Skeinforge settings

Posted by Enrique

|

Re: Skeinforge settings May 17, 2011 09:52AM |

Registered: 13 years ago Posts: 113 |

Hi Grogyan

From SF40 onwards it requires a change to your firmware. You need to recalculate the E-STEPS-PER-MM value to represent the steps required to push 1mm of filament into the extruder (as opposed to steps required to push 1mm out of the extruder). For details of how to do this see this post:

[forums.reprap.org]

You will also need to set flow rate and feed rate to the same value with SF40+.

I have attached some of my skeinforge settings. The most recent dates are my current settings I use. Also included is my archival and retrieval tool for Skeinforge. Look at my blog for details of how to use it.

Regards,

James

--

Check out my blog: AdventuresIn3-DPrinting

From SF40 onwards it requires a change to your firmware. You need to recalculate the E-STEPS-PER-MM value to represent the steps required to push 1mm of filament into the extruder (as opposed to steps required to push 1mm out of the extruder). For details of how to do this see this post:

[forums.reprap.org]

You will also need to set flow rate and feed rate to the same value with SF40+.

I have attached some of my skeinforge settings. The most recent dates are my current settings I use. Also included is my archival and retrieval tool for Skeinforge. Look at my blog for details of how to use it.

Regards,

James

--

Check out my blog: AdventuresIn3-DPrinting

|

Re: Skeinforge settings May 29, 2011 03:12PM |

Registered: 12 years ago Posts: 24 |

I have a reprap prusa mendel with wade extruder ... fairly wide nozzle and I'm extruding 3mm translucent pla. It seemed every one else's settings didn't put out enough material and the parts looked horrible. This might be too much, but it's a start anyhow!

|

Re: Skeinforge settings May 29, 2011 03:23PM |

Registered: 13 years ago Posts: 2,947 |

@unexpectedly

Looking at your Speed settings make me think you have your E_steps_per_mm set wrong.

I run my machine with skeinforges feedrate and flowrate equal but it does require having the E_steps_per_mm set perfectly.

So instead of changing the flow rate in skeinforge to get it right change the E_steps_per_mm in the firmware until you have it correct.

Looking at your Speed settings make me think you have your E_steps_per_mm set wrong.

I run my machine with skeinforges feedrate and flowrate equal but it does require having the E_steps_per_mm set perfectly.

So instead of changing the flow rate in skeinforge to get it right change the E_steps_per_mm in the firmware until you have it correct.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Skeinforge settings May 30, 2011 07:40PM |

Registered: 12 years ago Posts: 24 |

@subline : Thanks for your help. This is a setting I wasn't yet aware of... Once I'm done with the project I'm printing at the moment, I'll work on the settings so I have things set up properly. And also share this info with the guy helping me so he'll know where we both went wrong.

Thanks!

Chris

Thanks!

Chris

|

Re: Skeinforge settings May 30, 2011 08:45PM |

Registered: 14 years ago Posts: 458 |

|

Re: Skeinforge settings May 30, 2011 08:47PM |

Registered: 13 years ago Posts: 2,947 |

@unexpectedly

It looks like you have your setting off by about 30 times. So start by dividing your E_steps_per_mm by 30.

Are you using Inches in your models and/or Skeinforge by any chance?

It looks like you have your setting off by about 30 times. So start by dividing your E_steps_per_mm by 30.

Are you using Inches in your models and/or Skeinforge by any chance?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Skeinforge settings May 30, 2011 08:56PM |

Registered: 13 years ago Posts: 2,947 |

@ unexpectedly

Actually now that I read back a bit I see that some of you are using SF40 which uses feed stock input vs. extruded length output for 39 and earlier. Which could be the cause for your issue in the first place. A circle of 3mm has a surface area of 7.069 which is 29.702 times larger than than 0.238 which is the surface area of a 0.55mm circle. Sounds awfully close to the 500 extrude rate over 16 feedrate that you're using. Which works out to 31.25 faster extrude than feed.

Actually now that I read back a bit I see that some of you are using SF40 which uses feed stock input vs. extruded length output for 39 and earlier. Which could be the cause for your issue in the first place. A circle of 3mm has a surface area of 7.069 which is 29.702 times larger than than 0.238 which is the surface area of a 0.55mm circle. Sounds awfully close to the 500 extrude rate over 16 feedrate that you're using. Which works out to 31.25 faster extrude than feed.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Skeinforge settings June 29, 2011 09:58AM |

Registered: 13 years ago Posts: 202 |

|

Re: Skeinforge settings June 29, 2011 04:04PM |

Registered: 14 years ago Posts: 458 |

|

Re: Skeinforge settings November 07, 2011 09:38AM |

Registered: 13 years ago Posts: 615 |

Months ago, theses two topic helped me a lot to get started with skeinforge :

Setting up Skeinforge for the first time

Skeinforge 40 setup notes

and just in case that can be useful to someone (even if a profile is quite machine-specific), I putted all my settings in a google spreadhseet :

[docs.google.com];

Setting up Skeinforge for the first time

Skeinforge 40 setup notes

and just in case that can be useful to someone (even if a profile is quite machine-specific), I putted all my settings in a google spreadhseet :

[docs.google.com];

|

Re: Skeinforge settings January 07, 2012 05:38PM |

Registered: 12 years ago Posts: 36 |

Can someone please tell me which setting in skeinforge determines the initial travel speed of the print head? i.e. when I start a print, the print head just crawls to the start position determined by 'multiple' at, in my case, 60mm/min when I would like it to make the movement at a speed of at least 760mm/min. The rest of the print goes at a reasonable speed of about 1300mm/min.

Prusa Mendel running Marlin firmware, Pronterface and latest Skeinforge, printing PLA.

Thanks, Ian

Prusa Mendel running Marlin firmware, Pronterface and latest Skeinforge, printing PLA.

Thanks, Ian

|

Re: Skeinforge settings January 09, 2012 10:46AM |

Registered: 13 years ago Posts: 113 |

Check the limit plug-in. Skeinforge may be trying to limit the speed of a largish move incorrectly.

JB

--

Check out my blog: AdventuresIn3-DPrinting

JB

--

Check out my blog: AdventuresIn3-DPrinting

|

Re: Skeinforge settings January 10, 2012 07:18AM |

Registered: 12 years ago Posts: 36 |

|

Re: Skeinforge settings March 05, 2012 03:48PM |

Registered: 12 years ago Posts: 62 |

|

Re: Skeinforge settings March 06, 2012 12:19AM |

Registered: 14 years ago Posts: 458 |

I don't have a Prusa, mine is quite old, but the settings I use seem to give adequate results.

I use SkeinForge 49

Alteration

- Activate Alteration Yes

- Remove Redundant M Code Yes

- Replace Variable with Setting Yes

Bottom

- Activate Bottom No

- Additional height over Layer Thickness 0.5

- Altitude 0.1

Carve

- Add Layer Template to SVG Yes

- Edge Width over Height 1.4

- Extra Decimal Places 2.0

- Import Coarseness 1.0

- Layer Height 0.4

- Layers From 0

- Layers to 912345678

- Correct Mesh Yes

Chamber

- Activate Chamber No

- Bed Temp 20

- Bed Temp Begin -1

- Bed Temp End -1

- Bed Temp 20.0

- Chamber Temp 30

- Holding Force 0.0

Clip

- Activate Clip Yes

- Clip Over Perimeter Ratio 0.15

- Maximum Connection Distance Over Perimeter 10.0

Comb

- Activate Comb Yes

- Running Jump Space 2.0

Cool

- Activate Cool No

- Bridge Cool 1.0

- Cool Type Orbit

- Max Cool 2.0

- Min Layer time 5.0

- Min Orbit Radius 10.0

- Orbital Outset 2.0

- Turn Fan On at Beginning No

- Turn Fan Off at Ending No

Dimension

- Activate Dimension Yes

- Absolute Extrusion Distance Yes

- Extruder Retraction Speed 20.0

- Filament Diameter 2.85 (measure your own filament!)

- Filament Packing Density 0.85

- Maximum E Value before Reset 91234

- Minimum Travel for Retraction 1.0

- Retract within Island No

- Retraction Distance 1.0

- Restart Extra Distance 0.0

Dwindle

- Activate Dwindle No

- End Rate Multiplier 0.5

- Pent up Volume 0.4

- Slowdown Steps 3

- Slowdown Volume 2.0

Export

- Activate Export Yes

- Add Descriptive Extension No

- Add Export Suffix No

- Add Profile Extension No

- Add Timestamp Extension Yes (I use this for experimenting with different settings)

- Analyze GCode Yes

- Delete All Comments Yes

- Do Not Change Output Yes

- Save Penultimate GCode No

Fill

- Activate Fill Yes

- Diapragm Period 100

- Diapragm Thickness 0

- Extra Shells On Alternating Layer 0 (Extra Shells are good for printing things like Gears)

- Extra Shells on Base 0

- Extra Shells on Sparse Layer 0

- Grid Circle Seperation over Perimeter Width 0.2

- Grid Extra Overlap 0.1

- Grid Junction Band Height 10

- Grid Junction Separation over Octogon Radius End 0.0

- Grid Junction Separation over Octogon Radius Mid 0.0

- Infill Begin Rotation 45

- Infill Begin Rotation Repeat 1

- Infill Odd Layer Extra Rotation 90

- Infill Pattern -> Line Yes

- Infill Perimeter Overlap Ratio 0.0

- Infill Solidity 0.35

- Infill Width over Thickness 1.4

- Solid Surface Thickness Layers 3

- Start From Choice Lower Left

- Surrounding Angle 60.0

- Thread Sequence Choice Loops > Perimeter > Infill

Fillet

- Activate Fillet No

- Bevel Yes

- Corner Feed Rate Multiplier 1.0

- Fillet Radius over Perimeter Width 0.35

- Reversal slowdown Distance over Perimeter Width 0.5

- Use Intermediate Feed Rate in Corners Yes

Home

- Activate Home Yes

Hop

- Activate Hop No

- Hop over Layer Thickness 1.0

- Minimum Hop Angle 30

Inset

- Add Custom Code for Temperature Reading Yes

- Infill in Direction of Bridge Yes

- Infill Width over Thickness 1.4

- Loop Order Choice Ascending Area

- Overlap Removal Width over Perimeter Width 0.6

- Turn Extruder Heater off at Shut Down Yes

- Volume Fraction 0.82

Jitter

- Activate Jitter Yes

- Jitter over Perimeter Width 2.0

Lash

- Activate Lash No

- X Backlash 0.2

- Y Backlash 0.3

Limit

- Activate Limit Yes

- Maximum Initial Feed Rate 30.0 (This moves the nozzle from Home to print start speed)

Multiply

- Activate Multiply Yes

- Center X 100.0

- Center Y 100.0

- Number of Columns 1

- Number of Rows 1

- Reverse Sequence every Odd Layer No

- Separation over Perimeter Width 15.0

Oozebane ( I don't use, leave with defaults)

- Activate Oozebane No

Preface

- Set Positioning to Absolute Yes

- Set Units to Millimeters Yes

- Start at Home Yes

- Turn Extruder Off at Shut Down No

- Turn Extruder Off at Start Up No

Raft

- Activate Raft Yes

- Add Raft, Elevate Nozzle, Orbit No

(Someone else will have to give you Raft Settings, as I don't use a Raft)

Scale

- Activate Scale No

- XY Plane Scale 1.0

- Z Axis Plane Scale 1.0

Skin (New feature, I don't use)

- Activate Skin No

Skirt

- Activate Skirt Yes

- Convex Yes

- Gap over Perimeter Width 3.0

- Layers to 1

Smooth

- Activate Smooth No

- Layers From 1

- Maximum Shortening over Width 2.0

Speed (work with Temperature to find what works best for you)

- Activate Speed Yes

- Add Flow Rate Yes

- Bridge Feed Rate Multiplier 1.0

- Bridge Flow Rate Multiplier 1.0

- Duty Cycle at Beginning 1.0

- Duty Cycle at Ending 0.0

- Feed Rate (Speed at which the nozzle moves) 30.0

- Flow Rate (Speed at which the extruder turns ratio) 27.0 (For ABS this may be 30.0 I think)

- Object First Layer Feed Rate Infill Multiplier 0.6

- Object First Layer Feed Rate Perimeter Multiplier 0.6

- Object First Layer Flow Rate Infill Multiplier 0.6

- Object First Layer Flow Rate Perimeter Multiplier 0.6

- Orbital Feed Rate over Operating Feed Rate 1.0

- Maximum Z Feed Rate 1.0

- Perimeter Feed Rate Multiplier 1.0

- Perimeter Flow Rate Multiplier 1.0

- Travel Feed Rate (When not Extruding) 30.0

Splodge (I don't use)

- Activate Splodge No

Stretch

- Activate Stretch Yes

- Cross Limit Distance over Perimeter Width 5.0

- Loop Stretch over Perimeter Width 0.11

- Path Stretch over Perimeter Width 0.0

- Perimeter Inside Stretch over Perimeter Width 0.2

- Perimeter Outside Stretch over Perimeter Width 0.1

- Stretch from Distance over Perimeter Width 1.0

Temperature (I don't know what temps to start out with for ABS)

- Activate Temperature Yes

- Cooling Rate 3.0

- Heating Rate 10.0

Temps I use here are 165 degrees for PLA

Tower

- Activate Tower No

- Extruder Possible Collision Cone Angle 60.0

- Maximum Tower Height 5

- Tower Start Layer 1

Unpause

- Activate Unpause No

- Delay 28.0

- Maximum Speed 1.3

Widen

- Activate Widen No

Wipe (Not used)

- Activate Wipe No

Analyze settings

Clairvoyance

- Activate Clairvoyance No

Comment

- Activate Comment No

Interpret

- Activate Interpret No

- Print Interpretation No

Skeiniso

- Activate Skeniso No

Skeinlayer

- Activate Skein Layer Yes

(Use Defaults)

Statistic

- Activate Statistic Yes

Use your settings for machine time anf Material cost

- Print Statistics No

- Save Statistics Yes (Produces a text file about the print)

I use SkeinForge 49

Alteration

- Activate Alteration Yes

- Remove Redundant M Code Yes

- Replace Variable with Setting Yes

Bottom

- Activate Bottom No

- Additional height over Layer Thickness 0.5

- Altitude 0.1

Carve

- Add Layer Template to SVG Yes

- Edge Width over Height 1.4

- Extra Decimal Places 2.0

- Import Coarseness 1.0

- Layer Height 0.4

- Layers From 0

- Layers to 912345678

- Correct Mesh Yes

Chamber

- Activate Chamber No

- Bed Temp 20

- Bed Temp Begin -1

- Bed Temp End -1

- Bed Temp 20.0

- Chamber Temp 30

- Holding Force 0.0

Clip

- Activate Clip Yes

- Clip Over Perimeter Ratio 0.15

- Maximum Connection Distance Over Perimeter 10.0

Comb

- Activate Comb Yes

- Running Jump Space 2.0

Cool

- Activate Cool No

- Bridge Cool 1.0

- Cool Type Orbit

- Max Cool 2.0

- Min Layer time 5.0

- Min Orbit Radius 10.0

- Orbital Outset 2.0

- Turn Fan On at Beginning No

- Turn Fan Off at Ending No

Dimension

- Activate Dimension Yes

- Absolute Extrusion Distance Yes

- Extruder Retraction Speed 20.0

- Filament Diameter 2.85 (measure your own filament!)

- Filament Packing Density 0.85

- Maximum E Value before Reset 91234

- Minimum Travel for Retraction 1.0

- Retract within Island No

- Retraction Distance 1.0

- Restart Extra Distance 0.0

Dwindle

- Activate Dwindle No

- End Rate Multiplier 0.5

- Pent up Volume 0.4

- Slowdown Steps 3

- Slowdown Volume 2.0

Export

- Activate Export Yes

- Add Descriptive Extension No

- Add Export Suffix No

- Add Profile Extension No

- Add Timestamp Extension Yes (I use this for experimenting with different settings)

- Analyze GCode Yes

- Delete All Comments Yes

- Do Not Change Output Yes

- Save Penultimate GCode No

Fill

- Activate Fill Yes

- Diapragm Period 100

- Diapragm Thickness 0

- Extra Shells On Alternating Layer 0 (Extra Shells are good for printing things like Gears)

- Extra Shells on Base 0

- Extra Shells on Sparse Layer 0

- Grid Circle Seperation over Perimeter Width 0.2

- Grid Extra Overlap 0.1

- Grid Junction Band Height 10

- Grid Junction Separation over Octogon Radius End 0.0

- Grid Junction Separation over Octogon Radius Mid 0.0

- Infill Begin Rotation 45

- Infill Begin Rotation Repeat 1

- Infill Odd Layer Extra Rotation 90

- Infill Pattern -> Line Yes

- Infill Perimeter Overlap Ratio 0.0

- Infill Solidity 0.35

- Infill Width over Thickness 1.4

- Solid Surface Thickness Layers 3

- Start From Choice Lower Left

- Surrounding Angle 60.0

- Thread Sequence Choice Loops > Perimeter > Infill

Fillet

- Activate Fillet No

- Bevel Yes

- Corner Feed Rate Multiplier 1.0

- Fillet Radius over Perimeter Width 0.35

- Reversal slowdown Distance over Perimeter Width 0.5

- Use Intermediate Feed Rate in Corners Yes

Home

- Activate Home Yes

Hop

- Activate Hop No

- Hop over Layer Thickness 1.0

- Minimum Hop Angle 30

Inset

- Add Custom Code for Temperature Reading Yes

- Infill in Direction of Bridge Yes

- Infill Width over Thickness 1.4

- Loop Order Choice Ascending Area

- Overlap Removal Width over Perimeter Width 0.6

- Turn Extruder Heater off at Shut Down Yes

- Volume Fraction 0.82

Jitter

- Activate Jitter Yes

- Jitter over Perimeter Width 2.0

Lash

- Activate Lash No

- X Backlash 0.2

- Y Backlash 0.3

Limit

- Activate Limit Yes

- Maximum Initial Feed Rate 30.0 (This moves the nozzle from Home to print start speed)

Multiply

- Activate Multiply Yes

- Center X 100.0

- Center Y 100.0

- Number of Columns 1

- Number of Rows 1

- Reverse Sequence every Odd Layer No

- Separation over Perimeter Width 15.0

Oozebane ( I don't use, leave with defaults)

- Activate Oozebane No

Preface

- Set Positioning to Absolute Yes

- Set Units to Millimeters Yes

- Start at Home Yes

- Turn Extruder Off at Shut Down No

- Turn Extruder Off at Start Up No

Raft

- Activate Raft Yes

- Add Raft, Elevate Nozzle, Orbit No

(Someone else will have to give you Raft Settings, as I don't use a Raft)

Scale

- Activate Scale No

- XY Plane Scale 1.0

- Z Axis Plane Scale 1.0

Skin (New feature, I don't use)

- Activate Skin No

Skirt

- Activate Skirt Yes

- Convex Yes

- Gap over Perimeter Width 3.0

- Layers to 1

Smooth

- Activate Smooth No

- Layers From 1

- Maximum Shortening over Width 2.0

Speed (work with Temperature to find what works best for you)

- Activate Speed Yes

- Add Flow Rate Yes

- Bridge Feed Rate Multiplier 1.0

- Bridge Flow Rate Multiplier 1.0

- Duty Cycle at Beginning 1.0

- Duty Cycle at Ending 0.0

- Feed Rate (Speed at which the nozzle moves) 30.0

- Flow Rate (Speed at which the extruder turns ratio) 27.0 (For ABS this may be 30.0 I think)

- Object First Layer Feed Rate Infill Multiplier 0.6

- Object First Layer Feed Rate Perimeter Multiplier 0.6

- Object First Layer Flow Rate Infill Multiplier 0.6

- Object First Layer Flow Rate Perimeter Multiplier 0.6

- Orbital Feed Rate over Operating Feed Rate 1.0

- Maximum Z Feed Rate 1.0

- Perimeter Feed Rate Multiplier 1.0

- Perimeter Flow Rate Multiplier 1.0

- Travel Feed Rate (When not Extruding) 30.0

Splodge (I don't use)

- Activate Splodge No

Stretch

- Activate Stretch Yes

- Cross Limit Distance over Perimeter Width 5.0

- Loop Stretch over Perimeter Width 0.11

- Path Stretch over Perimeter Width 0.0

- Perimeter Inside Stretch over Perimeter Width 0.2

- Perimeter Outside Stretch over Perimeter Width 0.1

- Stretch from Distance over Perimeter Width 1.0

Temperature (I don't know what temps to start out with for ABS)

- Activate Temperature Yes

- Cooling Rate 3.0

- Heating Rate 10.0

Temps I use here are 165 degrees for PLA

Tower

- Activate Tower No

- Extruder Possible Collision Cone Angle 60.0

- Maximum Tower Height 5

- Tower Start Layer 1

Unpause

- Activate Unpause No

- Delay 28.0

- Maximum Speed 1.3

Widen

- Activate Widen No

Wipe (Not used)

- Activate Wipe No

Analyze settings

Clairvoyance

- Activate Clairvoyance No

Comment

- Activate Comment No

Interpret

- Activate Interpret No

- Print Interpretation No

Skeiniso

- Activate Skeniso No

Skeinlayer

- Activate Skein Layer Yes

(Use Defaults)

Statistic

- Activate Statistic Yes

Use your settings for machine time anf Material cost

- Print Statistics No

- Save Statistics Yes (Produces a text file about the print)

|

Re: Skeinforge settings June 01, 2013 08:41PM |

Registered: 12 years ago Posts: 1 |

Hello, I just played with skeinforge, worked properly once, I modified some parameters (carving/milling if I remember), and now I get an ugly python error (opening the test.stl file bundled) : "AttributeError: LoopLayer instance has no attribute 'segmentTable'" (full log in joined file)

Assuming my tests were inconsistent, I erased the skeinforge folder, and redeployed the archive, but then I get the same error. So I think settings are saved somewhere else, but I can't find where.

Any idea ? (I use windows 7)

Assuming my tests were inconsistent, I erased the skeinforge folder, and redeployed the archive, but then I get the same error. So I think settings are saved somewhere else, but I can't find where.

Any idea ? (I use windows 7)

|

Re: Skeinforge settings September 13, 2013 05:58AM |

Registered: 10 years ago Posts: 7 |

Hi,

here is one that works fine with my mendel prusa with wade and .5 nozzle.

I tried the settings I found under the ultimachine link above but had to change the extruder settings to work. I also changes the start and end sequence to the same code that slic3r generates and added that useful skirt.

HF!

here is one that works fine with my mendel prusa with wade and .5 nozzle.

I tried the settings I found under the ultimachine link above but had to change the extruder settings to work. I also changes the start and end sequence to the same code that slic3r generates and added that useful skirt.

HF!

|

Re: Skeinforge settings "STRETCH" October 06, 2013 09:28AM |

Registered: 13 years ago Posts: 202 |

This is also posted as a seperate thread. So if any discussion please post there...

Hi All,

yes long time no hear from me

I have done some research on the "stretch" plugin today and it is actually working quite well.

The naming is "Skeinforge traditional" impossible to understand of course....

So here the settings and what they accomplish...

Increase:

Cross Limit Distance over Perimeter width(ratio) Decrease: Decreases the diameter of innermost perimeter, also adjusting the loops. Extreme (over defaults range) Increase: Pushes outer loops out, does not effect outer perimeter.

Loop Stretch Over Perimeter Width(Ratio) Decrease: Moves the inner loops closer to the inner perimeter not effecting the inner perimeter itself. Increase: Moves the inner loops away from the inner perimeter not effecting the inner perimeter itself.

Path Stretch Over Perimeter Width(ratio) Decrease: 0 is default and minimum. Having to increase this value means probably that you have some miscalibration..) Increase: Extends the fill lines onto the inner loops. (For fixing disjoined inner fill)

Perimeter Inside Stretch over Perimeter Width (ratio) Decrease: Decreases the effect of the increase in diameter of the inner perimeter. (loops not effected) Increase: Increases the effect of the increase in diameter of the inner perimeter. (loops not effected)

Perimeter Outside Stretch over Perimeter Width (ratio) Decrease: Leave at default. Dont really know what this is a fix for. Increase: Creates a slow increase of extrusion flow along the first path. Pulls the startpoint outwards a slight bit.

Stretch from Distance Over Perimeter Width (ratio) Decrease: moves the effect of the increase in diameter towards smaller holes. (Loops affected) Increase: moves the effect of the increase in diameter towards bigger holes.(Loops affected)

Obviously I advise to use SFACT that is easier to use than Skeinforge.

Picasa Album with results of different settings...

Edited 1 time(s). Last edit at 10/06/2013 09:30AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Hi All,

yes long time no hear from me

I have done some research on the "stretch" plugin today and it is actually working quite well.

The naming is "Skeinforge traditional" impossible to understand of course....

So here the settings and what they accomplish...

Increase:

Cross Limit Distance over Perimeter width(ratio) Decrease: Decreases the diameter of innermost perimeter, also adjusting the loops. Extreme (over defaults range) Increase: Pushes outer loops out, does not effect outer perimeter.

Loop Stretch Over Perimeter Width(Ratio) Decrease: Moves the inner loops closer to the inner perimeter not effecting the inner perimeter itself. Increase: Moves the inner loops away from the inner perimeter not effecting the inner perimeter itself.

Path Stretch Over Perimeter Width(ratio) Decrease: 0 is default and minimum. Having to increase this value means probably that you have some miscalibration..) Increase: Extends the fill lines onto the inner loops. (For fixing disjoined inner fill)

Perimeter Inside Stretch over Perimeter Width (ratio) Decrease: Decreases the effect of the increase in diameter of the inner perimeter. (loops not effected) Increase: Increases the effect of the increase in diameter of the inner perimeter. (loops not effected)

Perimeter Outside Stretch over Perimeter Width (ratio) Decrease: Leave at default. Dont really know what this is a fix for. Increase: Creates a slow increase of extrusion flow along the first path. Pulls the startpoint outwards a slight bit.

Stretch from Distance Over Perimeter Width (ratio) Decrease: moves the effect of the increase in diameter towards smaller holes. (Loops affected) Increase: moves the effect of the increase in diameter towards bigger holes.(Loops affected)

Obviously I advise to use SFACT that is easier to use than Skeinforge.

Picasa Album with results of different settings...

Edited 1 time(s). Last edit at 10/06/2013 09:30AM by ahmetcemturan.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

|

Re: Skeinforge settings "STRETCH" October 11, 2013 02:08PM |

Registered: 10 years ago Posts: 36 |

Hello,

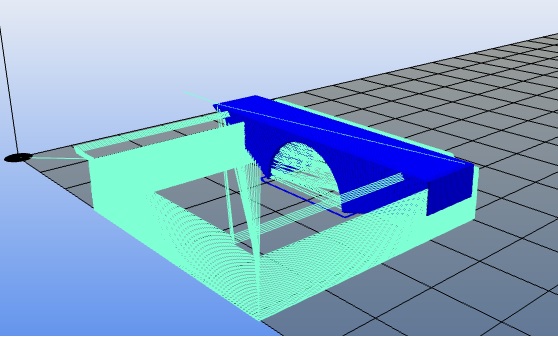

Im starting to learn skeinforge in repetier host, I have been through a setup guide and got it to print. Now Im stuck trying to add support.

What is this? how can I remove it? Ive tried "everyting" but with no success... Looks like skirt, but skirt is deactivated.

Any suggestions are appreciated!

Im starting to learn skeinforge in repetier host, I have been through a setup guide and got it to print. Now Im stuck trying to add support.

What is this? how can I remove it? Ive tried "everyting" but with no success... Looks like skirt, but skirt is deactivated.

Any suggestions are appreciated!

|

Re: Skeinforge settings "STRETCH" October 12, 2013 03:47AM |

Registered: 10 years ago Posts: 36 |

|

Re: Skeinforge settings May 28, 2015 09:29AM |

Registered: 8 years ago Posts: 4 |

|

Re: Skeinforge settings June 01, 2015 03:11AM |

Registered: 12 years ago Posts: 799 |

Quote

iorek_nhuvasarim

Hi, I might just seem dull here, but I was wondering, where exactly is the Profiles Folder in Skeinforge, that you said you'd gather the settings into?

at your Userprofile there is a hidden folder called ".skeinforge"

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Skeinforge settings June 01, 2015 07:55AM |

Registered: 8 years ago Posts: 4 |

Thanks...

But I meant what this guy was referring to.. where he said he'd gather profiles to for everyone to see;

Thank you all.

Peace out!

But I meant what this guy was referring to.. where he said he'd gather profiles to for everyone to see;

Quote

Enrique

This is a thread for people to post your skeinforge settings and your skeinforge scripts. Every once in a while I will gather the posted settings and put them into the profiles folder in skeinforge.

Thank you all.

Peace out!

Sorry, only registered users may post in this forum.