Linear stepper motors

Posted by klcjr89

|

Re: Linear stepper motors April 23, 2018 03:02AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Linear stepper motors April 23, 2018 03:53AM |

Admin Registered: 16 years ago Posts: 13,886 |

... common CA glue is too brittle for this (thermal variances and vibration) - better 2K-glue with some dust or short fibers as additive ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 23, 2018 10:13AM |

Registered: 6 years ago Posts: 207 |

|

Re: Linear stepper motors April 23, 2018 10:29AM |

Admin Registered: 16 years ago Posts: 13,886 |

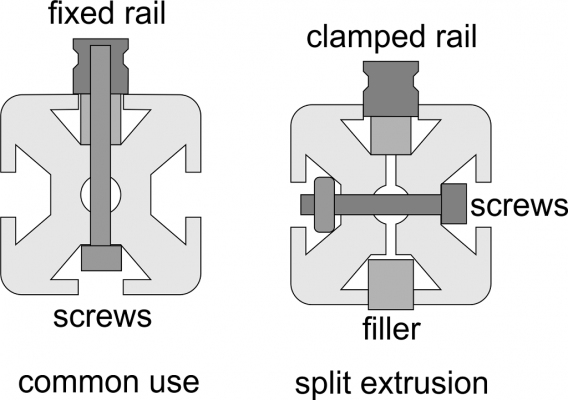

... then either a row of screws into the rail (common use), or "clamping" inside the (split) extrusion with a row of screws through the extrusion ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 23, 2018 10:33AM |

Registered: 6 years ago Posts: 207 |

Quote

VDX

... then either a row of screws into the rail (common use), or "clamping" inside the (split) extrusion with a row of screws through the extrusion ...

I mentioned on the previous page that both options would not be acceptable.

Quote

klcjr89

No holes in the middle of the rail, one hole on each end could be permissible, but that leaves the center floating (not what I want at all).

No holes from the bottom of rail tapped, because this wouldn't really be adoptable on 3D printers if you have to drill a bunch of holes into the length of your extrusions precisely.

|

Re: Linear stepper motors April 23, 2018 10:46AM |

Admin Registered: 16 years ago Posts: 13,886 |

... but you have to fix the rail along the complete length, or it will bend or oscillate/clang with moved loads

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 23, 2018 11:45AM |

Registered: 6 years ago Posts: 207 |

|

Re: Linear stepper motors April 23, 2018 11:52AM |

Admin Registered: 16 years ago Posts: 13,886 |

... this would be similar to my "split extrusion clamp" suggestion

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 28, 2018 01:26PM |

Registered: 6 years ago Posts: 207 |

|

Re: Linear stepper motors April 28, 2018 01:57PM |

Admin Registered: 16 years ago Posts: 13,886 |

... here's a fast sketch to show the difference between common fixature and clamping inside of a split extrusion:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 28, 2018 03:55PM |

Registered: 6 years ago Posts: 207 |

Quote

VDX

... here's a fast sketch to show the difference between common fixature and clamping inside of a split extrusion:

[attachment 104635 Splitextrusion.png]

Cool! I didn't know anyone made split extrusions. I'd love to buy some, or do you mean I'd have to modify or make my own?

Right now I'm just leaning toward doing it the common way, to have holes drilled through the extrusions that match up to holes in the bottom side of the rail, since this is something that Misumi can do I believe easily enough.

Edited 4 time(s). Last edit at 04/28/2018 04:02PM by klcjr89.

|

Re: Linear stepper motors April 28, 2018 08:58PM |

Registered: 6 years ago Posts: 207 |

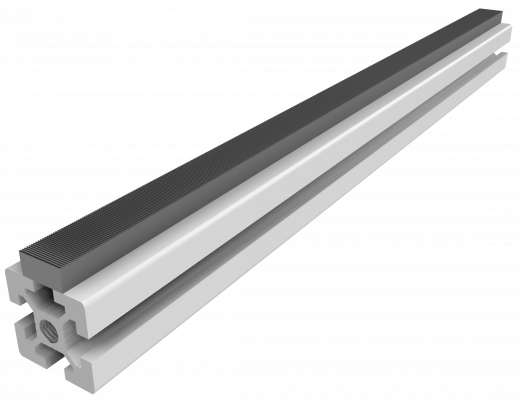

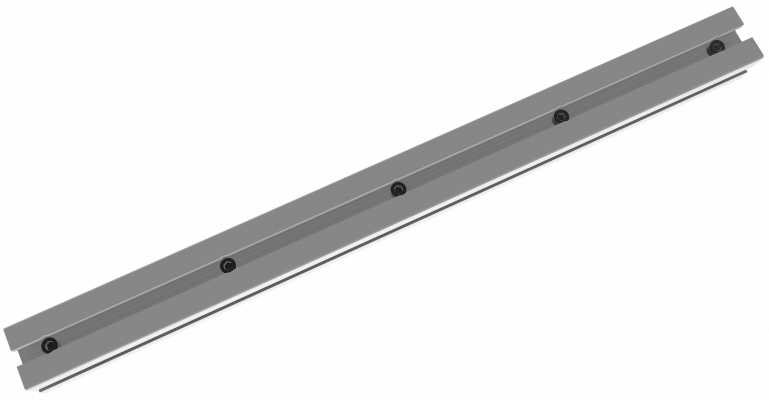

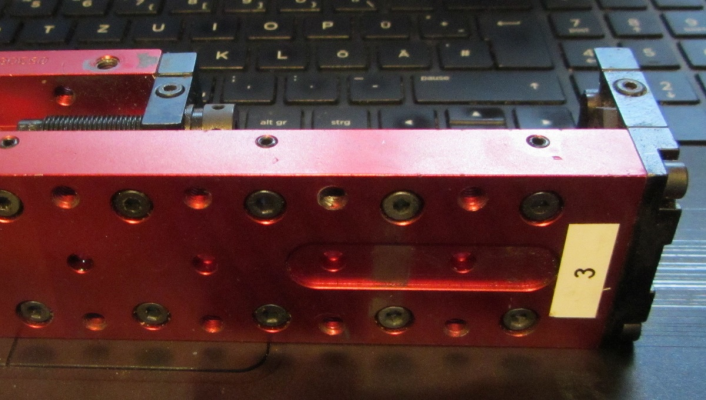

While I wait for materials to arrive from Misumi, this is what I have rendered:

Platen bolted from the bottom to Misumi 40x40 milled face extrusions.

Edited 3 time(s). Last edit at 04/28/2018 09:15PM by klcjr89.

Platen bolted from the bottom to Misumi 40x40 milled face extrusions.

Edited 3 time(s). Last edit at 04/28/2018 09:15PM by klcjr89.

|

Re: Linear stepper motors April 29, 2018 10:01AM |

Admin Registered: 16 years ago Posts: 13,886 |

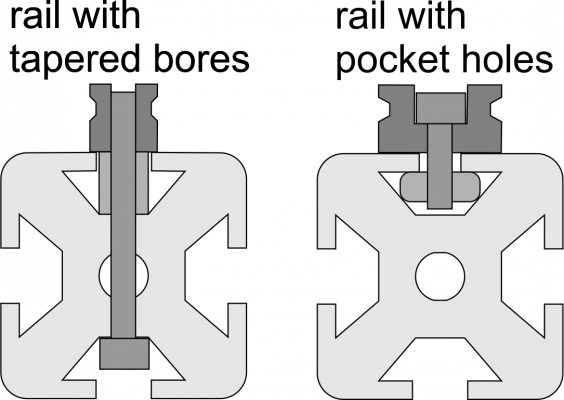

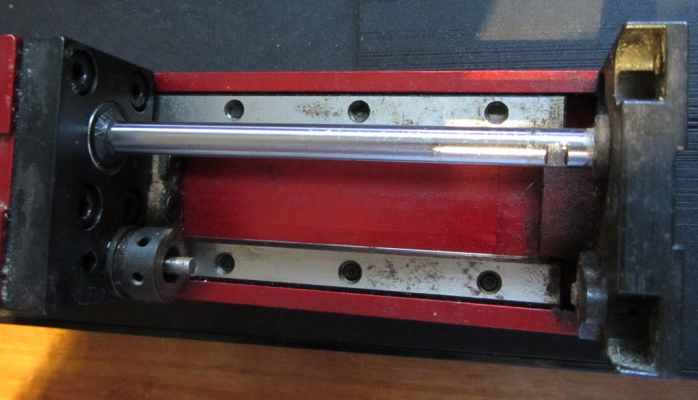

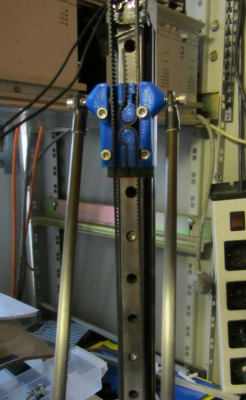

... there are different types of rails and fixation methodes - "slim" ones with tapped bores, bigger ones with pocket holes without threads:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 29, 2018 10:05AM |

Registered: 6 years ago Posts: 207 |

|

Re: Linear stepper motors April 29, 2018 11:25AM |

Admin Registered: 16 years ago Posts: 13,886 |

...sure? - have both types (and some others too) in different linear feeding setups.

Here one with tapped bores:

- and here with pocket holes on a Delta:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Here one with tapped bores:

- and here with pocket holes on a Delta:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear stepper motors April 29, 2018 11:27AM |

Registered: 6 years ago Posts: 207 |

Sorry, only registered users may post in this forum.