About that nasty ridge/seam, or: How dwindle changed my life

Posted by ahmetcemturan

About that nasty ridge/seam, or: How dwindle changed my life  October 17, 2012 04:18AM |

Registered: 13 years ago Posts: 202 |

Hi all,

I just wanted to write an informative piece about teh awesome dwindle feature in Skeinforge (and obviously latest SFACT)

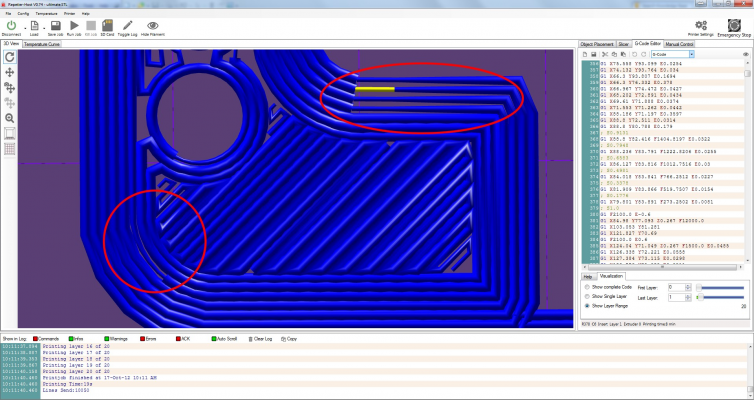

Thats what dwindle does (Repetier host screenshot):

It reduces the flow of filament before an upcoming travel move so the pressure is reduced and flow can be cut off precisely at the end of the line before the travel move.

The different settings work as follows: (Enrique correct me if I am wrong..)

End Rate Multiplier will let your printing speed slow down before the end of the line. I am not using this option as I like to print really fast and this would slow the prints down. Actually if You have set your Slowdown volume correct it is not necessary to slow down. Or if You slow down then You can leave the Slowdown volume almost 0 as the deceleratioon will allow the pressure to go down..

So its a matter of preference.. A similar effect can be achieved by setting a very low acceleration value for E in the firmware or by Gcode.

(syntax: e.g. M201 E50) that will definitely slow down Your prints but You will also get rid of Your bumpy corners... (For fix of bumpy corners alone set your XY jerk in firmware higher...)

The Pent up volume is next in the configuration but should logically be last in line.. (As it is being used last in the process... Slowdown whil reducing flowrate using x-steps, make the travel move and then pent up that last bit of plastic that escaped/vanished )

)

Here You set the amount that is missing at the start of your print. So if extruder is extruding air at the start of the print then You need to set this to a value.. ( Start with a real low value like 0.1 or so) I have 0.05

Slowdown steps is the "resolution of your slowdown. If you have problems with communication of Printer/PC then set this to a low value like 2-3, If you have hassle free communication and Your printer is not prone to G-code starvation then set it higher.

And the Star of this page the Slowdown Volume:

I am visualising it like this: This is the amount of filament that squirts out of the nozzle when you are extruding, then stop extruding an wipe off the nozzle instantly.. There will be some filament coming out at almost the rate of extrusion. Either measure or calculate: half Diameter ^2*pi * length . Do not measure the part that is getting thinner as this is not caused by pressure but by oozing.. (Oozing You prevent with retraction... )

That should work now...

Ahh well: It is safe to disable Clip now (I have jitter enabled and set to 3)

(I have jitter enabled and set to 3)

Feedback please....

And please use the most up to date version of SFACT from github ...

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

I just wanted to write an informative piece about teh awesome dwindle feature in Skeinforge (and obviously latest SFACT)

Thats what dwindle does (Repetier host screenshot):

It reduces the flow of filament before an upcoming travel move so the pressure is reduced and flow can be cut off precisely at the end of the line before the travel move.

The different settings work as follows: (Enrique correct me if I am wrong..)

End Rate Multiplier will let your printing speed slow down before the end of the line. I am not using this option as I like to print really fast and this would slow the prints down. Actually if You have set your Slowdown volume correct it is not necessary to slow down. Or if You slow down then You can leave the Slowdown volume almost 0 as the deceleratioon will allow the pressure to go down..

So its a matter of preference.. A similar effect can be achieved by setting a very low acceleration value for E in the firmware or by Gcode.

(syntax: e.g. M201 E50) that will definitely slow down Your prints but You will also get rid of Your bumpy corners... (For fix of bumpy corners alone set your XY jerk in firmware higher...)

The Pent up volume is next in the configuration but should logically be last in line.. (As it is being used last in the process... Slowdown whil reducing flowrate using x-steps, make the travel move and then pent up that last bit of plastic that escaped/vanished

)

)Here You set the amount that is missing at the start of your print. So if extruder is extruding air at the start of the print then You need to set this to a value.. ( Start with a real low value like 0.1 or so) I have 0.05

Slowdown steps is the "resolution of your slowdown. If you have problems with communication of Printer/PC then set this to a low value like 2-3, If you have hassle free communication and Your printer is not prone to G-code starvation then set it higher.

And the Star of this page the Slowdown Volume:

I am visualising it like this: This is the amount of filament that squirts out of the nozzle when you are extruding, then stop extruding an wipe off the nozzle instantly.. There will be some filament coming out at almost the rate of extrusion. Either measure or calculate: half Diameter ^2*pi * length . Do not measure the part that is getting thinner as this is not caused by pressure but by oozing.. (Oozing You prevent with retraction... )

That should work now...

Ahh well: It is safe to disable Clip now

(I have jitter enabled and set to 3)

(I have jitter enabled and set to 3)Feedback please....

And please use the most up to date version of SFACT from github ...

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 18, 2012 09:53AM |

Registered: 11 years ago Posts: 1,320 |

I'm not sure that I fully agree with your definitions of these parameters.

My take on it is this:

The end rate multiplier is the slowdown factor as the head reaches the end of a thread. The default value of 0.5 means that is printing the end of the thread (and only the end of the thread) at half speed. Your value of 1 means no slowdown at all - which is fine, but according to my interpretation, a value of 1 will mean the final two parameters below are meaningless.

Pent up volume is what you describe as slowdown volume. It is the volume of plastic that is in the extruder under pressure after extrusion is stopped. This is the volume we are trying to get rid of. Your measurement technique would apply here.

Slowdown steps has nothing to do with communications stability or speed. This is the number of discrete steps that the logic uses to slow things down. If you set this to 1, it will go from full speed to the slow speed all at once. If you set it to 2, you will slow down halfway for a bit and then slow down the remaining amount, and so on. Too many steps could increase the gcode size dramatically.

Slowdown volume is the total amount of plastic you want to extrude over the slowdown period. The way I see it, this value has to AT LEAST equal the pent-up volume. If it is less than the pent up volume, this means the extruder will be switched off prior to the slowdown so that some of the pent up volume will be released before the slowdown period. I would think that you want this parameter to be about twice the pent up volume so that the pent up plastic is only extruded in the slowdown area.

I tried your settings of 1/0.05/5/2.0 last night and it made absolutely no difference in my print. Tonight I am going to retry using the above logic and the following values:

end rate multiplier - the default of 0.5

pent-up volume - calculated as per the first post

slowdown steps - the default value of 3

slowdown volume - twice the pent-up volume

and I'll go from there. I'll post my results.

My take on it is this:

The end rate multiplier is the slowdown factor as the head reaches the end of a thread. The default value of 0.5 means that is printing the end of the thread (and only the end of the thread) at half speed. Your value of 1 means no slowdown at all - which is fine, but according to my interpretation, a value of 1 will mean the final two parameters below are meaningless.

Pent up volume is what you describe as slowdown volume. It is the volume of plastic that is in the extruder under pressure after extrusion is stopped. This is the volume we are trying to get rid of. Your measurement technique would apply here.

Slowdown steps has nothing to do with communications stability or speed. This is the number of discrete steps that the logic uses to slow things down. If you set this to 1, it will go from full speed to the slow speed all at once. If you set it to 2, you will slow down halfway for a bit and then slow down the remaining amount, and so on. Too many steps could increase the gcode size dramatically.

Slowdown volume is the total amount of plastic you want to extrude over the slowdown period. The way I see it, this value has to AT LEAST equal the pent-up volume. If it is less than the pent up volume, this means the extruder will be switched off prior to the slowdown so that some of the pent up volume will be released before the slowdown period. I would think that you want this parameter to be about twice the pent up volume so that the pent up plastic is only extruded in the slowdown area.

I tried your settings of 1/0.05/5/2.0 last night and it made absolutely no difference in my print. Tonight I am going to retry using the above logic and the following values:

end rate multiplier - the default of 0.5

pent-up volume - calculated as per the first post

slowdown steps - the default value of 3

slowdown volume - twice the pent-up volume

and I'll go from there. I'll post my results.

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 18, 2012 10:23AM |

Registered: 13 years ago Posts: 202 |

jbernardis: thanks for the feedback, You have your points in Your answer and its great that You will experiment... Not many ppl willing in experimenting..

It is maybe because I really print at high speeds most of the time, so the chopping up of the Gcode segment maybe slows down the print and that helps... I will report back anyway..

Are You using SF or SFACT?

Edited 1 time(s). Last edit at 10/18/2012 10:29AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

It is maybe because I really print at high speeds most of the time, so the chopping up of the Gcode segment maybe slows down the print and that helps... I will report back anyway..

Are You using SF or SFACT?

Edited 1 time(s). Last edit at 10/18/2012 10:29AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 18, 2012 12:08PM |

Registered: 11 years ago Posts: 1,320 |

For now I'm using SF. For the longest time, I didn't know that SFACT was different from SF - I thought it was just an alternate name for the same thing. I downloaded the latest SFACT and have started looking at it. I just haven't adopted it yet. I like your ability to iteratively calibrate the extrusion factors. I've done the standard calibration with measuring the amount of filament being pulled into the extruder, but I'm not convinced that it's accurate enough. I've been searching for a better way to do it, and maybe SFACT provides that answer.

I don't mind experimenting with this at all. That's the beauty of these forums. We solve each others problems.

I don't mind experimenting with this at all. That's the beauty of these forums. We solve each others problems.

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 18, 2012 10:34PM |

Registered: 11 years ago Posts: 1,320 |

I did some experimentation with this tonight. First, let's look at the original print:

I tried to use jitter with a value of 20 to hide these blobs in randomness. Obviously it didn't work. So based on the above discussion, I tried dwindle to see what would happen. I originally tried the values I suggested above, but I was a little aggressive in terms of calculating the volumes, and I found that the end rate multiple of 0.5 resulted in too much slow down. I ended up with parameter settings of 0.8/0.25/3/0.5, and the result was this:

So the blobs are gone, but now I have holes. Actually if you look at the original image, you can see that the holes are there too right beside each blob. So it seemed like dwindle was helping. So now my strategy switched to trying to get rid of the holes. So I turned jitter off completely and I'm pleased with the results:

It's hard to see in the picture, but there are still holes in there, but they are MUCH smaller than before.

So thanks for pointing me in the direction of dwindle!

I tried to use jitter with a value of 20 to hide these blobs in randomness. Obviously it didn't work. So based on the above discussion, I tried dwindle to see what would happen. I originally tried the values I suggested above, but I was a little aggressive in terms of calculating the volumes, and I found that the end rate multiple of 0.5 resulted in too much slow down. I ended up with parameter settings of 0.8/0.25/3/0.5, and the result was this:

So the blobs are gone, but now I have holes. Actually if you look at the original image, you can see that the holes are there too right beside each blob. So it seemed like dwindle was helping. So now my strategy switched to trying to get rid of the holes. So I turned jitter off completely and I'm pleased with the results:

It's hard to see in the picture, but there are still holes in there, but they are MUCH smaller than before.

So thanks for pointing me in the direction of dwindle!

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 19, 2012 05:27AM |

Registered: 13 years ago Posts: 202 |

I updated SFACT to ignore the feedrate slowdown.. That should work better now..

So the value entered will only reflect in the volume reduction of the flowrate..

Edited 1 time(s). Last edit at 10/19/2012 05:28AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

So the value entered will only reflect in the volume reduction of the flowrate..

Edited 1 time(s). Last edit at 10/19/2012 05:28AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 23, 2012 03:12AM |

Registered: 11 years ago Posts: 29 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 23, 2012 03:31AM |

Registered: 13 years ago Posts: 202 |

acc, turn clip off entirely with dwindle...

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 23, 2012 05:00AM |

Registered: 11 years ago Posts: 29 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 27, 2012 01:53AM |

Registered: 11 years ago Posts: 1,320 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  October 29, 2012 05:48AM |

Registered: 11 years ago Posts: 29 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  November 02, 2012 10:56PM |

Registered: 11 years ago Posts: 1,320 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  November 09, 2012 01:17AM |

Registered: 11 years ago Posts: 29 |

Hi guys!

This plugin is awesome Tried it yesterday with 0.2mm layer. I really really enjoy the sound of motors slowing down before moving to another island

Tried it yesterday with 0.2mm layer. I really really enjoy the sound of motors slowing down before moving to another island  It's also great to turn CLIP off

It's also great to turn CLIP off  AND, one more thing you didn't mention - we can lower retraction distance! There's much lower pressure, so no need to rectract so much. I used 1mm previously, now tried 0.6mm with success, will try to lower it more. Maybe it will be safe to turn it off totally?

AND, one more thing you didn't mention - we can lower retraction distance! There's much lower pressure, so no need to rectract so much. I used 1mm previously, now tried 0.6mm with success, will try to lower it more. Maybe it will be safe to turn it off totally?

However I have still one more question - the holes which are visible at last jbernardis' photo. I had them in lower-left corner. It's a matter of the layer-starting-point I believe. I have 'lower left', while jbernardis has 'nearest' I think, am I right?

Anyway - how to avoid them? Maybe it has something in common with shells? I use 0 extra shells. Maybe I should try different layer sequence, right now I have perimeters/loops/infill.

Edited 1 time(s). Last edit at 11/09/2012 01:46AM by acc.

This plugin is awesome

Tried it yesterday with 0.2mm layer. I really really enjoy the sound of motors slowing down before moving to another island

Tried it yesterday with 0.2mm layer. I really really enjoy the sound of motors slowing down before moving to another island  It's also great to turn CLIP off

It's also great to turn CLIP off  AND, one more thing you didn't mention - we can lower retraction distance! There's much lower pressure, so no need to rectract so much. I used 1mm previously, now tried 0.6mm with success, will try to lower it more. Maybe it will be safe to turn it off totally?

AND, one more thing you didn't mention - we can lower retraction distance! There's much lower pressure, so no need to rectract so much. I used 1mm previously, now tried 0.6mm with success, will try to lower it more. Maybe it will be safe to turn it off totally?However I have still one more question - the holes which are visible at last jbernardis' photo. I had them in lower-left corner. It's a matter of the layer-starting-point I believe. I have 'lower left', while jbernardis has 'nearest' I think, am I right?

Anyway - how to avoid them? Maybe it has something in common with shells? I use 0 extra shells. Maybe I should try different layer sequence, right now I have perimeters/loops/infill.

Edited 1 time(s). Last edit at 11/09/2012 01:46AM by acc.

Re: About that nasty ridge/seam, or: How dwindle changed my life  November 09, 2012 06:03AM |

Admin Registered: 12 years ago Posts: 2,569 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  November 09, 2012 06:12AM |

Registered: 11 years ago Posts: 29 |

Re: About that nasty ridge/seam, or: How dwindle changed my life  November 09, 2012 08:08AM |

Admin Registered: 12 years ago Posts: 2,569 |

Yeah loops are all the inner shells, perimeter is the single outside one.

When you add extra shells, you actually add loops, they add inside the object (otherwise it would grow).

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

When you add extra shells, you actually add loops, they add inside the object (otherwise it would grow).

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Sorry, only registered users may post in this forum.