A4982SLPT compatable A4988 Driver

Posted by Roberts_Clif

|

A4982SLPT compatable A4988 Driver January 21, 2019 09:30AM |

Registered: 6 years ago Posts: 1,863 |

The A4982SLPT is an improved version of the A4988 stepper motor controller driver chip.

The advantage to this chip is a larger package for heat dissipation.

Note: This driver does not allow 1/8 micro stepping, 1/2, 1/4 and 1/16 only.

Now for my question.

I would like to know replacement stepper motors to use for Hictop 3DP11/12.

3DP11 - 42HD4027-01 original steppers and 42HD2037-01. 12V power supply

3DP12 - Stepper Motors only have manufactures date on them. 24V power supply // This printer is the one that is skipping steps

I do searches for stepper motors and get such a large variety including binoculars and Drill Motors.

The Steppers on my 3DP12 are missing steps after the first year. This is not all the time I can 3D Print almost a perfect circle Bird Feeder.

However I have Problems with a SD Card Holder. Looking at the Front on the Y-Axis.

Edited 3 time(s). Last edit at 01/21/2019 09:33AM by Roberts_Clif.

Computer Programmer / Electronics Technician

The advantage to this chip is a larger package for heat dissipation.

Note: This driver does not allow 1/8 micro stepping, 1/2, 1/4 and 1/16 only.

Now for my question.

I would like to know replacement stepper motors to use for Hictop 3DP11/12.

3DP11 - 42HD4027-01 original steppers and 42HD2037-01. 12V power supply

3DP12 - Stepper Motors only have manufactures date on them. 24V power supply // This printer is the one that is skipping steps

I do searches for stepper motors and get such a large variety including binoculars and Drill Motors.

The Steppers on my 3DP12 are missing steps after the first year. This is not all the time I can 3D Print almost a perfect circle Bird Feeder.

However I have Problems with a SD Card Holder. Looking at the Front on the Y-Axis.

Edited 3 time(s). Last edit at 01/21/2019 09:33AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: A4982SLPT compatable A4988 Driver January 21, 2019 11:47AM |

Registered: 6 years ago Posts: 1,863 |

The A4982SLPT like its predecessor the A4988 are constant current devices.

Does this mean that If I upgrade the Supply Power Supply from 12 to 24 VDC that I will not have to readjust the V-Ref voltage and they should be OK!

This would also mean that If I take a spare stepper from my 3DP11 : 12vdc printer.

Then there should be no problems connecting it to the 3DP12 : 24VDC printer.

If I adjust the same the stepper V-Ref adjustable current limiting that is was using on the 12V - 3D Printer.

Computer Programmer / Electronics Technician

Does this mean that If I upgrade the Supply Power Supply from 12 to 24 VDC that I will not have to readjust the V-Ref voltage and they should be OK!

This would also mean that If I take a spare stepper from my 3DP11 : 12vdc printer.

Then there should be no problems connecting it to the 3DP12 : 24VDC printer.

If I adjust the same the stepper V-Ref adjustable current limiting that is was using on the 12V - 3D Printer.

Computer Programmer / Electronics Technician

|

Re: A4982SLPT compatable A4988 Driver January 22, 2019 09:50AM |

Registered: 6 years ago Posts: 1,863 |

I believe have figured it all out!

I have stepper motors on my 3DP12 that have not a laser etched labels with the date codes.

Known Data for "Date code only Steppers" 1.8º 200 steps 5.5ohms coil resistance.

Doing some mathematical calculations of known information about the unknown Stepper motor.

I have came up with an ideal of some of the Specs for the "Date code only Steppers".

1.8º 200 steps ~900ma 5.5ohms coil resistance puts us in the neighborhood of 48~54 mN/m torque.

With this information I believe that the steppers are being under driven with only .425 V-Ref.

By my calculations .9 * 8 *.1 = V-Ref .720 will test on The Controller that already has one burnt out a4982SLPT Driver chip.

******************* SOME TESTING TIME LATTER ********************

After completing the initial setup of a spare Controller to test my theories I connected the Stepper and tested with a V-Ref Voltage of .700v

Testing with 1mm steps first then changing to 10mm steps.

I cannot believe I have been running this 3D Printer with only about 1/2 the required V-Ref voltage needed.

And it only took 1 year for it to mess up and force me to start testing to see why it was acting up an going so wrong.

Originally I used the setting that were on the controller having this 2nd 3D Printer working so well.

Did not think that the controller adjustments was incorrectly done as It was purchased used from E-Bay and work so well on every print.

Until last week when it suddenly started to print with only the Y-Axis shifting the layers...

Computer Programmer / Electronics Technician

I have stepper motors on my 3DP12 that have not a laser etched labels with the date codes.

Known Data for "Date code only Steppers" 1.8º 200 steps 5.5ohms coil resistance.

Doing some mathematical calculations of known information about the unknown Stepper motor.

I have came up with an ideal of some of the Specs for the "Date code only Steppers".

1.8º 200 steps ~900ma 5.5ohms coil resistance puts us in the neighborhood of 48~54 mN/m torque.

With this information I believe that the steppers are being under driven with only .425 V-Ref.

By my calculations .9 * 8 *.1 = V-Ref .720 will test on The Controller that already has one burnt out a4982SLPT Driver chip.

******************* SOME TESTING TIME LATTER ********************

After completing the initial setup of a spare Controller to test my theories I connected the Stepper and tested with a V-Ref Voltage of .700v

Testing with 1mm steps first then changing to 10mm steps.

I cannot believe I have been running this 3D Printer with only about 1/2 the required V-Ref voltage needed.

And it only took 1 year for it to mess up and force me to start testing to see why it was acting up an going so wrong.

Originally I used the setting that were on the controller having this 2nd 3D Printer working so well.

Did not think that the controller adjustments was incorrectly done as It was purchased used from E-Bay and work so well on every print.

Until last week when it suddenly started to print with only the Y-Axis shifting the layers...

Computer Programmer / Electronics Technician

|

Re: A4982SLPT compatable A4988 Driver January 22, 2019 10:05AM |

Admin Registered: 13 years ago Posts: 7,000 |

You still miss understand

the calculation is for max torque, most printers don't need to run at max torque and thus can run fine with lower vrefs. (and much lower noise levels)

when printers suddenly start layer shifting they normally need lubrication, not re adjusting the vref to force the printer to overcome the additional friction.

the calculation is for max torque, most printers don't need to run at max torque and thus can run fine with lower vrefs. (and much lower noise levels)

when printers suddenly start layer shifting they normally need lubrication, not re adjusting the vref to force the printer to overcome the additional friction.

|

Re: A4982SLPT compatable A4988 Driver January 22, 2019 05:47PM |

Registered: 6 years ago Posts: 1,863 |

Thank You!

Still learning.

I have checked the Y-Axis belt and drive belt pulley for debris

I have Replaced all bearings on the Y axis Cleaned and lubricated Lead-Screws and Smooth-rods.

I Replaced the Y-Axis Stepper.

I Replaced the Controller with a backup controller.

I have re-adjusted the V-Ref constant current. Will drop it back down it was only for this test.

Nothing is binding. With power off you can easily push the X,Y Axis without any friction.

Beginning to think I'm Chasing a Ghost, printed the CD Card holder using Octoprint over USB and LCD SD Card images.

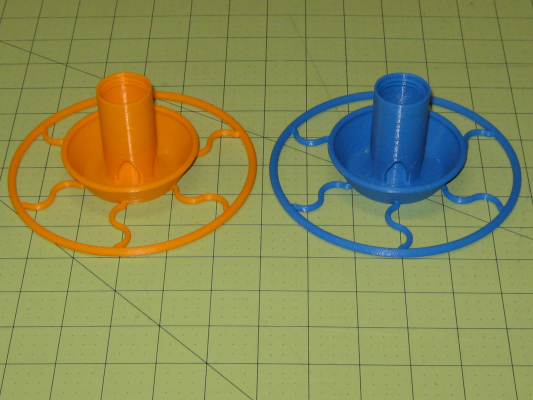

I printed Other Models A large Pop Bottle Bird Feeder, Y Axis Belt Holder and neither have layer Shifting.

May just forget about it and keep printing an see if it shows up with other models later on.

Edited 1 time(s). Last edit at 01/22/2019 09:16PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Still learning.

I have checked the Y-Axis belt and drive belt pulley for debris

I have Replaced all bearings on the Y axis Cleaned and lubricated Lead-Screws and Smooth-rods.

I Replaced the Y-Axis Stepper.

I Replaced the Controller with a backup controller.

I have re-adjusted the V-Ref constant current. Will drop it back down it was only for this test.

Nothing is binding. With power off you can easily push the X,Y Axis without any friction.

Beginning to think I'm Chasing a Ghost, printed the CD Card holder using Octoprint over USB and LCD SD Card images.

I printed Other Models A large Pop Bottle Bird Feeder, Y Axis Belt Holder and neither have layer Shifting.

May just forget about it and keep printing an see if it shows up with other models later on.

Edited 1 time(s). Last edit at 01/22/2019 09:16PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: A4982SLPT compatable A4988 Driver January 23, 2019 09:43AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Dust

You still miss understand

the calculation is for max torque, most printers don't need to run at max torque and thus can run fine with lower vrefs. (and much lower noise levels)

when printers suddenly start layer shifting they normally need lubrication, not re adjusting the vref to force the printer to overcome the additional friction.

Most machines are over constrained and if not flexible enough (two bad things compensating each other

) they bind ! Lubrication reduce the binding till the next time !

) they bind ! Lubrication reduce the binding till the next time !High current lead to more vibration too (noise), so it is indeed better to adjust for enough torque.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: A4982SLPT compatable A4988 Driver January 24, 2019 06:56PM |

Registered: 6 years ago Posts: 1,863 |

Y-Axis is not binding!!!!!!!!!

It has been completely rebuilt Brand New Bearings, Smooth rods cleaned and adjusted for the smoothest possible travel.

I have now replaced the Y-Axis stepper motor twice still layer shifting. Re-flashed the Firmware back to a known good Marlin 1.1.5 and then back to Marlin 1.1.9

Reapplied Aluminum foil Duct tape used for shielding the LCD / SD card cables from EFI / Stepper motor noise.

Carefully testing both firmware's have the same layer shifting, the only thing that has not been tested is the new power supply for noise.

Hold it! Why do I not have the New power supply on the 3D Printer and only this small 24 volt 360watt 15A supply.

I remember now the brand new S-500-24 power supply arrived dead and had to get a replacement so threw on this cheep supply for testing when supply died.

Will replace the Supply and Get back!

Forgot have not tried to replace the Drive Belt.

If the Layer Shifting always occurs at almost exact layer height on every model this could occur because of the Z-Axis Bearings will rebuild the Z-Axis today.

Today I will be rebuilding the Z-Axis replacing all linear bearings on the smooth rods, maybe some kind of debris entered the bearing that's causing a Y-Shift.

Edited 7 time(s). Last edit at 01/25/2019 07:55AM by Roberts_Clif.

Computer Programmer / Electronics Technician

It has been completely rebuilt Brand New Bearings, Smooth rods cleaned and adjusted for the smoothest possible travel.

I have now replaced the Y-Axis stepper motor twice still layer shifting. Re-flashed the Firmware back to a known good Marlin 1.1.5 and then back to Marlin 1.1.9

Reapplied Aluminum foil Duct tape used for shielding the LCD / SD card cables from EFI / Stepper motor noise.

Carefully testing both firmware's have the same layer shifting, the only thing that has not been tested is the new power supply for noise.

Hold it! Why do I not have the New power supply on the 3D Printer and only this small 24 volt 360watt 15A supply.

I remember now the brand new S-500-24 power supply arrived dead and had to get a replacement so threw on this cheep supply for testing when supply died.

Will replace the Supply and Get back!

Forgot have not tried to replace the Drive Belt.

If the Layer Shifting always occurs at almost exact layer height on every model this could occur because of the Z-Axis Bearings will rebuild the Z-Axis today.

Today I will be rebuilding the Z-Axis replacing all linear bearings on the smooth rods, maybe some kind of debris entered the bearing that's causing a Y-Shift.

Edited 7 time(s). Last edit at 01/25/2019 07:55AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: A4982SLPT compatable A4988 Driver February 10, 2019 03:34PM |

Registered: 6 years ago Posts: 1,863 |

Quote

Dust

You still miss understand

the calculation is for max torque, most printers don't need to run at max torque and thus can run fine with lower vrefs. (and much lower noise levels)

when printers suddenly start layer shifting they normally need lubrication, not re adjusting the vref to force the printer to overcome the additional friction.

No, I did not misunderstand, Without knowing what Max Torque you have no ideal the max V-Ref you are allowed and adjusting past this point can be disastrous.

I am not running Max Torque my calculations .9 * 8 *.1 = V-Ref .720 I have been running .400 this value is too low and causes stepper motors to skip steps.

In turn it directly causes the layer shifting that the 3D Printer has been experiencing.

Took the calculations off my other 3D Printer where I was given factory settings for the V-Ref of 0.800 calculated the percentage from Max Torque to get 67%.

Actually I have been running the 2nd 3D Printer at .700 which is ~60% of the Max Torque calculated V-Ref setting. When I lower the V-Ref I get the same Layer Shifting.

Took this calculation into perspective for calculating an average for the 2nd 3D Printer By the Same Company came up with ~60% Adjusted V-Ref to .500

Only increased the V-Ref voltage up by 5%

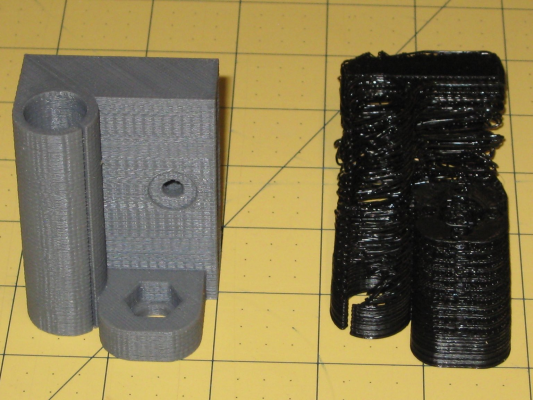

Lowering V-Ref on the 2nd 3D Printer resulted in this Print.

Left Image is a similar Model, Right Image Incorrect V-Ref is Layer Shifted.

Edited 1 time(s). Last edit at 02/10/2019 03:37PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Sorry, only registered users may post in this forum.