SF 41 Modifications for Bowden Extruders

Posted by theodleif

|

SF 41 Modifications for Bowden Extruders July 21, 2011 03:12AM |

Registered: 13 years ago Posts: 1,918 |

Hello,

as I had trouble with ooze from my Bowden extruder, I made two minor changes in SF 41 that turned out to reduce oozing.

The first is in cool.py where I discovered that the travel feed rate was slown down as well. Since this means more time for ooze, I fixed it.

The second is in dimension.py where I restricted retraction to those cases, where the travel distance is >5 mm. I discovered that for shorter distances the retraction only slows down the printing, but has no effect on ooze with the bowden extruder.

You may find the files and diffs enclosed.

as I had trouble with ooze from my Bowden extruder, I made two minor changes in SF 41 that turned out to reduce oozing.

The first is in cool.py where I discovered that the travel feed rate was slown down as well. Since this means more time for ooze, I fixed it.

The second is in dimension.py where I restricted retraction to those cases, where the travel distance is >5 mm. I discovered that for shorter distances the retraction only slows down the printing, but has no effect on ooze with the bowden extruder.

You may find the files and diffs enclosed.

|

Re: SF 41 Modifications for Bowden Extruders July 21, 2011 01:49PM |

Registered: 13 years ago Posts: 2,947 |

Thanks for this, I have been using them since you posted in the other thread and have had good success with them. Before moving to SF40 and adding these I could not use retraction with my bowden because of all the extra retractions (@75mm/s for 3.5mm) would chew the filament up and jam the extruder.

The cool.py one is great too but I would like to see it slow down the infill only until its the same speed as the perimeter, then slow down both if needed. I print @ 50mm/s and perimeter @ 25mm/s but cool slows down the infill to say 15mm/s and the perimeter slows down to 7.5mm/s which is so slow.

The cool.py one is great too but I would like to see it slow down the infill only until its the same speed as the perimeter, then slow down both if needed. I print @ 50mm/s and perimeter @ 25mm/s but cool slows down the infill to say 15mm/s and the perimeter slows down to 7.5mm/s which is so slow.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 21, 2011 03:15PM |

Admin Registered: 17 years ago Posts: 7,879 |

When you are printing tiny things you need it very slow. I set a time limit of say 20 seconds. If the layer is less than that I slow infill and outline so that it takes 20 seconds. The smaller it is the slower it goes.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: SF 41 Modifications for Bowden Extruders July 21, 2011 03:55PM |

Registered: 13 years ago Posts: 2,947 |

I didn't say to make it faster, It would still be 20 seconds if you have it set to 20 seconds. It would just slow down the infill to the same as the perimeter before slowing down the perimeter. If I go back to printing at 120mm/s infill / 25mm/s perimeter and cool stays the way it is I will be printing the perimeter at a speed slower than the ooze of the extruder. Plus the heat being transferred to the object because the hotend is in the same place for so long does not help either.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 21, 2011 04:12PM |

Registered: 13 years ago Posts: 2,947 |

Just though I would show some results.

Quote

My comment on Thing:9803

I made the switch to SF40 and with the addition of this patch [forums.reprap.org] I find my self being able to print stuff I thought impossible with my Repstrap with Bowden cable.

Printed @

50mm/s infill 25mm/s perimeter

.25mm layers

75mm/s retract @ 3.5mm

1 extra shell 0% infill

Natural 120%

Blue 140%

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 22, 2011 01:00AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 22, 2011 01:04AM |

Registered: 13 years ago Posts: 2,947 |

Yes I am running an older commit of Teacup with the acceleration steepness set to 37500 which seems to be about 1500mm/s^2 when comparing it to the newest commit.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 22, 2011 01:58AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 23, 2011 09:10AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 24, 2011 06:30AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 25, 2011 02:39PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 25, 2011 04:00PM |

Registered: 13 years ago Posts: 2,947 |

I used 3mm but since then I have figured out why I can reverse so fast. I have/had a 2.5/1 extruder and was only running it at 1/4 stepping allowing me to reach really high speeds. I have just made 5/1 gears for it and changed to 1/8 stepping and now I can't reverse any faster than 18mm/s which is not enough for really clean prints. But I can now print stuff with really short lines which were less than one step long with the old setup. So its one or the other right now.

2.5/1 with 1/4 stepping would drop E moves less than .00714

5/1 with 1/8 stepping allows down to .00178 but can only run 1/4 of the speed.

I have also tried your Cool.py patch with the slowed infill but it has the same issue as the original, where one axis will slow below the reliable print speed. It would need to slow the infill to match the perimeter then slow the perimeter too.

I have also found that a bowden cable needs a little restart distance even if it does not ooze during the move to compensate for the time it takes to build up pressure at the beginning of a move. (0.15 - .5)

2.5/1 with 1/4 stepping would drop E moves less than .00714

5/1 with 1/8 stepping allows down to .00178 but can only run 1/4 of the speed.

I have also tried your Cool.py patch with the slowed infill but it has the same issue as the original, where one axis will slow below the reliable print speed. It would need to slow the infill to match the perimeter then slow the perimeter too.

I have also found that a bowden cable needs a little restart distance even if it does not ooze during the move to compensate for the time it takes to build up pressure at the beginning of a move. (0.15 - .5)

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 25, 2011 05:45PM |

Registered: 12 years ago Posts: 1,611 |

Hi theodleif, I tried out the new bug-fixed version of dimension.py, and set the distance to 8mm. I had a little bit more stringing between parts that were close together as I was printing a plate of small Prusa parts, but as there were lots of small sections that didn't have retraction I think it saved a lot of print time, and stopped some of the blobbing on really small parts. So, success! As to the actual setting, I think anything up to 10mm would save a lot of retractions on fills and when moving between perimeter and infill, though it will result in more stringing between parts and across holes. 5mm is probably the best compromise setting.

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 05:55AM |

Registered: 13 years ago Posts: 1,918 |

@sublime:

I use 5/1 gears and 1/16 microstepping. 20 mm/s retraction speed is the limit I can reach. 2 mm retraction seems sufficient.

In most cases I get good results, but the crown was too much.

I didn't try the restart extra distance yet. But I have a 0.5 mm nozzle and I guess yours is smaller, causing higher pressure in the bowden cable.

> I have also found that a bowden cable needs a little restart distance even if it does not ooze during the move to compensate for the time it takes to build up pressure at the beginning of a move. (0.15 - .5)

0.5 mm x 1.5 mm x 1.5 mm x Pi x 2 = 7.06 mm^3

Where do you think that extra material will go?

@droftarts

> it will result in more stringing between parts and across holes

Do you have comb activated?

Edited 2 time(s). Last edit at 07/26/2011 06:53AM by theodleif.

I use 5/1 gears and 1/16 microstepping. 20 mm/s retraction speed is the limit I can reach. 2 mm retraction seems sufficient.

In most cases I get good results, but the crown was too much.

I didn't try the restart extra distance yet. But I have a 0.5 mm nozzle and I guess yours is smaller, causing higher pressure in the bowden cable.

> I have also found that a bowden cable needs a little restart distance even if it does not ooze during the move to compensate for the time it takes to build up pressure at the beginning of a move. (0.15 - .5)

0.5 mm x 1.5 mm x 1.5 mm x Pi x 2 = 7.06 mm^3

Where do you think that extra material will go?

@droftarts

> it will result in more stringing between parts and across holes

Do you have comb activated?

Edited 2 time(s). Last edit at 07/26/2011 06:53AM by theodleif.

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 06:52AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 06:53AM |

Registered: 12 years ago Posts: 1,611 |

theodleif Wrote:

-------------------------------------------------------

> Do you have comb activated?

I thought I did, but checking my settings it appears not. I'll give it another go soon with comb activated. Though this won't effect stringing between parts that are closer than the retraction threshold, which I can live with. I'll try and remember to take a picture of anything I print before I remove it from the bed, and post it here.

-------------------------------------------------------

> Do you have comb activated?

I thought I did, but checking my settings it appears not. I'll give it another go soon with comb activated. Though this won't effect stringing between parts that are closer than the retraction threshold, which I can live with. I'll try and remember to take a picture of anything I print before I remove it from the bed, and post it here.

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 07:08AM |

Registered: 13 years ago Posts: 1,918 |

Sublime Wrote:

-------------------------------------------------------

> I have also tried your Cool.py patch with the

> slowed infill but it has the same issue as the

> original, where one axis will slow below the

> reliable print speed. It would need to slow the

> infill to match the perimeter then slow the

> perimeter too.

At the end both (perimeter and infill) would drop below your reliable print speed. Wouldn't it be better to define a minimal print speed and let the nozzle loop around the perimeter for the rest of the time?

-------------------------------------------------------

> I have also tried your Cool.py patch with the

> slowed infill but it has the same issue as the

> original, where one axis will slow below the

> reliable print speed. It would need to slow the

> infill to match the perimeter then slow the

> perimeter too.

At the end both (perimeter and infill) would drop below your reliable print speed. Wouldn't it be better to define a minimal print speed and let the nozzle loop around the perimeter for the rest of the time?

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 07:29AM |

Registered: 13 years ago Posts: 1,918 |

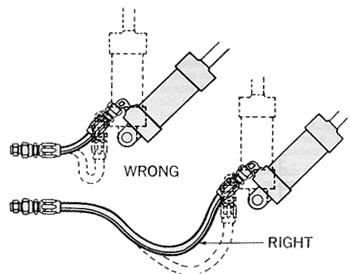

@ sublime:

I just watched your Huxley repstrap and noticed your bowden cable is quite long and forming a 180 degree upside down U. Don't you think it would be better to have a 90 degree bowden cable of half that length?

I just watched your Huxley repstrap and noticed your bowden cable is quite long and forming a 180 degree upside down U. Don't you think it would be better to have a 90 degree bowden cable of half that length?

|

Re: SF 41 Modifications for Bowden Extruders July 26, 2011 01:45PM |

Registered: 13 years ago Posts: 2,947 |

theodleif Wrote:

-------------------------------------------------------

> @sublime:

> I use 5/1 gears and 1/16 microstepping. 20 mm/s

> retraction speed is the limit I can reach. 2 mm

> retraction seems sufficient.

>

> In most cases I get good results, but the crown

> was too much.

>

> I didn't try the restart extra distance yet. But I

> have a 0.5 mm nozzle and I guess yours is smaller,

> causing higher pressure in the bowden cable.

Actually I had a .4xx that I just redrilled to .5mm

> > I have also found that a bowden cable needs a

> little restart distance even if it does not ooze

> during the move to compensate for the time it

> takes to build up pressure at the beginning of a

> move. (0.15 - .5)

>

> 0.5 mm x 1.5 mm x 1.5 mm x Pi x 2 = 7.06 mm^3

>

> Where do you think that extra material will go?

It gets distributed through out the next E move. I do it because of the hysteresis in the cable. Skeinforge expects the plastic to start exactly when the axis moves but this is not the case with a bowden cable. (it basically works like splodge does to nail down the beginning of the move )

I find .15 is enough for most stuff but when trying to print the hollow pyramid or crown it needs more because of how often it retracts and it seems to accumulate pressure loss.

> At the end both (perimeter and infill) would drop

> below your reliable print speed. Wouldn't it be better

> to define a minimal print speed and let the nozzle

> loop around the perimeter for the rest of the time?

I agree with this, but I am not a programmer so I can not make it happen.

> I just watched your Huxley repstrap and noticed

> your bowden cable is quite long and forming a

> 180 degree upside down U. Don't you think it would

> be better to have a 90 degree bowden cable of half that length?

Yes shorter could be better except it would put a lot of load on the carriage when at the side. Plus the minimum bend radius of PLA is around 75mm (3") which means to have a short cable I would have to have my extruder mounted out out over the top of the machine. But then I have the issue of the radius changing a lot with different heights. Right now I can have my hotend any where it will go without any stress on the cable. Plus I worked in the hydraulic industry for a few years and learnt about proper bends for hydraulic lines and applied them to this application.

-------------------------------------------------------

> @sublime:

> I use 5/1 gears and 1/16 microstepping. 20 mm/s

> retraction speed is the limit I can reach. 2 mm

> retraction seems sufficient.

>

> In most cases I get good results, but the crown

> was too much.

>

> I didn't try the restart extra distance yet. But I

> have a 0.5 mm nozzle and I guess yours is smaller,

> causing higher pressure in the bowden cable.

Actually I had a .4xx that I just redrilled to .5mm

> > I have also found that a bowden cable needs a

> little restart distance even if it does not ooze

> during the move to compensate for the time it

> takes to build up pressure at the beginning of a

> move. (0.15 - .5)

>

> 0.5 mm x 1.5 mm x 1.5 mm x Pi x 2 = 7.06 mm^3

>

> Where do you think that extra material will go?

It gets distributed through out the next E move. I do it because of the hysteresis in the cable. Skeinforge expects the plastic to start exactly when the axis moves but this is not the case with a bowden cable. (it basically works like splodge does to nail down the beginning of the move )

I find .15 is enough for most stuff but when trying to print the hollow pyramid or crown it needs more because of how often it retracts and it seems to accumulate pressure loss.

> At the end both (perimeter and infill) would drop

> below your reliable print speed. Wouldn't it be better

> to define a minimal print speed and let the nozzle

> loop around the perimeter for the rest of the time?

I agree with this, but I am not a programmer so I can not make it happen.

> I just watched your Huxley repstrap and noticed

> your bowden cable is quite long and forming a

> 180 degree upside down U. Don't you think it would

> be better to have a 90 degree bowden cable of half that length?

Yes shorter could be better except it would put a lot of load on the carriage when at the side. Plus the minimum bend radius of PLA is around 75mm (3") which means to have a short cable I would have to have my extruder mounted out out over the top of the machine. But then I have the issue of the radius changing a lot with different heights. Right now I can have my hotend any where it will go without any stress on the cable. Plus I worked in the hydraulic industry for a few years and learnt about proper bends for hydraulic lines and applied them to this application.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 28, 2011 03:29AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: SF 41 Modifications for Bowden Extruders July 28, 2011 01:22PM |

Registered: 13 years ago Posts: 2,947 |

theodleif Wrote:

-------------------------------------------------------

> I tried out the extra restart distance. With 0.25

> mm I was able to build the crown.

Strange isn't it? Logic would dictate it is not needed but practice says it is.

-------------------------------------------------------

> I tried out the extra restart distance. With 0.25

> mm I was able to build the crown.

Strange isn't it? Logic would dictate it is not needed but practice says it is.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 28, 2011 04:40PM |

Registered: 13 years ago Posts: 485 |

|

Re: SF 41 Modifications for Bowden Extruders July 28, 2011 05:29PM |

Registered: 13 years ago Posts: 2,947 |

Dale Dunn Wrote:

-------------------------------------------------------

> Not really. That's 0.25 of ooze, compressing the

> molten plastic in melt chamber (try higher temp?),

> and taking slack out of the bowden tube. I suspect

> it's mostly that last one, except for very long

> moves or Cool orbit.

As I mentioned before it has nothing to do with ooze, I have done test prints using the hollow pyramid and you do end up with more material than you call for. But without the extra restart it has moved a mm before it starts to print which means you don't get proper adhesion. (and yes I could print really slowly but why have a bowden then?) I suspect it is simply to deal with the hysteresis of the cable and it basically pauses the print long enough to start in the right place.

I already run at 225 for PLA (35 over its specs)

And yes a smaller diameter bowden cable would solve a lot of the issue but then I would have to buy something and that is not in the spirit of my machine. (found wood, salvaged steppers, salvaged rods and bushings, salvaged gears, salvaged belts and pulleys, scrap airline for the bowden, etc, etc)

On a related note. Is anyone with a bowden cable able to print slowly? My prints never work below about 15mm/s. A pulley for example looks good for about 15mm high and then it basically runs out of plastic. I think all the pressure in the cable is lost and it just turns the movement into compression basically smoothing the output the way a capacitor does for pulsed electricity. I have tried at temps from 205 - 235.

-------------------------------------------------------

> Not really. That's 0.25 of ooze, compressing the

> molten plastic in melt chamber (try higher temp?),

> and taking slack out of the bowden tube. I suspect

> it's mostly that last one, except for very long

> moves or Cool orbit.

As I mentioned before it has nothing to do with ooze, I have done test prints using the hollow pyramid and you do end up with more material than you call for. But without the extra restart it has moved a mm before it starts to print which means you don't get proper adhesion. (and yes I could print really slowly but why have a bowden then?) I suspect it is simply to deal with the hysteresis of the cable and it basically pauses the print long enough to start in the right place.

I already run at 225 for PLA (35 over its specs)

And yes a smaller diameter bowden cable would solve a lot of the issue but then I would have to buy something and that is not in the spirit of my machine. (found wood, salvaged steppers, salvaged rods and bushings, salvaged gears, salvaged belts and pulleys, scrap airline for the bowden, etc, etc)

On a related note. Is anyone with a bowden cable able to print slowly? My prints never work below about 15mm/s. A pulley for example looks good for about 15mm high and then it basically runs out of plastic. I think all the pressure in the cable is lost and it just turns the movement into compression basically smoothing the output the way a capacitor does for pulsed electricity. I have tried at temps from 205 - 235.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: SF 41 Modifications for Bowden Extruders July 29, 2011 05:30AM |

Registered: 13 years ago Posts: 1,918 |

@sublime:

I looked up cool.py and I think there is no need to rewrite it again, as orbit seems to do what I had in mind.

Just switch to cool orbit instead of slow down. Set Minimum Orbital Radius to 0 and edit two files:

cool_start.gcode with

G92 E0

G1 F4500.0

G1 E-2.0

G1 F5760.0

G92 E0

cool_end.gcode with

G92 E0

G1 F4500.0

G1 E2.25

G1 F5760.0

G92 E0

Turn Limit off.

I looked up cool.py and I think there is no need to rewrite it again, as orbit seems to do what I had in mind.

Just switch to cool orbit instead of slow down. Set Minimum Orbital Radius to 0 and edit two files:

cool_start.gcode with

G92 E0

G1 F4500.0

G1 E-2.0

G1 F5760.0

G92 E0

cool_end.gcode with

G92 E0

G1 F4500.0

G1 E2.25

G1 F5760.0

G92 E0

Turn Limit off.

|

Re: SF 41 Modifications for Bowden Extruders July 29, 2011 12:58PM |

Registered: 13 years ago Posts: 2,947 |

|

Re: SF 41 Modifications for Bowden Extruders August 18, 2011 11:03AM |

Registered: 13 years ago Posts: 39 |

Hey Sublime,

At huge risk of breaching usual forum etiquette (hijack, necro etc. etc.) how about salvaging a bicycle break line for the bowden cable of your next 1.75 mm bowden extruder? Break cables are 2mm internal diameter odd and lined with PTFE. I have a cable I keep meaning to work up into a full extruder. Can't seem to find the time.

woodsmoke.

At huge risk of breaching usual forum etiquette (hijack, necro etc. etc.) how about salvaging a bicycle break line for the bowden cable of your next 1.75 mm bowden extruder? Break cables are 2mm internal diameter odd and lined with PTFE. I have a cable I keep meaning to work up into a full extruder. Can't seem to find the time.

woodsmoke.

Sorry, only registered users may post in this forum.