is this problem Fill or Temperature?

Posted by TheCase

|

is this problem Fill or Temperature? August 04, 2011 11:53PM |

Registered: 12 years ago Posts: 141 |

newbie alert - I'm on day 6 of my first build (day 3 of calibration)... machine is Prusa, stock Wade's extruder.

I'm pretty happy with the print quality so far. Still a few outstanding issues. The one I'm working on now is this:

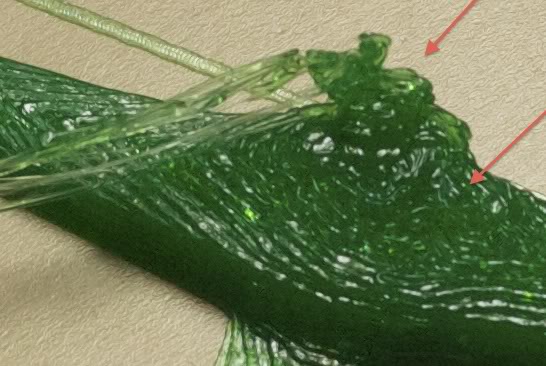

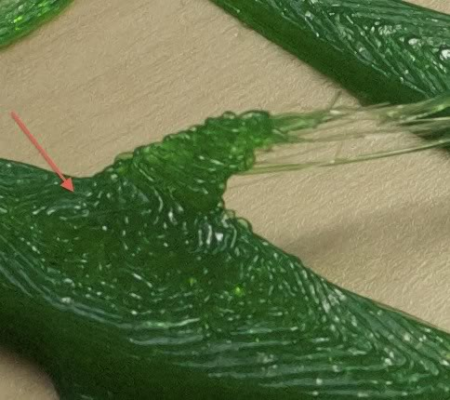

Everything looks good and on the level until I get to the 10th or 11th slice. The shells (2) are where they should be, but the fill layers start to "sink" deeper than the outer shell height. It is very drastic as it gets past the 20th layer, as the fills are maybe two or three slices lower than the outer shell...

Top most layer shells have no place to rest as they start closing off the top of dome-like structures (as seen in the side of the Shark print pictures I've included later) - so the extruded threads start going all over the place randomly as they squirt into the air...

I'm running PLA - and my Temperature module settings are all set to 212 (default from prusajr's "starter" Prusa skeinforge settings). I think that sounds high, but I tried running them all at 190 and I started having issues where nothing would extrude from the hot-end eventually. I could list all of my Fill module settings too, if someone thinks that might be the source of the problem.

Do you think it might be a Temperature (or Cool module) setting issue? Or a Fill setting issue?

Edited 3 time(s). Last edit at 08/04/2011 11:59PM by TheCase.

I'm pretty happy with the print quality so far. Still a few outstanding issues. The one I'm working on now is this:

Everything looks good and on the level until I get to the 10th or 11th slice. The shells (2) are where they should be, but the fill layers start to "sink" deeper than the outer shell height. It is very drastic as it gets past the 20th layer, as the fills are maybe two or three slices lower than the outer shell...

Top most layer shells have no place to rest as they start closing off the top of dome-like structures (as seen in the side of the Shark print pictures I've included later) - so the extruded threads start going all over the place randomly as they squirt into the air...

I'm running PLA - and my Temperature module settings are all set to 212 (default from prusajr's "starter" Prusa skeinforge settings). I think that sounds high, but I tried running them all at 190 and I started having issues where nothing would extrude from the hot-end eventually. I could list all of my Fill module settings too, if someone thinks that might be the source of the problem.

Do you think it might be a Temperature (or Cool module) setting issue? Or a Fill setting issue?

Edited 3 time(s). Last edit at 08/04/2011 11:59PM by TheCase.

|

Re: is this problem Fill or Temperature? August 05, 2011 02:54AM |

Admin Registered: 17 years ago Posts: 7,879 |

If the infill sags then it can be because you are not stretching the filament enough. If you try to extrude a filament bigger than it actually comes out of the nozzle then it will manage to do solid layers, but not span gaps. What size is your nozzle and what is your layer height and width / thickness ratio?

If you run your extruder into mid air and measure the filament diameter it produces than the maximum layer height will be about 0.8 times that with W/T set to 1.5.

[www.hydraraptor.blogspot.com]

If you run your extruder into mid air and measure the filament diameter it produces than the maximum layer height will be about 0.8 times that with W/T set to 1.5.

[www.hydraraptor.blogspot.com]

|

Re: is this problem Fill or Temperature? August 05, 2011 12:36PM |

Registered: 12 years ago Posts: 141 |

has width/thickness ratio been renamed to "Filament Packing Density" in the Dimension module in skeinforge 41?

I have a .5mm nozzle. If the above is true, it is currently set to .85

I'm not sure how to read your last sentence. I should measure the extruded diameter... and then do what with that number?

Edited 1 time(s). Last edit at 08/05/2011 01:59PM by TheCase.

I have a .5mm nozzle. If the above is true, it is currently set to .85

I'm not sure how to read your last sentence. I should measure the extruded diameter... and then do what with that number?

Edited 1 time(s). Last edit at 08/05/2011 01:59PM by TheCase.

|

Re: is this problem Fill or Temperature? August 05, 2011 01:03PM |

Registered: 13 years ago Posts: 1,780 |

TheCase Wrote:

-------------------------------------------------------

> has width/thickness ratio been renamed to

> "Filament Packing Density" in the Dimension module

> in skeinforge 41?

>

No. They are different parameters. I think that the documentation that came with SF explains these parameters.

-------------------------------------------------------

> has width/thickness ratio been renamed to

> "Filament Packing Density" in the Dimension module

> in skeinforge 41?

>

No. They are different parameters. I think that the documentation that came with SF explains these parameters.

|

Re: is this problem Fill or Temperature? August 05, 2011 03:54PM |

Registered: 12 years ago Posts: 141 |

|

Re: is this problem Fill or Temperature? August 05, 2011 04:21PM |

Admin Registered: 17 years ago Posts: 7,879 |

If the extruded filament measures 0.5mm it means you can't use a layer height more than 0.4mm when W/T is set to 1.5. If W/T is bigger then the layer height will need to be even less. Lower W/T makes objects that are too weak.

Try 0.35mm layers with W/T = 1.5.

FPD is just a fudge factor that corrects flow rate to compensate for the fact that softer filaments sink into the pinch wheel further and thus feed slower.

Edited 1 time(s). Last edit at 08/05/2011 04:25PM by nophead.

[www.hydraraptor.blogspot.com]

Try 0.35mm layers with W/T = 1.5.

FPD is just a fudge factor that corrects flow rate to compensate for the fact that softer filaments sink into the pinch wheel further and thus feed slower.

Edited 1 time(s). Last edit at 08/05/2011 04:25PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: is this problem Fill or Temperature? August 06, 2011 01:10AM |

Registered: 12 years ago Posts: 141 |

|

Re: is this problem Fill or Temperature? August 06, 2011 02:08AM |

Registered: 12 years ago Posts: 141 |

|

Re: is this problem Fill or Temperature? August 06, 2011 04:03AM |

Admin Registered: 17 years ago Posts: 7,879 |

You don't need to tweak layer height and W/T experimentally. You just set them to values that are compatible with the nozzle and then tweak FPD to get the right amount of plastic on the solid layers.

I normally leave W/T at 1.5 as that is about as close to 1 as you can go and still have strong objects. Bigger values trade horizontal resolution for vertical resolution. The layer height can be varied (within a range determined by the nozzle aperture and the die swell) to trade resolution for build speed.

If the layer height is too big such that the filament is not being stretched then it will not span gaps and tends to squirm instead of making straight lines. If it is too low then the filament is stretched too much and will tend to snap when it crosses gaps in the infill. It also tends to cut corners when stretched too much.

[www.hydraraptor.blogspot.com]

I normally leave W/T at 1.5 as that is about as close to 1 as you can go and still have strong objects. Bigger values trade horizontal resolution for vertical resolution. The layer height can be varied (within a range determined by the nozzle aperture and the die swell) to trade resolution for build speed.

If the layer height is too big such that the filament is not being stretched then it will not span gaps and tends to squirm instead of making straight lines. If it is too low then the filament is stretched too much and will tend to snap when it crosses gaps in the infill. It also tends to cut corners when stretched too much.

[www.hydraraptor.blogspot.com]

|

Re: is this problem Fill or Temperature? August 06, 2011 11:11PM |

Registered: 12 years ago Posts: 141 |

|

Re: is this problem Fill or Temperature? August 08, 2011 02:10PM |

Registered: 12 years ago Posts: 141 |

I was thinking that Flow rate could also be affecting the "stretch" of the filament - or lack of strech-ability due to the strand being thicker than it needs to be.

My Feed and Flow rates are set to 40 (perimeter ratios are both .5). Is this perhaps too much?

UPDATE: disregard the above question. I think I grok the whole, flow, feed, layer, ratio thing now. I upgraded my extruder to Frost's Wade's Accessible. Had to re-tweak my settings - getting familiar with the settings and how I need to change them.

Edited 1 time(s). Last edit at 08/10/2011 03:00PM by TheCase.

My Feed and Flow rates are set to 40 (perimeter ratios are both .5). Is this perhaps too much?

UPDATE: disregard the above question. I think I grok the whole, flow, feed, layer, ratio thing now. I upgraded my extruder to Frost's Wade's Accessible. Had to re-tweak my settings - getting familiar with the settings and how I need to change them.

Edited 1 time(s). Last edit at 08/10/2011 03:00PM by TheCase.

Sorry, only registered users may post in this forum.