Blobbed hot end from printer parts & shapelock

Posted by jgilmore

|

Blobbed hot end from printer parts & shapelock November 16, 2010 12:35PM |

Registered: 16 years ago Posts: 438 |

awhile ago I got ahold of an old dot-matrix printer. It had among other things two steppers. They're six-wire steppers, and turning the shaft they feel like they have 24 "stopping points" in a revolution. They're different, with one being beefier.

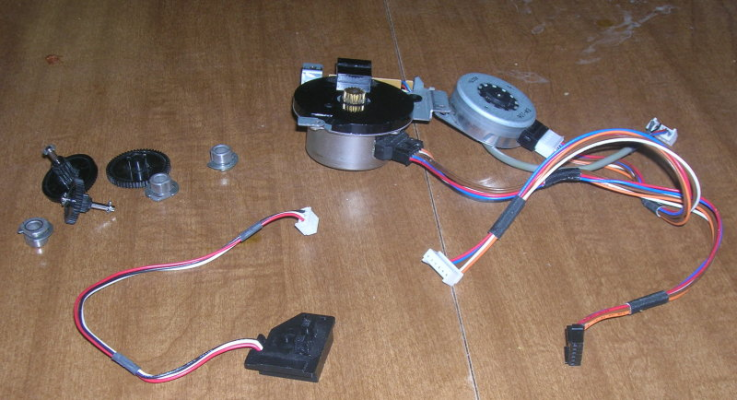

Here the two steppers (the beefier one has a optical position sensor thing attached) along with a few other parts I felt might be useful. These include a couple metal bushings, and three gears.

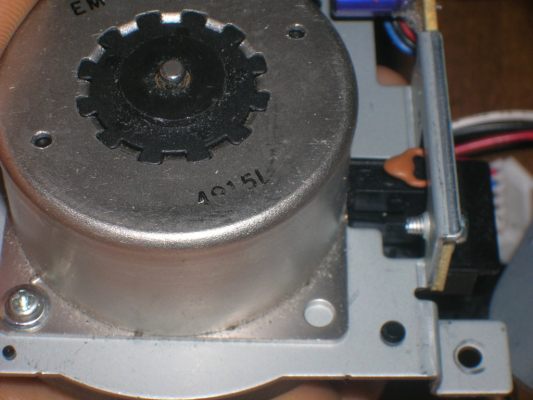

Here's a closeup of the back of the beefier one. The optical encoder disk on it is really nice, and it's a press-fit plastic disk that fits around the metal gear attached to the stepper's shaft. I didn't use it though - open loop control, right?

I cut a piece of the steel rod that was in the printer, hobbed it with a 6/32 tap (I should have used my 1/4-20 in retrospect) and cut grooves into it by spinning it in my drill and hitting it with a hacksaw blade. The grooves are for the circlips to fit into. This is the result:

You can see the three gears meshing together supported by a frame of blobbed-together shapelock. Note the place where the shapelock wraps around the motor's frame. That particular screw's threads didn't seem to want to grip the shapelock on the other side. You'll also see a blob of loctite 315 stuck to the metal gear. I used that to verify that yes, the stepper does take 24 steps per revolution in full-stepping mode.

I figure that the main problem with using this stepper as the extruder stepper is the resolution, if I can gear it down far enough to get the right resolution it should have plenty of torque. Wade's cold end has about a 5:1 ratio, giving 1000 steps per revolution of the hobbed bolt. To get that resolution, I needed to gear this stepper down by 1000/24=~41 times. The gears I scavenged from the printer included:

15x40 reducing gear (small hole)

19 metal gear on optical feedbacked stepper.

12 metal gear on smaller stepper (24-step)

15x54 angled reducing gear

2 60 gears w/ hole sized to go on hobbed shaft

60 gear w/ small hole

38x20 gear/cog

33x60 green knurled wheel (the 'knurl' is for moving by hand, but it meshes with the gears just fine)

Looking at the picture, you can see I elected to put the angled reducing gear next to the motor, followed by the 15x54 gear, which meshes with one of 60 tooth gears that fit on the hobbed shaft. This gives a gear ratio of (54/19)*(40/15)*(60/15) which only gives me a overall ratio of 30. Dang. I thought I'd checked this out before I put it together and come up with a smidge over 1000 steps/rev, guess I should have double-checked my calculations. That gives me only 727 steps per revolution on the hobbed shaft. Hopefully it will be enough for printing on my slow-moving mcwire-style repstrap.

Here you can see that the skate bearing is just blobbed on, with no visible provision of adjusting it. With this setup I'm getting what feels like about 10-15lbs of force on the pulled filament. I'd test it empirically, but my wife took the fish scale to weigh a friend's new baby.

I'm planning on blobbing a screw into one side of the gear-side attachment point to allow adjustment. I figure it doesn't have to be too straight.

Which brings me to my current problem. You can see white stuff in the hobbed bolt's teeth left over from my pulling tests. What's the easy way to clean that out?

And how much force do I need to have, really? I'm fairly certain that if I add an adjustment screw I can get a pretty good grip, but do I need to?

wiki link

--

I'm building it with Baling Wire

Here the two steppers (the beefier one has a optical position sensor thing attached) along with a few other parts I felt might be useful. These include a couple metal bushings, and three gears.

Here's a closeup of the back of the beefier one. The optical encoder disk on it is really nice, and it's a press-fit plastic disk that fits around the metal gear attached to the stepper's shaft. I didn't use it though - open loop control, right?

I cut a piece of the steel rod that was in the printer, hobbed it with a 6/32 tap (I should have used my 1/4-20 in retrospect) and cut grooves into it by spinning it in my drill and hitting it with a hacksaw blade. The grooves are for the circlips to fit into. This is the result:

You can see the three gears meshing together supported by a frame of blobbed-together shapelock. Note the place where the shapelock wraps around the motor's frame. That particular screw's threads didn't seem to want to grip the shapelock on the other side. You'll also see a blob of loctite 315 stuck to the metal gear. I used that to verify that yes, the stepper does take 24 steps per revolution in full-stepping mode.

I figure that the main problem with using this stepper as the extruder stepper is the resolution, if I can gear it down far enough to get the right resolution it should have plenty of torque. Wade's cold end has about a 5:1 ratio, giving 1000 steps per revolution of the hobbed bolt. To get that resolution, I needed to gear this stepper down by 1000/24=~41 times. The gears I scavenged from the printer included:

15x40 reducing gear (small hole)

19 metal gear on optical feedbacked stepper.

12 metal gear on smaller stepper (24-step)

15x54 angled reducing gear

2 60 gears w/ hole sized to go on hobbed shaft

60 gear w/ small hole

38x20 gear/cog

33x60 green knurled wheel (the 'knurl' is for moving by hand, but it meshes with the gears just fine)

Looking at the picture, you can see I elected to put the angled reducing gear next to the motor, followed by the 15x54 gear, which meshes with one of 60 tooth gears that fit on the hobbed shaft. This gives a gear ratio of (54/19)*(40/15)*(60/15) which only gives me a overall ratio of 30. Dang. I thought I'd checked this out before I put it together and come up with a smidge over 1000 steps/rev, guess I should have double-checked my calculations. That gives me only 727 steps per revolution on the hobbed shaft. Hopefully it will be enough for printing on my slow-moving mcwire-style repstrap.

Here you can see that the skate bearing is just blobbed on, with no visible provision of adjusting it. With this setup I'm getting what feels like about 10-15lbs of force on the pulled filament. I'd test it empirically, but my wife took the fish scale to weigh a friend's new baby.

I'm planning on blobbing a screw into one side of the gear-side attachment point to allow adjustment. I figure it doesn't have to be too straight.

Which brings me to my current problem. You can see white stuff in the hobbed bolt's teeth left over from my pulling tests. What's the easy way to clean that out?

And how much force do I need to have, really? I'm fairly certain that if I add an adjustment screw I can get a pretty good grip, but do I need to?

wiki link

--

I'm building it with Baling Wire

|

Re: Blobbed hot end from printer parts & shapelock November 16, 2010 01:37PM |

Admin Registered: 17 years ago Posts: 7,879 |

I use a wire brush to clean the teeth. You need something in the order of 40N of thrust to have some margin for reliable extrusion. A lot depends on the plastic, the nozzle size and the length and shape of the transition zone as well as how fast you want to extrude.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Blobbed hot end from printer parts & shapelock November 16, 2010 01:58PM |

Registered: 16 years ago Posts: 438 |

40N? That's only about 9lbs of force! Looks like I'll probably not have to add that screw to tighten it. Thanks. Now I just need to find a wire brush. I've got a couple around here somewhere... And since I'll be needing it regularly I might as well take the time to find it and keep it on hand.

Thanks.

Edited 1 time(s). Last edit at 11/16/2010 01:58PM by jgilmore.

--

I'm building it with Baling Wire

Thanks.

Edited 1 time(s). Last edit at 11/16/2010 01:58PM by jgilmore.

--

I'm building it with Baling Wire

Sorry, only registered users may post in this forum.