6-lead steppers: lower current = more torque?

Posted by o_lampe

6-lead steppers: lower current = more torque? June 08, 2017 07:14AM |

Registered: 8 years ago Posts: 5,232 |

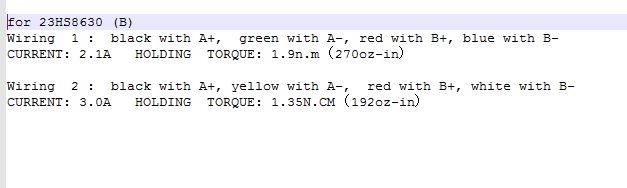

I found these steppers and want to know if it's a typo or real?

I can only imagine their max. speed is much lower then?

I can only imagine their max. speed is much lower then?

Re: 6-lead steppers: lower current = more torque? June 08, 2017 09:14AM |

Registered: 9 years ago Posts: 119 |

Numbers look reasonable.

Wiring 1 is using full coil so it would have twice the inductance of using split coil.

As a result the speed would be reduced. This is the same as wiring an 8 wire motor in series.

Wiring 2 uses only half of the coil so it would run faster but have lower low end torque.

It is best to get an 8 wire motors as you then use both coils in parallel.

George

Wiring 1 is using full coil so it would have twice the inductance of using split coil.

As a result the speed would be reduced. This is the same as wiring an 8 wire motor in series.

Wiring 2 uses only half of the coil so it would run faster but have lower low end torque.

It is best to get an 8 wire motors as you then use both coils in parallel.

George

Re: 6-lead steppers: lower current = more torque? June 08, 2017 09:43AM |

Registered: 8 years ago Posts: 5,232 |

Re: 6-lead steppers: lower current = more torque? June 22, 2017 01:26PM |

Registered: 8 years ago Posts: 5,232 |

It seems, the inductance in full torque config ( 2.1A/1.9Nm ) is to high for 24V. The torque drops pretty fast at higher RPM .

I made some travel speed tests and with a pulley gear ratio of 3:1 max travel speed was ~200mm/min ( 6400 steps/mm )

Then I changed gear ratio to 1:1 ( 2133.33 steps/mm ) and got +400mm/min travel.

I'll try the 3A/1.35Nm config with 3:1 gear ratio tomorrow. IMHO this will be the best compromise...

I made some travel speed tests and with a pulley gear ratio of 3:1 max travel speed was ~200mm/min ( 6400 steps/mm )

Then I changed gear ratio to 1:1 ( 2133.33 steps/mm ) and got +400mm/min travel.

I'll try the 3A/1.35Nm config with 3:1 gear ratio tomorrow. IMHO this will be the best compromise...

Re: 6-lead steppers: lower current = more torque? June 23, 2017 04:47AM |

Registered: 10 years ago Posts: 14,672 |

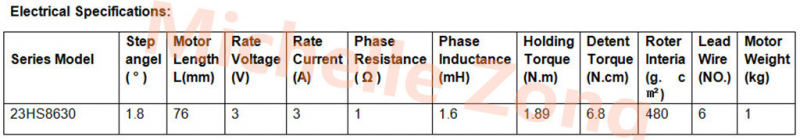

If this specification is correct:

then, relating it to the data in your earlier post, the inductance is 1.6mH for half a phase so it will be 6.4mH for a full phase. You can work out the supply voltage you need to maintain torque up to a desired target speed, see [duet3d.com].

Edited 1 time(s). Last edit at 06/23/2017 04:48AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

then, relating it to the data in your earlier post, the inductance is 1.6mH for half a phase so it will be 6.4mH for a full phase. You can work out the supply voltage you need to maintain torque up to a desired target speed, see [duet3d.com].

Edited 1 time(s). Last edit at 06/23/2017 04:48AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: 6-lead steppers: lower current = more torque? June 23, 2017 10:33AM |

Registered: 8 years ago Posts: 5,232 |

Thanks David for the link.

It seems our datas are mixed up...holding torque in 3A-config should be 1.35Nm or do they run the stepper at 3A with full phase?

I'll do the math with your formulas, although they are for "no load" scenarios. But it's save to use 50% of the calculated max. speed as this is the typical point where torque descends.

It seems our datas are mixed up...holding torque in 3A-config should be 1.35Nm or do they run the stepper at 3A with full phase?

I'll do the math with your formulas, although they are for "no load" scenarios. But it's save to use 50% of the calculated max. speed as this is the typical point where torque descends.

Re: 6-lead steppers: lower current = more torque? June 23, 2017 11:13AM |

Registered: 10 years ago Posts: 14,672 |

Actually the calcs work out better for loaded scenarios, because the back emf due to rotation then lags the back emf due to inductance, reducing the total drive voltage needed. So you can take the no-load scenario as the worst case.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: 6-lead steppers: lower current = more torque? June 23, 2017 11:55AM |

Registered: 8 years ago Posts: 5,232 |

Yes, that explains why I got lower rev/s values at higher motor current ( read required current )

I revers calculated max. rev/s at 24V and got

~4 rev/s for the 6.4mH@2A_1.9Nm wiring *

~7.3rev/s for the [email protected]_1.35Nm

* In fact I could run the stepper almost twice as fast as 4 rev/s. How is that possible?

edit: Does your formulas fit for yerk movement, but accelerated moves reach higher speed?

Edited 1 time(s). Last edit at 06/23/2017 12:02PM by o_lampe.

I revers calculated max. rev/s at 24V and got

~4 rev/s for the 6.4mH@2A_1.9Nm wiring *

~7.3rev/s for the [email protected]_1.35Nm

* In fact I could run the stepper almost twice as fast as 4 rev/s. How is that possible?

edit: Does your formulas fit for yerk movement, but accelerated moves reach higher speed?

Edited 1 time(s). Last edit at 06/23/2017 12:02PM by o_lampe.

Re: 6-lead steppers: lower current = more torque? June 23, 2017 04:17PM |

Registered: 10 years ago Posts: 14,672 |

My formula estimates the voltage you need to maintain full torque at a given speed. But motors in 3D printers generally produce much more torque than you need to produce motion. The greater the excess torque, the more accurate the positioning is.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: 6-lead steppers: lower current = more torque? June 25, 2017 01:53PM |

Registered: 8 years ago Posts: 5,232 |

Finally tested the other wiring option ( 1.6mH ) and it made all the difference. I could run the M10 leadscrew at 600mm/min which is 4 times faster than before. ( although I turned the current down to 2.4A )

It's the best setting for 24V and a pulley gear ratio of 3:1

Edited 1 time(s). Last edit at 06/25/2017 01:53PM by o_lampe.

It's the best setting for 24V and a pulley gear ratio of 3:1

Edited 1 time(s). Last edit at 06/25/2017 01:53PM by o_lampe.

Sorry, only registered users may post in this forum.