give 25Watts optical output -- have a diode bank with 8x 4.5Watt-diodes, summed up for 35Watts, but pretty complex beam combining to 0,3mm spot)!!

The NIR-diodes can be found with "dilas 976nm" - here some actual links:

[www.ebay.de]

[www.ebay.de]

Or here another type with "only" 130Watt output:

[www.ebay.de]

Edited 1 time(s). Last edit at 04/20/2021 12:44AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The NIR-diodes can be found with "dilas 976nm" - here some actual links:

[www.ebay.de]

[www.ebay.de]

Or here another type with "only" 130Watt output:

[www.ebay.de]

Edited 1 time(s). Last edit at 04/20/2021 12:44AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 20, 2021 07:17AM |

Registered: 2 years ago Posts: 11 |

I see! I never thought to search in other languages or for region-specific companies! note taken!

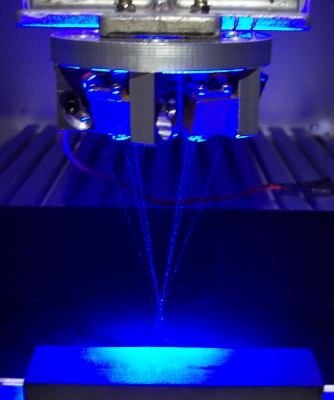

[laserpointerforums.com] is a laser pointer thread with some demonstration videos (with the always manic styropyro, king of stupid ideas and overpowered tech) but on the second page, note that a poorly focused beam was able to go through .4mm, reflective steel in 16 seconds. That steel had to have been able to spread the heat beforehand as well. These arrays I'm looking at seem to be the real deal. I'm not talking about those laser engraver modules (which I would actually prefer, no joke) that have built in fans and controllers, and are rated at the wattage of the entire module (though most pages now also quote the actual optical output if you know where to look. they all seem to only use one of 5 or 6 common diodes.)

and when I said I'd prefer the engraver modules, I was serious. These things are super dangerous, like, you generally don't want to be in the same room levels of dangerous, and containing all the radiation from it is important. intermittent reflections from the metal as it's melted could feasibly go through some materials (and certainly eyes) at this level. a fully enclosed chamber is a MINIMUM here in my opinion, preferably with a case- mounted connection that disables the laser whenever open.

all things considered, a fiber laser is probably the better option. not only is it easy to focus, but keeping the source and output separate is easy, and the print head can be even smaller than a creality cr-10s FDM printer... as well, it's an extant and common technology, meaning it's more reliable and "safer" simply because the connections are more tried and true. if only I could use one of these arrays and pass it into a fiber. but I'm pretty sure at that point the fiber itself would need a different diffraction grating, and at half the wavelength it may even be infeasible to make at any decent price... though looking here [www.civillaser.com] it's certainly been done at a "hobbyist price" (I consider anything below $5000 hobbyist accessible) but if you look, this setup only allows single diodes, while a preferred laser setup would use a number of diodes and merge them into a single collimated beam by that point... which may be possible? if that's achievable, that, I think, would be the best case scenario. it would lower the power needs for the diodes, enable copper printing, allow the use of standard galvo-heads and make temperature control a lot easier and safer. [www.youtube.com] suggests that with a good enough setup, it should be possible if the correct lenses and fibers are used.

also, I was doing some thought experiments, and the about galvo-heads- they might truly be the missing component. if you were to pass a laser over a bed of powder, of course the bead would follow the laser and grow, till friction, size, weight, cooling, etc, cause it to become unable to continue.... but if the laser moved so fast that it didn't allow anything to follow, that would be very effective at doing many small passes in order to lay down an even melted layer, by lowering the speed of the particles' melting, but also keep the melted particles from trying to spread excess heat to others and melting them in turn till it's a single sintered layer. I think you need to sinter the layer, before the full melt, or you'll likely run into beading, pooling, and spattering issues because the dust's properties will cause it to attract extra powder into the melt pool

[laserpointerforums.com] is a laser pointer thread with some demonstration videos (with the always manic styropyro, king of stupid ideas and overpowered tech) but on the second page, note that a poorly focused beam was able to go through .4mm, reflective steel in 16 seconds. That steel had to have been able to spread the heat beforehand as well. These arrays I'm looking at seem to be the real deal. I'm not talking about those laser engraver modules (which I would actually prefer, no joke) that have built in fans and controllers, and are rated at the wattage of the entire module (though most pages now also quote the actual optical output if you know where to look. they all seem to only use one of 5 or 6 common diodes.)

and when I said I'd prefer the engraver modules, I was serious. These things are super dangerous, like, you generally don't want to be in the same room levels of dangerous, and containing all the radiation from it is important. intermittent reflections from the metal as it's melted could feasibly go through some materials (and certainly eyes) at this level. a fully enclosed chamber is a MINIMUM here in my opinion, preferably with a case- mounted connection that disables the laser whenever open.

all things considered, a fiber laser is probably the better option. not only is it easy to focus, but keeping the source and output separate is easy, and the print head can be even smaller than a creality cr-10s FDM printer... as well, it's an extant and common technology, meaning it's more reliable and "safer" simply because the connections are more tried and true. if only I could use one of these arrays and pass it into a fiber. but I'm pretty sure at that point the fiber itself would need a different diffraction grating, and at half the wavelength it may even be infeasible to make at any decent price... though looking here [www.civillaser.com] it's certainly been done at a "hobbyist price" (I consider anything below $5000 hobbyist accessible) but if you look, this setup only allows single diodes, while a preferred laser setup would use a number of diodes and merge them into a single collimated beam by that point... which may be possible? if that's achievable, that, I think, would be the best case scenario. it would lower the power needs for the diodes, enable copper printing, allow the use of standard galvo-heads and make temperature control a lot easier and safer. [www.youtube.com] suggests that with a good enough setup, it should be possible if the correct lenses and fibers are used.

also, I was doing some thought experiments, and the about galvo-heads- they might truly be the missing component. if you were to pass a laser over a bed of powder, of course the bead would follow the laser and grow, till friction, size, weight, cooling, etc, cause it to become unable to continue.... but if the laser moved so fast that it didn't allow anything to follow, that would be very effective at doing many small passes in order to lay down an even melted layer, by lowering the speed of the particles' melting, but also keep the melted particles from trying to spread excess heat to others and melting them in turn till it's a single sintered layer. I think you need to sinter the layer, before the full melt, or you'll likely run into beading, pooling, and spattering issues because the dust's properties will cause it to attract extra powder into the melt pool

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 20, 2021 08:32AM |

Admin Registered: 16 years ago Posts: 13,884 |

... ah, OK -- your "high-power-445nm-lasers" are similar modules to my older 24x1W- or the newer 8x4,5W-laserbanks salvaged out from DLP-beamers.

The beam-quality is not good enough, to use them with galvos - when fokussing for more than 100mm, then expect some Millimeters beam diameter (I've got 0,3mm in 60mm FL with my 6x-heads).

So perfect comparable to the 270Watt-diodes -- but then you have 30-40Watts @445nm to 270Watts @975nm ... when counting for absorption rates, then even with the lower rate, the NIR will give much better results.

But fiber-lasers are way better than both of the diode modules -- much better fokussing (0,03mm in 200mm FL) and much, much higher energy densities too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The beam-quality is not good enough, to use them with galvos - when fokussing for more than 100mm, then expect some Millimeters beam diameter (I've got 0,3mm in 60mm FL with my 6x-heads).

So perfect comparable to the 270Watt-diodes -- but then you have 30-40Watts @445nm to 270Watts @975nm ... when counting for absorption rates, then even with the lower rate, the NIR will give much better results.

But fiber-lasers are way better than both of the diode modules -- much better fokussing (0,03mm in 200mm FL) and much, much higher energy densities too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 20, 2021 11:32PM |

Registered: 2 years ago Posts: 11 |

yeah, sorry for the confusion, but is it really not possible to couple one of those arrays with a fiber? from my new understanding, the technology is basically just lining up the output with the end of the fiber. I do imagine it would take at least two lenses, the first collimator to focus it into a second collimator, which focuses it to a much further distance, or even near-linear. The beam will hit the edges of the fiber in both cases, and the fiber itself can contain a beam even when bent, so as long as the focus is somewhere inside the fiber it should work I'd think. It would need to be a pretty massive fiber all things considered.

*does more research on laser fiber coupling*

[www.youtube.com] or [www.youtube.com] is a pretty good demonstration, and so long as you can focus the array down to the size of a collimated beam from a single diode (about a millimeter or two wide) it seems to work... I think a double clad fiber would be unavoidable, just for sheer convenience, and using a proper fiber collimator is definitely the way to go, just trying to focus it onto the fiber is liable to cause 90% or more loss in power.

I truly think you don't need more than 100W, or even 80W of optical output to melt steel dust. [www.youtube.com] This guy is simply using a single lens with one of those modules it turns out, and he's getting what I would consider too much power at .4mm focus, and moving too slow with it, even then! if I were him, I would try doing multiple passes at 100+mm/s. It looks to me like, if you got a 40W laser, and were able to focus it to .2mm, that might at least be able to sinter it together. theoretically there's no minimum power needed, just time but there's probably some kind of exponential graph that explains how heat losses overtake power before a certain point. maybe a vacuum could minimize that!

if I did my calculations right... that guy in the video is melting steel powder at an energy density of 53.1W/mm^2 at about 10mm/s, because of his about 80w laser at a square focus of .4mm, and that supposed fiber laser at 975nm would give you 38,200W/mm^2, over a much smaller area. You don't want to pump too much power into something too quickly, and he's melting into his baseplate for the first couple layers at 10-20mm/s, so you'll want to move it faster the more you exceed the material's energy requirements. I think we can assume about 1 to 1.5J is a workable theoretical standard for how much total energy is needed to melt a square millimeter of at steel powder at .1mm layer height (I used known physical values of volume, density, and enthalpy of fusion for this, and multiplied by the inefficiency of the laser- just 50% for easy calculations). This would mean, then, that he should be printing at 50mm/s... or about 10-20% below due to other energy losses, so 40mm/s. This also means that your 270W laser, if it really does have a focus of .03mm, should be able to move at about 30,000mm/s and still be able to do the same job- though I'm not sure I could find a galvo head that fast, even, and .03mm might be so small that the powder's thermodynamics produces different results. At that point it might be too focused!

but on the other hand, 50W fiber marking lasers in 1064nm exist, with pre-installed galvo-heads and working software, and laser focus of .1mm +/-.05mm. I wonder if no one has tried using them to fuse metal, seeing as they're capable of engraving solid steel blocks .3mm deep, and even cutting thinner than that. It would be pretty ironic if after all this, you just needed was a wiper assembly and some new slicing software to turn one into a $4000 DMLS printer. I think they use pulsed lasers though, which might just throw the metal dust around, but who knows? if you do it in a vacuum, it should work more easily, even.

I think the only thing 1064nm fiber lasers have going for them (at least in DMLS printing) is economies of scale. they're produced specifically for marking, which has the same laser needs as DMLS which makes them attractive, but compared to 808nm and 455nm, it's more economical to go straight to blue or NIR, because above above 30W, they all get more expensive, but blue and NIR seem to remain rather cheap(less than a week of minimum wage pay) to about 100W. blue has the advantage of being cheap as used NIR straight from the manufacturer too, which is most of my interest (along with copper printing, which would be great, and achievable at lower energy levels... man I have to stop using watts...) I was able to find a 355nm to 700nm galvo head for cheap, but it's just for DJ laser light shows, so the high power uses could likely ruin it.

808nm fiber lasers are more attractive, but I was unable to find any good galvo mirrors for that wavelength... but you probably could. I know the US has very little industrial surplus/availability compared to others, as I understand. have you actually tried using that 6x head laser on metal powder? you were right before, I think. sheer power is the wrong way to look at it- but I think pure energy density may be just an extension of that. Our first concern should probably be lowering the energy requirement to melt steel as close to theoretical values as we can, so long as it's economical. lower power diodes will always be both easier to work with, more economical, and more available.

*does more research on laser fiber coupling*

[www.youtube.com] or [www.youtube.com] is a pretty good demonstration, and so long as you can focus the array down to the size of a collimated beam from a single diode (about a millimeter or two wide) it seems to work... I think a double clad fiber would be unavoidable, just for sheer convenience, and using a proper fiber collimator is definitely the way to go, just trying to focus it onto the fiber is liable to cause 90% or more loss in power.

I truly think you don't need more than 100W, or even 80W of optical output to melt steel dust. [www.youtube.com] This guy is simply using a single lens with one of those modules it turns out, and he's getting what I would consider too much power at .4mm focus, and moving too slow with it, even then! if I were him, I would try doing multiple passes at 100+mm/s. It looks to me like, if you got a 40W laser, and were able to focus it to .2mm, that might at least be able to sinter it together. theoretically there's no minimum power needed, just time but there's probably some kind of exponential graph that explains how heat losses overtake power before a certain point. maybe a vacuum could minimize that!

if I did my calculations right... that guy in the video is melting steel powder at an energy density of 53.1W/mm^2 at about 10mm/s, because of his about 80w laser at a square focus of .4mm, and that supposed fiber laser at 975nm would give you 38,200W/mm^2, over a much smaller area. You don't want to pump too much power into something too quickly, and he's melting into his baseplate for the first couple layers at 10-20mm/s, so you'll want to move it faster the more you exceed the material's energy requirements. I think we can assume about 1 to 1.5J is a workable theoretical standard for how much total energy is needed to melt a square millimeter of at steel powder at .1mm layer height (I used known physical values of volume, density, and enthalpy of fusion for this, and multiplied by the inefficiency of the laser- just 50% for easy calculations). This would mean, then, that he should be printing at 50mm/s... or about 10-20% below due to other energy losses, so 40mm/s. This also means that your 270W laser, if it really does have a focus of .03mm, should be able to move at about 30,000mm/s and still be able to do the same job- though I'm not sure I could find a galvo head that fast, even, and .03mm might be so small that the powder's thermodynamics produces different results. At that point it might be too focused!

but on the other hand, 50W fiber marking lasers in 1064nm exist, with pre-installed galvo-heads and working software, and laser focus of .1mm +/-.05mm. I wonder if no one has tried using them to fuse metal, seeing as they're capable of engraving solid steel blocks .3mm deep, and even cutting thinner than that. It would be pretty ironic if after all this, you just needed was a wiper assembly and some new slicing software to turn one into a $4000 DMLS printer. I think they use pulsed lasers though, which might just throw the metal dust around, but who knows? if you do it in a vacuum, it should work more easily, even.

I think the only thing 1064nm fiber lasers have going for them (at least in DMLS printing) is economies of scale. they're produced specifically for marking, which has the same laser needs as DMLS which makes them attractive, but compared to 808nm and 455nm, it's more economical to go straight to blue or NIR, because above above 30W, they all get more expensive, but blue and NIR seem to remain rather cheap(less than a week of minimum wage pay) to about 100W. blue has the advantage of being cheap as used NIR straight from the manufacturer too, which is most of my interest (along with copper printing, which would be great, and achievable at lower energy levels... man I have to stop using watts...) I was able to find a 355nm to 700nm galvo head for cheap, but it's just for DJ laser light shows, so the high power uses could likely ruin it.

808nm fiber lasers are more attractive, but I was unable to find any good galvo mirrors for that wavelength... but you probably could. I know the US has very little industrial surplus/availability compared to others, as I understand. have you actually tried using that 6x head laser on metal powder? you were right before, I think. sheer power is the wrong way to look at it- but I think pure energy density may be just an extension of that. Our first concern should probably be lowering the energy requirement to melt steel as close to theoretical values as we can, so long as it's economical. lower power diodes will always be both easier to work with, more economical, and more available.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 21, 2021 01:23AM |

Admin Registered: 16 years ago Posts: 13,884 |

... the 200W@975nm diodes have a fiber-coupler with a special fiber-head and 0,2mm fiber core diameter, so maybe 0,2 to 0,3mm focus at 50mm FL (not 0,03mm!! - this is only with the fiberlasers) ... but around 1-2mm focus at 200mm FL!

When thesting with my own fibers and the 200W-diodes, then I've only got up to 100 Watts through the fiber until it burned either at the input or output.

When testing with injecting a blue 6W-diode with a 0,08mm focus into a 0,1mm fiber I've only got roughly 4W out of the fiber, so a loss of 30%!! -- here you'll need special AR-coated fibers and expect 10-20% losses anyway.

As you can't focus the combined beam of your module much smaller than 0,5mm, you'll have something like 80% of the optical energy of the module out of a 0,6mm fiber at best ... or a spot of roughly 3-4mm in 200mm FL.

Best would be to use single 0,1mm fibers for every single diode (with an awfull complex justage setup), then you can combine all the fibers to a bundle, but expect only 0,2-0,3mm best wth the "bundled" focus in 50mm FL ... or you'll need a really big focussing head and a special arrangement of the fiber-ends, to get something like 0,1mm in 50mm FL ... but too, around 0,5 to 1mm focus in 200mm FL ...

Edited 2 time(s). Last edit at 04/21/2021 01:27AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

When thesting with my own fibers and the 200W-diodes, then I've only got up to 100 Watts through the fiber until it burned either at the input or output.

When testing with injecting a blue 6W-diode with a 0,08mm focus into a 0,1mm fiber I've only got roughly 4W out of the fiber, so a loss of 30%!! -- here you'll need special AR-coated fibers and expect 10-20% losses anyway.

As you can't focus the combined beam of your module much smaller than 0,5mm, you'll have something like 80% of the optical energy of the module out of a 0,6mm fiber at best ... or a spot of roughly 3-4mm in 200mm FL.

Best would be to use single 0,1mm fibers for every single diode (with an awfull complex justage setup), then you can combine all the fibers to a bundle, but expect only 0,2-0,3mm best wth the "bundled" focus in 50mm FL ... or you'll need a really big focussing head and a special arrangement of the fiber-ends, to get something like 0,1mm in 50mm FL ... but too, around 0,5 to 1mm focus in 200mm FL ...

Edited 2 time(s). Last edit at 04/21/2021 01:27AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 21, 2021 07:22AM |

Registered: 2 years ago Posts: 11 |

huh, interesting!

I was considering some gear that had AR-coatings, but didn't know that fibers could come with them, too... these were the ones I was curious about. [www.laserglow.com] and [www.laserglow.com] (note the .5 to 1mm diameter fibers!)

as well, I was curious how this might work! [www.thorlabs.com] (the cone shaped collimator. I imagine it would result in a similarly wide output as the tiny focal length of the input.)

so, to clarify- these diodes come with a collimator grating that keeps the beams linear, so my plan was to have a large lens that focused the collimated light into another, small collimator, which would project the focused beam into a proper fiber coupling- essentially an extra set of collimators right at the beginning, to allow me to treat the beam as if it came from a single diode in the first place.

however, it may be that it's simply more efficient to use that first collimator to focus the light directly, like in that video I posted above. That will come down to whether the increase of energy density because of precision can make up for the losses (I'm expecting up to 50% loss with so much hardware, but as I said before, I think that's feasible). because of the inverse square law, if the original has 80W/mm^2 at .3mm focus, 40W/mm^2 at .22mm focus will give equivalent power, and the galvo head will give you many more choices on how to apply that power, giving more testing and production capability. it seems that even the slightest increase in precision is worth the initial loss of power.

I linked my suggested setups in the attached file.

The bundled fiber setup also sounded interesting, if more expensive- the accessories can easily become more expensive than the lasers themselves in that case, but the idea of something like the Death Star laser is interesting, and mirrors my first concept a year ago of taking a number of 7.5W diodes with focus lenses in a star shaped mount! Then I did some research and found these probably more stable ideas. This diode array is basically what you're talking about already- a specialized mount that collimates 16 to 32 weaker lasers into a single wide beam that can be focused and adjusted into a more useable one for our purpose.

like my previous post, I'd rather find a way to reduce energy needs than require extreme precision in the machine.

I think doing this in a vacuum would do well to reduce heat loss to atmosphere, but may increase heat loss to the powder and forming part itself, because there won't be air pockets to absorb heat. and the powder may become denser without them.

there's also the idea of pre-heating it, which comes with the cost of a hugely inefficient machine (basically a 1000c block of ceramic whenever it's on) and in that case you can't easily have the lasers in the same chamber.

An addendum on that... is simply to use another one of these array lasers! if left relatively unfocused, at about 1mm, to 2mm, it could pre-heat the metal around the main laser quickly!... but this method cannot be used with a galvo head, and both puts a heavy cap on the maximum speed you can run it at, and probably increases melt pool spreading.

What might you suggest in lowering the power density needed to fuse metal?

Edited 2 time(s). Last edit at 04/21/2021 07:29AM by nubnubbud.

I was considering some gear that had AR-coatings, but didn't know that fibers could come with them, too... these were the ones I was curious about. [www.laserglow.com] and [www.laserglow.com] (note the .5 to 1mm diameter fibers!)

as well, I was curious how this might work! [www.thorlabs.com] (the cone shaped collimator. I imagine it would result in a similarly wide output as the tiny focal length of the input.)

so, to clarify- these diodes come with a collimator grating that keeps the beams linear, so my plan was to have a large lens that focused the collimated light into another, small collimator, which would project the focused beam into a proper fiber coupling- essentially an extra set of collimators right at the beginning, to allow me to treat the beam as if it came from a single diode in the first place.

however, it may be that it's simply more efficient to use that first collimator to focus the light directly, like in that video I posted above. That will come down to whether the increase of energy density because of precision can make up for the losses (I'm expecting up to 50% loss with so much hardware, but as I said before, I think that's feasible). because of the inverse square law, if the original has 80W/mm^2 at .3mm focus, 40W/mm^2 at .22mm focus will give equivalent power, and the galvo head will give you many more choices on how to apply that power, giving more testing and production capability. it seems that even the slightest increase in precision is worth the initial loss of power.

I linked my suggested setups in the attached file.

The bundled fiber setup also sounded interesting, if more expensive- the accessories can easily become more expensive than the lasers themselves in that case, but the idea of something like the Death Star laser is interesting, and mirrors my first concept a year ago of taking a number of 7.5W diodes with focus lenses in a star shaped mount! Then I did some research and found these probably more stable ideas. This diode array is basically what you're talking about already- a specialized mount that collimates 16 to 32 weaker lasers into a single wide beam that can be focused and adjusted into a more useable one for our purpose.

like my previous post, I'd rather find a way to reduce energy needs than require extreme precision in the machine.

I think doing this in a vacuum would do well to reduce heat loss to atmosphere, but may increase heat loss to the powder and forming part itself, because there won't be air pockets to absorb heat. and the powder may become denser without them.

there's also the idea of pre-heating it, which comes with the cost of a hugely inefficient machine (basically a 1000c block of ceramic whenever it's on) and in that case you can't easily have the lasers in the same chamber.

An addendum on that... is simply to use another one of these array lasers! if left relatively unfocused, at about 1mm, to 2mm, it could pre-heat the metal around the main laser quickly!... but this method cannot be used with a galvo head, and both puts a heavy cap on the maximum speed you can run it at, and probably increases melt pool spreading.

What might you suggest in lowering the power density needed to fuse metal?

Edited 2 time(s). Last edit at 04/21/2021 07:29AM by nubnubbud.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 21, 2021 07:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

... forget using galvos with this diode-array-modules -- or calculate with spot diameters after the galvo of some 5 mm or more.

Even my "death-star" setup focussing 6 diodes on a spot of 0,3mm, injected into a 0,4mm fiber will result in a spot of 3 to 5mm diameter after the galvo!

Best guess would be a lightweight "direct focussing head", where you inject every diode in a separate fiber and then arrange the fiber-ends into a "death-star"-head, which is moving above the surface with 50 to 60mm FL and then maybe 0,3 to 0,4mm focus diameter ...

Edited 1 time(s). Last edit at 04/21/2021 07:39AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Even my "death-star" setup focussing 6 diodes on a spot of 0,3mm, injected into a 0,4mm fiber will result in a spot of 3 to 5mm diameter after the galvo!

Best guess would be a lightweight "direct focussing head", where you inject every diode in a separate fiber and then arrange the fiber-ends into a "death-star"-head, which is moving above the surface with 50 to 60mm FL and then maybe 0,3 to 0,4mm focus diameter ...

Edited 1 time(s). Last edit at 04/21/2021 07:39AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 21, 2021 10:35PM |

Registered: 2 years ago Posts: 11 |

I figured- the more separate lasers you have the harder they are to work with. I sorta expected that a single-focus would be the best case for those arrays, economically, but with their low price, it might still be worth experimenting to see what the various limits are. my goal, after all, is to lower the entry price for DMLS

as for setting a fiber to a number of powerful diodes, I may have an idea, though I'm not sure how viable it is. [fibertronics.com] <---these splitters also work to merge lasers when used in reverse, and even up to 1x16 splitter/combiners can be found at a much cheaper rate than the lasers themselves, which is good. The only issue is they are primarily for communications fiber optics, which may mean they are not suited for 5W+ lasers. The cheaper multimode ones should be able to hold more optical power, regardless, simply due to the properties of fiber optics itself. As well, having a number of separate diodes would make cooling much easier, and standard slot-in fiber couplers for T0-9 diodes would make replacements, construction, calibration, and reliability far higher.

These 5W diodes can be obtained from manufacturers in arrays at $4/diode, if I remove them from the array, factor in the 25$ per fiber coupling, and $10 per heatsink and chassis needed for each, add in the splitter, a 40W blue fiber laser source would cost about $500-$600... which I wouldn't do. I could just get one of those dilas modules if I'm going to go through the trouble of second hand hardware. I'm even more likely to get one of those projector pucks and try that, as that would at least tell me whether or not 72W of blue laser is overkill like I suspect.

I also looked up mirror coatings, and only a few were able to handle blue lasers well. Even then the coatings I was able to find for blue lasers were only able to handle 1Kw/cm^2 power densities, which equates to a 3.5mm beam spot on the galvo mirrors at 50W- not exactly feasible. I wonder if [optlasers.com] would work for a slower galvo head, but I somewhat doubt it at these power levels.

Edited 1 time(s). Last edit at 04/21/2021 10:36PM by nubnubbud.

as for setting a fiber to a number of powerful diodes, I may have an idea, though I'm not sure how viable it is. [fibertronics.com] <---these splitters also work to merge lasers when used in reverse, and even up to 1x16 splitter/combiners can be found at a much cheaper rate than the lasers themselves, which is good. The only issue is they are primarily for communications fiber optics, which may mean they are not suited for 5W+ lasers. The cheaper multimode ones should be able to hold more optical power, regardless, simply due to the properties of fiber optics itself. As well, having a number of separate diodes would make cooling much easier, and standard slot-in fiber couplers for T0-9 diodes would make replacements, construction, calibration, and reliability far higher.

These 5W diodes can be obtained from manufacturers in arrays at $4/diode, if I remove them from the array, factor in the 25$ per fiber coupling, and $10 per heatsink and chassis needed for each, add in the splitter, a 40W blue fiber laser source would cost about $500-$600... which I wouldn't do. I could just get one of those dilas modules if I'm going to go through the trouble of second hand hardware. I'm even more likely to get one of those projector pucks and try that, as that would at least tell me whether or not 72W of blue laser is overkill like I suspect.

I also looked up mirror coatings, and only a few were able to handle blue lasers well. Even then the coatings I was able to find for blue lasers were only able to handle 1Kw/cm^2 power densities, which equates to a 3.5mm beam spot on the galvo mirrors at 50W- not exactly feasible. I wonder if [optlasers.com] would work for a slower galvo head, but I somewhat doubt it at these power levels.

Edited 1 time(s). Last edit at 04/21/2021 10:36PM by nubnubbud.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 22, 2021 01:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

... when experimenting with one of this cheap chinese galvo-sets and a DIY-servohead (servos instead of galvos) I've managed to explode the small mirrors with a CW-fiberlaser-beam of 3mm and Power or 3-4 Watts ... then started to glue even bigger mirrors, exploded them too with slightly higher CW-powers ... ended with 45x40x5mm mirror (on the servo-head) and a beam-diameter of 16mm, but too -- cracked the heavy mirrors at roughly 20 Watts @1070nm.

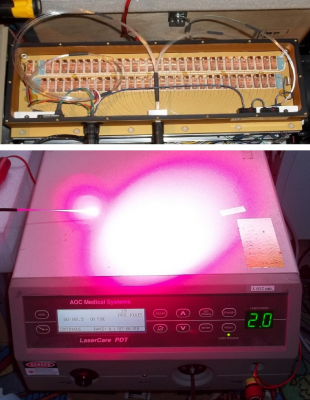

Attached some images of "multi-diode-lasers" - first a red (652nm) diode module with 60x diodes with 0,4W each, combinedt to 20Watts:

Another beamer-setup:

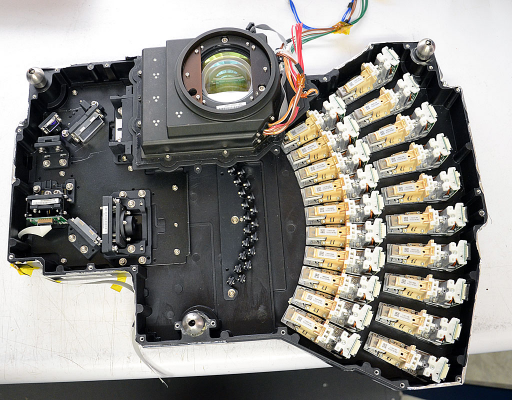

My 8x4.5W-module with a DIY-combiner:

And my "death-star"-head:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Attached some images of "multi-diode-lasers" - first a red (652nm) diode module with 60x diodes with 0,4W each, combinedt to 20Watts:

Another beamer-setup:

My 8x4.5W-module with a DIY-combiner:

And my "death-star"-head:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 23, 2021 12:41PM |

Registered: 2 years ago Posts: 11 |

...wait- YOU'RE the guy who made that thing? I'm honored to be talking to you- that's straight out of my dreams/nightmares. I'll honestly admit when I searched my concepts, your stuff was one of the top results.

so, as I thought, you need something seriously hardcore to galvo these lasers- but it has to be doable- as those cheap chinese galvos ship WITH those 50W marking systems, though admittedly 1064nm stuff is cheaper in higher quality. Perhaps pulsed lasers are easier to reflect.

Luckily, I'm up for even just moving around an entire diode array on a gantry, though those fber modules you mentioned are looking very attractive about now. I'm probably going to go for a galvo head and one of those first, just for a couple proof of concepts- one normally focused, and one with a galvo. With some metal dust and a metal plate, it should be workable for some initial tests. I think the first order of business is to establish a minimum power density needed in order to melt metal powder, and how the same density in different wavelengths affects heat transfer and efficiency. As well, I want to test various metal grain sizes, shapes, or sources if I can do it economically.

I really want to see how feasible it might be to use ground down scrap steel as well. If we can use industrial waste directly as a 3D printer material, we could drastically lower the price, I think. As well, we'd be able to figure out what energy levels would be needed for steel sand, instead of powder, which would be much easier to handle and safer to work with, and be just as good or better, economically, for many parts that don't require extreme precision. The atomized, or at least plasma processed powders are designed with spherical grains for maximum flowability, and measurable, precise flow. Because we are simply intending to cover a build plate with a wiper, we might not need those features unless we use a gravity-fed system. If, perhaps, we were using gas to blow the powder through a slit, and have it pass through a focused laser just before impacting the part, then we would require it- but as far as we know, just taking a burr grinder to some steel might produce a decent enough powder for our use. I expect at a certain minimum and maximum powder size, you will absolutely need the spherical grains for it to not clump together.

Edited 1 time(s). Last edit at 04/23/2021 12:42PM by nubnubbud.

so, as I thought, you need something seriously hardcore to galvo these lasers- but it has to be doable- as those cheap chinese galvos ship WITH those 50W marking systems, though admittedly 1064nm stuff is cheaper in higher quality. Perhaps pulsed lasers are easier to reflect.

Luckily, I'm up for even just moving around an entire diode array on a gantry, though those fber modules you mentioned are looking very attractive about now. I'm probably going to go for a galvo head and one of those first, just for a couple proof of concepts- one normally focused, and one with a galvo. With some metal dust and a metal plate, it should be workable for some initial tests. I think the first order of business is to establish a minimum power density needed in order to melt metal powder, and how the same density in different wavelengths affects heat transfer and efficiency. As well, I want to test various metal grain sizes, shapes, or sources if I can do it economically.

I really want to see how feasible it might be to use ground down scrap steel as well. If we can use industrial waste directly as a 3D printer material, we could drastically lower the price, I think. As well, we'd be able to figure out what energy levels would be needed for steel sand, instead of powder, which would be much easier to handle and safer to work with, and be just as good or better, economically, for many parts that don't require extreme precision. The atomized, or at least plasma processed powders are designed with spherical grains for maximum flowability, and measurable, precise flow. Because we are simply intending to cover a build plate with a wiper, we might not need those features unless we use a gravity-fed system. If, perhaps, we were using gas to blow the powder through a slit, and have it pass through a focused laser just before impacting the part, then we would require it- but as far as we know, just taking a burr grinder to some steel might produce a decent enough powder for our use. I expect at a certain minimum and maximum powder size, you will absolutely need the spherical grains for it to not clump together.

Edited 1 time(s). Last edit at 04/23/2021 12:42PM by nubnubbud.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 23, 2021 04:02PM |

Admin Registered: 16 years ago Posts: 13,884 |

... I've made only the 6x-"death-star" (have a bigger with 12x at home, but not assembled yet) -- the blue 8x4.5W-module made a friend, the red 60x module is salvaged out from a medicine laser, the 20x beamer setup is only a photo, I've found somewhere.

Good luck with your experiments!

Where ar you located? I have a bunch of fiber-coupled 975nm-diodes with 9Watts out of a 0,1mm-fiber, I could give you for cheap (salvaged out from exploded fiberlasers, where up to 40 of them are "pumping" the 1064nm laser resonator fiber) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Good luck with your experiments!

Where ar you located? I have a bunch of fiber-coupled 975nm-diodes with 9Watts out of a 0,1mm-fiber, I could give you for cheap (salvaged out from exploded fiberlasers, where up to 40 of them are "pumping" the 1064nm laser resonator fiber) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 25, 2021 12:54AM |

Registered: 2 years ago Posts: 11 |

I'm located in california, US, but if you want a more specific location I can PM it to you, if me being in CA isn't a deal breaker. I'd gladly take the deal if it's in any way a better price per watt than what's normally available. I've accepted that I'm not gonna test with the exact same gear that it would be produced with. If my calculations are right, just a couple to a few of those may be enough to do the job in the right configuration. I've gotten in touch with a couple people familiar with mechanical/safety interlocks for this device (I don't wanna fly hot and loose with these things, so it should only power on when in a safe configuration) and I should have the actual design fleshed out soon enough. My first 3D printer exploded on me (back in the wild west of 2015, after a company gave me the wrong directions as well as the wrong power supply for my country's mains- and I followed it blindly- dumb mistakes all around) and I found a box of off-brand arduinos and sensors in the dump behind a tech school, so I have enough parts to make everything I need except the lasers themselves- so maybe I should start building it out early. I also checked powder prices, and the metal dust isn't as expensive as it first seemed either. it's only about 3-6x the price of steel stock bars per weight, which is relatively affordable for makers, and I expect it to become much, much cheaper if metal 3d printing becomes more common, or at the very least, not exclusively an industrial process.

Edited 1 time(s). Last edit at 04/25/2021 12:56AM by nubnubbud.

Edited 1 time(s). Last edit at 04/25/2021 12:56AM by nubnubbud.

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 25, 2021 03:53AM |

Admin Registered: 16 years ago Posts: 13,884 |

... hmmm ... shipping to the US, especially laserdiodes, could be a problem

You can search at ebay for "defective CW-fiberlasers" from IPG (they are/were pretty common in the US) - this is, where all my fibercoupled 5W, 9W, 25W and 30W @975nm-laserdiodes are from (got them from a friend, which was in laser-service for a German company, repairing/binning this lasers) - in one of the older 60 to 120W-CW-fiberlaser are typically up to 40 diodes with 5W or 9Watts output power, in newer ones up to 7 diodes with 25W or 30W ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

You can search at ebay for "defective CW-fiberlasers" from IPG (they are/were pretty common in the US) - this is, where all my fibercoupled 5W, 9W, 25W and 30W @975nm-laserdiodes are from (got them from a friend, which was in laser-service for a German company, repairing/binning this lasers) - in one of the older 60 to 120W-CW-fiberlaser are typically up to 40 diodes with 5W or 9Watts output power, in newer ones up to 7 diodes with 25W or 30W ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 28, 2021 10:35AM |

Registered: 2 years ago Posts: 11 |

(ah, forgot to press post a couple days back!)

is there a particular issue you had in mind? so far as I know, the laws only relate to laser pointers and end-use products... let me see...

yeah, upon reading the entire law on it, it's pretty specific, and handled by the very first section:

(a) Applicability. The provisions of this section and § 1040.11, as amended, are applicable as specified to all laser products manufactured or assembled after August 1, 1976, except when:

(1) Such a laser product is either sold to a manufacturer of an electronic product for use as a component (or replacement) in such electronic product, or-

and it shouldn't need to go any further, seeing as I am using it as a component, and you're shipping it in a nonfunctional state. the law is meant to stop 10mW laser pointers and laser light show projectors from being untracked. if you put a certain form in there noting its class and use case, it should be even better.

so long as it's a component, it should be fine, which is how I can get those diode arrays- but there's extra safety if:

-it is a nonfunctional component, and has notes on how to "install" it and the original manufacturer's name.

-it is noted as nonfunctional if removed from the machine

-noted as for experimental testing and Research and Development

...or you could, like, call it something else it resembles, like a power coupler or transformer component for a 3D printer. and technically, you could call it a 3D printer light and not be wrong... the FDA is notoriously overworked with all these laws. depending on its shape it probably looks like a power coupler or transformer of some sort, but I wouldn't suggest it because that's realllly bad program right there and the law wouldn't like me saying I endorse that kinda thing if there was trouble XD

but if your price is over $110 USD per 50W, I have some FAP800 50W modules being sold in-state that I'm thinking of instead. benefits of such a populous area I guess, but that's all that's around. nothing higher power without a much, much higher price. or those array diodes. (hence my interest in them) still, I think it should be enough, or at least right on the edge.

also, found some new info- looks like big companies actually are beginning to make use of blue fiber lasers, and supposedly more effective for copper "and other highly reflective metals" and "quiet melt pool characteristics"? Taking it with a grain of salt, it is promotional in nature after all. not sure if it's their proprietary stuff or the wavelength that supposedly makes melt pools more stable. I'd imagine certain pulse durations would be better for melt pools.

[www.laserline.com]

is there a particular issue you had in mind? so far as I know, the laws only relate to laser pointers and end-use products... let me see...

yeah, upon reading the entire law on it, it's pretty specific, and handled by the very first section:

(a) Applicability. The provisions of this section and § 1040.11, as amended, are applicable as specified to all laser products manufactured or assembled after August 1, 1976, except when:

(1) Such a laser product is either sold to a manufacturer of an electronic product for use as a component (or replacement) in such electronic product, or-

and it shouldn't need to go any further, seeing as I am using it as a component, and you're shipping it in a nonfunctional state. the law is meant to stop 10mW laser pointers and laser light show projectors from being untracked. if you put a certain form in there noting its class and use case, it should be even better.

so long as it's a component, it should be fine, which is how I can get those diode arrays- but there's extra safety if:

-it is a nonfunctional component, and has notes on how to "install" it and the original manufacturer's name.

-it is noted as nonfunctional if removed from the machine

-noted as for experimental testing and Research and Development

...or you could, like, call it something else it resembles, like a power coupler or transformer component for a 3D printer. and technically, you could call it a 3D printer light and not be wrong... the FDA is notoriously overworked with all these laws. depending on its shape it probably looks like a power coupler or transformer of some sort, but I wouldn't suggest it because that's realllly bad program right there and the law wouldn't like me saying I endorse that kinda thing if there was trouble XD

but if your price is over $110 USD per 50W, I have some FAP800 50W modules being sold in-state that I'm thinking of instead. benefits of such a populous area I guess, but that's all that's around. nothing higher power without a much, much higher price. or those array diodes. (hence my interest in them) still, I think it should be enough, or at least right on the edge.

also, found some new info- looks like big companies actually are beginning to make use of blue fiber lasers, and supposedly more effective for copper "and other highly reflective metals" and "quiet melt pool characteristics"? Taking it with a grain of salt, it is promotional in nature after all. not sure if it's their proprietary stuff or the wavelength that supposedly makes melt pools more stable. I'd imagine certain pulse durations would be better for melt pools.

[www.laserline.com]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 28, 2021 12:25PM |

Admin Registered: 16 years ago Posts: 13,884 |

... my last experiences with shipping to US or receiving from there were nothing more than "catastrophical"!

A used book for 29$ cost me around 120€ (2x bank fee, custom, VAT) ... two parcels with laserdiodes sent to US never arrived (lost in translation) ... one parcel with IR-fluorescence nanoparticles (and an IR-laser to activate them) from an US-company was cancelled (and later exterminated) by German custom ... and some more not so harsh occasions -- in short, I don't ship or receive anymore across the pond

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

A used book for 29$ cost me around 120€ (2x bank fee, custom, VAT) ... two parcels with laserdiodes sent to US never arrived (lost in translation) ... one parcel with IR-fluorescence nanoparticles (and an IR-laser to activate them) from an US-company was cancelled (and later exterminated) by German custom ... and some more not so harsh occasions -- in short, I don't ship or receive anymore across the pond

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: lasers for DMLS, and their properties- what would we need to make one on the cheap? April 28, 2021 10:27PM |

Registered: 2 years ago Posts: 11 |

that's a shame. I mean, given the fact that they're literally non-functional parts out of a broken component, I would expect that just labelling it as broken electronics for scrapping and parts reuse would work.., and it's not a lie by any stretch- that's exactly what it is.

buuut yeah. I think getting a near-brand-new 50W from ebay is my best bet anyway. if only there were companies you could pay a commission to handle shipping nonsense for you. there's almost no system for unincorporated people to ship overseas for less than an exorbitant price, probably because there's no bulk pricing- which is a shame- like I said, the US is inundated with consumer goods for everything, but anything industrial, second hand, or surplus is nonexistant, thanks to our hyper-capitalist ways of making it cheaper to replace machines on a schedule than reuse and fix old ones. imagine how many repair and maintenance jobs there would be... but all the big companies lobby to make it so you have to buy at least replacement parts or full machines, and prove the old ones were destroyed. If you can't tell, I've got a personal stake in the on-site-fabrication revolution. "=3=

I'll look around for more deals, but a FAP800 would be ideal for a test bench, seeing as I know EXACTLY the amperage and voltage I need to feed it, and there are some controller designs floating around, with how common they are. it's a little tough, because in this space there's a company called endurance lasers who get sales of up to $800 for a 1W laser diode pushing the prices up a bit. they honestly just buy coherent and chinese lasers and resell in the US, then charge at 5x to 40x the price while adding on a warranty. I understand they're a startup, but prices like those for 3d printed enclosures and hand-soldered control boards is a bit high, especially considering it still seems to be run out of a guy's garage, by the promo videos... I would be glad there's a supplier, but their exorbitant prices are driving up the average price and perception of "a good deal" a bit.

man, I'm just on a rant today. I'm mostly just salty because I know the component prices, but no one outside of ebay is willing to sell to me without at least a 100-200% price increase. feels bad man. Oh well. I'm gonna see if I can manage one of these lasers with relative ease on ebay.

any clue where to get a driver for one? I haven't made one myself before, and having finer control would definitely help tests... but then again, I might be able to repurpose cura for controls if I'm really precise with an arduino, some transistors, fuses and mosfets.

Edited 3 time(s). Last edit at 04/28/2021 10:30PM by nubnubbud.

buuut yeah. I think getting a near-brand-new 50W from ebay is my best bet anyway. if only there were companies you could pay a commission to handle shipping nonsense for you. there's almost no system for unincorporated people to ship overseas for less than an exorbitant price, probably because there's no bulk pricing- which is a shame- like I said, the US is inundated with consumer goods for everything, but anything industrial, second hand, or surplus is nonexistant, thanks to our hyper-capitalist ways of making it cheaper to replace machines on a schedule than reuse and fix old ones. imagine how many repair and maintenance jobs there would be... but all the big companies lobby to make it so you have to buy at least replacement parts or full machines, and prove the old ones were destroyed. If you can't tell, I've got a personal stake in the on-site-fabrication revolution. "=3=

I'll look around for more deals, but a FAP800 would be ideal for a test bench, seeing as I know EXACTLY the amperage and voltage I need to feed it, and there are some controller designs floating around, with how common they are. it's a little tough, because in this space there's a company called endurance lasers who get sales of up to $800 for a 1W laser diode pushing the prices up a bit. they honestly just buy coherent and chinese lasers and resell in the US, then charge at 5x to 40x the price while adding on a warranty. I understand they're a startup, but prices like those for 3d printed enclosures and hand-soldered control boards is a bit high, especially considering it still seems to be run out of a guy's garage, by the promo videos... I would be glad there's a supplier, but their exorbitant prices are driving up the average price and perception of "a good deal" a bit.

man, I'm just on a rant today. I'm mostly just salty because I know the component prices, but no one outside of ebay is willing to sell to me without at least a 100-200% price increase. feels bad man. Oh well. I'm gonna see if I can manage one of these lasers with relative ease on ebay.

any clue where to get a driver for one? I haven't made one myself before, and having finer control would definitely help tests... but then again, I might be able to repurpose cura for controls if I'm really precise with an arduino, some transistors, fuses and mosfets.

Edited 3 time(s). Last edit at 04/28/2021 10:30PM by nubnubbud.

|